Farashin GEA Bock F76

Farashin GEA Bock F76

umarnin majalisa

96438-02.2020-Gb

Fassarar umarnin asali F76/1570 FX76/1570

F76/1570 FX76/1570

F76/1800 FX76/1800

F76/2050 FX76/2050

F76/2425 FX76/2425

BOCK F76 Buɗe Nau'in Compressor

Game da waɗannan umarnin

Karanta waɗannan umarnin kafin haɗuwa da kafin amfani da kwampreso. Wannan zai kauce wa rashin fahimta da kuma hana lalacewa. Haɗuwar da ba daidai ba da amfani da kwampreta na iya haifar da mummunan rauni ko m.

Kula da umarnin aminci da ke ƙunshe a cikin waɗannan umarnin.

Dole ne a wuce waɗannan umarnin akan abokin ciniki na ƙarshe tare da naúrar da aka shigar da kwampreso a ciki.

Mai ƙira

GEA Bock GmbH

72636 Frickenhausen

Tuntuɓar

GEA Bock GmbH

Benzstrasse 7

72636 Frickenhausen

Jamus

Waya +49 7022 9454-0

Fax+49 7022 9454-137

gaba.com

gea.com/contact

Tsaro

1.1 Gano umarnin aminci

| HADARI | Yana nuna yanayi mai haɗari wanda, idan ba a kauce masa ba, zai haifar da kisa ko mummunan rauni nan da nan. | |

| GARGADI | Yana nuna yanayi mai haɗari wanda, idan ba a kauce masa ba, zai iya haifar da mutuwa ko mummunan rauni. | |

| HANKALI | Yana nuna yanayi mai haɗari wanda, idan ba a kauce masa ba, zai iya haifar da mummunan rauni ko ƙananan rauni. | |

| HANKALI | Yana nuna yanayin da, idan ba a kauce masa ba, zai iya haifar da lalacewar dukiya. | |

| BAYANI | Muhimmiyar bayanai ko shawarwari akan sauƙaƙe aiki. |

1.2 Abubuwan da ake buƙata na ma'aikata

![]() GARGADI

GARGADI

Rashin cancantar ma'aikata yana haifar da haɗarin haɗari, sakamakon zama mai tsanani ko rauni. Don haka an keɓance aiki akan compressors don ma'aikata waɗanda suka cancanci yin aiki akan na'urorin firiji masu matsa lamba:

- Don misaliample, ƙwararren injiniya, injiniyan injin firiji. Kazalika da sana'o'i tare da kwatankwacin horo, wanda ke baiwa ma'aikata damar haɗawa, girka, kulawa da gyara na'urori masu sanyaya da kuma sanyaya iska. Dole ne ma'aikata su kasance masu iya tantance aikin da za a gudanar da kuma gane duk wani haɗari mai haɗari.

1.3 Umarnin aminci

![]() GARGADI

GARGADI

Hadarin haɗari.

Na'urar damfara da injinan firji ne da ake matsa lamba kuma don haka kira don ƙara taka tsantsan da kulawa cikin kulawa.

Ba za a wuce iyakar matsi da aka halatta ba, koda don dalilai na gwaji.

Hadarin konewa!

- Dangane da yanayin aiki, ana iya kaiwa ga yanayin zafi sama da 60 ° C a gefen fitarwa ko ƙasa da 0 ° C a gefen tsotsa.

– Kauce wa lamba tare da refrigerant dole.

Tuntuɓar na'urar sanyaya na iya haifar da ƙonewa mai tsanani da lalacewar fata.

1.4 Amfani da niyya

![]() GARGADI

GARGADI

Maiyuwa ba za a yi amfani da kwampreta a cikin mahalli masu yuwuwar fashewa ba!

Waɗannan umarnin taro sun bayyana daidaitaccen sigar compressor mai suna a cikin taken da GEA Bock ya ƙera. GEA Bock compressors na firiji an yi niyya don shigarwa a cikin na'ura (a cikin EU bisa ga Dokokin EU 2006/42/EC Directive Machinery, 2014/68/Uwararfin Kayan aiki na matsa lamba EU).

Yin aiki yana halatta kawai idan an shigar da kwampreso daidai da waɗannan umarnin taro kuma an bincika kuma an amince da duk tsarin da aka haɗa shi a ciki bisa ga ƙa'idodin doka.

An yi nufin compressors don amfani a cikin tsarin firiji don dacewa da iyakokin aikace-aikace.

Na'urar firji da aka ƙayyade a cikin waɗannan umarnin kawai za a iya amfani da su.

An haramta duk wani amfani da kwampreso!

Bayanin samfur

2.1 Takaitaccen bayanin

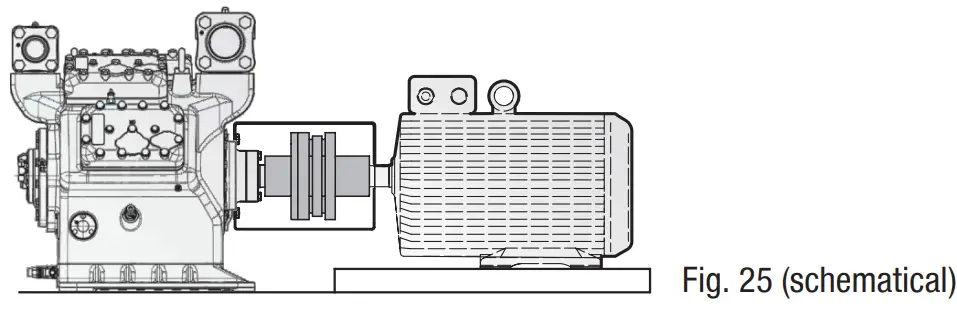

- 6-Silinda buɗaɗɗen nau'in kwampreso don fitar da waje (V-belt ko hada guda biyu)

- tare da lubrication na famfo mai

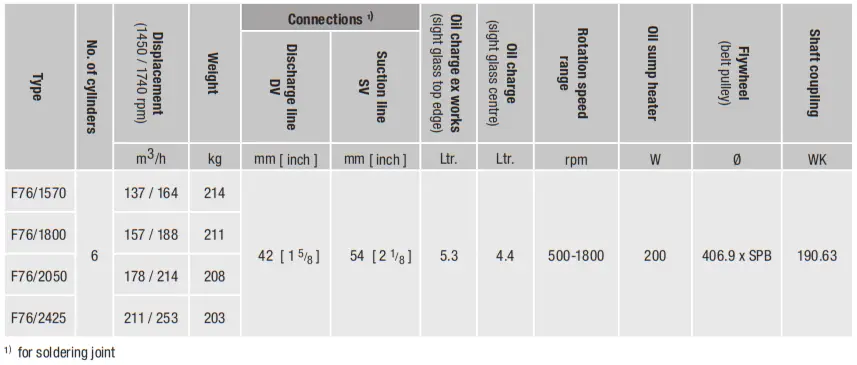

Ana iya samun girman girman da ƙimar haɗin kai a Babi na 9.

Ana iya samun girman girman da ƙimar haɗin kai a Babi na 9.

2.2 Farantin suna (misaliample)

- Nau'in nadi

- Lambar injin

- Matsakaicin saurin jujjuyawa tare da madaidaicin matsi

- Matsakaicin saurin jujjuyawa tare da masu gudun hijira daidai

- ND (LP): Max. m matsa lamba na aiki bangaren tsotsa HD(HP): Max. m matsa lamba aiki

Babban matsin lamba - Ana cajin nau'in mai a masana'anta

![]() Kula da iyakar zane-zane na aikace-aikacen!

Kula da iyakar zane-zane na aikace-aikacen!

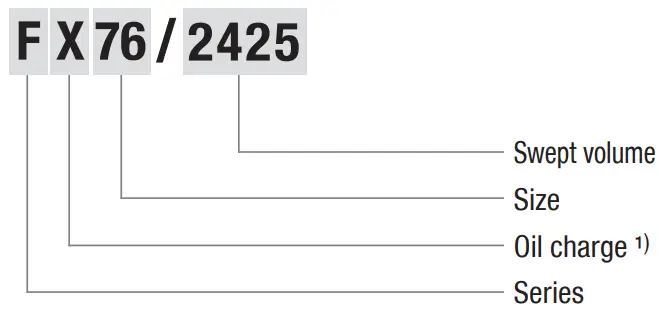

2.3 Nau'in lambar (misaliample) ¹) X - Cajin mai Ester (firijin HFC R134a, R404A/R507, R407C)

¹) X - Cajin mai Ester (firijin HFC R134a, R404A/R507, R407C)

Yankunan aikace-aikace

3.1 Masu sanyaya ruwa

- HFKW/HFC:

R134a, R404A/R507, R407C - (H)FCKW / (H)CFC:

R22

3.2 Cajin mai

- An cika compressors da nau'in mai a masana'anta:

- na R134a, R404A/R507, R407C

FUCHS Reniso Triton SE 55

da R22

FUCHS Reniso SP 46

Compressors tare da cajin mai na ester (FUCHS Reniso Triton SE 55) ana yiwa alama da X a cikin nau'in nadi (misali FX76/2425).

![]() BAYANI

BAYANI

Don sake cikawa, muna ba da shawarar nau'ikan mai na sama.

Madadin: duba tebur mai mai, Babi 6.4

HANKALI

HANKALI

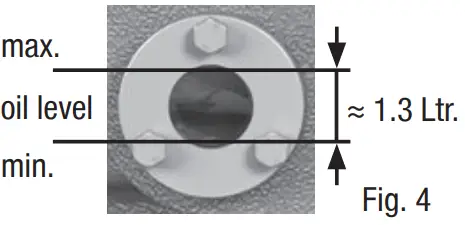

Ana nuna madaidaicin matakin mai a hoto na 4.

Lalacewa ga kwampreso yana yiwuwa idan an cika ko an cika shi!

3.3 Iyakar aiki

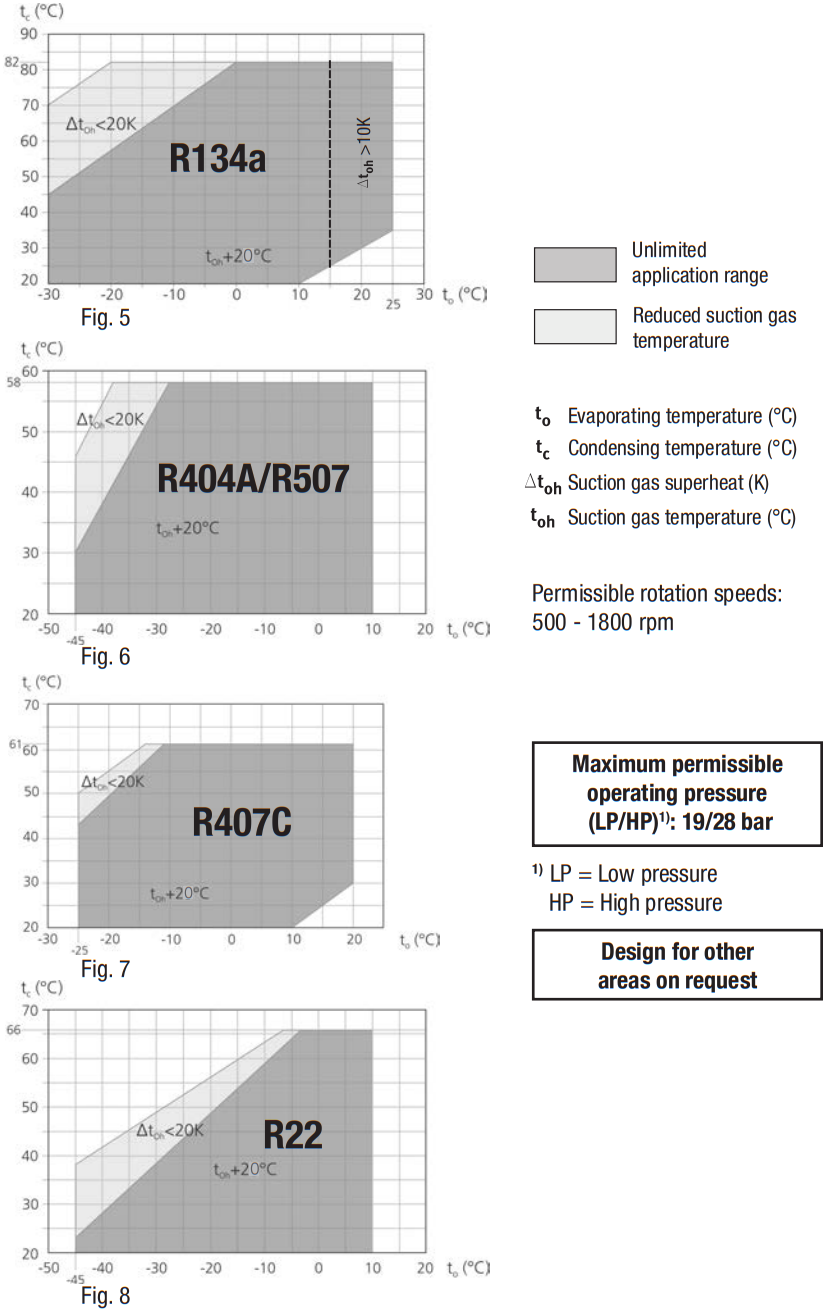

HANKALI Ayyukan kwampreso yana yiwuwa a cikin iyakokin aiki da aka nuna a cikin zane-zane. Da fatan za a lura da mahimmancin wuraren inuwa. Kada a zaɓi ƙofofin azaman ƙira ko wuraren aiki masu ci gaba.

- Halatta zafin yanayi (-20 °C) - (+60 °C)

– Max. halaltaccen zazzabi ƙarshen fitarwa: 140 °C

– Max. halatta mitar sauyawa: Da fatan za a koma zuwa umarnin mai kera injin.

– Mafi ƙarancin lokacin gudu na 3 min. Dole ne a cimma daidaiton yanayin (aiki na ci gaba).

Guji ci gaba da aiki kusa da bakin kofa.

Don aiki tare da ƙarin sanyaya:

- Yi amfani da mai kawai tare da kwanciyar hankali mai zafi.

Don aiki tare da mai sarrafa ƙarfin aiki:

- Za a iya buƙatar rage zafin zafin zafin gas ɗin mai zafi ko saita shi daban-daban yayin aiki kusa da bakin kofa.

Lokacin aiki a cikin kewayon injin, akwai haɗarin iska ta shiga ta gefen tsotsa. Wannan na iya haifar da halayen sinadarai, hawan matsin lamba a cikin na'urar da kuma matsananciyar zafin iskar gas. Hana shigowar iska ta kowane hali!

3.3 Iyakar aiki

Compressor taro

![]() BAYANI

BAYANI

Sabbin kwampressors suna cike da masana'anta da iskar gas mara amfani. Bar wannan cajin sabis a cikin kwampreso har tsawon lokacin da zai yiwu kuma hana shigar da iska. Bincika compressor don lalacewar sufuri kafin fara kowane aiki.

4.1 Adana da sufuri

- Ajiye a (-30 °C) - (+70 °C), matsakaicin izinin dangi zafi 10% - 95 %, babu tari

- Kada a adana a cikin gurɓataccen yanayi, ƙura, tururi ko a cikin mahalli mai fashewa.

- Yi amfani da gashin ido na sufuri.

- Kar a ɗaga da hannu!

- Yi amfani da kayan ɗagawa tare da isassun ƙarfin lodi!

- Naúrar sufuri da dakatarwa akan ƙwanƙolin ido (Fig. 11).

4.2 Saita

HANKALI Haɗe-haɗe (misali masu riƙe bututu, ƙarin raka'a, sassa masu ɗaure, da sauransu) kai tsaye zuwa kwampreso ba su halatta ba!

HANKALI Haɗe-haɗe (misali masu riƙe bututu, ƙarin raka'a, sassa masu ɗaure, da sauransu) kai tsaye zuwa kwampreso ba su halatta ba!

|

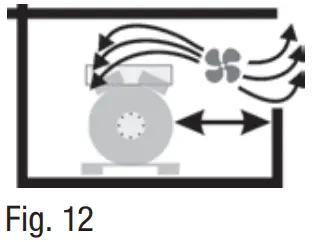

• Samar da isasshen izini don aikin kulawa. Samar da isassun iskar shaka don motar tuƙi. |

|

• Kada a yi amfani da shi a cikin gurɓataccen abu, mai ƙura, damp yanayi ko yanayi mai ƙonewa. |

|

• Compressors da injin tuƙi suna da tsauri kuma yakamata a ɗaura su tare akan firam ɗin tushe. Saita a kan madaidaicin saman ko firam tare da isassun ƙarfin ɗaukar kaya. Yi amfani da duk maki 4 masu ɗaurewa. • Daidaitaccen saitin na'ura mai kwakwalwa da hawan bel din yana da mahimmanci don gudana ta'aziyya, aminci aiki da rayuwar sabis na kwampreso. |

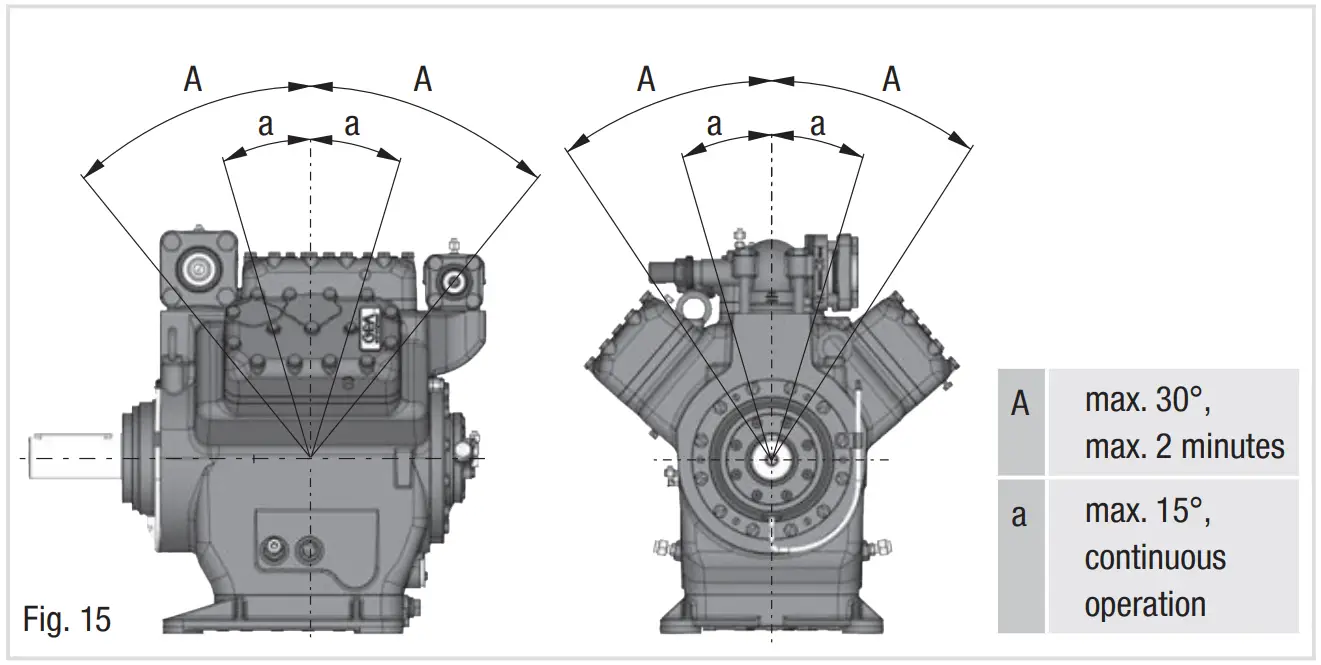

4.3 Matsakaicin yarda da karkata

HANKALI Hadarin lalacewar kwampreso.

HANKALI Hadarin lalacewar kwampreso.

Lubrication mara kyau na iya lalata kwampreso.

Mutunta dabi'u da aka bayyana.

4.4 Haɗin bututu

HANKALI Hadarin lalacewa.

HANKALI Hadarin lalacewa.

Yin zafi zai iya lalata bawul.

Cire tallafin bututu daga bawul don siyarwa.

Solder kawai ta amfani da iskar gas don hana samfuran iskar shaka (ma'auni).

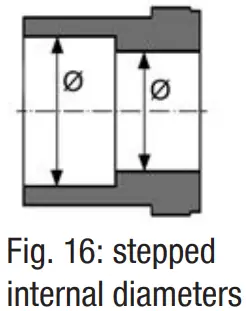

- Hanyoyin haɗin bututu sun tako diamita na ciki ta yadda za a iya amfani da bututu masu daidaitattun milimita da inch girma.

- An tsara diamita na haɗin haɗin bawul ɗin kashewa don matsakaicin fitarwa na kwampreso. Dole ne a daidaita sashin giciye bututun da ake buƙata da ƙarfin aiki. Hakanan ya shafi bawuloli marasa dawowa.

- Matsakaicin ƙarfin ƙarfi da ake buƙata don haɗin flange shine 60 Nm.

4.5 Bututu

- Bututu da sassan tsarin dole ne su kasance masu tsabta da bushewa a ciki kuma marasa ma'auni, swarf da yadudduka na tsatsa da phosphate. Yi amfani da sassa masu hana iska kawai.

- Sanya bututu daidai. Dole ne a samar da madaidaitan ma'aunin girgiza don hana fasa bututu da karye ta hanyar girgiza mai tsanani.

- Tabbatar da dawowar mai daidai.

- Ci gaba da asarar matsin lamba zuwa cikakkiyar ƙarancin ƙima.

4.6 Fara saukewa (na waje)

Babu tsohuwar masana'anta mai saukewa na ciki. A madadin za a iya shigar da saukewar farawa a cikin shuka.

Aiki:

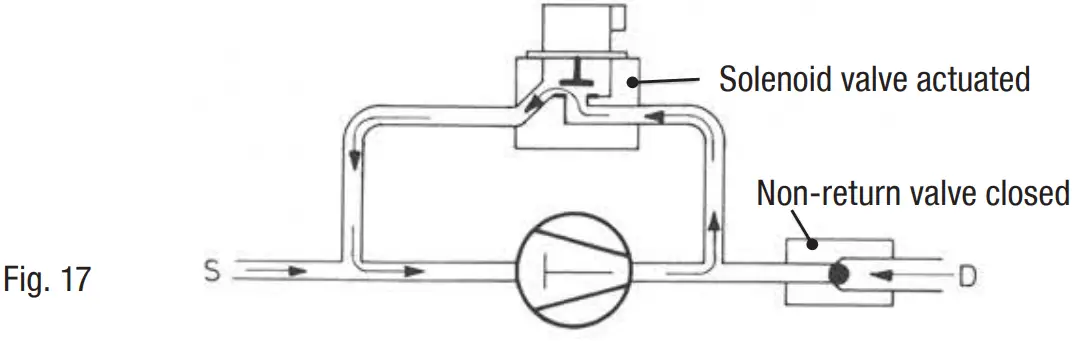

Lokacin da aka fara kwampreso, bawul ɗin solenoid yana karɓar iko ta hanyar sauya lokaci kuma yana buɗe hanyar wucewa tsakanin layin fitarwa- da tsotsa. A lokaci guda, bawul ɗin da ba zai dawo ba a cikin layin fitarwa yana rufewa kuma yana hana sake dawowa na refrigerant daga na'urar (Fig. 17).

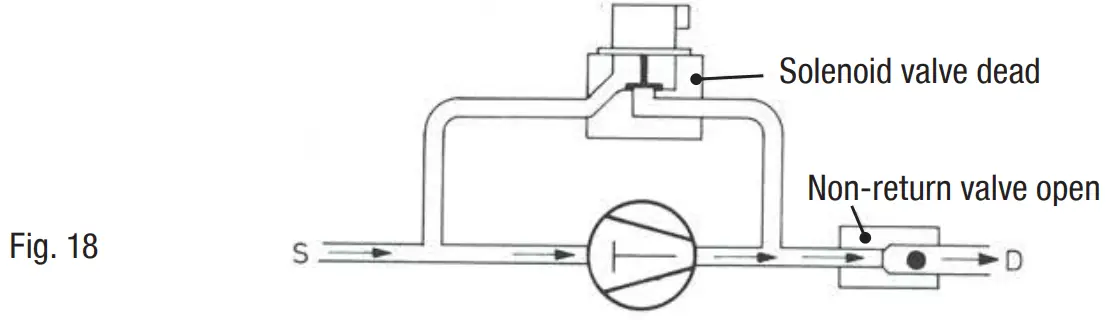

Compressor yanzu gajere ne kuma yana isar da shi daga fitowar kai tsaye cikin abin sha. Bambancin matsin lamba saboda haka yana raguwa sosai. A sakamakon haka, da karfin juyi a kan tuƙi shaft na kwampreso ya ragu sosai. Motar tuƙi na iya farawa yanzu tare da ƙaramin matakin farawa. Da zaran motar da kwampreta suka kai ga ƙimar ƙimar su, bawul ɗin solenoid ya rufe kuma bawul ɗin da ba zai dawo ba ya buɗe (Fig. 18). Compressor yanzu yana aiki a ƙarƙashin al'ada kaya.

Muhimmi:

Muhimmi:

– Za a iya amfani da mai sauke farawa kawai a lokacin farawa.

– Bincika bawul ɗin solenoid da bawul ɗin da baya dawowa akai-akai don matsewa.

- Bugu da ƙari, muna ba da shawarar yin amfani da ma'aunin zafi da sanyio a gefen fitarwa na com presser. Wannan yana kare kwampreso daga zazzagewar zafi. Haɗa ma'aunin zafi da sanyio a jeri akan sarkar aminci na da'irar sarrafawa, don kashe kwampreso idan ya cancanta.

– Bi waɗannan umarnin don guje wa wuce gona da iri.

4.7 Kwance layukan tsotsa da fitarwa

HANKALI Bututun da ba a shigar da shi ba daidai ba zai iya haifar da tsagewa da hawaye, sakamakon shine asarar firiji.

HANKALI Bututun da ba a shigar da shi ba daidai ba zai iya haifar da tsagewa da hawaye, sakamakon shine asarar firiji.

![]() BAYANI

BAYANI

Daidaitaccen shimfidar layukan tsotsa da fitarwa kai tsaye bayan kwampreso suna da alaƙa da tsarin tafiyar da yanayin jijjiga.

Ka'idar babban yatsan hannu: Koyaushe sanya sashin bututu na farko yana farawa daga bawul ɗin kashewa zuwa ƙasa kuma daidai da mashin tuƙi. 4.8 Yin aiki da bawul ɗin rufewa

4.8 Yin aiki da bawul ɗin rufewa

- Kafin buɗe ko rufe bawul ɗin rufewa, saki hatimin sandal ɗin bawul ta kusan. 1/4 na juyi counter-clockwise.

- Bayan kunna bawul ɗin rufewa, sake manne madaidaicin madaidaicin madaurin hatimin hatimin agogon agogo.

4.9 Yanayin aiki na haɗin sabis na kullewa Buɗe bawul ɗin kashewa:

Buɗe bawul ɗin kashewa:

Spindle: juya zuwa hagu (na agogo baya) gwargwadon yadda zai tafi.

-> Bawul ɗin kashewa yana buɗe cikakke kuma haɗin sabis yana rufe. Buɗe haɗin sabis

Buɗe haɗin sabis

Spindle: 1/2 - 1 juyawa zuwa dama (madaidaicin agogo).

-> Haɗin sabis yana buɗewa kuma bawul ɗin kashewa shima yana buɗe.

Bayan kunna sandar, gabaɗaya sake dacewa da hular kariyar sandar kuma a ƙara da 14 – 16 Nm. Wannan yana aiki azaman fasalin rufewa na biyu yayin aiki.

4.10 Tuƙi

![]() HANKALI Hadarin rauni.

HANKALI Hadarin rauni.

Hana kariyar da ta dace yayin tuƙi da kwampreso ta hanyar V-bels ko haɗin haɗin shaft!

HANKALI Daidaitaccen daidaitawa yana haifar da gazawar haɗin kai da lalacewa da wuri!

HANKALI Daidaitaccen daidaitawa yana haifar da gazawar haɗin kai da lalacewa da wuri!

Za a iya korar da compressors ta V-belts ko kai tsaye ta hanyar haɗin kai.

V-bel: • Haɗin bel ɗin da ya dace:

• Haɗin bel ɗin da ya dace:

– Dole ne a ɗora mashinan kwampreso da injin tuƙi da ƙarfi kuma a kan layi.

- Yi amfani da bel ɗin V kawai tare da tsayin tsayi.

- Zaɓi tazarar axis, tsayin V-bel da bel pre-tension bisa ga umarnin da masana'anta V-belt suka bayar. Kauce wa bel na girgiza.

- Duba bel pre-tashin hankali bayan gudu-in lokaci.

- Matsakaicin izinin axle saboda ƙarfin tashin hankali: 9500 N.

Direbobi kai tsaye tare da haɗin kai: • Direbobi kai tsaye tare da kayan haɗin kai yana buƙatar daidaitaccen daidaitawa na injin kwampreso da shaft ɗin mota.

• Direbobi kai tsaye tare da kayan haɗin kai yana buƙatar daidaitaccen daidaitawa na injin kwampreso da shaft ɗin mota.

GEA Bock yana ba da shawarar tuƙi kai tsaye tare da daidaita mahalli masu haɗawa (na'urorin haɗi).

Gudanarwa

5.1 Shirye-shiryen farawa

![]() BAYANI

BAYANI

Don kare kwampreso daga yanayin aiki mara izini, babban matsa lamba da ƙananan matsa lamba suna da mahimmanci a gefen shigarwa.

Compressor ya yi gwaji a masana'anta kuma an gwada dukkan ayyuka. Don haka babu umarnin shiga na musamman.

Duba compressor don lalacewar sufuri!

HANKALI Idan an ɗora mai sarrafa ƙarfin aiki a masana'anta, ɓangaren sarrafawa (bawul ɗin matukin jirgi) ana hawa kuma an haɗa shi daga baya abokin ciniki. Idan ba a haɗa ɓangaren sarrafawa ba, bankin silinda yana kashe har abada. Lalacewa ga kwampreso yana yiwuwa! Duba babi na 7.

HANKALI Idan an ɗora mai sarrafa ƙarfin aiki a masana'anta, ɓangaren sarrafawa (bawul ɗin matukin jirgi) ana hawa kuma an haɗa shi daga baya abokin ciniki. Idan ba a haɗa ɓangaren sarrafawa ba, bankin silinda yana kashe har abada. Lalacewa ga kwampreso yana yiwuwa! Duba babi na 7.

5.2 Gwajin ƙarfin matsi

An gwada compressor a cikin masana'anta don amincin matsi. Duk da haka, duk da haka duk tsarin za a yi gwajin ingancin matsi, ya kamata a aiwatar da shi daidai da EN 378-2 ko daidaitaccen ma'aunin aminci ba tare da haɗa da kwampreso ba.

5.3 Gwajin Leak

![]() HADARI Hadarin fashewa!

HADARI Hadarin fashewa!

Dole ne kawai a matsi da kwampreso ta amfani da nitrogen (N2).

Kada a taɓa matsawa da iskar oxygen ko wasu iskar gas!

Matsakaicin izinin wuce gona da iri na compressor ba dole ba ne a wuce shi a kowane lokaci yayin aikin gwaji (duba bayanan farantin suna)! Kada a haxa duk wani abin sanyi da nitrogen saboda wannan zai iya haifar da iyakar ƙonewa zuwa kewayo mai mahimmanci.

- Aiwatar da gwajin ɗigon ruwa akan injin firiji daidai da EN 378-2 ko daidaitaccen ma'aunin aminci, yayin da koyaushe yana lura da matsakaicin izinin wuce gona da iri na kwampreso.

5.4 Ficewa

- Da farko fitar da tsarin sannan kuma haɗa da kwampreso a cikin aikin ƙaura.

- Sauke matsa lamba na kwampreso.

- Bude igiyar tsotsa da matsi na kashe bawuloli.

- Cire ɓangaren tsotsa da zubar da matsi ta amfani da injin famfo.

- A ƙarshen aikin ƙaura, injin ya kamata ya zama <1.5 mbar lokacin da aka kashe famfo.

- Maimaita wannan tsari sau da yawa kamar yadda ake buƙata.

5.5 Cajin firiji

![]() HANKALI

HANKALI

Hadarin rauni!

Tuntuɓar na'urar sanyaya na iya haifar da ƙonewa mai tsanani da lalacewar fata.

Guji tuntuɓar na'urar sanyaya kuma sanya kayan kariya na sirri kamar tabarau da safar hannu masu kariya!

- Tabbatar cewa bawul ɗin layin tsotsa da fitarwa a buɗe suke.

- Tare da na'urar damfara a kashe, ƙara refrigeren ruwa kai tsaye zuwa na'ura ko mai karɓa, karya injin.

- Idan refrigerant yana buƙatar toshe sama bayan ya fara kwampreso, ana iya sanya shi cikin sigar tururi a gefen tsotsa, ko kuma, ɗaukar matakan da suka dace, shima a cikin sigar ruwa a mashigar zuwa mashin.

HANKALI

HANKALI

- Guji cika tsarin tare da firiji!

- Don guje wa sauye-sauye a cikin maida hankali, gaurayawan refrigerant na zeotropic dole ne kawai a cika su a cikin injin sanyaya a cikin ruwa.

- Kada a zuba ruwa mai sanyaya ta cikin bawul ɗin layin tsotsa akan kwampreso.

- Ba ya halatta a haxa abubuwan da ake ƙarawa da mai da firji.

5.6 Shaft hatimi

HANKALI Rashin kiyaye waɗannan umarni na iya haifar da asarar firiji da lalacewa ga hatimin shaft!

HANKALI Rashin kiyaye waɗannan umarni na iya haifar da asarar firiji da lalacewa ga hatimin shaft!

![]() BAYANI

BAYANI

Hatimin shaft ɗin yana shafawa kuma yana rufe da mai. Ruwan mai na 0.05 ml a kowace sa'a mai aiki ya zama al'ada. Wannan ya shafi musamman lokacin lokacin gudu (200-300 h).

An sanye da compressor tare da haɗaɗɗen ɗigon mai magudanar ruwa. Ta hanyar magudanar ruwa za a iya zubar da mai.

A zubar da man fetur din da aka zuba daidai da ingantattun dokokin kasa.

An rufe shaft ɗin compressor zuwa waje ta amfani da hatimin shaft. Abun rufewa yana juyawa tare da shaft. Abubuwan da ke biyowa suna da mahimmanci musamman don tabbatar da aiki mara laifi:

- Dole ne a aiwatar da cikakken da'irar firij daidai kuma a tsaftace a ciki.

- Ya kamata a guje wa girgiza mai nauyi da girgizawa zuwa ramin da kuma ci gaba da aiki na keke-da-keke.

- Filayen rufewa na iya mannewa tare a lokacin tsawan lokaci mai tsawo (misali hunturu). Saboda haka, gudanar da tsarin kowane mako 4 na minti 10.

5.7 Farawa

GARGADI Tabbatar cewa duka bawul ɗin rufewa suna buɗe kafin fara kwampreso!

Bincika cewa aminci da na'urorin kariya (matsi, kariyar mota, matakan kariyar lambar sadarwa, da sauransu) duk suna aiki da kyau.

Kunna compressor kuma ba da damar yin aiki na akalla mintuna 10.

Duba matakin mai ta: Dole ne mai ya kasance a bayyane a cikin gilashin gani.

HANKALI Idan ya zama dole a kara yawan mai, akwai haɗarin tasirin guduma mai.

HANKALI Idan ya zama dole a kara yawan mai, akwai haɗarin tasirin guduma mai.

Idan haka ne a duba dawo da mai!

5.8 Gujewa slugging

HANKALI Slugging na iya lalata kwampreta kuma ya sa firiji ya zube.

HANKALI Slugging na iya lalata kwampreta kuma ya sa firiji ya zube.

Don hana slugging:

- Dole ne a tsara cikakken tsarin firiji yadda ya kamata.

- Dole ne a ƙididdige duk abubuwan da aka haɗa tare da juna dangane da fitarwa (musamman magudanar ruwa da bawul ɗin faɗaɗawa).

- Suction gas superheat a shigar da kwampreso ya zama min. 7 - 10 K. (duba saitin bawul ɗin haɓakawa).

- Dole ne tsarin ya kai matsayin daidaito.

- Musamman ma a cikin tsarin mahimmanci (misali maki da yawa na evaporator), ana ba da shawarar matakan kamar maye gurbin tarkon ruwa, bawul ɗin solenoid a cikin layin ruwa, da sauransu.

Kada a sami motsi na sanyaya komai yayin da compressor ke tsaye.

5.9 Mai raba mai

HANKALI Slugging mai na iya haifar da lalacewa ga kwampreso.

HANKALI Slugging mai na iya haifar da lalacewa ga kwampreso.

Don hana slugging mai:

- Dawowar mai daga mai raba mai dole ne a jagorance shi zuwa haɗin da aka yi niyya (D1) akan mahalli na kwampreso.

- Komawar mai kai tsaye cikin layin tsotsa daga mai raba mai bai halatta ba.

- Tabbatar cewa mai raba mai yana da girma sosai.

Kulawa

6.1 Shiri

![]() GARGADI

GARGADI

Kafin fara kowane aiki akan compressor:

- Kashe compressor kuma ka tsare shi don hana sake farawa.

- Rage kwampreso na tsarin matsin lamba.

- Hana iska daga kutsawa cikin tsarin!

Bayan an yi gyara: - Haɗa maɓallin aminci.

- Fitar da kwampreso.

- Saki makullin sauyawa.

6.2 Aikin da za a yi

Don ba da garantin ingantacciyar amincin aiki da rayuwar sabis na kwampreso, muna ba da shawarar yin sabis da duba aiki a tazara na yau da kullun:

- Canjin mai:

- A cikin jerin tsire-tsire da aka samar a masana'anta ba dole ba.

- A cikin shigarwa na filin ko aiki a cikin iyakar aikace-aikacen, canjin mai na farko bayan kimanin 100 - 200 hours aiki, sannan kimanin. kowace shekara 3 ko 10,000 - 12,000 hours aiki.

A zubar da tsohon mai bisa ka'ida, a kiyaye dokokin kasa.

Binciken shekara-shekara: Matsayin mai, matsananciyar hayaniya, hayaniya mai gudana, matsa lamba, yanayin zafi, aikin na'urori masu taimako kamar na'urar dumama mai, matsa lamba. Bi dokokin ƙasa!

6.3 Shawarar kayan gyara

| F76/... | 1570 | 1800 | 2050 | 2425 |

| Nadi | Ref. A'a. | |||

| Saitin gaskets | 81303 | 81304 | 81305 | 81306 |

| Kit ɗin farantin karfe | 81616 | 81617 | 81743 | 81744 |

| Kit piston / sanda mai haɗawa | 81287 | 81288 | 8491 | 81290 |

| Mai sarrafa kayan aiki | 80879 | 81414 | 80889 | 80879 |

| Kit ɗin famfo mai | 80116 | |||

| Kit shaft hatimi | 80897 | |||

| Man fetur SP 46, 1 lita | 2279 | |||

| Man SE 55, 1 lita | 2282 | |||

Yi amfani da kayan gyara GEA Bock na gaske!

6.4 Canjin hatimin shaft

Kamar yadda canza hatimin shaft ya haɗa da buɗe da'irar refrigerant, ana ba da shawarar wannan kawai idan hatimin yana rasa firiji. An kwatanta maye gurbin hatimin shaft a cikin kayan aikin da abin ya shafa.

Kulawa

6.5 Sake daga tebur mai mai

Matsayin mai da aka cika a matsayin ma'auni a masana'anta an lura da shi akan farantin suna. Ya kamata a yi amfani da wannan darajar mai da kyau. Ana jera madadin wannan a cikin wani yanki mai zuwa daga teburin mu mai mai.

| Mai firiji | GEA Bock jerin maki mai | Nasihar madadin |

| HFKW/HFC(misali R134a,R404A/R507, R407C) | Fuchs Reniso Triton SE 55 | FUCHS Reniso Triton SEZ 32 ICI Emkarate RL 32 H, S MOBIL Arctic EAL 32 SHELL Clavus R 32 |

| (H) FCKW / (H) CFC (misali R22) | Fuchs Reniso SP 46 | FUCHS Reniso, zB KM, HP, SP 32 SHELL Clavus SD 22-12 TEXACO Capella WF 46 |

Bayani kan ƙarin dacewa mai akan buƙata.

6.6 Ragewa

Rufe bawul ɗin kashewa akan kwampreso. Cire na'urar sanyaya (dole ne a fitar da shi cikin muhalli) kuma a jefar da shi bisa ga ƙa'idodi. Lokacin da kwampreso ya ɓaci, gyara skru masu ɗaure na bawul ɗin kashewa. Cire compressor ta amfani da hawan da ya dace.

Zubar da mai a ciki daidai da dokokin kasa da suka dace.

Na'urorin haɗi

HANKALI Lokacin haɗa na'urorin haɗi tare da kebul na lantarki, mafi ƙarancin lanƙwasa radius na 3 x diamita na USB dole ne a kiyaye don shimfiɗa kebul ɗin.

HANKALI Lokacin haɗa na'urorin haɗi tare da kebul na lantarki, mafi ƙarancin lanƙwasa radius na 3 x diamita na USB dole ne a kiyaye don shimfiɗa kebul ɗin.

7.1 Hutar mai

Lokacin da kwampreso ya tsaya cik, firiji yana bazuwa cikin man mai na gidan kwampreso, dangane da matsa lamba da zafin yanayi. Wannan yana rage karfin man mai. Lokacin da compressor ya fara tashi, firijin da ke cikin mai yana ƙafewa ta hanyar raguwar matsa lamba. Sakamakon zai iya zama rashin lubrication, kumfa da ƙaura na man fetur, wanda zai iya haifar da lalacewar kwampreso.

Don hana wannan, ana iya dumama mai ta hanyar dumama mai.

HANKALI Dole ne injin dakon mai ya yi aiki koda gazawar tsarin ta faru.

HANKALI Dole ne injin dakon mai ya yi aiki koda gazawar tsarin ta faru.

Don haka ba dole ba ne a haɗa hitar tarar mai zuwa da'irar lantarki na sarkar kula da aminci!

Aiki: ON HOTON Sump na mai a tsaye na kwampreso.

KASHE mai dumama dumama mai yayin aiki na kwampreso

Haɗin kai: Dole ne a haɗa hita tarar mai ta hanyar sadarwar taimako (ko lambar sadarwa ta layi daya) na mai tuntuɓar motar zuwa wani keɓantaccen da'irar lantarki.

Bayanan lantarki: 230V - 1 - 50/60 Hz, 200 W.

7.2 Mai sarrafa ƙarfi

HANKALI Idan an ɗora mai sarrafa ƙarfin aiki a masana'anta, ɓangaren sarrafawa (bawul ɗin matukin jirgi) ana hawa kuma an haɗa shi daga baya abokin ciniki.

HANKALI Idan an ɗora mai sarrafa ƙarfin aiki a masana'anta, ɓangaren sarrafawa (bawul ɗin matukin jirgi) ana hawa kuma an haɗa shi daga baya abokin ciniki.

Matsayin bayarwa 2 (tsohon aiki):

Matsayin bayarwa 2 (tsohon aiki):

Mai sarrafa ƙarfin da aka haɗa tare da murfin (kariyar sufuri).

Matsayin bayarwa 1 (tsohon aiki):

Matsayin bayarwa 1 (tsohon aiki):

Murfin Silinda da aka shirya don mai sarrafa iya aiki. Kafin farawa, cire murfin a ma'aunin ƙarfin aiki kuma musanya shi tare da rukunin kulawa da ke kewaye (bawul ɗin matukin jirgi).

Kafin farawa, cire murfin a ma'aunin ƙarfin aiki kuma musanya shi tare da rukunin kulawa da ke kewaye (bawul ɗin matukin jirgi).

Tsanaki! Compressor yana cikin matsin lamba! Depressurize da kwampreso da farko.

Dunƙule a cikin naúrar sarrafawa (bawul ɗin matukin jirgi) tare da zoben rufewa da matsewa tare da 15 Nm.

Rigar zaren gefe tare da man ester.

Saka na'urar maganadisu, ɗaure shi da knurled nut kuma haɗa shi.

![]() GARGADI

GARGADI

Yawancin masu kula da iya aiki ba za su iya canzawa a lokaci guda yayin aikin kwampreso ba! In ba haka ba kwatsam canjin kaya na iya lalata kwampreso! Yi aiki tare da tazarar sauyawa na 60s.

- Bi tsarin sauyawa:

Ana kunna CR1-60s→ CR2

Kashe CR2-60s→ CR1

HANKALI

HANKALI

- Ayyukan da aka tsara ƙarfin aiki yana canza saurin iskar gas da ƙimar matsa lamba na injin refrigerating: Daidaita layin layin tsotsa da ƙima daidai da haka, kar a saita tazarar sarrafawa kusa kuma kar a bar tsarin ya canza fiye da sau 12 a cikin awa ɗaya ( injin firiji dole ne. sun kai matsayin daidaito). Ci gaba da aiki a cikin sarrafawa stage ba a yarda ba.

- Muna ba da shawarar canzawa zuwa aiki mara tsari (100 % iya aiki) na aƙalla mintuna 5 kowace sa'ar aiki da aka kayyade iya aiki.

- Hakanan ana iya samun tabbataccen dawowar mai ta hanyar buƙatun iya aiki 100 % bayan kowace kwampreso zata sake farawa.

- Kunna wutar lantarki na bawul ɗin solenoid: Kullum buɗewa, (cor - yana amsa ƙarfin kwampreso 100%).

Na'urorin haɗi na musamman ana saka su a cikin masana'anta kawai idan abokin ciniki ya ba da oda ta musamman. Sake gyarawa yana yiwuwa cikin cikakken yarda da umarnin aminci da umarnin gyara da ke kewaye da kayan.

Ana samun bayanai game da amfani, aiki, kiyayewa da kuma hidimar abubuwan da aka haɗa a cikin wallafe-wallafen da aka buga ko a intanet a ƙarƙashin www.gea.com.

Ƙarfin tushe mai tsayi

Ana iya sanye da kwampreso da farantin tushe mai tsayi.

Wannan yana ƙara yawan man fetur da lita 2.7, nauyin yana ƙaruwa da 7.3 kg.

Bayanan fasaha

Girma da haɗin kai

F76

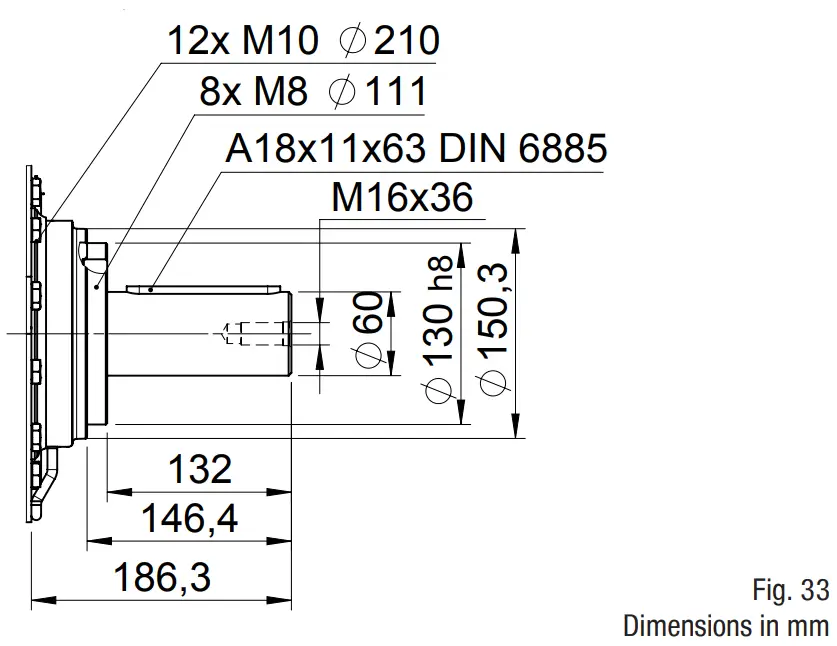

Ƙarshen shaft

Ƙarshen shaft

| SV DV |

Layin tsotsa Layin fitarwa duba bayanan fasaha, Babi na 8 |

|

| A | Haɗin tsotsa gefen, ba a kulle ba | 1/8 ″ NPTF |

| Al | Haɗin tsotsa gefen. mai kullewa | 7/16 ″ UNF |

| B | Haɗin fitarwa gefen. ba a kulle ba | 1/g'• NPTF |

| B1 | Haɗin fitarwa gefen. mai kullewa | 7/16- UNF |

| B2 | Haɗin fitarwa gefen. ba a kulle ba | 7/16. UNF |

| C | Connection mai matsa lamba aminci canza OIL | 7/16- UNF |

| D | Connection mai matsa lamba aminci canza LP | 7/16. UNF |

| D1 | Connection mai dawowa daga mai raba mai | 5/8' UNF |

| E | Haɗin ma'aunin man fetur | 7/16 ″ UNF |

| F | Magudanar ruwan mai | M22x1.5 |

| I-1 | Toshe cajin mai | M22x1.5 |

| J | Connection man sump hita | M22x1.5 |

| K | Gilashin gani | 3 x m6 |

| L | Haɗin ma'aunin zafi mai zafi | 1/8 NPTF |

| OV | Bawul ɗin sabis na mai haɗin haɗi | 1/4 NPTF |

| P | Haɗi mai matsa lamba bambancin firikwensin | M20x1.5 |

| Q | Haɗin zafin mai | 1/8. NPTF |

View X

- Gilashin gani mai

- Yiwuwar haɗi zuwa mai daidaita matakin mai

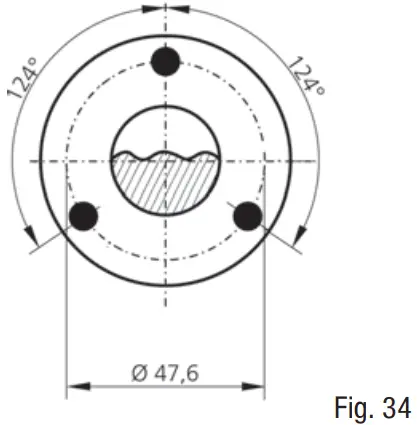

![]() Haɗin ramuka uku don mai daidaita matakin mai yana yin ESK, AC + R, CARLY (3 x M6, zurfin 10)

Haɗin ramuka uku don mai daidaita matakin mai yana yin ESK, AC + R, CARLY (3 x M6, zurfin 10)

Sanarwa na haɗawa

Sanarwa na haɗawa don injunan da ba su cika ba

daidai da EC Directive Machinery 2006/42/EC, Annex II 1.B

| Mai ƙira: | GEA Bock GmbH Benzstrasse 7 72636 Frickenhausen, Jamus |

| Mu, a matsayin masana'anta, muna bayyana cikin alhakin kawai cewa injin bai cika ba | |

| Suna: | Semi-hermetic kwampreso |

| Nau'u: | HG(X) 12P/60-4 S (HC) …….. HG88e/3235-4(S) (HC) HG(X)22(P)(e)/125-4 A …….. HG(X)34(P)(e)/380-4 (S) A HGX34(P)(e)/255-2 (A) ………….. HGX34(P)(e)/380-2 (A)(K) HA(X)12P/60-4 ……………….. HA(X)6/1410-4 HGX12e/20-4 S CO2 ……….. HGX44e/565-4 S CO2 HGX2/70-4 CO2T …………………. HGX46/440-4 CO2 T HGZ(X)7/1620-4 ……………… HGZ(X)7/2110-4 |

| Suna: | Buɗe nau'in kwampreso |

| Nau'u: | AM(X)2/58-4 …………………… AM(X)5/847-4 F(X)2 …………………………………………. F(X)88/3235 (NH3) FK (X) 1…………………………………………. FK (X) 3 FK(X)20/120 (K/N/TK)………. FK(X)50/980 (K/N/TK) |

| Lambar serial: | BB00000A001 - BF99999Z999 |

| ya bi waɗannan tanade-tanade na umarnin da aka ambata a sama: | A cewar Annex I, maki 1.1.2, 1.1.3, 1.1.5, 1.3.2, 1.3.3, 1.3.7, 1.5.1, 1.5.2, 1.5.13 da kuma 1.7.1 zuwa 1.7.4 (sai 1.7.4 f) sun cika |

| Aiwatar da ƙa'idodi masu jituwa, musamman: | TS EN ISO 12100 Tsaro na injin - Ka'idodin ƙira - Kimanta haɗari da raguwar haɗari Farashin EN12693 : 2008 Tsarin firiji da famfo mai zafi - Tsaro da buƙatun muhalli - Maɓalli mai kyau na firijin |

| Bayani: | Mun kuma ayyana cewa an ƙirƙiri takaddun fasaha na musamman don wannan injin ɗin da bai cika ba daidai da Annex VII, Sashe na B kuma muna wajabta samar da waɗannan bisa ga buƙatu daga hukumomin ƙasa guda ɗaya ta hanyar canja wurin bayanai. An haramta aiwatar da aikin har sai an tabbatar da cewa injin ɗin da za a shigar da na'urar da ba ta cika ba a cikinta ta bi ka'idodin Injin EC da EC Declaration of Conformity, Annex II. 1. Akwai. |

| Mutumin da aka ba da izini don haɗawa da ba da takaddun fasaha: | GEA Bock GmbH Alexander Layh Benzstrasse 7 72636 Frickenhausen, Jamus |

| Frickenhausen, 02 ga Janairu, 2019 |  i. A. Alexander Layi i. A. Alexander LayiShugaban Matsi - Piston Compressors na Kasuwanci |

Sabis

Ya ku abokin ciniki,

GEA Bock compressors sune mafi inganci, abin dogaro da samfuran ingancin sabis. Idan kuna da wasu tambayoyi game da shigarwa, aiki da na'urorin haɗi, tuntuɓi sabis na fasaha ko ƙwararrun dillalai da/ko wakilinmu. Za a iya tuntuɓar ƙungiyar sabis ɗin GEA Bock ta waya tare da layin waya kyauta 00 800/800 000 88 ko ta hanyar gea.com/contact.

Haza wassalam

GEA Bock GmbH

Benzstrasse 7

72636 Frickenhausen

Jamus

Muna rayuwa da dabi'un mu.

Kyakkyawan

Sha'awa

Mutunci

Nauyi

Babban darajar GEA

GEA Group kamfani ne na injiniya na duniya tare da tallace-tallace na biliyoyin Yuro da ayyuka a cikin ƙasashe sama da 50. An kafa shi a cikin 1881, kamfanin yana ɗaya daga cikin manyan masu samar da sabbin kayan aiki da fasahar sarrafawa. An jera rukunin GEA a cikin ma'aunin STOXX® Turai 600.

Danfoss Bock GmbH

Danfoss Bock GmbH

Benzstrasse 7

72636 Frickenhausen, Jamus

Tel. +49 (0) 7022 9454-0

Fax +49 (0) 7022 9454-137

gaba.com

gea.com/contact

Takardu / Albarkatu

|

Danfoss BOCK F76 Buɗe Nau'in Compressor [pdf] Manual mai amfani BOCK F76 Buɗe Nau'in Kwamfuta, BOCK F76, Buɗe Nau'in Kwamfuta, Nau'in Kwamfuta, Kwamfuta |