Danfoss DGS Gwaje-gwajen Aiki da Tsarin daidaitawa

Gabatarwa

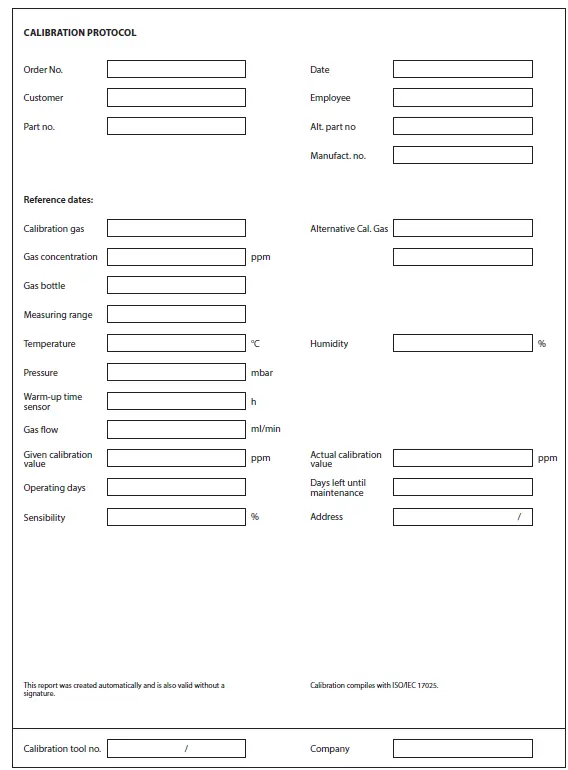

An daidaita firikwensin DGS a masana'anta. Ana isar da takardar shaidar daidaitawa tare da firikwensin. Bayan shigar da sifili calibration da recalibration (gain calibration) yakamata a aiwatar da shi kawai idan firikwensin ya kasance yana aiki fiye da tazarar daidaitawa ko kuma ya kasance a hannun jari fiye da lokacin ajiya da aka fallasa a cikin tebur na ƙasa:

| Samfura | Daidaitawa tazara | Adana lokaci |

| Bayanan Bayani na DGS-IR CO2 | Wata 60 | kimanin. Wata 6 |

| Bayanan Bayani na DGS-SC | Wata 12 | kimanin. Wata 12 |

| Babban firikwensin DGS-PE Propane | Wata 6 | kimanin. Wata 6 |

Tsanaki:

- Bincika ƙa'idodin gida akan ƙa'idodi ko buƙatun gwaji.

- DGS yana ƙunshe da kayan aikin lantarki masu mahimmanci waɗanda za a iya lalacewa cikin sauƙi. Kar a taɓa ko dagula kowane ɗayan waɗannan abubuwan yayin da ake cire murfi da lokacin maye gurbinsa.

Muhimmi:

- Idan DGS ta fallasa zuwa babban ɗigo ya kamata a gwada don tabbatar da aiki daidai ta hanyar sake saita saitin sifili da aiwatar da gwaji. Duba hanyoyin da ke ƙasa.

- Don biyan buƙatun EN378 da ƙa'idar F-GAS ta Turai, dole ne a gwada na'urori masu auna sigina aƙalla kowace shekara.

Ko ta yaya, mita da yanayin gwaji ko ƙila za a iya tantance ta ta ƙa'ida ko ƙa'idodi na gida. - Rashin gwada ko daidaita sashin daidai da umarnin da aka zartar kuma tare da jagororin masana'antu na iya haifar da mummunan rauni ko mutuwa. Mai sana'anta ba shi da alhakin kowane asara, rauni, ko lalacewa da ta taso daga gwajin da bai dace ba, daidaitaccen daidaitawa, ko rashin dacewa na naúrar.

- Kafin gwada na'urori masu auna firikwensin da ke wurin, dole ne an kunna DGS kuma an ba su damar daidaitawa.

- Gwajin da/ko daidaita sashin dole ne ƙwararren masani ne ya yi shi, kuma dole ne a yi:

- daidai da wannan jagorar.

- a yarda da ƙa'idodi da ƙa'idodi na gida.

Ƙwararren ƙwararren mai fasaha na iya aiwatar da sake gyarawa da maye gurbin sashi a cikin filin tare da kayan aikin da suka dace. A madadin, ana iya maye gurbin ɓangaren firikwensin firikwensin da ake iya cirewa.

Akwai ra'ayoyi guda biyu da ya kamata a bambanta:

- gwajin kumbura ko gwajin aiki

- calibration ko sake daidaitawa (samun calibration)

Gwajin bugun jini:

- Nuna firikwensin ga gas da kuma lura da martaninsa ga iskar.

- Manufar ita ce tabbatarwa idan firikwensin yana amsa gas kuma idan duk abubuwan firikwensin suna aiki daidai.

- Akwai nau'ikan gwaji iri biyu

- Ƙididdiga: ta amfani da sananniya na iskar gas

- Mara ƙididdigewa: ta amfani da iskar gas da ba a sani ba

Daidaitawa:

Nuna firikwensin ga iskar daidaitawa, saita “sifili” ko juzu'in jiran aikitage zuwa tazara / kewayon, da dubawa / daidaita duk abubuwan da aka fitar, don tabbatar da cewa an kunna su a ƙayyadaddun iskar gas.

Tsanaki (kafin yin gwaji ko calibration)

- Ba da shawara ga masu zama, masu aikin shuka, da masu kulawa.

- Bincika idan an haɗa DGS zuwa tsarin waje kamar tsarin sprinkler, rufewar shuka, siren waje da tashoshi, samun iska, da sauransu, kuma cire haɗin kamar yadda abokin ciniki ya umarta.

Gwajin bugun jini

- Don cin karo, gwaji yana fallasa na'urori masu auna firikwensin don gwada gas (R134A, CO2, da sauransu). Gas ya kamata ya sanya tsarin cikin ƙararrawa.

- Manufar wannan cak shine tabbatar da cewa iskar gas na iya isa ga firikwensin (s) kuma duk ƙararrawar da ke akwai suna aiki.

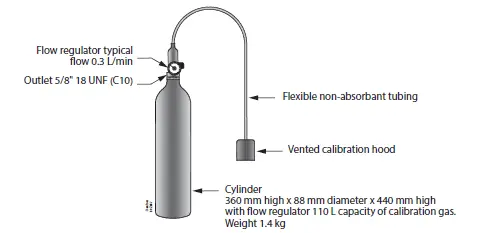

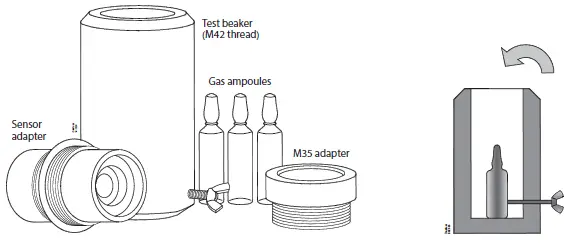

- Don ƙumburi, ana iya amfani da gwaje-gwajen Gas Silinda ko Gas Ampoules (duba siffa 1 da 2).

Hoto 1: Silinda gas da kayan gwaji

Hoto 2: Gas ampoules don gwaji

Muhimmi: Bayan an fallasa na'urar firikwensin semiconductor zuwa ga kwararan iskar gas, firikwensin ya kamata a daidaita shi da sifili kuma a gwada shi kuma a maye gurbinsa idan ya cancanta.

Lura: Domin safarar iskar gas ampOules da cylinders iskar gas gwamnatoci da yawa ne ke sarrafa su, ana ba da shawarar samo su daga dillalan gida.

Matakai don gwajin kumbura ta amfani da silinda na iskar gas

- Cire murfin shinge na injin gano iskar gas (ba a wurin da ake shayewa ba).

- Haɗa kayan aikin sabis na hannu kuma saka idanu akan martani.

- Fitar da firikwensin ga gas daga silinda. Yi amfani da bututun filastik don kai gas zuwa kan firikwensin. Idan firikwensin ya nuna karatun don amsa gas kuma mai ganowa ya shiga cikin ƙararrawa, to wannan kayan aiki yana da kyau a tafi.

Lura: Gas ampoules ba su da inganci don daidaitawa ko bincikar firikwensin. Waɗannan suna buƙatar ainihin daidaitawar iskar gas, ba gwaji da yawa ba ampoles.

Daidaitawa

Kayan aikin da ake buƙata don daidaitawa

- Kayan aikin Sabis na Hannu 080Z2820

- Calibration an haɗa shi da ayyuka guda biyu: sifili da samun calibration

- Sifili calibration: Gwada kwalban iskar gas tare da iska ta roba (21% O2. 79% N) ko iska mai tsabta

- Sifili calibration don carbon dioxide / oxygen: Gwajin silinda gas tare da tsantsar nitrogen 5.0

- Samun daidaitawa: Gwada kwalban iskar gas tare da gwajin gas a cikin kewayon 30 - 90% na kewayon aunawa. Sauran iskar roba ce.

- Samun daidaitawa don na'urori masu auna sigina: Adadin iskar gas ɗin gwajin dole ne ya zama 50 % na kewayon aunawa. Sauran iskar roba ce.

- Saitin cirewa wanda ya ƙunshi mai sarrafa iskar gas da mai kula da kwarara

- Adaftar daidaitawa tare da bututu: lambar 148H6232.

Bayanan kula game da gwajin kwalban iskar gas don daidaitawa (duba siffa 1): saboda safarar iskar gas ampOules da cylinders iskar gas ana sarrafa shi ta gwamnatoci da yawa a duk faɗin duniya, ana ba da shawarar samo su daga dillalan gida. Kafin yin gyare-gyare, haɗa Kayan aikin Sabis na Hannu 080Z2820 zuwa na'urar DGS.

Kafin a daidaita, dole ne a ba da na'urori masu auna firikwensin da wutar lantarkitage ba tare da katsewa ba don gudu-ciki da kwanciyar hankali.

Lokacin gudu ya dogara da nau'in firikwensin kuma ana nuna shi a cikin tebur masu zuwa, da sauran bayanan da suka dace:

| Sensor Element | Gas | Lokacin gudu daidaitawa (h) | Dumama lokaci (s) | Yawan gudu (ml/min) | Gas aikace-aikace lokaci (s) |

| Infrared | Carbon dioxine | 1 | 30 | 150 | 180 |

| Semiconductor | HFC | 24 | 300 | 150 | 180 |

| Pellistore | Mai ƙonewa | 24 | 300 | 150 | 120 |

Matakan daidaitawa

Da farko shiga cikin Yanayin Sabis

- Danna Shigar don shigarwa a cikin menu kuma danna ƙasa har sai menu na shigarwa & Calibration

- Danna Shigar kuma an nuna Yanayin Sabis

- Danna Shigar, shigar da kalmar wucewa ****, danna Shigar da kibiya ta ƙasa don canza matsayi daga KASHE zuwa ON sannan kuma danna Shigar.

Lokacin da naúrar ke cikin Yanayin Sabis ɗin nunin rawaya LED yana kyalli.

Daga menu na shigarwa & Sabis, ta amfani da gungurawar kibiya ta ƙasa har zuwa menu na Calibration kuma latsa Shigar.

Ana nuna nau'in firikwensin gas. Ta amfani da maɓallan kibiya na Shiga da sama/ƙasa suna saita adadin iskar gas a ppm:

- don firikwensin CO2, zaɓi 10000 ppm wanda yayi daidai da 50% na kewayon auna firikwensin

- don firikwensin HFC, zaɓi 1000 ppm wanda yayi daidai da 50% na kewayon auna firikwensin

- don firikwensin PE, zaɓi 250 ppm wanda yayi daidai da 50% na kewayon auna firikwensin

Siffar ma'auni

- Zaɓi menu na daidaitawa Zero.

- Idan akwai firikwensin CO2, Zero Calibration dole ne a aiwatar da shi ta hanyar fallasa firikwensin zuwa tsarkakakken Nitrogen, kwararar iskar gas iri ɗaya.

- Kafin aiwatar da gyare-gyaren sifili, ƙayyadadden lokacin dumama dole ne a kiyaye sosai kafin fara aikin.

- Haɗa silinda gas ɗin daidaitawa zuwa kan firikwensin ta amfani da adaftar daidaitawa 148H6232. Hoto 3

Bude mai daidaita kwararar iskar gas na silinda. Yayin lissafin maƙiyi a layi na biyu, yana gudana daga hagu zuwa dama kuma ƙimar yanzu tana faɗuwa zuwa sifili. Lokacin da ƙimar halin yanzu ta tsaya latsa Shigar don adana lissafin sabuwar ƙima. Ana nuna "SAVE", muddin aikin ya cika. Bayan an yi nasarar adana darajar, murabba'i yana bayyana a hannun dama na ɗan gajeren lokaci = an gama daidaita ma'aunin sifili kuma an adana sabon sifili tare da nasara. Nunin yana zuwa ta atomatik zuwa nunin ƙimar yanzu.

Yayin lokacin lissafin, saƙonni masu zuwa na iya faruwa:

| Sako | Bayani |

| Ƙimar yanzu ta yi girma sosai | Gas mara daidai don daidaita ma'aunin sifili ko na'urar firikwensin mara lahani. Sauya kan firikwensin. |

| Ƙimar yanzu ta yi ƙanƙanta | Gas mara daidai don daidaita ma'aunin sifili ko na'urar firikwensin mara lahani. Sauya kan firikwensin |

| Ƙimar yanzu mara karko | Yana bayyana lokacin da siginar firikwensin bai isa wurin sifili ba a cikin lokacin da aka yi niyya. Yana ɓacewa ta atomatik lokacin da siginar firikwensin ya tsaya. |

|

Lokaci ya yi takaice sosai |

Saƙon "darajar mara ƙarfi" yana farawa mai ƙidayar lokaci. Da zarar mai ƙidayar lokaci ya ƙare kuma ƙimar halin yanzu ba ta da ƙarfi, za a nuna rubutun. Tsarin yana sake farawa. Idan ƙimar ta tsaya tsayin daka, ana nuna ƙimar halin yanzu kuma ana ci gaba da aikin daidaitawa. Idan an maimaita sake zagayowar sau da yawa, kuskuren ciki ya faru. Dakatar da tsarin daidaitawa kuma maye gurbin kan firikwensin. |

| Kuskuren ciki | Calibration ba zai yiwu ba ® duba idan an gama aikin tsabta mai kona ko katse shi da hannu ko duba/masanya kan firikwensin. |

Idan zubar da sifili na daidaitawa, ba za a sabunta ƙimar da aka biya ba. Shugaban firikwensin ya ci gaba da amfani da “tsohuwar” sifili. Dole ne a gudanar da cikakken tsari na yau da kullun don adana kowane canjin daidaitawa.

Samun Calibration

- Ta amfani da maɓallin kibiya, zaɓi menu na Gain.

- Haɗa silinda gas ɗin daidaitawa zuwa kan firikwensin ta amfani da adaftar daidaitawa (Fig. 1).

- Bude mai sarrafa kwararar Silinda don fara ƙyale kwararar wanda aka ba da shawarar zama mafi ƙarancin 150 ml/min.

- Danna Shigar don nuna ƙimar da aka karanta a halin yanzu, bayan wasu mintuna, da zarar ƙimar ppm ta daidaita, sake danna Shigar don fara daidaitawa.

- A cikin layi na 2, yayin lissafin, ƙididdiga yana gudana daga hagu zuwa dama kuma ƙimar halin yanzu tana haɗuwa zuwa saitin gas ɗin gwajin da ya gudana.

- Lokacin da ƙimar halin yanzu ta tsaya tsayin daka kuma kusa da ƙimar ma'aunin daidaitawar iskar gas ɗin da aka saita, danna Shigar don kammala lissafin sabuwar ƙimar.

- Bayan an yi nasarar adana darajar, murabba'i yana bayyana a hannun dama na ɗan gajeren lokaci = An gama haɓaka haɓaka sabon riba an adana shi tare da nasara.

- Nunin yana zuwa ta atomatik zuwa nunin ƙimar ppm na yanzu.

Yayin lokacin lissafin, saƙonni masu zuwa na iya faruwa:

| Sako | Bayani |

| Ƙimar yanzu ta yi girma sosai | Gwaji maida hankali gas> fiye da saita ƙimar Kuskuren ciki® maye gurbin firikwensin kan |

| Ƙimar yanzu tayi ƙasa sosai | Babu gwajin gas ko iskar gwajin kuskure da aka shafa akan firikwensin. |

| Gwajin gas yayi girma Gwajin iskar gas yayi ƙasa sosai | Saitin gwajin iskar gas dole ne ya kasance tsakanin 30% zuwa 90% na kewayon aunawa. |

| Ƙimar yanzu mara karko | Yana bayyana lokacin da siginar firikwensin bai isa wurin daidaitawa a cikin lokacin da aka yi niyya ba. Yana ɓacewa ta atomatik lokacin da siginar firikwensin ya tsaya. |

|

Lokaci ya yi takaice sosai |

Saƙon "darajar mara ƙarfi" yana farawa mai ƙidayar lokaci. Da zarar mai ƙidayar lokaci ya ƙare kuma ƙimar halin yanzu ba ta da ƙarfi, za a nuna rubutun. Tsarin yana sake farawa. Idan ƙimar ta tsaya tsayin daka, ana nuna ƙimar halin yanzu kuma ana ci gaba da aikin daidaitawa. Idan an maimaita sake zagayowar sau da yawa, kuskuren ciki ya faru. Dakatar da tsarin daidaitawa kuma maye gurbin kan firikwensin. |

| Hankali | Sensitivity na firikwensin kai <30%, daidaitawa ba zai yiwu ba ® maye gurbin kan firikwensin. |

|

Kuskuren ciki |

Calibration ba zai yiwu ba ® duba idan an gama aikin tsabta mai kona ko katse shi da hannu

ko duba/masanya shugaban firikwensin. |

A ƙarshen hanyar daidaitawa fita daga Yanayin Sabis.

- Latsa ESC

- Danna kibiya sama har sai menu na Yanayin Sabis

- Danna Shigar kuma Ana nuna Yanayin Sabis ON

- Danna Shigar da kibiya ta ƙasa don canza hali daga ON zuwa KASHE sannan kuma danna Shigar kuma. Naúrar tana cikin Yanayin Aiki kuma nunin koren LED yana da ƙarfi.

Danfoss A / S

Maganin Yanayi danfoss.com +45 7488 2222 Duk wani bayani, gami da, amma ba'a iyakance ga bayanin zaɓi na samfur, aikace-aikacen sa ko amfani da shi ba, ƙirar samfur, nauyi, girma, iya aiki ko duk wani bayanan fasaha a cikin littattafan samfuran, kwatancen kasida, tallace-tallace, da dai sauransu kuma ko samuwa a rubuce, da baki, ta hanyar lantarki, kan layi ko ta hanyar saukewa, za a yi la'akari da bayani ne, kuma yana dauri kawai idan kuma har zuwa iyakar, an yi bayani a sarari a cikin zance ko tabbatarwa. Danfoss ba zai iya karɓar kowane alhakin yuwuwar kurakurai a cikin kasida, ƙasidu, bidiyo da sauran abubuwa ba. Danfoss yana da haƙƙin canza kayan sa ba tare da sanarwa ba. Wannan kuma ya shafi samfuran da aka ba da oda amma ba a isar da su ba muddin ana iya yin irin waɗannan sauye-sauye ba tare da canje-canje don ƙirƙira, dacewa ko Gyara samfurin ba. Duk alamun kasuwancin da ke cikin wannan kayan mallakar Danfoss A/S ne ko kamfanonin rukunin Danfoss. Danfoss da tambarin Danfoss alamun kasuwanci ne na Danfoss A/S. An kiyaye duk haƙƙoƙi.

Takardu / Albarkatu

|

Danfoss DGS Gwaje-gwajen Aiki da Tsarin daidaitawa [pdf] Jagorar mai amfani Gwaje-gwajen Aiki na DGS da Tsarin daidaitawa, DGS, Gwajin Aiki na DGS, Gwajin Aiki, Tsarin daidaitawa na DGS, Tsarin daidaitawa |