STM32 Sarrafa Motoci SDK Mataki na Firmware Sensor Ƙananan Sigo

Ƙayyadaddun bayanai

- Sunan samfur: STM32 sarrafa motar SDK - 6-mataki firmware firikwensin inganta siga

- Lambar samfurin: UM3259

- Bita: Rev 1 - Nuwamba 2023

- Mai ƙera: STMicroelectronics

- Website: www.st.com

Ƙarsheview

An ƙera samfurin don aikace-aikacen sarrafa motar inda ake buƙatar ƙaddara matsayin rotor ba tare da amfani da firikwensin ba. Firmware yana haɓaka sigogi don ƙarancin aiki na firikwensin, yana ba da damar aiki tare da canjin mataki tare da matsayi na rotor.

BEMF Gane-Cire-Zero:

Ƙarfin wutar lantarki na baya (BEMF) yana canzawa tare da matsayi da sauri. Akwai dabaru guda biyu don gano ƙetare sifili:

Komawar EMF a lokacin PWM KASHE-lokaci: Nemi lokaci mai iyo voltage ta ADC lokacin da babu mai gudana a halin yanzu, yana gano ketare sifili dangane da bakin kofa.

Komawar EMF a lokacin PWM ON-lokaci: Cibiyar = matsa voltage ya kai rabin bas voltage, gano ƙetare sifili dangane da bakin kofa (VS/2).

STM32 mai sarrafa motar SDK - 6-mataki firmware firikwensin inganta siga

Gabatarwa

Wannan daftarin aiki yana bayyana yadda ake haɓaka sigogin daidaitawa don mataki na 6, algorithm mara ƙarancin firikwensin. Manufar ita ce a sami tsarin farawa mai santsi da sauri, amma kuma tsayayyiyar halayyar rufaffiyar madauki. Bugu da ƙari, daftarin aiki kuma yayi bayanin yadda ake samun canjin da ya dace tsakanin baya-bayan EMF sifilin gano-tsare-tsare lokacin PWM KASHE-lokaci da PWM ON-lokaci yayin jujjuya motar a babban gudu tare da vol.tage dabaran yanayin tuƙi. Don ƙarin cikakkun bayanai game da 6-mataki firmware algorithm da voltage/dabarun tuƙi na yanzu, koma zuwa mai alaƙa da littafin mai amfani wanda aka haɗa a cikin fakitin takaddun X-CUBE-MCSDK.

Acronyms da gajarta

| Acronym |

Bayani |

| MCSDK |

Kayan haɓaka software na sarrafa motoci (X-CUBE-MCSDK) |

| HW |

Hardware |

| IDE |

Hadaddiyar yanayin ci gaba |

| MCU |

Naúrar Microcontroller |

| GPIO |

Gabaɗaya shigarwa/fitarwa |

| ADC |

Analog-zuwa-dijital Converter |

| VM |

Voltage yanayin |

| SL |

Sensor-ƙasa |

| BEMF |

Ƙarfin lantarki na baya |

| FW |

Firmware |

| ZC |

Sifili-ketare |

| GUI |

Ƙwararren mai amfani da hoto |

| MC |

Sarrafa motoci |

| OCP |

Kariyar wuce gona da iri |

| PID |

Matsakaicin-haɗe-haɗe-haɓaka (mai sarrafawa) |

| SDK |

Kayan haɓaka software |

| UI |

Mai amfani dubawa |

| MC aiki bench |

Kayan aikin benci na sarrafa motoci, wani ɓangare na MCSDK |

| matukin jirgi |

Kayan aikin matukin jirgi, wani bangare na MCSDK |

Ƙarsheview

A cikin yanayin tuƙi mara matakin firikwensin mataki 6, firmware yana amfani da ƙarfin lantarki na baya (BEMF) da aka sani a lokacin iyo. Ana samun matsayi na rotor ta hanyar gano sifili-ƙetare na BEMF. Ana yin wannan yawanci ta amfani da ADC, kamar yadda aka nuna a hoto na 1. Musamman, lokacin da filin maganadisu na rotor ya ketare matakin babban-Z, daidaitaccen BEMF vol.tage yana canza alamar sa (sifili-ƙetare). BEMF voltage za a iya ƙididdigewa a shigarwar ADC, godiya ga cibiyar sadarwa ta resistor wanda ke raba voltage yana fitowa daga tsarin motar.

Duk da haka, tun da siginar BEMF ya yi daidai da gudun, ba za a iya ƙayyade matsayi na rotor a farawa ba, ko kuma a cikin ƙananan gudu. Don haka, dole ne a haɓaka motar a cikin buɗaɗɗen madauki har sai isassun BEMF voltage yana isa. Wannan BEMF voltage yana ba da damar aiki tare da motsi na mataki tare da matsayi na rotor.

A cikin sakin layi masu zuwa, an bayyana tsarin farawa da rufaffiyar madauki, tare da sigogi don daidaita su.

BEMF Gane-Cikin Sifili

Siffar igiyar ruwa ta EMF ta baya na injin mara gogewa yana canzawa tare da matsayi na rotor da sauri kuma yana cikin siffar trapezoidal. Hoto na 2 yana nuna yanayin motsi na EMF na yanzu da baya na lokacin lantarki ɗaya, inda tsayayyen layin ke nuna halin yanzu (an yi watsi da ripples saboda sauƙi), layin da aka datse yana wakiltar ƙarfin electromotive na baya, kuma daidaitawar kwance tana wakiltar wutar lantarki. hangen nesa na jujjuyawar mota.

Tsakanin kowane maki-canzawa lokaci biyu yayi daidai da aya ɗaya wanda aka canza polarity na ƙarfin lantarki na baya: madaidaicin sifili. Da zarar an gano madaidaicin sifili, ana saita lokacin sauya lokaci bayan jinkirin lantarki na 30°. Don gano sifilin ketare na BEMF, tsakiyar matsa voltage dole ne a sani. Matsarar ta tsakiya tana daidai da wurin da aka haɗa matakan motsi guda uku tare. Wasu injina suna samar da fam ɗin tsakiya. A wasu lokuta, ana iya sake gina shi ta hanyar voltage matakai. Algorithm na mataki 6 da aka kwatanta a nan yana ɗaukar advantage na kasancewar cibiyar sadarwa ta BEMF da aka haɗa zuwa matakan motsi wanda ke ba da damar ƙididdige maɓallin tsakiyar voltage.

- Akwai dabaru daban-daban guda biyu don gano madaidaicin sifili

- Komawar EMF a lokacin KASHE-lokacin PWM

- Komawar EMF a lokacin PWM ON-lokaci (a halin yanzu ana tallafawa a cikin voltage yanayin kawai)

A lokacin KASHE-lokacin PWM, yanayin iyo voltage yana samun ta ADC. Tun da babu halin yanzu da ke gudana a cikin lokaci mai iyo, kuma sauran biyun suna da alaƙa da ƙasa, lokacin da BEMF ke ƙetare sifili a cikin lokacin iyo, yana da daidai kuma sabanin polarity akan sauran matakan: tsakiyar famfo vol.tage saboda haka zero. Don haka, ana gano madaidaicin sifili lokacin da canjin ADC ya tashi sama, ko faɗuwa ƙasa, ƙayyadaddun ƙofa.

A gefe guda, yayin PWM ON-lokaci, an haɗa kashi ɗaya zuwa bas voltage, da kuma wani zuwa ƙasa (Hoto na 3). A cikin wannan yanayin, tsakiyar famfo voltage ya kai rabin bas voltage darajar lokacin da BEMF a cikin yanayin iyo ya zama sifili. Kamar a baya, ana gano madaidaicin sifili lokacin da canjin ADC ya tashi sama (ko faɗuwa ƙasa) ƙayyadaddun ƙofa. Ƙarshen ya yi daidai da VS/2.

Ƙirar hanyar sadarwa ta BEMF

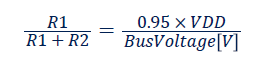

A cikin hoto 4 cibiyar sadarwar da aka saba amfani da ita don jin an nuna BEMF. Manufarsa ita ce a raba lokaci na motar voltage da za a samu da kyau ta ADC. Dole ne a zaɓi ƙimar R2 da R1 bisa ga juzu'in bastage daraja. Dole ne mai amfani ya sani cewa aiwatar da rabon R1 / (R2 + R1) da yawa ƙasa da yadda ake buƙata, siginar BEMF na iya haifar da ƙarancin ƙarfi kuma kulawar ba ta da ƙarfi sosai.

A gefe guda, rabon da ya fi yadda ake buƙata zai haifar da kunnawa akai-akai/kashe na diodes na kariya na D1 wanda halin yanzu na dawo da su na iya shigar da hayaniya. Ƙimar da aka ba da shawarar ita ce:

Dole ne a guji ƙima maras ƙanƙanta na R1 da R2 don iyakance taɓin halin yanzu daga lokacin motsi.

R1 wani lokaci ana haɗa shi zuwa GPIO maimakon GND. Yana ba da damar cibiyar sadarwa don kunna lokacin aiki ko kashewa.

A cikin firmware mataki 6, GPIO koyaushe yana cikin sake saiti kuma ana kunna hanyar sadarwa. Koyaya, kasancewar D3 na ƙarshe dole ne a yi la'akari da lokacin saita ƙofofin BEMF don ganewa yayin PWM ON-lokaci: yawanci yana ƙara 0.5 ÷ 0.7 V zuwa madaidaicin madaidaicin.

C1 don dalilai ne masu tacewa kuma dole ne kada ya iyakance bandwidth na sigina a cikin kewayon mitar PWM.

D4 da R3 sune don fitarwa da sauri na kumburin BEMF_SENSING_ADC yayin tafiyar PWM, musamman a babban vol.tage alluna.

Diodes D1 da D2 na zaɓi ne kuma dole ne a ƙara su kawai idan akwai haɗarin keta madaidaicin ƙimar tashar BEMF ta ADC.

Haɓaka sigogin sarrafa algorithm

Hanyar farawa

Hanyar farawa yawanci ana yin ta ne da jerin s ukutage:

- Daidaitawa. An daidaita na'ura mai jujjuyawa a wuri da aka riga aka kayyade.

- Buɗe madauki hanzari. Voltage pulses ana amfani da su a cikin jerin ƙayyadaddun don ƙirƙirar filin maganadisu wanda zai sa rotor ya fara juyawa. Ana ƙara ƙimar jeri a hankali don ba da damar rotor ya kai wani takamaiman gudu.

- Sauya-over. Da zarar na'ura mai juyi ya kai ga wani ƙayyadaddun gudu, algorithm yana canzawa zuwa rufaffiyar madauki mai lamba 6 jerin sarrafawa don kula da sarrafa saurin motar da alkibla.

Kamar yadda aka nuna a cikin Hoto 5, mai amfani zai iya tsara sigogin farawa a cikin MC workbench kafin samar da lambar. Akwai nau'ikan tuƙi daban-daban guda biyu:

- Voltage yanayin. Algorithm yana sarrafa saurin ta hanyar canza yanayin aikin PWM da aka yi amfani da shi zuwa matakan motsi: maƙasudin Mataki na Vol.tage an bayyana shi ga kowane bangare na mai farawafile

- Yanayin yanzu. Algorithm yana sarrafa saurin ta hanyar canza yanayin halin yanzu da ke gudana a cikin matakan motsi: an ayyana maƙasudin na yanzu don kowane yanki na farkon farawa.file

Hoto 5. Farawa sigogi a cikin MC workbench

Daidaitawa

A cikin hoto na 5, mataki na 1 koyaushe yana daidai da matakin daidaitawa. Rotor yana daidaitawa zuwa matsayi na 6-mataki mafi kusa da "kusurwar lantarki na farko".

Yana da mahimmanci a lura cewa, ta tsohuwa, tsawon lokaci na Mataki na 1 shine 200 ms. A lokacin wannan mataki ana ƙara zagayowar aiki a layi don isa ga maƙasudin Mataki na Voltage (Kashi na yanzu, idan an zaɓi yanayin tuƙi na yanzu). Koyaya, tare da manyan injina ko kuma a cikin yanayin rashin ƙarfi, tsawon lokacin da aka ba da shawarar, ko ma maƙasudin Mataki na Vol.tage/Yanzu bazai isa ba don fara juyi yadda yakamata.

A cikin hoto na 6, an ba da kwatanta tsakanin yanayin daidaitawa mara kyau da wanda ya dace.

Idan darajar manufa ko tsawon lokaci na Mataki na 1 bai isa ya tilasta mai rotor a wurin farawa ba, mai amfani zai iya ganin motsin motar ba tare da fara juyawa ba. A halin yanzu, sha na yanzu yana ƙaruwa. A lokacin farkon lokacin farawa, haɓakar halin yanzu yana ƙaruwa, amma juzu'i bai isa ya shawo kan inertia na motar ba. A saman Hoto na 6 (A), mai amfani zai iya ganin karuwa na yanzu. Duk da haka, babu wata shaida ta BEMF: motar tana tsayawa. Da zarar an fara matakin haɓakawa, matsayi mara tabbas na rotor yana hana algorithm daga kammala aikin farawa da tafiyar da motar.

Ƙara voltage/ halin yanzu lokaci a lokacin lokaci 1 na iya gyara batun.

A cikin voltage yanayin, manufa voltage a lokacin farawa za a iya keɓance shi tare da Matukin Mota ba tare da buƙatar sake sabunta lambar ba. A cikin matukin jirgi na Motoci, a cikin sashin sakewa, wannan haɓakawar profile na Hoto 1 an ruwaito (duba Hoto 7). Lura cewa a nan voltage lokaci ana iya nuna shi azaman bugun bugun jini da aka saita a cikin rajistar mai ƙidayar lokaci (S16A unit), ko kuma daidai da ƙarfin fitarwa.tage (Naúrar Vrms).

Da zarar mai amfani ya sami ingantattun ƙimar da suka dace da motar, waɗannan ƙimar za a iya aiwatar da su cikin aikin MC workbench. Yana ba da damar sabunta lambar don amfani da ƙimar tsoho. Wannan dabarar da ke ƙasa tana bayyana alaƙar da ke tsakanin voltage lokaci a cikin Vrms da S16A raka'a.

A cikin yanayin yanzu, a cikin GUI Pilot na Motar, ana nuna maƙasudin halin yanzu a cikin S16A kawai. Juyawansa a ampere ya dogara da ƙimar shunt da ampRibar lification da aka yi amfani da shi a cikin kewayawar iyaka na yanzu.

Buɗe madauki hanzari

A cikin Hoto na 5, Mataki na 2 yayi daidai da lokacin haɓakawa. Ana amfani da jerin matakai 6 don haɓaka motar a cikin madauki mai buɗewa, don haka, matsayi na rotor ba ya aiki tare da jerin matakai 6. Matsalolin na yanzu sun fi mafi kyau kuma karfin juyi yana ƙasa.

A cikin MC workbench (Hoto 5) mai amfani zai iya ayyana ɗaya ko fiye sassan haɓakawa. Musamman, don babban motar motsa jiki, ana bada shawara don hanzarta shi tare da hankali ramp don shawo kan rashin aiki kafin yin steeper ramp. A yayin kowane bangare, ana ƙara zagayowar aiki a layi don isa ga maƙasudin ƙarshe na voltage/lokacin yanzu na wannan sashin. Don haka, yana tilasta sauye-sauyen matakan a daidai saurin da aka nuna a cikin tebur ɗin daidaitawa ɗaya.

A cikin hoto na 8, kwatanta tsakanin haɓakawa tare da juzu'itage lokaci (A) yayi ƙasa da ƙasa kuma an samar da wanda ya dace (B).

Idan manufa voltage/na halin yanzu na lokaci ɗaya ko tsawon lokacinsa bai isa ba don ƙyale motar ta kai ga wannan gudun daidai ba, mai amfani zai iya ganin motar ta daina jujjuyawa kuma ta fara girgiza. A saman Hoto 8, halin yanzu yana ƙaruwa ba zato ba tsammani lokacin da motar ta tsaya yayin da, lokacin da aka haɓaka da kyau, halin yanzu yana ƙaruwa ba tare da katsewa ba. Da zarar motar ta tsaya, hanyar farawa ta kasa.

Ƙara voltage/ halin yanzu lokaci zai iya gyara matsalar.

A gefe guda, idan voltage/ halin yanzu da aka ayyana yana da girma sosai, tunda motar ba ta aiki da ƙarfi a cikin buɗaɗɗen madauki, na yanzu na iya tashi kuma ya kai ga jujjuyawa. Motar ta tsaya ba zato ba tsammani, kuma matukin motar ya nuna ƙararrawar ƙararrawa. Ana nuna halin halin yanzu a hoto na 9.

Rage voltage/ halin yanzu lokaci zai iya gyara matsalar.

Kamar matakin daidaitawa, manufa voltage/na halin yanzu ana iya keɓance lokacin gudu yayin farawa tare da matuƙin motar ba tare da buƙatar sabunta lambar ba. Bayan haka, ana iya aiwatar da shi a cikin aikin MC workbench lokacin da aka gano yanayin da ya dace.

Sauya-over

Mataki na ƙarshe na hanyar farawa shine sauyawa. A yayin wannan matakin, algorithm yana amfani da BEMF mai hankali don daidaita jerin matakai 6 tare da matsayi na rotor. Sauyawa yana farawa a cikin sashin da aka nuna a cikin ma'aunin da aka jadada a cikin Hoto 10. Ana iya daidaita shi a cikin sashin ma'auni mara ƙarancin farawa na MC workbench.

Bayan ingantaccen siginar gano sifili na BEMF (don cika wannan yanayin duba Sashe na 2.1), algorithm ɗin yana canzawa zuwa aiki na rufaffiyar. Matakin sauya sheka na iya gazawa saboda dalilai masu zuwa:

- Ba a daidaita saurin sauyawa da kyau ba

- Ribar PI na madauki na sauri sun yi yawa

- Ba a saita madaidaitan madaidaitan don gano taron ketare sifili na BEMF ba

Ba a daidaita saurin sauyawa da kyau ba

Gudun da sauyawa-over ke farawa ta tsohuwa daidai yake da saurin manufa na farko wanda za'a iya saita shi a sashin saitin tuƙi na MC workbench. Dole ne mai amfani ya sani cewa, da zaran an rufe madauki na sauri, ana haɓaka motar nan take daga saurin sauyawa zuwa saurin da aka yi niyya. Idan waɗannan dabi'u biyu sun yi nisa sosai, gazawar da ta wuce kima na iya faruwa.

Ribar PI na madauki gudun yayi girma sosai

Yayin sauyawa, algorithm yana motsawa daga tilasta jerin da aka riga aka ƙayyade don auna gudu da ƙididdige ƙimar fitarwa daidai. Don haka, yana rama ainihin gudu wanda shine sakamakon haɓakar buɗaɗɗen madauki. Idan ribar PI ta yi yawa, za a iya samun rashin zaman lafiya na ɗan lokaci, amma yana iya haifar da gazawar da ta wuce gona da iri idan aka yi karin gishiri.

Hoto na 11 ya nuna da misaliample na irin wannan rashin zaman lafiya a lokacin sauyawa daga buɗaɗɗen madauki zuwa aiki mai rufewa.

Ƙofar BEMF mara kyau

- Idan an saita ƙofofin BEMF da ba daidai ba, ana gano ƙetare sifili ko dai a gaba ko a makare. Wannan yana haifar da babban tasiri guda biyu:

- Siffofin igiyoyin igiyar ruwa ba su da asymmetric kuma ba su da inganci wanda ke haifar da manyan ripples na juzu'i (Hoto 12)

- Madaidaicin madaidaicin ya zama mara ƙarfi ta ƙoƙarin rama magudanar ruwa

- Mai amfani zai fuskanci rashin kwanciyar hankali da sarrafa saurin gudu kuma, a cikin mafi munin yanayi, de-synchronization na motar tuki tare da sarrafawa da ke kaiwa ga abin da ya wuce kima.

- Daidaitaccen saitin ƙofofin BEMF yana da mahimmanci don kyakkyawan aiki na algorithm. Har ila yau, iyakoki sun dogara da bas voltage darajar da kuma ji na cibiyar sadarwa. Ana ba da shawarar komawa zuwa Sashe na 2.1 don duba yadda ake daidaita juzu'itage matakan zuwa na ƙididdiga wanda aka saita a cikin MC workbench.

Rufe madauki aiki

Idan motar ta cika lokacin haɓakawa, an gano sifirin BEMF. Ana aiki tare da rotor tare da jerin matakai 6 kuma an sami aikin rufaffiyar madauki. Koyaya, ana iya aiwatar da ƙarin haɓaka siga don haɓaka wasan kwaikwayon.

Misali, kamar yadda aka bayyana a cikin Sashe na 3.1.3 na baya ("Ba daidai ba ƙofofin BEMF"), madauki na sauri, koda kuwa yana aiki, na iya zama mara ƙarfi kuma ƙofofin BEMF na iya buƙatar ɗan gyarawa.

Bugu da ƙari, dole ne a yi la'akari da waɗannan abubuwa masu zuwa idan an nemi mota don yin aiki da babban sauri ko kuma a motsa shi tare da babban aikin PWM:

Mitar PWM

- Speed madauki PI riba

- Demagnetization blanking lokaci lokaci

- Jinkirta tsakanin sifili da hawan mataki

- Canja tsakanin PWM KASHE-lokaci da ON-lokaci ji

Mitar PWM

Algorithm-mataki mara ƙarancin firikwensin 6 yana aiwatar da siyan BEMF kowane zagayowar PWM. Don gano daidai abin da ya faru na tsallake sifiri, ana buƙatar isassun adadin saye. A matsayinka na babban yatsan hannu, don aiki mai kyau, aƙalla saye 10 sama da kusurwoyin lantarki 60 suna ba da aiki tare na rotor mai kyau da tsayayye.

Saboda haka

Speed madauki PI riba

Ribar madauki na sauri PI yana shafar amsawar motar zuwa kowane umarni na haɓakawa ko ragewa. Bayanin ka'idar yadda mai sarrafa PID ke aiki ya wuce iyakar wannan daftarin aiki. Koyaya, dole ne mai amfani ya sani cewa ana iya canza ribar madaidaicin madauki a lokacin aiki ta hanyar Matukin Mota kuma a daidaita shi yadda ake so.

Demagnetization blanking lokaci lokaci

Demagnetization na lokaci mai iyo shine lokaci bayan canji na ƙarfin lokaci a lokacin da, saboda fitarwa na yanzu (Figure 14), karatun EMF na baya ba abin dogara ba ne. Don haka, algorithm dole ne yayi watsi da siginar kafin ya wuce. An bayyana wannan lokacin a cikin MC workbench a matsayin kashitage na mataki (digiri na lantarki 60) kuma za'a iya canza lokacin gudu ta hanyar Matukin Mota kamar yadda aka nuna a Hoto 15. Mafi girman saurin motar, da sauri lokacin lalatawar. Demagnetization, ta tsohuwa, ya kai ƙananan iyaka da aka saita zuwa zagayowar PWM guda uku a 2/3 na matsakaicin matsakaicin ƙimar ƙimar. Idan lokacin inductance na motar yana da ƙasa kuma baya buƙatar lokaci mai yawa don ragewa, mai amfani zai iya rage lokacin masking ko saurin da aka saita mafi ƙarancin lokacin. Koyaya, ba a ba da shawarar rage lokacin rufe fuska da ke ƙasa da hawan keke na PWM 2 – 3 saboda sarrafawa na iya haifar da rashin kwanciyar hankali kwatsam yayin tafiyar matakai.

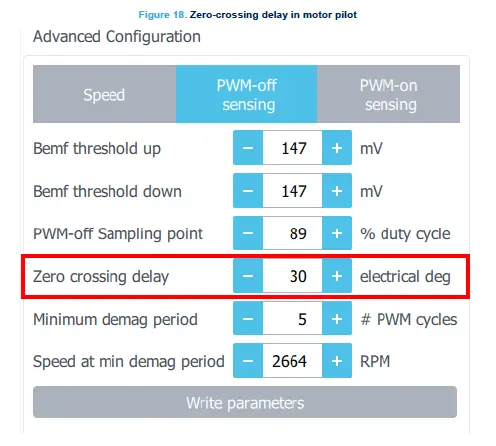

Jinkirta tsakanin BEMF sifili da hawan mataki

Da zarar an gano taron sifili na BEMF, algorithm ɗin yakan jira digiri na lantarki 30 har sai an daidaita matakan mataki (Hoto 16). Ta wannan hanyar, sifili-cross ɗin ana sanya shi a tsakiyar matakin matakin don ƙaddamar da mafi girman inganci.

Tunda daidaiton gano sifili ya dogara da adadin saye, don haka akan mitar PWM (duba Sashe na 3.2.1), daidaiton gano shi na iya zama dacewa a babban saurin. Sannan yana haifar da tabbataccen asymmetricity na raƙuman raƙuman raƙuman ruwa da karkatar da halin yanzu (duba Hoto 17). Ana iya rama wannan ta hanyar rage jinkiri tsakanin tsinkayar sifili da motsin mataki. Za a iya canza jinkirin tsallake-tsallake ta hanyar mai amfani ta hanyar Matukin Mota kamar yadda aka nuna a Hoto 18.

Canja tsakanin PWM KASHE-lokaci da ON-lokaci ji

Yayin da ake ƙara saurin gudu ko kayan aiki na yanzu (wato juzu'in fitar da mota), zagayowar aikin tuƙi na PWM yana ƙaruwa. Don haka, lokacin sampling da BEMF a lokacin KASHE-lokaci an rage. Don isa 100% na sake zagayowar aiki, ana yin jujjuyawar ADC a lokacin ON-lokaci na PWM, don haka canzawa daga ji na BEMF yayin lokacin PWM KASHE zuwa PWM ON-lokaci.

Tsarin da ba daidai ba na ƙofofin BEMF a lokacin ON-lokaci yana haifar da batutuwa iri ɗaya da aka kwatanta a Sashe na 3.1.3 ("Ba daidai ba madaidaicin BEMF").

Ta hanyar tsoho, BEMF ON-hankali kofa an saita zuwa rabin voltage (duba Sashe na 2.1). Dole ne mai amfani yayi la'akari da cewa ainihin ƙofofin sun dogara da voltage darajar da ji na cibiyar sadarwa. Bi alamun da ke cikin Sashe na 2.1 kuma tabbatar da daidaita voltage matakin zuwa maras muhimmanci wanda aka saita a cikin MC workbench.

Ƙimar ƙira da sake zagayowar aikin PWM wanda algorithm ke musanya tsakanin KASHE da ON-ji ana iya daidaita lokacin aiki ta hanyar matukin jirgi (Hoto 19) kuma ana samunsa a cikin Vol.tage yanayin tuki kawai.

Shirya matsala

Menene zan kula don jujjuya motar da kyau tare da na'urar firikwensin-ƙasa 6-mataki algorithm?Fitar da mota tare da na'ura mai ƙarancin mataki na 6 na nuni da samun damar gano siginar BEMF da kyau, haɓaka motar, da aiki tare da rotor tare da algorithm sarrafawa. Daidaitaccen ma'auni na siginar BEMF ya ta'allaka ne a cikin ingantaccen ƙira na cibiyar sadarwa ta BEMF (duba Sashe na 2.1). Manufar voltage (voltage yanayin tuƙi) ko halin yanzu (tuɓar yanayin halin yanzu) yayin jerin farawa ya dogara da sigogin motar. Ma'anar (da kuma ƙarshe tsawon lokaci) na voltage/lokaci na yanzu yayin daidaitawa, haɓakawa, da matakan canjawa suna da mahimmanci don kyakkyawan tsari (duba Sashe na 3).

A ƙarshe, aiki tare da na'ura mai juyi da ikon haɓaka motar gudu har zuwa ƙimar da aka ƙididdigewa ya dogara ne akan ingantawa na mitar PWM, madaidaicin BEMF, lokacin lalatawa da jinkirtawa tsakanin sifili-ƙetare ganowa da motsi mataki, kamar yadda aka bayyana a cikin. Sashi na 3.2.

Menene madaidaicin ƙimar mai raba resistor BEMF?

Dole ne mai amfani ya sani cewa ƙimar mai raba juzu'i na BEMF ba daidai ba na iya cire duk wata dama ta tuƙi motar da kyau. Don ƙarin cikakkun bayanai kan yadda ake ƙirƙira cibiyar sadarwa ta BEMF, koma zuwa Sashe 2.1.

Ta yaya zan daidaita tsarin farawa?

- Don inganta tsarin farawa, ana ba da shawarar ƙara tsawon kowane mataki na lokacin sakewa zuwa daƙiƙa da yawa. Daga nan ana iya fahimtar ko motar ta yi sauri sosai, ko kuma a wane irin gudu/mataki na hanyar buɗe madauki ya gaza.

- Ba abu mai kyau ba don hanzarta babban inertia mota tare da madaidaicin ramp.

- Idan an saita voltage lokaci ko halin yanzu yayi ƙasa da ƙasa sosai, motar tana tsayawa. Idan ya yi tsayi da yawa, zazzagewar za ta kunna. A hankali ƙara voltage lokaci (voltage yanayin tuƙi) ko halin yanzu (tuɓar yanayin halin yanzu) yayin daidaitawa da matakan haɓakawa suna ba mai amfani damar fahimtar kewayon aikin injin. Lalle ne, yana taimakawa wajen gano mafi kyau.

- Lokacin da yazo don canzawa zuwa aiki mai rufaffiyar, dole ne a rage abubuwan da aka samu na PI a farkon don ware cewa asarar sarrafawa ko rashin kwanciyar hankali ya faru ne saboda madauki na sauri. A wannan gaba, tabbatar da cewa an tsara hanyar sadarwar BEMF da kyau (duba Sashe na 2.1) kuma siginar BEMF da aka samu da kyau yana da mahimmanci. Mai amfani zai iya samun damar karanta BEMF, kuma ya ƙirƙira shi a cikin Matukin Mota (duba Hoto 20) ta zaɓin rijistar da ke akwai BEMF_U, BEMF_V da BEMF_U a cikin sashin makircin ASYNC na kayan aiki. Da zarar motar ta kasance a cikin Run jihar, za a iya inganta ribar mai sarrafa saurin gudu. Don ƙarin cikakkun bayanai ko haɓaka sigogi, duba Sashe na 3 da Sashe na 3.2.

Menene zan iya yi idan motar ba ta motsawa a farawa?

- A lokacin farawa, ƙarar layi na haɓaka voltage (voltage yanayin tuƙi) ko halin yanzu (tuɓar yanayin halin yanzu) an ba da shi zuwa matakan motsi. Manufar ita ce a daidaita shi a matsayi sananne kuma an riga an bayyana shi. Idan voltage bai isa ba (musamman tare da injiniyoyi tare da tsayin daka mai tsayi), motar ba ta motsawa kuma hanya ta kasa. Don ƙarin bayani game da yiwuwar mafita, koma zuwa Sashe na 3.1.1.

Menene zan iya yi idan motar ba ta kammala aikin hanzari ba?

Kamar lokacin daidaitawa, motar tana haɓakawa cikin buɗaɗɗen madauki ta hanyar amfani da ƙarar juzu'i na layi.tage (voltage yanayin tuƙi) ko halin yanzu (tuɓar yanayin halin yanzu) zuwa matakan motsi. Ƙimar ta asali ba ta yin la'akari da nauyin injin da aka yi amfani da shi na ƙarshe, ko madaidaicin mota ba daidai ba ne da/ko sananne. Don haka, hanyar haɓakawa na iya gazawa tare da rumbun mota ko abin da ya wuce kima. Don ƙarin bayani game da yiwuwar mafita, koma zuwa Sashe na 3.1.2.

Me yasa motar baya juyewa zuwa rufaffen madauki na sauri?

Idan motar ta yi sauri don saurin niyya amma ta tsaya ba zato ba tsammani, wani abu na iya zama ba daidai ba a cikin daidaitawar ƙofar BEMF ko ribar mai sarrafa PI. Koma zuwa Sashe na 3.1.3 don ƙarin cikakkun bayanai.

Me yasa madauki gudun yayi kama da maras tabbas?

Ana sa ran karuwar hayaniyar ma'auni tare da gudun tun lokacin da mafi girma ya kasance, ƙananan adadin BEMF s.ampLes don gano ƙetare sifili kuma, saboda haka, daidaiton lissafinsa. Duk da haka, rashin kwanciyar hankali da yawa na madauki na sauri na iya zama alamar kuskuren madaidaicin BEMF ko ribar PI waɗanda ba a daidaita su da kyau ba, kamar yadda aka nuna a Sashe na 3.1.3.

- Ta yaya zan iya ƙara matsakaicin saurin da ake iya kaiwa?

Matsakaicin saurin da za'a iya kaiwa yawanci ana iyakance shi da abubuwa da yawa: Mitar PWM, asarar aiki tare (saboda wuce kima lokacin lalatawa ko jinkirin kuskure tsakanin gano sifili da motsin mataki), kuskuren BEMF mashigin. Don ƙarin cikakkun bayanai kan yadda ake inganta waɗannan abubuwan, koma zuwa Sashe na 3.2.1, Sashe na 3.2.3, Sashe na 3.2.4 da Sashe na 3.2.5.

Me yasa motar ke tsayawa ba zato ba tsammani a wani takamaiman gudu?

Yana yiwuwa saboda kuskuren PWM akan-ji na BEMF daidaitawar bakin kofa. Koma zuwa Sashe na 3.2.5 don ƙarin cikakkun bayanai.

Tarihin bita

Tebur 2. Tarihin bitar daftarin aiki

| Kwanan wata |

Sigar |

Canje-canje |

| 24-Nuwamba-2023 |

1 |

Sakin farko. |

MUHIMMAN SANARWA – KU KARANTA A HANKALI

STMicroelectronics NV da rassan sa ("ST") sun tanadi haƙƙin yin canje-canje, gyare-gyare, haɓakawa, gyare-gyare, da haɓakawa ga samfuran ST da/ko ga wannan takaddar a kowane lokaci ba tare da sanarwa ba. Ya kamata masu siye su sami sabbin bayanai masu dacewa akan samfuran ST kafin yin oda. Ana siyar da samfuran ST bisa ga sharuɗɗa da sharuɗɗan siyarwa na ST a wurin lokacin amincewa.

Masu siye ke da alhakin zaɓi, zaɓi, da amfani da samfuran ST kuma ST ba ta ɗaukar alhakin taimakon aikace-aikacen ko ƙirar samfuran masu siye.

Babu lasisi, bayyananne ko fayyace, ga kowane haƙƙin mallakar fasaha da ST ke bayarwa a nan.

Sake siyar da samfuran ST tare da tanadi daban-daban da bayanan da aka gindaya a ciki zai ɓata kowane garantin da ST ya bayar don irin wannan samfurin.

ST da tambarin ST alamun kasuwanci ne na ST. Don ƙarin bayani game da alamun kasuwanci na ST, koma zuwa

www.st.com/trademarks. Duk sauran samfuran ko sunayen sabis mallakin masu su ne.

Bayanin da ke cikin wannan takarda ya maye gurbin bayanan da aka kawo a baya a cikin kowane juzu'in wannan takaddar.

© 2023 STMicroelectronics – Duk haƙƙin mallaka

Takardu / Albarkatu

Magana