STM32 Motor Control SDK 6 Step Firmware Sensor Ngaphantsi Parameter

Iinkcukacha

- Igama leMveliso: I-STM32 yokulawula i-motor SDK - i-6-step firmware sensor-less parameter optimization

- Inombolo yomzekelo: UM3259

- Uhlaziyo: Rev 1-Novemba 2023

- Umenzi: STMicroelectronics

- Webindawo: www.st.com

Ngaphezuluview

Imveliso yenzelwe izicelo zokulawula iimoto apho indawo ye-rotor idinga ukumiselwa ngaphandle kokusebenzisa izinzwa. I-firmware ilungiselela iiparameters ze-sensor-less operation, eyenza ungqamaniso lwenyathelo lokutshintshela kunye nesikhundla se-rotor.

Ukufunyanwa kwe-BEMF kuZero-Okuwelayo:

I-electromotive force yangasemva (BEMF) iyatshintsha ngokuma kwe-rotor kunye nesantya. Amacebo amabini akhoyo ukuze kufunyanwe i-zero-crossing:

Ukuva i-EMF yangasemva ngexesha le-PWM OFF-time: Fumana isigaba esidadayo voltage nge-ADC xa kungekho mpompozo wangoku, uchonga u-zero-unqumla ngokusekelwe kumqobo.

Ukuva i-EMF yangasemva ngexesha le-PWM NGELIXESHA: Iziko=mpompo voltage ifikelela kwisiqingatha ibhasi voltage, ukuchonga i-zero-crossing esekelwe kwi-threshold (VS / 2).

I-STM32 yokulawula i-motor SDK-inyathelo eli-6 le-firmware ye-sensor-less parameter optimization

Intshayelelo

Olu xwebhu luchaza indlela yokwandisa iiparameters zoqwalaselo lwe-6-step, i-sensor-less algorithm. Injongo kukufumana inkqubo yokuqalisa egudileyo nekhawulezayo, kodwa kunye nokuziphatha okuzinzileyo okuvaliweyo. Ukongeza, olu xwebhu lukwachaza indlela yokufikelela kutshintsho olufanelekileyo phakathi kwe-EMF engasemva yokuwela i-zero ngexesha le-PWM OFF-ixesha kunye ne-PWM ON-ixesha xa ujikeleza i-motor ngesantya esiphezulu nge-voltage.tagubuchule bendlela yokuqhuba. Ukufumana iinkcukacha ezithe vetshe malunga ne-algorithm ye-6-step firmware kunye ne-voltage/ubuchule bokuqhuba obukhoyo, bhekisa kwincwadana yomsebenzisi enxulumeneyo ebandakanywe kwiphakheji yamaxwebhu e-X-CUBE-MCSDK.

Izifinyezo kunye nezifinyezo

| Isifinyezo |

Inkcazo |

| I-MCSDK |

Ikiti yophuhliso lwesoftware yolawulo lweemoto (X-CUBE-MCDK) |

| HW |

Hardware |

| IDE |

Indawo yophuhliso edibeneyo |

| MCU |

Iyunithi yokulawula iMicrocontroller |

| GPIO |

Injongo ngokubanzi igalelo/imveliso |

| ADC |

Isiguquli se-Analog-to-digital |

| VM |

UmqulutagImo |

| SL |

Isivamvo-ngaphantsi |

| BEMF |

Umva amandla e-electromotive |

| FW |

I-Firmware |

| ZC |

Zero-ukuwela |

| GUI |

Ujongano lomsebenzisi womzobo |

| MC |

Ulawulo lweemoto |

| I-OCP |

Ukhuseleko lwangoku |

| PID |

I-Proportional-integral-derivative (umlawuli) |

| SDK |

Ikhithi yophuhliso lwesoftware |

| UI |

Indawo yomsebenzisi |

| MC workbench |

Isixhobo sokulawula ibhentshi yemoto, inxalenye ye-MCSDK |

| Umqhubi wemoto |

Motor pilot isixhobo, inxalenye MCSDK |

Ngaphezuluview

Kwi-6-step sensor-less drive mode, i-firmware ixhaphaza amandla e-electromotive yangemva (BEMF) avakalelwe kwinqanaba lokudada. Isikhundla se-rotor sifunyenwe ngokufumanisa i-zero-crossing ye-BEMF. Oku ngokuqhelekileyo kwenziwa ngokusebenzisa i-ADC, njengoko kuboniswe kuMfanekiso 1. Ngokukodwa, xa i-magnetic field ye-rotor iwela i-high-Z isigaba, i-BEMF ehambelana nayo.tage itshintsha uphawu lwayo (zero-crossing). IBEMF voltagi-e inokulinganiswa kwigalelo le-ADC, ngenxa yenethiwekhi ye-resistor eyahlula i-voltage evela kwisigaba semoto.

Nangona kunjalo, ekubeni isibonakaliso se-BEMF silingana nesantya, indawo ye-rotor ayikwazi ukumiselwa ekuqaleni, okanye ngesantya esiphantsi kakhulu. Ke ngoko, i-motor kufuneka ikhawuleziswe kwindawo evulekileyo kude kube yi-BEMF voltage ifikelelwe. Loo BEMF voltage ivumela ungqamaniso lwenyathelo lokuhamba kunye nesikhundla se-rotor.

Kule mihlathi ilandelayo, inkqubo yokuqalisa kunye nokusebenza kwe-loop evaliweyo, kunye neeparitha zokuzilungisa, zichazwe.

BEMF ubhaqo wokuwela zero

Umva we-EMF waveform ye-brushless motor iyatshintsha kunye nendawo yerotor kunye nesantya kwaye ikwimo yetrapezoidal. Umzobo 2 ubonisa i-waveform ye-EMF yangoku kunye nomva kwithuba elinye lombane, apho umgca oqinileyo uchaza okwangoku (ii-ripples azihoywa ngenxa yokulula), umgca odayiweyo umele amandla angasemva e-electromotive, kwaye ulungelelwaniso oluthe tye lumele umbane. imbono yokujikeleza kwemoto.

Umbindi wazo zonke izigaba ezimbini zokutshintsha iindawo zihambelana nenqaku elinye apho umva we-electromotive force polarity utshintshiwe: i-zero-cross-point. Emva kokuba indawo yokuwela i-zero ichongiwe, umzuzu wokutshintsha isigaba umiselwe emva kokulibaziseka kombane we-30 °. Ukubona i-zero-crossing ye-BEMF, i-central tap voltagkufuneka yaziwe. Umpompo ophakathi ulingana nendawo apho izigaba ezintathu zeemoto zidibene kunye. Ezinye iinjini zenza itephu esembindini ifumaneke. Kwezinye iimeko, inokwakhiwa ngokutsha ngevolthitagizigaba. I-algorithm ye-6-step echazwe apha ithatha i-advantage yobukho be-BEMF inzwa womnatha eqhagamshelwe kwizigaba motor evumela ukubala iziko impompo voltage.

- Kukho izicwangciso ezimbini ezahlukeneyo zokuchongwa kwendawo yokuwela i-zero

- Ukuva i-EMF yangasemva ngexesha le-PWM OFF-time

- Umva i-EMF yokuva ngexesha le-PWM ON-ixesha (okwangoku ixhaswa kwi-voltagimowudi ye-e kuphela)

Ngexesha le-PWM OFF-ixesha, isigaba esidadayo voltage ifunyanwa yi-ADC. Ekubeni akukho msinga uqukuqelayo kwisigaba esidadayo, kwaye ezinye ezimbini ziqhagamshelwe emhlabeni, xa i-BEMF inqumla i-zero kwisigaba sokudada, ine-polarity elinganayo kunye nechaseneyo kwezinye izigaba: i-voltage ye-tap yeziko.tage ke ngoko nguziro. Ngenxa yoko, i-zero-cross point ichongiwe xa ukuguqulwa kwe-ADC kuphakama ngasentla, okanye iwela ngaphantsi, umyinge ochaziweyo.

Ngakolunye uhlangothi, ngexesha le-PWM ON-ixesha, isigaba esinye sixhunyiwe kwi-bus voltage, kunye nomnye emhlabeni (Umfanekiso 3). Kule meko, i tap embindini voltage ifikelela kwisiqingatha ibhasi voltagIxabiso xa i-BEMF kwisigaba esidadayo ingu-zero. Njengangaphambili, indawo yokuwela i-zero ichongiwe xa ukuguqulwa kwe-ADC kuphakama ngaphezulu (okanye iwela ngaphantsi) kwinqanaba elichaziweyo. Le yokugqibela ihambelana ne-VS / 2.

Uyilo lwenethiwekhi yokubona i-BEMF

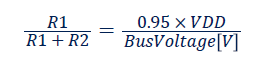

KuMfanekiso 4 inethiwekhi esetyenziswa ngokuqhelekileyo ukuva i-BEMF ibonisiwe. Injongo yayo kukwahlula i-motor phase voltage ukuba ifunyanwe ngokufanelekileyo yi-ADC. Amaxabiso e-R2 kunye ne-R1 kufuneka akhethwe ngokomthamo webhasitage kwinqanaba. Umsebenzisi kufuneka aqaphele ukuba ukuphumeza umlinganiselo we-R1 / (R2 + R1) ophantsi kakhulu kunokuba uyimfuneko, isignali ye-BEMF inokubangela ukuba iphantsi kakhulu kwaye ulawulo alunamandla ngokwaneleyo.

Ngakolunye uhlangothi, umlinganiselo ophezulu kunokuba uyimfuneko uya kukhokelela ekuvuleni / ukuvala rhoqo i-D1 yokukhusela i-diodes apho ukubuyisela okwangoku kunokufaka ingxolo. Ixabiso elicetyiswayo ngu:

Amaxabiso aphantsi kakhulu e-R1 kunye ne-R2 kufuneka aphetshwe ukucutha umbane okhoyo ukusuka kwinqanaba lemoto.

I-R1 ngamanye amaxesha idityaniswe kwi-GPIO endaweni ye-GND. Ivumela inethiwekhi ukuba isebenze okanye ingasebenzi.

Kwi-firmware ye-6-step, i-GPIO ihlala ikwimo yokusetha kwakhona kwaye inethiwekhi ivuliwe. Nangona kunjalo, ubukho bokugqibela be-D3 kufuneka buqwalaselwe xa ubeka i-BEMF thresholds yokuva ngexesha le-PWM ON-time: ngokuqhelekileyo yongeza i-0.5÷0.7 V kwi-threshold efanelekileyo.

I-C1 yenzelwe iinjongo zokucoca kwaye akufunekanga ithintele i-bandwidth yesignali kuluhlu lwamaza e-PWM.

I-D4 kunye ne-R3 zezokukhutshwa ngokukhawuleza kwe-BEMF_SENSING_ADC node ngexesha lohambo lwe-PWM, ngakumbi kwivolthi ephezulu.tagiibhodi e.

I-D1 kunye ne-D2 diode ziyi-optional kwaye kufuneka zongezwe kuphela xa kukho umngcipheko wokuphulwa kwe-BEMF iva i-ADC channel ratings ubuninzi.

Ukuphuculwa kweeparamitha zealgorithm yolawulo

Inkqubo yokuqalisa

Inkqubo yokuqalisa ikholisa ukwenziwa ngolandelelwano lwemizuzwana emithathutages:

- Ulungelelwaniso. I-rotor ihambelana kwindawo echazwe kwangaphambili.

- Ukukhawulezisa i-loop. UmqulutagIipulses ze-e zisetyenziswe ngokulandelelana kwangaphambili ukudala intsimi yamagnetic eyenza i-rotor iqale ukujikeleza. Izinga lokulandelelana linyuka ngokuqhubekayo ukuvumela i-rotor ukuba ifikelele kwisantya esithile.

- Ukutshintsha-ngaphaya. Emva kokuba i-rotor ifikelele kwisantya esithile, i-algorithm itshintshela kwi-loop evaliweyo ye-6-step ulandelelwano lokulawula ukugcina ulawulo lwesantya kunye nolwalathiso lwemoto.

Njengoko i-shwn kwi-Figure 5, umsebenzisi unokwenza ngokwezifiso iiparitha zokuqalisa kwi-MC workbench ngaphambi kokuvelisa ikhowudi. Iindlela zokuqhuba ezimbini ezahlukeneyo ziyafumaneka:

- Umqulutagimowudi ye. I-algorithm ilawula isantya ngokuguqula umjikelo womsebenzi we-PWM osetyenziswa kwizigaba zemoto: iSigaba esijoliswe kuyotage ichazwa kwicandelo ngalinye loqaliso lweprofile

- Imo yangoku. I-algorithm ilawula isantya ngokutshintsha indlela yangoku equkuqelayo kwizigaba zemoto: Ithagethi yangoku ichazwa kwicandelo ngalinye lepro.file

Umzobo 5. Iiparamitha zokuqalisa kwi-workbench ye-MC

Ulungelelwaniso

KuMfanekiso 5, iSigaba 1 sihlala sihambelana nesinyathelo sokulungelelanisa. I-rotor ihambelana ne-6-step position esondeleyo "kwi-angle yokuqala yombane".

Kubalulekile ukuqaphela ukuba, ngokungagqibekanga, ubude beSigaba soku-1 ngama-200 ms. Ngeli nyathelo umjikelo womsebenzi uye wandiswa ngokulandelelana ukufikelela kwiSigaba ekujoliswe kuso uMqulutage (Isigaba Sangoku, ukuba imo yokuqhuba yangoku ikhethiwe). Nangona kunjalo, ngeenjini ezinkulu okanye kwimeko ye-inetia ephezulu, ubude bexesha eliphakanyisiweyo, okanye iSigaba ekujoliswe kuso.tagI-e/Yangoku isenokungonelanga ukuqalisa ngokufanelekileyo ukujikeleza.

KuMzobo we-6, uthelekiso phakathi kwemeko yolungelelwaniso olungalunganga kunye nolufanelekileyo lubonelelwe.

Ukuba ixabiso elijoliswe kuyo okanye ubude beSigaba 1 akwanelanga ukunyanzela i-rotor kwindawo yokuqala, umsebenzisi unokubona i-motor vibrating ngaphandle kokuqala ukujikeleza. Okwangoku, ukufunxa kwangoku kuyanda. Ngethuba lokuqala lenkqubo yokuqalisa, ukunyuka kwangoku kwanda, kodwa i-torque ayanele ukunqoba i-inertia yemoto. Phezulu kwi-Figure 6 (A), umsebenzisi unokubona ukwanda kwangoku. Nangona kunjalo, akukho bungqina be-BEMF: i-motor iye yamiswa. Emva kokuba inyathelo lokukhawulezisa liqalisiwe, indawo engaqinisekanga ye-rotor ithintela i-algorithm ekugqibeni inkqubo yokuqalisa kunye nokuqhuba i-motor.

Ukwandisa umthamotage/isigaba sangoku ngexesha lesigaba 1 singawulungisa umcimbi.

Kumqulutagimowudi, umthamo ekujoliswe kuwotage ngexesha lokuqalisa kungenziwa ngokwezifiso kunye ne-Motor Pilot ngaphandle kwesidingo sokuhlaziya ikhowudi. Kwi-Motor Pilot, kwicandelo le-rev-up, i-acceleration pro efanayofile yoMfanekiso 1 uxeliwe (jonga umfanekiso 7). Qaphela ukuba apha umqulutagIsigaba se-e sinokuboniswa njenge-pulse ebekwe kwirejista yexesha (iyunithi ye-S16A), okanye njengoko ihambelana nomthamo wemveliso.tage (iyunithi yeeVrms).

Nje ukuba umsebenzisi afumane amaxabiso afanelekileyo afanele imoto, la maxabiso anokuphunyezwa kwiprojekthi ye-MC workbench. Ivumela ukuhlaziya ikhowudi ukusebenzisa ixabiso elingagqibekanga. Le fomula ingezantsi icacisa unxulumano phakathi komthamotagIsigaba se-e kwiiyunithi zeVrms kunye ne-S16A.

Kwimodi yangoku, kwi-Motor Pilot GUI, i-target yangoku iboniswa kuphela kwi-S16A. Ukuguqulwa kwayo kwi ampere ixhomekeke kwixabiso le-shunt kunye ne ampInzuzo ye-liification esetyenziswa kwisekethe ye-limiter yangoku.

Ukukhawulezisa i-loop

KuMzobo 5, iSigaba sesi-2 sihambelana nesigaba sokukhawuleza. Ukulandelelana kwamanyathelo ama-6 kusetyenziswe ukukhawulezisa i-motor kwi-open-loop, ngoko ke, indawo ye-rotor ayihambelani kunye ne-6-step sequence. Izigaba zangoku ziphezulu kunezona zilungileyo kwaye i-torque iphantsi.

Kwi-workbench ye-MC (Umfanekiso 5) umsebenzisi unokuchaza icandelo elinye okanye ngaphezulu kokukhawuleza. Ngokukodwa, kwi-motor bulky, kucetyiswa ukuba ikhawulezise nge-r ecothayoamp ukoyisa inertia phambi kokwenza umnqantsa ramp. Ngexesha lecandelo ngalinye, umjikelo womsebenzi unyuswa ngokomgca ukufikelela kwithagethi yokugqibela yomthamotage/inqanaba langoku lelo candelo. Ngaloo ndlela, inyanzelisa ukuguqulwa kwezigaba kwisantya esihambelanayo esiboniswe kwitheyibhile efanayo yokucwangcisa.

KuMzobo 8, uthelekiso phakathi kokukhawuleza kunye nomthamotagIsigaba (A) siphantsi kakhulu kwaye esifanelekileyo (B) sinikezelwe.

Ukuba ithagethi voltagI-e / yangoku yesigaba esinye okanye ubude bayo akwanelanga ukuvumela i-motor ukuba ifikelele kweso santya esihambelanayo, umsebenzisi unokubona i-motor ukuyeka ukujikeleza kwaye iqale ukungcangcazela. Phezulu kwi-Figure 8, i-current iyanda ngokukhawuleza xa i-motor stalls ngelixa, xa ikhawuleza ngokufanelekileyo, ukunyuka kwangoku ngaphandle kokuyeka. Nje ukuba injini iyeke, inkqubo yokuqalisa ayiphumeleli.

Ukwandisa umthamotage/isigaba sangoku sinokuwulungisa umcimbi.

Kwelinye icala, ukuba voltagI-e / isigaba sangoku esichazwe siphezulu kakhulu, ekubeni i-motor isebenza ngokungafanelekanga kwi-open-loop, i-current ingaphakama kwaye ifikelele kwi-overcurrent. I-motor iyama ngequbuliso, kwaye i-alarm ye-overcurrent iboniswa yi-Motor Pilot. Indlela yokuziphatha yangoku iboniswe kuMfanekiso 9.

Ukunciphisa umthamotage/isigaba sangoku sinokuwulungisa umcimbi.

Njengenyathelo lokulungelelanisa, ithagethi voltagi-e/ yangoku inokuba yi-runtime eyenziwe ngokwezifiso ngexesha lokuqalisa kunye ne-Motor Pilot ngaphandle kwesidingo sokuhlaziya ikhowudi. Emva koko, inokuphunyezwa kwiprojekthi ye-workbench ye-MC xa isethingi efanelekileyo ichongiwe.

Ukutshintsha-ngaphaya

Inyathelo lokugqibela lenkqubo yokuqalisa kukutshintshela phezulu. Ngeli nyathelo, i-algorithm ixhaphaza i-BEMF evakalelwayo ukuvumelanisa ukulandelelana kwe-6-step kunye ne-rotor position. Ukutshintsha-ukuqala kuqala kwicandelo eliboniswe kwipharamitha echazwe kwi-Figure 10. Iyalungiseka kwicandelo leparameter yokuqalisa inzwa ye-MC workbench.

Emva kwe-BEMF esebenzayo ye-zero-crossing signal yokufumanisa (ukuzalisekisa le meko jonga iCandelo 2.1), i-algorithm itshintshela kwi-loop-loop operation. Inyathelo lokutshintshela ngaphezulu linokusilela ngenxa yezi zizathu zilandelayo:

- Isantya sokutshintsha asilungiswanga kakuhle

- Iinzuzo zePI zelophu yesantya ziphezulu kakhulu

- Imiqobo yokubona isiganeko se-BEMF sokuwela u-zero ayimiselwanga kakuhle

Isantya sokutshintsha asibulelwanga kakuhle

Isantya apho utshintsho luqala khona ngokungagqibekanga lufana nesantya sokuqala ekujoliswe kuso esinokuthi siqwalaselwe kwicandelo lokubeka i-drive ye-workbench ye-MC. Umsebenzisi kufuneka aqaphele ukuba, ngokukhawuleza ukuba i-loop yesantya ivaliwe, i-motor ikhawuleza ngokukhawuleza ukusuka kwisantya sokutshintsha ukuya kwisantya esijoliswe kuyo. Ukuba la maxabiso mabini aqelelene kakhulu, ukusilela kwe-overcurrent kunokwenzeka.

Iinzuzo zePI zelophu yesantya iphezulu kakhulu

Ngexesha lokutshintsha, i-algorithm isuka ekunyanzeleni ulandelelwano oluchazwe ngaphambili ukulinganisa isantya kwaye ubale ixabiso lemveliso ngokufanelekileyo. Ngaloo ndlela, ihlawulela esona santya sisiphumo sokuvuleka kwe-loop. Ukuba iinzuzo ze-PI ziphezulu kakhulu, ukungazinzi kwexeshana kunokuba namava, kodwa kunokukhokelela ekungaphumelelini okugqithisileyo xa kugqithiswa.

Umfanekiso we-11 ubonisa kunye nomzekeloampUkungazinzi okunjalo ngexesha lotshintsho ukusuka kwi-open-loop ukuya kwi-loop-loop evaliweyo.

I-BEMF engalunganga imida

- Ukuba i-BEMF threshold engalunganga isetiwe, i-zero-crossing ibonakala kwangaphambili okanye emva kwexesha. Oku kuxhokonxa iziphumo ezimbini eziphambili:

- Iifom zamaza zi-asymmetric kunye nolawulo olungasebenziyo olukhokelela kwi-ripples ephezulu ye-torque (Umfanekiso we-12)

- I-loop yesantya iba yinto engazinzanga ngokuzama ukubuyisela i-ripples of torque

- Umsebenzisi uya kuba namava okulawula isantya esingazinzanga kwaye, kwiimeko ezimbi kakhulu, ukulungelelaniswa kwe-motor drive kunye nolawulo olukhokelela kwisiganeko esidlulayo.

- Ukusetwa okufanelekileyo kwe-BEMF thresholds kubalulekile ekusebenzeni kakuhle kwe-algorithm. I-Thresholds nayo ixhomekeke kumthamo webhasitagIxabiso le-e kunye nenethiwekhi yeemvakalelo. Kucetyiswa ukuba ubhekisele kwiCandelo 2.1 ukujonga indlela yokulungelelanisa umqulutage amanqanaba ukuya kwelo lisezantsi iseti kwi MC workbench.

Umsebenzi ovaliweyo

Ukuba i-motor igqiba isigaba sokukhawulezisa, i-BEMF i-zero-crossing ifunyenwe. I-rotor ivumelanisa kunye nokulandelelana kwezinyathelo ezi-6 kunye nokusebenza kwe-loop evaliweyo kufunyenwe. Nangona kunjalo, ukwenziwa ngcono kweparamitha kunokwenziwa ukuphucula ukusebenza.

Ngokomzekelo, njengoko kuchazwe kwiCandelo le-3.1.3 yangaphambili ("Ii-BEMF ezingalunganga"), i-loop yesantya, nokuba iyasebenza, ingabonakala ingazinzanga kwaye i-BEMF threshold ingadinga ukulungiswa.

Ukongeza, le miba ilandelayo kufuneka ithathelwe ingqalelo ukuba imoto iceliwe ukuba isebenze ngesantya esiphezulu okanye iqhutywe ngomjikelo ophezulu womsebenzi we-PWM:

Ukuhamba rhoqo kwePWM

- Isantya loop PI iinzuzo

- Isigaba sexesha le-Demagnetization blanking period

- Ukulibaziseka phakathi kokuwela iqanda kunye nenyathelo lokuhamba

- Tshintsha phakathi kwe-PWM OFF-ixesha kunye ne-ON-time sensing

Ukuhamba rhoqo kwePWM

I-sensor-less 6-step algorithm yenza ukufunyanwa kwe-BEMF yonke imijikelo ye-PWM. Ukubona ngokufanelekileyo isiganeko sokuwela i-zero, inani elaneleyo lokufunyanwa liyafuneka. Njengomthetho wesithupha, ekusebenzeni ngokufanelekileyo, ubuncinane ukuthengwa kwe-10 ngaphezu kwee-angles zombane ze-60 kunika ukulungelelaniswa kwe-rotor okulungileyo kunye nokuzinza.

Ngoko ke

Isantya loop PI iinzuzo

I-speed loop ye-PI iinzuzo zichaphazela ukuphendula kwemoto kuwo nawuphi na umyalelo wokukhawulezisa okanye wokunciphisa. Inkcazo yethiyori yendlela umlawuli we-PID asebenza ngayo ingaphaya kwemida yolu xwebhu. Nangona kunjalo, umsebenzisi kufuneka aqonde ukuba iinzuzo zokulawula i-loop yesantya zinokutshintshwa ngexesha lokuqhuba nge-Motor Pilot kwaye zihlengahlengiswe njengoko ufuna.

Isigaba sexesha le-Demagnetization blanking period

I-demagnetization yesigaba sokudada yithuba emva kokutshintshwa kwamandla esigaba apho, ngenxa yokukhutshwa kwangoku (Umfanekiso we-14), ukufundwa kwe-EMF yangasemva akuthembekanga. Ngoko ke, i-algorithm kufuneka ingawunaki umqondiso ngaphambi kokuba idlule. Eli xesha lichazwe kwi-workbench ye-MC njengepesentitaginyathelo (izidanga zombane ezingama-60) kwaye inokutshintshwa ixesha lokubaleka ngeMotor Pilot njengoko kubonisiwe kuMfanekiso 15. Okukhona siphezulu isantya semoto, kokukhona sikhawuleza ixesha lokumisa imagnethi. I-demagnetization, ngokungagqibekanga, ifikelela kumda osezantsi obekwe kwimijikelo emithathu ye-PWM kwi-2/3 yesantya esiphezulu esilinganiselweyo. Ukuba isigaba se-inductance se-motor siphantsi kwaye ayifuni ixesha elininzi lokukhupha i-demagnetize, umsebenzisi unokunciphisa ixesha lokufihla okanye isantya apho elona xesha lincinci libekwe khona. Nangona kunjalo, akukhuthazwa ukuba unciphise ixesha lokufihla ngaphantsi kwe-2 - 3 imijikelezo ye-PWM kuba ulawulo lunokubangela ukungazinzi ngokukhawuleza ngexesha lokuhamba kwesinyathelo.

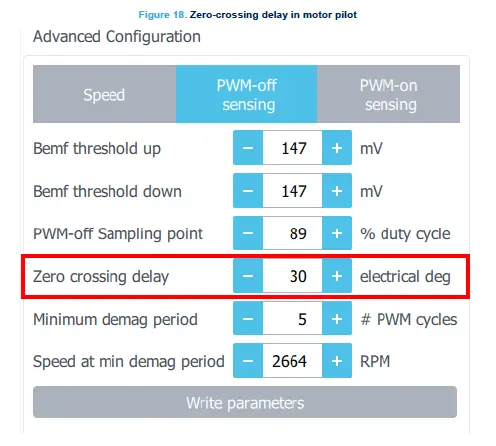

Ukulibaziseka phakathi kwe-BEMF i-zero-crossing kunye nenyathelo lokuhamba

Emva kokuba isiganeko se-BEMF se-zero-crossing sifunyenwe, i-algorithm ngokuqhelekileyo ilinda i-degrees zombane ze-30 kude kube yinkqubo yokulandelelana kwesinyathelo (Umfanekiso 16). Ngale ndlela, i-zero-crossing ibekwe kwi-midpoint yesinyathelo ukujolisa ukusebenza okuphezulu.

Ekubeni ukuchaneka kokufunyanwa kwe-zero-crossing kuxhomekeke kwinani lokufunyanwa, ngoko ke kwi-frequency ye-PWM (jonga iCandelo 3.2.1), ukuchaneka kokufunyanwa kwayo kunokubaluleka kwisantya esiphezulu. Emva koko ivelisa i-asymmetricity ecacileyo ye-waveforms kunye nokuphazamiseka kwangoku (jonga umfanekiso we-17). Oku kunokubuyekezwa ngokunciphisa ukulibaziseka phakathi kokufunyanwa kwe-zero-crossing kunye noguqulo lwenyathelo. Ukulibaziseka kweZero-crossing kungatshintshwa ngumsebenzisi ngeMoto Pilot njengoko kubonisiwe kuMfanekiso 18.

Tshintsha phakathi kwe-PWM OFF-ixesha kunye ne-ON-time sensing

Ngelixa ukonyusa isantya okanye umthwalo wangoku (oko kukuthi i-torque ye-motor output), umjikelo womsebenzi wePWM wokuqhuba uyanda. Ngaloo ndlela, ixesha le-sampi-BEMF ngexesha le-OFF-time iyancitshiswa. Ukufikelela kwi-100% yomjikelezo womsebenzi, ukuguqulwa kwe-ADC kuqhutywe ngexesha le-ON-time ye-PWM, ngaloo ndlela itshintshe kwi-BEMF sensing ngexesha le-PWM OFF-time ukuya kwi-PWM ON-time.

Ukucwangciswa okungalunganga kwemigangatho ye-BEMF ngexesha le-ON-time kukhokelela kwimiba efanayo echazwe kwiCandelo 3.1.3 ("Ii-BEMF eziphosakeleyo").

Ngokungagqibekanga, i-BEMF ON-sensing thresholds imiselwe kwisiqingatha somthamo webhasitage (jonga iCandelo 2.1). Umsebenzisi kufuneka athathele ingqalelo ukuba imiqobo yokwenyani ixhomekeke kumthamo webhasitagIxabiso kunye nenethiwekhi yokuva. Landela izalathiso kwiCandelo 2.1 kwaye uqinisekise ukulungelelanisa umqulutage inqanaba ukuya kweyesiqhelo iseti kwi MC workbench.

Amaxabiso emithamo kunye nomjikelo womsebenzi we-PWM apho i-algorithm itshintshana phakathi kwe-OFF kunye ne-ON-sensing lixesha lokuqhuba elilungiselelwa nge-Motor Pilot (Figure 19) kwaye ifumaneka kwiVol.tagemowudi ukuqhuba kuphela.

Ukulungisa ingxaki

Yintoni endifanele ndiyinyamekele ngokufanelekileyo ukujikeleza i-motor kunye ne-algorithm ye-sensor-less 6-step algorithm? vumelanisa i-rotor kunye ne-algorithm yokulawula. Umlinganiselo ofanelekileyo weempawu zeBEMF ulele kuyilo olusebenzayo lwenethiwekhi ye-BEMF yokubona (jonga iCandelo 6). Umthamo ekujoliswe kuwotage (voltagimowudi yokuqhuba) okanye yangoku (ukuqhuba imowudi yangoku) ngexesha lokulandelelana kokuqalisa kuxhomekeke kwiiparamitha zeemoto. Inkcazo (kwaye ekugqibeleni ubude bexesha) lomqulutagI-e/isigaba sangoku ngexesha lokulungelelaniswa, ukukhawuleza, kunye namanyathelo okutshintshela ngaphaya kubalulekile kwinkqubo eyimpumelelo (jonga iCandelo 3).

Ekugqibeleni, ungqamaniso lwerotor kunye nokukwazi ukunyusa isantya semoto ukuya kwisantya esilinganiselweyo kuxhomekeke ekulungelelaniseni i-PWM frequency, i-BEMF thresholds, ixesha le-demagnetization kunye nokulibaziseka phakathi kokufunyanwa kwe-zero-crossing kunye nenyathelo lokuhamba, njengoko kuchaziwe Icandelo 3.2.

Liliphi ixabiso elifanelekileyo le-BEMF resistor divider?

Umsebenzisi kufuneka aqonde ukuba ixabiso elingalunganga le-BEMF resistor divider linokususa naliphi na ithuba lokuqhuba kakuhle imoto. Ukufumana iinkcukacha ezithe vetshe malunga nendlela yokuyila inethiwekhi ye-BEMF yokuziva, jonga kwiCandelo 2.1.

Ndiyiqwalasela njani inkqubo yokuqalisa?

- Ukwandisa inkqubo yokuqalisa, kuyacetyiswa ukuba kwandiswe ixesha lenyathelo ngalinye lesigaba sokuvuselela ukuya kwimizuzwana emininzi. Emva koko kunokwenzeka ukuqonda ukuba i-motor ikhawuleza ngokufanelekileyo, okanye ngeyiphi isantya / inyathelo lenkqubo ye-open-loop iyasilela.

- Akukhuthazwa ukukhawulezisa injini ye-inertia ephezulu kunye ne-r eqinileamp.

- Ukuba voltagIsigaba se-e okanye isigaba sangoku siphantsi kakhulu, i-motor stalls. Ukuba iphezulu kakhulu, i-overcurrent ibangelwa. Ngokuthe ngcembe ukwandisa umthamotagisigaba se-e (voltagimowudi yokuqhuba) okanye yangoku (ukuqhuba imowudi yangoku) ngexesha lolungelelwaniso kunye namanyathelo okukhawulezisa avumela umsebenzisi ukuba aqonde uluhlu lokusebenza kwemoto. Ngokwenene, kuyanceda ukufumana eyona ilungileyo.

- Xa kuziwa ekutshintsheni kwi-loop-loop operation, iinzuzo zePI kufuneka zincitshiswe ekuqaleni ukuba zingabandakanyi ukuba ukulahlekelwa kolawulo okanye ukungazinzi ngenxa yesantya. Ngeli xesha, ukuqiniseka ukuba inethiwekhi ye-BEMF yokuziva iyilwe ngokufanelekileyo (jonga iCandelo 2.1) kunye nomqondiso we-BEMF ofunyenwe ngokufanelekileyo kubalulekile. Umsebenzisi unokufikelela kufundo lwe-BEMF, kwaye uyicwangcise kwi-Motor Pilot (jonga uMfanekiso 20) ngokukhetha iirejista ezikhoyo BEMF_U, BEMF_V kunye ne-BEMF_U kwicandelo le-ASYNC lesixhobo. Nje ukuba i-motor ikwi-Run state, isilawuli se-loop yesantya sinokuphuculwa. Ukufumana iinkcukacha ezithe vetshe okanye ukusetyenziswa kweparamitha, jonga iCandelo 3 kunye neCandelo 3.2.

Ndingenza ntoni ukuba injini ayihambi xa kuqalwa?

- Ekuqalweni, ivolumu ekhulayo ngokuhambelanatage (voltagUkuqhuba kwe-e mode) okanye yangoku (ukuqhuba kwemowudi yangoku) kubonelelwe kwizigaba zeemoto. Injongo kukuyilungelelanisa kwindawo eyaziwayo nechazwe kwangaphambili. Ukuba voltagi-e ayiphezulu ngokwaneleyo (ingakumbi ngeenjini ezine-inertia ephezulu engatshintshiyo), i-motor ayishukumi kwaye inkqubo iyasilela. Ngolwazi oluthe vetshe malunga nezisombululo ezinokuthi zibekho, jonga kwiCandelo 3.1.1.

Ndingenza ntoni ukuba i-motor ayigqibi isigaba sokukhawulezisa?

Njengakwisigaba solungelelwaniso, i-motor ikhawuleziswa kwi-loop evulekileyo ngokusebenzisa i-voltage ekhulayotage (voltagUkuqhuba kwe-e mode) okanye yangoku (ukuqhuba kwemowudi yangoku) ukuya kwizigaba zeemoto. Amaxabiso ahlala ekhona akajongi umthwalo womatshini osele usetyenziswa, okanye iimotor constants azichanekanga kwaye/okanye zaziwa. Ke ngoko, inkqubo yokukhawulezisa inokusilela kunye ne-motor stall okanye isiganeko esigqithileyo. Ngolwazi oluthe vetshe malunga nezisombululo ezinokubakho, jonga kwiCandelo 3.1.2.

Kutheni le nto i-motor ingatshintshi kwisantya esivaliweyo?

Ukuba i-motor ikhawuleza ngokufanelekileyo kwisantya esijoliswe kuyo kodwa iyeka ngokukhawuleza, into enokuthi iphosakele kwi-BEMF threshold configuration okanye isilawuli se-PI sizuza. Jonga kwiCandelo 3.1.3 ngeenkcukacha ezithe vetshe.

Kutheni i-loop yesantya ibonakala ingazinzanga?

Ukwanda kwengxolo yomlinganiselo kunye nesantya esilindelekileyo njengoko isantya esiphezulu siphezulu, inani eliphantsi le-BEMF sampI-les ekubhaqweni kwe-zero-crossing kwaye, ngenxa yoko, ukuchaneka kokubala kwayo. Nangona kunjalo, ukungazinzi okugqithisileyo kwesantya sesantya kunokuba luphawu lwe-BEMF engalunganga okanye iinzuzo zePI ezingacwangciswanga ngokufanelekileyo, njengoko kugxininiswe kwiCandelo 3.1.3.

- Ndingasinyusa njani esona santya siphezulu sifikelelekayo?

Esona santya sifikelelekayo sidla ngokukhawulwa zizinto ezininzi: ukuphindaphindwa kwe-PWM, ukulahleka kolungelelwaniso (ngenxa yexesha eligqithileyo le-demagnetization okanye ukulibaziseka okungalunganga phakathi kokufunyanwa kwe-zero-crossing kunye nenyathelo lokuhamba), imida ye-BEMF engachanekanga. Ukufumana iinkcukacha ezithe vetshe malunga nendlela yokuphucula ezi zinto, jonga kwiCandelo 3.2.1, iCandelo 3.2.3, iCandelo 3.2.4 kunye neCandelo 3.2.5.

Kutheni le nto injini isuka ime ngequbuliso ngesantya esithile?

Kunokwenzeka ukuba kungenxa ye-PWM engachanekanga kwi-BEMF uqwalaselo lomda. Jonga kwiCandelo 3.2.5 ngeenkcukacha ezithe vetshe.

Imbali yohlaziyo

Uluhlu 2. Imbali yohlaziyo loxwebhu

| Umhla |

Inguqulelo |

Iinguqu |

| 24-Nov-2023 |

1 |

Ukukhutshwa kokuqala. |

ISAZISO ESIBALULEKILEYO – FUNDA NGOKUQAPHELELEYO

I-STMicroelectronics NV kunye ne-subsidiaries yayo ("ST") inelungelo lokwenza utshintsho, izilungiso, iziphuculo, ukuguqulwa, kunye nokuphuculwa kweemveliso ze-ST kunye / okanye kolu xwebhu nangaliphi na ixesha ngaphandle kwesaziso. Abathengi kufuneka bafumane ulwazi lwamva nje olufanelekileyo kwiimveliso ze-ST ngaphambi kokubeka iiodolo. Iimveliso ze-ST zithengiswa ngokuhambelana nemigaqo ye-ST kunye neemeko zokuthengisa kwindawo ngexesha lokuvuma umyalelo.

Abathengi banoxanduva kuphela lokhetho, ukhetho, kunye nokusetyenziswa kweemveliso ze-ST kwaye i-ST ayithathi tyala loncedo lwesicelo okanye uyilo lweemveliso zabathengi.

Akukho layisensi, echaziweyo okanye echaziweyo, kulo naliphi na ilungelo lepropathi enomgangatho ophezulu wokuqonda linikezelwa ngu-ST apha.

Ukuthengiswa kwakhona kweemveliso ze-ST ezinamalungiselelo ahlukileyo kulwazi oluchazwe apha kuya kuphelisa nayiphi na iwaranti enikwe yi-ST yaloo mveliso.

I-ST kunye ne-logo ye-ST ziimpawu zorhwebo ze-ST. Ngolwazi olongezelelweyo malunga neempawu zentengiso ze-ST, bhekisa ku

www.st.com/trademarks. Zonke ezinye iimveliso okanye amagama eenkonzo ziyipropati yabanini bazo.

Ulwazi olukolu xwebhu luthatha indawo kwaye luthatha indawo yolwazi olwalunikelwe ngaphambili kulo naluphi na uguqulelo lwangaphambili lolu xwebhu.

© 2023 STMicroelectronics – Onke amalungelo agciniwe

Amaxwebhu / Izibonelelo

Iimbekiselo