![]()

Pulse Series Controller Pulse Red

PULSE

PULSE

Commercial Direct Drive Door Operator for Balanced Sectional and Rolling Steel Doors. Installation Manual and Setup/User Instructions

U.S. Patent No. 11105138

For more information, please contact www.devancocanada.com or call toll free at 1-855-931-3334

GENERAL OVERVIEW

Thank you for purchasing this Pulse Direct Drive Door operator. This dependable operator is designed for continuous-cycle duty for your Commercial Door and can extend the life of your counter-balanced sectional door with its integrated soft-start/soft-stop capability.

It also features adjustable opening speeds of up to approximately 24” per second, battery backup that can operate the door in case of power failure, over-current protection, and adjustable auto-reversing force monitoring, along with many other programmable functions.

THE PULSE 500-1000 SERIES IS UL325:2023 LISTED – A NOTE ON COMPLIANCE

These Operators are provided with a Polarized Reflective Photo-Eye, which is connected into Terminal 1 of the ‘Reversing Devices’ input on the Control Panel (Thru-Beam Photo-Eye on 1HP & -WP Models to Terminal 2). Once the Close button is activated, the operator verifies that the Photo-Eye is connected and functional, and it continues to monitor the sensor as the door closes.

A dedicated terminal (Terminal 2 Reversing Devices) is provided to operate with Monitored Reversing Devices.

Input (Terminal 3 Reversing Devices) for non-monitored reversing devices (i.e. standard pneumatic edge).

The Pulse Operator will initiate Push/Hold to CLOSE protocols should it not find a functional reversing device in either Terminal 1 or 2. Neither of these terminals can be bypassed or ‘jumped’. Note that during Push/Hold to Close protocols, the door will reverse should it not fully reach the closed limit per UL 325.

BOX INVENTORY

Before beginning installation, please verify that all components are accounted for:

- Motor, Gearbox, Encoder, Junction Box Assembly

- Control Panel

- Limit Brackets and Hardware (Angle Brackets for Stop Limit to mount on door tracks)

- Torque Arm, Mounting Bolts, Mounting Bracket

- Shaft Collar and Shaft Key

- Reversing Device – Reflective Photo-eye (Thru-Beam Photo-Eye included on 1HP & -WP Models)

- Two 12V, Lead-Acid Rechargeable Batteries

In case any of the above items is missing, please contact iControls and provide us with details of the missing part(s), as well as the serial number of your operator.

OPERATOR TECHNICAL OVERVIEW

Motor

| HORSEPOWER: | Pulse 500 = 1/2 HP | Pulse 750 = 3/4 HP | Pulse 1000 = 1 HP | ||

| SPEED: | 1750 RPM | ||||

| CURRENT (FLA): | 1/2 HP = 5A | 3/4 HP = 7.6A | 1 HP = 10A | ||

| OUTPUT TORQUE: | Pulse 500-1: | 30:1=55.3Nm | 40:1=73.7Nm | 50:1=92.2Nm | 60:1=110.5Nm |

| Pulse 750-1: | 30:1=55.2Nm | 40:1=73.6Nm | 50:1=92.2Nm | 60:1=110.5Nm | |

| Pulse 750-1.25: | 30:1=55.3Nm | 40:1=73.7Nm | 50:1=92.1Nm | 60:1=110.5Nm | |

| Pulse 1000-1: | 30:1=73.6Nm | 40:1=98.2Nm | 50:1=92.1Nm | 60:1=147.3Nm | |

| Pulse 1000-1.25: | 30:1=73.7Nm | 40:1=98.2Nm | 50:1=122.8Nm | 60:1=147.4Nm | |

Electrical

| SUPPLY VOLTAGE: | 110-130 or 208-240V Vac, 1ph Input (All incoming power to be connected in provided junction box) |

| BATTERIES: | ½ HP= 2 x 5Ah, ¾ HP= 2 x 7Ah, 1 HP= 2 x 9Ah |

| CONTROL VOLTAGE: | 24Vdc, 1A Power/Connections supplied for activation and reversing devices |

| AUX RELAY: | 1 SPDT Programmable Relay (factory default to activate on Open Limits) |

Safety

| PHOTO-EYE or THRU-BEAM SENSOR: | Polarized Photo-eye Sensor/Reflector with Bracket or Thru-Beam sensor provided with unit as non-impact reversing device protection. |

| POWER OUTAGE OPERATION: | Battery Backup to open/close the door in case of power-outage. 3/8” ratchet socket for manual crank open/close as added redundancy. |

Please Refer to Our Website for Maximum Recommended Counter Balance Sectional Door Sizes and Weights for each Operator (www.iControls.ca).

IMPORTANT

WARNING – These instructions are intended for experienced personnel trained for service and installation of sectional doors and operators. All safety precautions and local codes must be followed.

- READ AND FOLLOW ALL INSTALLATION INSTRUCTIONS.

- Have qualified service personnel make necessary repairs to ensure door is operating smoothly without any unusual noise. Install operator only on a smoothly operating and well balanced door.

- Remove all pull ropes and remove locks (unless mechanically and/or electrically interlocked to the power unit) connected to the door before installing the operator.

- A commercial/industrial door operator that has exposed moving parts capable of causing injury to persons or employs a motor deemed indirectly accessible by clause 10.6 by virtue of its location above the floor shall include:

a. Install the door operator at least 2.44m (8 ft) or more above the floor: or

b. If the operator must be installed less than 2.44m (8ft) above the floor, then exposed moving parts must be protected by covers or guarding; or

c. Both a. and b. - Do not connect the operator to the supply power until instructed to do so.

- Locate the control station: (a) within sight of the door, and (b) at a minimum height of 1.53m (5 ft) above floors, landings, steps, or any other adjacent walking surface and (c) away from all moving parts.

- Install an Entrapment Warning Placard next to the control station in a prominent location.

PRE-INSTALLATION ASSEMBLY REQUIREMENTS

BEFORE INSTALLATION, ENSURE THAT YOUR DOOR IS PROPERLY BALANCED AND RUNNING SMOOTHLY. ALSO ENSURE THAT THE LIMIT BRACKETS (SUPPLIED) ARE INSTALLED AND SECURED PROPERLY. BUMPER/PUSHER SPRINGS MAY BE USED IN PLACE OF, OR IN ADDITION TO LIMIT BRACKETS FOR PULSE OPERATORS, BUT MUST BE INSTALLED PRIOR TO OPERATION.

Operator Mounting Requirements

Pulse operators are mounted directly on the door shaft. Before installing the operator, please ensure following criteria is met:

The door is well balanced, is tested for smooth functioning without any unusual noise.

Provided Limit Brackets must be installed at least 2″ past door’s desired open position (and within allowable maximum cable height) to prevent the doors from over-travel. (See Fig. 1)

The door has a solid keyed shaft with a minimum exposed length of 4.5” on the operator side. Clearance of at least 12” horizontally from the side of the door (or 9” from end of shaft), and 24” vertically below the shaft. There is adequate structural support surface to securely install the torque arm mounting bracket, the torque arm and the junction box. For more details, see mounting installation instructions Fig: 1 & 7.

Clearance of at least 12” horizontally from the side of the door (or 9” from end of shaft), and 24” vertically below the shaft. There is adequate structural support surface to securely install the torque arm mounting bracket, the torque arm and the junction box. For more details, see mounting installation instructions Fig: 1 & 7.

Mounting space for the operator Control Panel (Min. 5 ft. from ground level, within clear sight of the door but far enough away as to prevent users from contacting moving parts). Operator Mounting Position/Encoder

Operator Mounting Position/Encoder

This operator has its position encoder installed on the top of the gearbox. This allows mounting of the operator anywhere along the length of the shaft where space allows. Right-mount, left-mount or center-mount positions are all acceptable, and no modifications to the operator, or operator software, are required.

Assembling Torque Arm to Gearbox

The torque arm must be assembled onto the gearbox on the opposite side of encoder using the enclosed 4 bolts. There are 6 possible positions for the torque arm, and its optimal mounting position should be predetermined prior to assembly. Tighten bolts appropriately. THE TORQUE ARM IS AN INTRINSIC COMPONENT OF THE OPERATOR’S SAFETY AND FUNCTIONALITY AND MUST BE INSTALLED SECURELY. See Fig: 4 See Fig: 4 A for recommendations on how to mount Torque Arm to Operator/Mounting Bracket in relation to Shaft Off-set.

See Fig: 4 A for recommendations on how to mount Torque Arm to Operator/Mounting Bracket in relation to Shaft Off-set.

TORQUE ARM POSITION IN RELATION TO OPERATOR

MOUNTING INSTALLATION INSTRUCTIONS

WARNING

- TO REDUCE THE RISK OF PERSONAL INJURY OR DEATH, DO NOT CONNECT ELECTRICAL POWER UNTIL COMPLETE OPERATOR, JUNCTION BOX AND CONTROL PANEL ARE INSTALLED, SECURED AND PROTECTED PER FOLLOWING INSTRUCTIONS.

- ENSURE THAT AREA IS CLEAR OF PERSONNEL AND CORDONED OFF TO ACCESS WHILE INSTALLING OPERATOR.

- USE PROPER SAFETY PROTOCOLS ACCORDING TO INTERNAL, LOCAL AND FEDERAL REQUIREMENTS.

MANDATORY FIRST STEP – Limit Bracket Installation

If your door is not already equipped with bumper/pusher springs, it is mandatory to install the supplied Limit Brackets. Mount one bracket to the top of each track (See Figure 1A) to prevent over-travel of the door, and enable automatic encoder recalibration prior to setting limits and after a power-loss. These should be mounted inside the door-tracks at the door’s maximum allowable travel point, and are required to be located at the same exact position on both tracks so that the top rollers of the door rest against them in a level position.

To install, manually open the door to the uppermost opening position allowable by the cables, clamp the door in place, and secure the brackets to the track as shown Figure 1A using the top rollers as the reference points for the brackets.

IN THE ABSENCE OF BUMPER/PUSHER SPRINGS, INSTALLATION OF LIMIT BRACKETS IS MANDATORY PRIOR TO OPERATOR INSTALLATION. WITHOUT PHYSICAL LIMITS, THE DOOR CAN RUN OUT OF ITS TRACKS AND CAUSE SEVERE PERSONAL INJURY AND/OR CAUSE SEVERE DAMAGE TO THE DOOR. FURTHERMORE, YOU WILL BE UNABLE TO SET THE LIMITS.

Shaft Collar/Bent Key Installation

The Shaft Collar serves as an end-stop for the bent shaft key to prevent it from sliding out of the gearbox. It is important that it is securely fastened prior to use of the operator, and needs to be mounted in conjunction with the key as shown in Fig: 5. Adjust the door so that the shaft keyway is facing up (you may have to open/wedge/clamp the door open slightly to achieve this).

Adjust the door so that the shaft keyway is facing up (you may have to open/wedge/clamp the door open slightly to achieve this).

Loosen the Shaft Collar set screw and slide it over the shaft.

Insert the bent key (provided with operator) into the door shaft keyway with the bent end facing the shaft collar at its desired position.

Slide the collar back so that it touches the key, see Fig: 5. Firmly tighten the set screw of the collar onto the shaft. Fasten the Torque Arm to the gearbox so that it will be facing the shaft collar upon installation and at an appropriate position as suggested on Fig: 4A.

Please note that adjustments to the position of the key and collar may be required to accomodate for torque arm mounting and fastening.

Operator Installation

WARNING

WARNING: THE OPERATOR ASSEMBLY IS HEAVY AND CAN CAUSE SERIOUS INJURY OR DEATH SHOULD IT BE DROPPED DURING INSTALLATION. TAKE ALL NECESSARY SAFETY PRECAUTIONS TO AVOID DROPPING THE OPERATOR (I.E. TETHER/TIE DOWN) PRIOR TO ATTEMPTING INSTALLATION. SCAFFOLDING OR SCISSOR-LIFTS/ PLATFORM-LIFTS ARE ADVISED FOR OPERATOR INSTALLATION. NEVER ATTEMPT TO INSTALL AN OPERATOR ABOVE EYE-LEVEL OR FROM A LADDER.

ENSURE THAT PREVIOUS STEPS FOR SHAFT COLLAR/KEY INSTALLATION HAVE BEEN PROPERLY FOLLOWED BEFORE PROCEEDING. FAILURE TO DO SO COULD RESULT IN DAMAGE TO THE ENCODER DURING OPERATOR INSTALLATION.

Align the keyway of the gearbox with the pre-mounted key (see Key Shaft Collar/Key Installation on previous page) located on the mounting side of the shaft.

Slide the gearbox onto the shaft until it makes contact with the bend of the Shaft Key.

Assemble the Torque Arm Bracket to the Torque arm using the fastener provided. NOTE: DO NOT TIGHTEN THE NUT FULLY). Anchor the Torque Arm Bracket to the solid structural support.

Fasten the torque arm to structural support by means of the supplied bolt, locking nut and washers. The supplied bracket may be required. If the torque arm does not align with structural support, you may try adjusting the torque arm position on the gearbox (see Assembling Torque Arm to Gearbox) accordingly or use the Torque Arm Bracket. FAILURE TO SECURELY FASTEN TORQUE ARM COULD RESULT IN DAMAGE, SERIOUS INJURIES OR DEATH AND WILL VOID THE WARRANTY.

FAILURE TO SECURELY FASTEN TORQUE ARM COULD RESULT IN DAMAGE, SERIOUS INJURIES OR DEATH AND WILL VOID THE WARRANTY.

Junction Box Mounting

The junction box contains terminals for power connections, as well as battery/communication connections for the control panel. Mount the junction box, by means of the mounting flanges and in accordance with the electrical code, in a conspicuous location that will provide access for both electrical power and control panel wiring connections. The junction box is pre- wired with 2 feet of flexible conduit, if longer lengths are required, consult with factory. Do not mount the junction box near moving parts or in an inaccessible area. Control Panel Mounting

Control Panel Mounting

The control panel should be securely mounted at or around eye level (minimum 5 ft. from floor) on the same side as the operator/junction box. Ensure that the control panel is mounted far enough away from the door as to avoid user contact with the door while in operation, but close enough that the user has clear view of the door at all times. Four (4) control mounting brackets are provided to facilitate mounting. See Fig: 8 Photo-Eye or Thru-Beam Sensor Mounting

Photo-Eye or Thru-Beam Sensor Mounting

The included reflective photo-eye or thru-beam sensor should be mounted so that it scans area that spans the entire width of the door at a height of no more than 6 inches from the ground. The sensor (reflective photo-eye) or receiver (thru-beam) should be mounted on the operator side (as it will be wired into the control panel), while the reflector or transmitter should be mounted on the opposite side of the door, facing the sensor/receiver so that its center meets the beam. Use the included mounting bracket(s) to secure to either the door tracks or the wall. Refer to the specific mounting details provided with the sensor. For final alignment of the sensor, put unit in STARTUP MENU (see page 18) to apply power to the sensor (after WIRING – see page 13 for additional wiring diagram). Once properly aligned in STARTUP MENU, the indicator will light up in confirmation. Note that upon exit from the STARTUP MENU, the sensor will only become active when the door is closing.

See Fig: 9 for mounting reference.

WIRING INSTRUCTIONS

WARNING

TO REDUCE THE RISK OF PERSONAL INJURY OR DEATH, ENSURE THAT THE FOLLOWING PRECAUTIONS HAVE BEEN FOLLOWED PRIOR TO MAKING ELECTRICAL CONNECTIONS:

- Disconnect power at fuse box/source and follow proper lockout/tag-out procedures per national and local electrical codes.

- Ensure that all electrical connections are made by qualified electricians/technicians only and meet national and local electrical codes.

- All wiring should be on a dedicated circuit and properly protected.

Junction Box Connections

Terminals inside the junction box are labeled and provided for input power (100-240Vac 1 Ph), and to connect power the battery backup, and supply low voltage power and communication for the control panel. Optional terminals are also provided for Fully Open Limit Reset connection to an external switch as an alternative to using the Limit Brackets as a reset for the encoder.

Power Connections (100-240Vac Single Phase)

- ENSURE POWER IS DISCONNECTED!

- Run power wires to junction box in accordance with local and national regulations.

- Connect incoming power to L/L1 and N/L2, and ensure that ground wire is properly affixed.

Control Panel Connections (24Vdc)

- Using minimum of 18AWG cable, connect individual wires to V+, GM, GS and COM terminals in the junction box. iControls recommends using wiring kit (Part# PDC-CABKIT) or equivalent.

- These will match the connections in the Control Panel and will be terminated in the same sequence (as labeled) to match the junction box (all control panel wiring shall enter through the bottom of the enclosure).

Battery Connections (24Vdc) 2 Batteries Connected in Series

- Using minimum of 18 AWG insulated stranded wire; connect to B+ and B- inside the junction box (two separate wires). NOTE: 14AWG is recommended for PULSE 1000 Operators.

- These wires should be run together with the Control Panel Connections (through the bottom of the enclosure) and connect to the ‘+’ and ‘-‘DRIVE terminals on the board.

- Place the batteries into the Control Panel. Connect the wires to the batteries: red lead connects between the ‘Battery +’ tab on the board and the red tab on the battery, blue lead between the ‘Battery -‘ tab on the board and the black tab on the battery.

Fully Open Reset Limit Switch Connections (24Vdc)(Optional H1 & H2 Terminals)

- Using minimum of 18 AWG insulated stranded wire; connect to H1 and H2 inside the junction box (two separate wires)

- Connect these wires through NO Contact of Limit Switch, Proximity Sensor, Reed Switch, etc., set to activate at uppermost limit of door. This is used in advance of physical stop limits (limit brackets) to reset encoder at startup or menu reset (fully open position) and to avoid rollers coming into contact with the brackets. Also used as Fully Open position settings in Menu. Note that installation of limit brackets (or alternate physical stopping device) is still mandatory as a redundant safety stop in case of switch failure, but can be mounted further back from the switch to avoid roller impact. If using external switch in lieu of limit brackets for Fully Open Position Reset, a menu setting must be changed. See Page 23.

Control Panel Board Connections

The Control Panel provides power and inputs for your Reversing Devices (up to 3), Activation Devices (up to 2), as well as a wired Push Button Station, and a Remote Radio Receiver. Two on-board relays provide signaling for a variety of programmable options. Further connections are available for Traffic Signals, a buzzer and flashing Amber signal (while the door is in motion) and a door lock switch (prevents the door from moving while activated). A receptacle for IControls’s wireless peripheral devices (impact/tilt sensor, reversing edge, etc.) is also provided.

Reversing Devices

The Pulse accepts UL325 Monitored Devices, as well as standard non-monitored Devices. Connect the provided reflective photo-eye into the terminal labelled ‘1’. Any UL325 ‘monitored’ reversing device should be connected into the terminal labelled ‘2’. Any other added standard reversing photo-eyes, light curtains and reversing edges should be connected into the terminal labelled ‘3’. Follow the wiring diagrams included in this manual, and installation instructions provided with your reversing device for further mounting and connection details. Please note that without a connected, functional reversing device in either R1 or R2, the Closing Timer and Single Push auto-closing features of the door are de-activated – Push/Hold to Close protocols will be initiated.

Activation Devices

Automated, wired activation devices, such as Floor Loop Detectors, Pull Cords, Motion Detectors and Photo-Eyes (up to a maximum of 2 wired devices) used to open the door are connected here. Follow wiring diagram below and refer to the instructions provided with your activation device for precise connection and mounting details. Note that all devices connected to terminal A1will open the door to a position just shy of the full opening height, and devices connected to terminal A2 will open the door to the set limit.

Push Button Station

Connect an added Push Button station to the other side of your door using these inputs. NO dry contacts are required. Note that Push Button Stations can be programmed to raise the door to the fully open or set limit position. Refer to the wiring diagram for further connection details. Push Button Stations are available from RW, please contact us for details.

Remote Radio

Connect your receiver to the provided terminals – as the Pulse control panel enclosure is non-metallic, external antenna not necessarily required. Note that Remote Radio can be programmed to raise the door to the fully open, or set limit position. Refer to the wiring diagram for further connection details. Remote radio transmitters and receivers are available from iControls, please contact us for details.

Door Lock

These terminals are available to de-activate door functionality, whether it is a simple switch, or a sensor providing a signal when the door is locked for the night. Another available option is connecting this to a programmable timer relay to allow door operation for a pre-determined schedule. Refer to the wiring diagram for further connection details. Contact IControls for information on their Door Lock Sensor Kit.

Traffic Light

To install an LED stop and go light, use the provided terminals at the bottom of the board. The red connects to the ‘R’ terminal, the green connects to the ‘G’ terminal and the common should be wired into the ‘+24’ terminal. Ensure that you are using LED traffic lights (not incandescent) with a maximum consumption of no more than 100mA. The traffic light will stay red when the door is in motion or the closed position, and will be green in the fully open position only. The red can also be programmed to flash when the door is in motion, and in advance of close when using the closing timer (See Page 22 for futher details). The ‘Y’ terminal is for a secondary flashing Amber LED beacon and/or audible signal to indicate when the door is in motion. While accessing the Setup Menu, the traffic lights will turn off, and the Amber beacon, if installed, will flash. LED Stop and Go Lights from IControls are highly recommended, please contact us for details. Refer to the wiring diagram for further connection details.

Note: DO NOT USE INCANDESCENT SIGNALS WITH THIS OPERATOR. LED LIGHTS ONLY.

Output Relay Connections

NO and NC relay output connections are provided for interlocking with other material handling equipment (i.e. dock leveller) or security/fire systems. These outputs can be programmed (see Output Relay Setup) to energize when the door is at the Open or Closed Limit. Refer to the wiring diagram for further instructions.

WIRING DIAGRAMS

Control Panel for Models 500, 750 & 1000 OPTIONAL ACTIVATION DEVICES

OPTIONAL ACTIVATION DEVICES

NOTE:

- WHEN A PUSH BUTTON STATION IS CONNECTED, REMOVE THE FACTORY INSTALLED JUMPER BETWEEN (+24) AND (S) TERMINALS.

- INPUT (A1) OPENS DOOR FULLY, INPUT A2 OPENS DOOR AT SET LIMIT.

- REMOTE RADIO AND PANEL PUSH BUTTON ARE MENU PROGRAMMABLE TO OPEN DOOR FULLY OR AT SET LIMIT.

- IF CLOSING TIMER IS SET TO ZERO ALL “OPEN” ACTIVATORS PERFORM OPEN/CLOSE FUNCTION

OPTIONAL AUXILIARY DEVICES

OPTIONAL AUXILIARY DEVICES OPTIONAL REVERSING DEVICES

OPTIONAL REVERSING DEVICES NOTES: Connect Non-Monitored Reversing Devices into R3 in addition to a functional device connected into either R1 or R2. Should you be using a Monitored Reversing Device in R2, R1 must be either connected to a functional device or jumpered with P+.

NOTES: Connect Non-Monitored Reversing Devices into R3 in addition to a functional device connected into either R1 or R2. Should you be using a Monitored Reversing Device in R2, R1 must be either connected to a functional device or jumpered with P+. MONITORED 2-WIRE THROUGH-BEAM SENSOR VITECTOR RAY-N

MONITORED 2-WIRE THROUGH-BEAM SENSOR VITECTOR RAY-N

Wiring Diagram MONITORED 2-WIRE THROUGH-BEAM SENSOR VITECTOR OPTOΕΥΕ (ΝΕΜΑ 4Χ)

MONITORED 2-WIRE THROUGH-BEAM SENSOR VITECTOR OPTOΕΥΕ (ΝΕΜΑ 4Χ)

Wiring Diagram

STARTUP PROCEDURE

CAUTION!

Before applying power to the Pulse operator, ensure that the unit is firmly in positioned on the door shaft and securely fastened to the torque arm/bolt. Also that Limit brackets are in place and that the encoder is properly fastened on the gearbox.

TESTING FOR DOOR SPRING BALANCE

THIS STEP MUST BE DONE BEFORE POWER IS CONNECTED.

The Pulse operator is intended for use only with balanced doors. Improperly balanced doors could significantly affect the performance of the operator. We recommend that once the door and operator are completely installed that you test the door’s balance prior to power up.

To do this, ensure that the batteries are connected, power is off, and attempt one full cycle up and down under battery power (push and hold the OPEN button, and push and hold the CLOSE button). The door should travel at a slow, steady pace upwards and downwards. If the door can achieve a full cycle under battery power, it is setup properly for use with the Pulse operator. If the battery cannot move the door in either direction fully, the spring tension on the door must be adjusted.

POWER UP

Apply power to the unit. The Control Panel LED Screen should light up and run a self-diagnostic. If LCD screen is not lit, refer to Trouble Shooting on Page 25. Once it has run through its self-diagnostic, the screen will read ‘Door is Ready’. DO NOT TRY TO OPEN THE DOOR AFTER INITIAL POWER UP – ACCESS STARTUP MENU ONLY!

STARTUP MENU & ACCESSING ALL MENU SELECTIONS

NOTE THAT ALL FACTORY MENU SETTINGS ARE RECOMMENDED FOR SECTIONAL DOORS ONLY. CONTACT iCONTROLS FOR SETTINGS FOR OTHER DOOR STYLES (i.e. Rolling Steel, etc.) For access to the STARTUP MENU press and hold the STOP BUTTON FOR 10 SECONDS – do not release until the words ‘STARTUP MENU’ appear on the screen.

For access to the STARTUP MENU press and hold the STOP BUTTON FOR 10 SECONDS – do not release until the words ‘STARTUP MENU’ appear on the screen.

Once accomplished, you can scroll between the various STARTUP MENU options by pressing the OPEN and CLOSE buttons. Once you have reached a selection that you would like to modify, press the STOP button. Use the OPEN and CLOSE buttons to scroll/toggle between options within the selection, and then press STOP to save your selection and return to the STARTUP MENU.

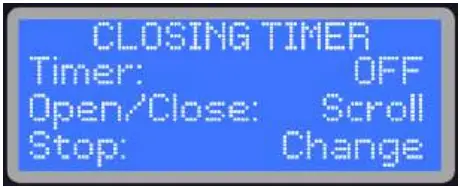

CLOSING TIMER

IT IS NOT RECOMMENDED TO SET THE CLOSING TIMER UNTIL AFTER THE UNIT HAS BEEN FULLY TESTED.

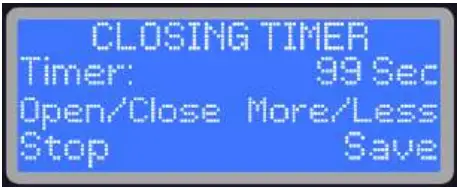

The Closing Timer will automatically close the door after opening by the preset number of seconds that have been programmed using this STARTUP MENU option. Once you have accessed this option, use the OPEN and CLOSE buttons to increase or decrease the closing timer value in 1 second intervals. If it is not required, ensure that the Closing Timer is set to OFF. If it is required, set it to any number of seconds from 1 to 99. Remember that this is the number of seconds that the door will remain open before automatically closing. Press the STOP button to save the value and return to the SETUP MENU.

Once you have accessed this option, use the OPEN and CLOSE buttons to increase or decrease the closing timer value in 1 second intervals. If it is not required, ensure that the Closing Timer is set to OFF. If it is required, set it to any number of seconds from 1 to 99. Remember that this is the number of seconds that the door will remain open before automatically closing. Press the STOP button to save the value and return to the SETUP MENU. The Closing Timer will de-activate in the event that a reversing device fails, and manual Push and Hold to Close protocols will apply to door closing operations.

The Closing Timer will de-activate in the event that a reversing device fails, and manual Push and Hold to Close protocols will apply to door closing operations.

VOLTAGE RANGE

NOTE: USING AN INCORRECT VOLTAGE SETTING COULD LEAD TO THE DOOR OPERATING AT AN UNSAFE SPEED.

This operator is designed to work with SINGLE PHASE voltages from 110-240Vac (for 3 phase voltage, use optional external transformer). There are 2 available settings, 110130V or 208-240V, and proper selection for your installation MUST to be made prior to

operation. Failure to do so could result in damage to the operator and door. To access this option, toggle between menu options using the OPEN or CLOSE buttons until VOLTAGE SETUP appears on the screen. Then press the STOP button to select. Press OPEN or CLOSE to toggle between Voltage Selections. Press STOP to Save and return to the STARTUP MENU. DOOR LIMITS

DOOR LIMITS

NOTE: PROGRAMMING OF LIMITS SHOULD BE PERFORMED BY TRAINED PERSONNEL ONLY. THE ENCODER WILL RETAIN THESE LIMITS UNTIL REPROGRAMMED.  Access the DOOR LIMITS selection from the STARTUP MENU and press the STOP button. Once selected, DOOR LIMITS heading will appear with a prompt to ‘Push OPEN to Start’. Push the OPEN button, and the door will open to the fully open position against the Limit Brackets (or until it engages switch connected to H1 and H2 terminals – see Junction Box Connections on Page 10). ENSURE THAT THE TOP ROLLERS OF THE DOOR ARE RESTING AGAINST THE LIMIT BRACKETS. The Open Limit now needs to be set.

Access the DOOR LIMITS selection from the STARTUP MENU and press the STOP button. Once selected, DOOR LIMITS heading will appear with a prompt to ‘Push OPEN to Start’. Push the OPEN button, and the door will open to the fully open position against the Limit Brackets (or until it engages switch connected to H1 and H2 terminals – see Junction Box Connections on Page 10). ENSURE THAT THE TOP ROLLERS OF THE DOOR ARE RESTING AGAINST THE LIMIT BRACKETS. The Open Limit now needs to be set.

SET OPEN LIMIT Press CLOSE (OPEN functional should you overshoot desired position) to jog the door to the desired Open Limit height. The Open Limit Setting Should be a minimum offset of 2″ from the Limit Bracket or Open Limit Switch. Press STOP button to save Open Limit and advance to SET CLOSE LIMIT.

Press CLOSE (OPEN functional should you overshoot desired position) to jog the door to the desired Open Limit height. The Open Limit Setting Should be a minimum offset of 2″ from the Limit Bracket or Open Limit Switch. Press STOP button to save Open Limit and advance to SET CLOSE LIMIT.

SET CLOSE LIMIT From the Open Limit, jog to the desired Close position, using the CLOSE button (OPEN available for fine tuning). Ensure that the door is properly sealed at the bottom. Press STOP button to save and return to STARTUP MENU.

From the Open Limit, jog to the desired Close position, using the CLOSE button (OPEN available for fine tuning). Ensure that the door is properly sealed at the bottom. Press STOP button to save and return to STARTUP MENU.

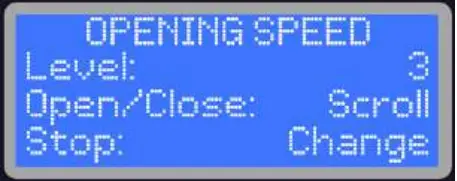

SETTING DOOR SPEEDS

On initial set up please use the factory default medium speed of ‘3’ or slower. As noted below the Motor, Door and Drum size may affect the opening speed of the door and this may be all that is required. Adjust speeds upwards only after having tested at lower speeds.

Pulse Operators have been developed with the same technology that is used in High Speed Doors. While limited to a maximum opening speed to ~24” per second for sectional doors (this is dependent on the door, drum, and gearbox ratio) and maximum closing speed to ~16” per second, we recommend that you set the speed to accommodate both your requirement, and the hardware of the door. To get the longest life out of your door, and to maximize your allowable speed, we recommend Stainless Steel cables and nylon rollers be installed if they are not already standard on your door.

OPENING SPEED

To access the Open Speed Settings, ensure you are in STARTUP MENU (see above instructions), then toggle between options using the OPEN or CLOSE buttons until Open Speed appears on the screen. Then press the STOP button to access and macke changes. The Pulse operator is factory equipped with 5 options of open speed settings, designated as 1 (slowest) to 5 (fastest). Toggle between these 5 options by using the OPEN and/ or CLOSE buttons, and press the Stop button once the desired selection appears on the

The Pulse operator is factory equipped with 5 options of open speed settings, designated as 1 (slowest) to 5 (fastest). Toggle between these 5 options by using the OPEN and/ or CLOSE buttons, and press the Stop button once the desired selection appears on the

screen to save and return to the STARTUP MENU.

CLOSING SPEED

To access the Closing Speed Settings, ensure you are in STARTUP MENU (see above instructions), then toggle between options using the OPEN or CLOSE buttons until Close Speed appears on the screen. Then press the STOP button to select. The Pulse operator is factory equipped with 5 options of close speed settings, from 1(slowest) to 5 (fastest). Toggle between these 5 options by using the OPEN and/or CLOSE buttons, and press the Stop button once the desired selection appears on the screen to save and return to the STARTUP menu.

The Pulse operator is factory equipped with 5 options of close speed settings, from 1(slowest) to 5 (fastest). Toggle between these 5 options by using the OPEN and/or CLOSE buttons, and press the Stop button once the desired selection appears on the screen to save and return to the STARTUP menu.

JOG MODE

To access the Jog Mode Setting, ensure you are in STARTUP MENU (see above instructions), then toggle between options using the OPEN or CLOSE buttons until Jog Mode appears on the screen. Then press the STOP button to begin using. Jog Mode enables manual control of the door using the OPEN and CLOSE buttons. During Jog Mode, all limits are de-activated, and push-hold protocols are initiated. This selection can be used to test door functionality without the encoder, ensure proper door balance, or as a method to operate the door under power should the encoder malfunction. The door will travel in each direction at the set OPEN SLOW SPEED and CLOSE SLOW SPEED (see Page 22), for safe operation.

Jog Mode enables manual control of the door using the OPEN and CLOSE buttons. During Jog Mode, all limits are de-activated, and push-hold protocols are initiated. This selection can be used to test door functionality without the encoder, ensure proper door balance, or as a method to operate the door under power should the encoder malfunction. The door will travel in each direction at the set OPEN SLOW SPEED and CLOSE SLOW SPEED (see Page 22), for safe operation. EXITING STARTUP MENU – CALIBRATION & TESTING

EXITING STARTUP MENU – CALIBRATION & TESTING

To exit from the Startup Menu, press and release the STOP button while STARTUP MENU appears on the LCD. If you have saved changes to the operator speed, or have reset limits, you will be required to do a quick system calibration. Screen prompts will provide real-time instruction on calibration requirements. See Page 22 for more detailed information on Calibration. Once Calibration is completed or if it was not required, the system will run a quick diagnostic, and the LCD should indicate current door postion (Open, Closed or Stopped). Testing of the door is now required.

Once Calibration is completed or if it was not required, the system will run a quick diagnostic, and the LCD should indicate current door postion (Open, Closed or Stopped). Testing of the door is now required.

BEFORE OPERATING THE DOOR, ENSURE THAT THE DOOR LIMIT BRACKETS (OR PUSHER SPRINGS OR LIMIT SWITCH) ARE IN PLACE, AND DOOR LIMITS HAVE BEEN SET.

Open and close the door a few times and observe whether the door is running smoothly and is stopping at the appropriate limits. Ensure that the door is set at the required speeds, and test each reversing and activation device to confirm their functionality.

NOTE: THESE FEATURES SHOULD BE ACCESSED ONLY BY A TRAINED TECHNICIAN AFTER INITIAL SET UP AND TESTING, ONLY IF REQUIRED. For access to the ADVANCED MENU options press and hold the STOP BUTTON FOR 10 SECONDS while on the STARTUP MENU screen. Do not release until ADVANCED MENU appears on the screen.

For access to the ADVANCED MENU options press and hold the STOP BUTTON FOR 10 SECONDS while on the STARTUP MENU screen. Do not release until ADVANCED MENU appears on the screen.

REVERSING TIMER Use this to set desired delay time for Door Reversing. If a reversing device or function is activated when door is closing (i.e. photo-eye, load-sensing, etc.) the door will pause by the set amount of time indicated.

Use this to set desired delay time for Door Reversing. If a reversing device or function is activated when door is closing (i.e. photo-eye, load-sensing, etc.) the door will pause by the set amount of time indicated.

Select between 0.5, 1.0, 1.5 seconds, or turn OFF. If turned OFF, door will not reverse, but remain in place until user intervention (This is recommended when using Closing Timer). Press STOP to Save this Setting and return to the ADVANCED MENU.

PWM FREQUENCY This Setting allows the user to change the operating frequency for the motor between 2.4 kHz, 12kHz and 20kHz. Certain frequencies can interfere with third-party accessories or cause a high-pitched noise and adjustment may be necessary. Factory default is set to 12kHz. Do not alter this setting unless advised by Technical Support.

This Setting allows the user to change the operating frequency for the motor between 2.4 kHz, 12kHz and 20kHz. Certain frequencies can interfere with third-party accessories or cause a high-pitched noise and adjustment may be necessary. Factory default is set to 12kHz. Do not alter this setting unless advised by Technical Support.

DYNAMIC BRAKE For doors that may be heavier than standard or have improperly balanced springs that cause high closing inertia, this operator has Dynamic Braking Options. If the door does not noticeably slow down during its intended ‘soft stop’ (approximately in the last foot of travel), it is likely that the door will require dynamic braking compensation.

For doors that may be heavier than standard or have improperly balanced springs that cause high closing inertia, this operator has Dynamic Braking Options. If the door does not noticeably slow down during its intended ‘soft stop’ (approximately in the last foot of travel), it is likely that the door will require dynamic braking compensation.

Factory default is for no Dynamic Braking (OFF), and is recommended for standard operation. Should Dynamic Braking prove necessary, press the OPEN/ CLOSE buttons to toggle between choices (Low, Medium & High). Note that the addition of Dynamic Braking is intended to assist doors with high inertia in achievement of a ‘soft stop’. It is recommend that before setting Dynamic Braking, you first test the door at a lower closing speed. Failing this, when setting Dynamic Braking you should start with the LOW setting first, and test the door. If further braking is required, move to the MEDIUM setting and test, and then the high setting. If you notice that the door makes a ‘jerking’ motion near the bottom of its travel, the setting is too high, and it should be lowered.

Note that the addition of Dynamic Braking is intended to assist doors with high inertia in achievement of a ‘soft stop’. It is recommend that before setting Dynamic Braking, you first test the door at a lower closing speed. Failing this, when setting Dynamic Braking you should start with the LOW setting first, and test the door. If further braking is required, move to the MEDIUM setting and test, and then the high setting. If you notice that the door makes a ‘jerking’ motion near the bottom of its travel, the setting is too high, and it should be lowered.

OPENING FORCE

If the door is obstructed from opening (ie. due to ice buildup, the door latch is engaged, etc.) this current monitoring feature will stop the door to prevent damage. The sensitivity of this monitoring can be changed in this setting, or the feature can be turned off entirely. Opening Force sensitivity can be adjusted from 1-20 (1 being most sensitive to obstructions/jams/imbalance) or OFF. Factory default is ‘5’.

Opening Force sensitivity can be adjusted from 1-20 (1 being most sensitive to obstructions/jams/imbalance) or OFF. Factory default is ‘5’.

CLOSING FORCE

If the door is obstructed from closing (ie. due to obstruction, jam, etc.) this current monitoring feature will stop and reverse the door to prevent damage. The sensitivity of this monitoring can be changed in this setting, or the feature can be turned off entirely. Closing Force sensitivity can be adjusted from 1-20 (1 being most sensitive to obstructions/jams/imbalance) or OFF. Factory default is ‘3’.

Closing Force sensitivity can be adjusted from 1-20 (1 being most sensitive to obstructions/jams/imbalance) or OFF. Factory default is ‘3’.

OPEN SLOW SPEED When the door is approaching open limit and decelerates down to slow speed before the stop (Soft Stop), added force/speed may be required to complete opening. While this is indcative of an improperly balanced door, this feature can be used to compensate. This setting should only be changed from the NORMAL to the HIGH setting if door becomes unbalanced over time and does not completely travel to Open limit. If it is a new installation, changing the spring tension for proper balance is a required first step. Factory default is ‘NORMAL’.

When the door is approaching open limit and decelerates down to slow speed before the stop (Soft Stop), added force/speed may be required to complete opening. While this is indcative of an improperly balanced door, this feature can be used to compensate. This setting should only be changed from the NORMAL to the HIGH setting if door becomes unbalanced over time and does not completely travel to Open limit. If it is a new installation, changing the spring tension for proper balance is a required first step. Factory default is ‘NORMAL’.

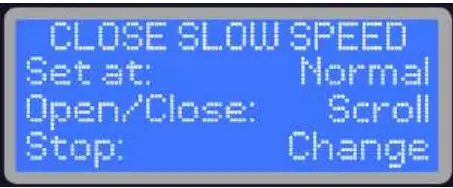

CLOSE SLOW SPEED When the door is approaching Close Limit and decelerates down to slow speed before the stop (Soft Stop), added force/speed may be required to complete closing. While this is indcative of an improperly balanced door, this feature can be used to compensate. This setting should only be changed from the NORMAL to the HIGH setting if door becomes unbalanced over time and does not completely travel to Close limit. If it is a new installation, changing the spring tension for proper balance is a required first step. Factory default is ‘NORMAL’.

When the door is approaching Close Limit and decelerates down to slow speed before the stop (Soft Stop), added force/speed may be required to complete closing. While this is indcative of an improperly balanced door, this feature can be used to compensate. This setting should only be changed from the NORMAL to the HIGH setting if door becomes unbalanced over time and does not completely travel to Close limit. If it is a new installation, changing the spring tension for proper balance is a required first step. Factory default is ‘NORMAL’.

OPEN RAMPDOWN DISTANCE This setting is used to change the point where the door begins to decelerate to slow speed as it approaches the Open Limit. The user can choose between auto (which is configured by the system) or the desired number of shaft rotations (between 0.5 turns and 3 turns in half rotation increments).

This setting is used to change the point where the door begins to decelerate to slow speed as it approaches the Open Limit. The user can choose between auto (which is configured by the system) or the desired number of shaft rotations (between 0.5 turns and 3 turns in half rotation increments).

The Factory setting for this feature is AUTO. This should not be changed unless recommended by Pulse Technical Support.

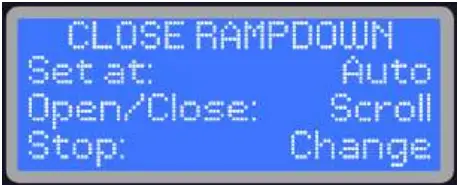

CLOSE RAMPDOWN DISTANCE This setting is used to change the point where the door begins to decelerate to slow speed as it approaches the Close Limit. The user can choose between auto (which is configured by the system) or the desired number of shaft rotations (between 0.5 turns and 3 turns in half rotation increments).

This setting is used to change the point where the door begins to decelerate to slow speed as it approaches the Close Limit. The user can choose between auto (which is configured by the system) or the desired number of shaft rotations (between 0.5 turns and 3 turns in half rotation increments).

The Factory setting for this feature is AUTO. This should not be changed unless recommended by Pulse Technical Support.

OPEN LIMIT OPTIONS (PUSH BUTTON) This setting allows the user to choose between the SET LIMIT or the FULLY OPEN limit for the “OPEN” button on the control panel or the “O” terminal (Push Button Station Inputs) on the control circuit board.

This setting allows the user to choose between the SET LIMIT or the FULLY OPEN limit for the “OPEN” button on the control panel or the “O” terminal (Push Button Station Inputs) on the control circuit board.

OPEN LIMIT OPTIONS (REMOTE RADIO) This setting allows the user to choose between the set limit or the fully open limit for the “REMOTE RADIO” connections on the control circuit board.

This setting allows the user to choose between the set limit or the fully open limit for the “REMOTE RADIO” connections on the control circuit board.

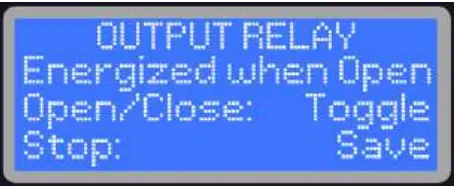

OUTPUT RELAY OPTIONS

The Output Relay is used for signalling/interlocking with other devices such as a dock leveller, security equipment, other doors, etc. There is one NO and one NC contact available that can be energized at either the open or closed limit, as chosen by the user in this setting.

The Output Relay is used for signalling/interlocking with other devices such as a dock leveller, security equipment, other doors, etc. There is one NO and one NC contact available that can be energized at either the open or closed limit, as chosen by the user in this setting.

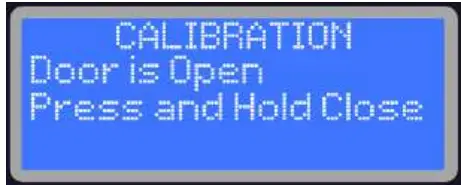

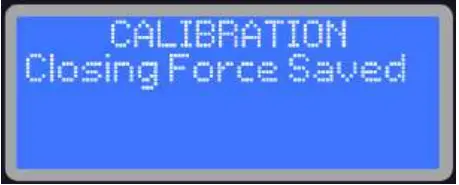

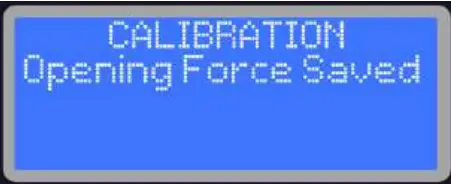

CALIBRATION This feature is required to calibrate load-sensing. Screen prompts guide user through calibration.

This feature is required to calibrate load-sensing. Screen prompts guide user through calibration.

NOTE: IF YOU CHANGE ANY OF THE FOLLOWING SETTINGS, THE OPERATOR WILL PROMPT YOU TO RECALIBRATE WHEN EXITING THE MENU: Voltage Range, Motor position, Door Limits, Open Speed, Close Speed, PWM Frequency, Open Rampdown and Close Rampdown.

THE CALIBRATION OF THE DOOR INVOLVES THE FOLLOWING STEPS:  – An automatic slow opening cycle of the door. (You will be prompted to open the door)

– An automatic slow opening cycle of the door. (You will be prompted to open the door)

– A manual close cycle of the door. Press and Hold the CLOSE button through this cycle. If the CLOSE button isn’t held until door is fully closed, the Operator will abort this step and prompt you to start again.

– You will be prompted to open the door to Calibrate Opening Force.

– Resetting the Encoder. Once the door is fully open, you will have to press OPEN again to reset the Encoder (The LCD screen will say “DOOR IS READY” as a prompt before the Encoder is to be reset.) MAINTENANCE SCHEDULE

MAINTENANCE SCHEDULE This feature sets a reminder, displayed on the LCD, to schedule maintenance after a selected number of operator cycles. Factory default is set to notify of Maintenance after 250,000 cycles (recommended for Motor Brush Replacement). It can be lowered in 1,000 cycle increments. Press the OPEN or CLOSE buttons to change, and Press and Hold the buttons for rapid scrolling to your required cycle setting.

This feature sets a reminder, displayed on the LCD, to schedule maintenance after a selected number of operator cycles. Factory default is set to notify of Maintenance after 250,000 cycles (recommended for Motor Brush Replacement). It can be lowered in 1,000 cycle increments. Press the OPEN or CLOSE buttons to change, and Press and Hold the buttons for rapid scrolling to your required cycle setting.

RED FLASHING Set this feature to ON if you prefer the red light of an attached LED Stop & Go Light to flash while the door is in motion.

Set this feature to ON if you prefer the red light of an attached LED Stop & Go Light to flash while the door is in motion.

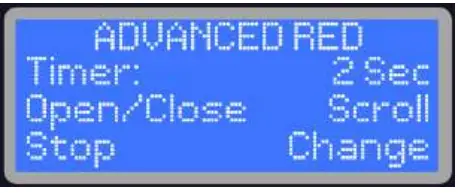

ADVANCED RED Used in conjuction with the CLOSING TIMER (Page 18), this safety feature turns on the red light (or flashing red light if this setting has been enabled) of an attached LED Stop & GO light in advance of the door closing by a programmed number of seconds. Note that should you choose a value that is greater than the CLOSING TIMER pre-set, it will begin at the same time. Factory Default is the ‘OFF’ setting, with options for 1-9 seconds of ADVANCED RED.

Used in conjuction with the CLOSING TIMER (Page 18), this safety feature turns on the red light (or flashing red light if this setting has been enabled) of an attached LED Stop & GO light in advance of the door closing by a programmed number of seconds. Note that should you choose a value that is greater than the CLOSING TIMER pre-set, it will begin at the same time. Factory Default is the ‘OFF’ setting, with options for 1-9 seconds of ADVANCED RED.

REMOTE RADIO MODE

This setting allows two options for how the remote operates if it is pressed while the door is opening. In ‘Open/Close’ mode when pressing the remote button from the Closed position, the door will open to the chosen limit setting (see Open Limit Options on page 14). Pressing the remote again during its travel will have no effect. Once it reaches the Open position, pressing the remote will command the door to close.

In ‘Open/Close’ mode when pressing the remote button from the Closed position, the door will open to the chosen limit setting (see Open Limit Options on page 14). Pressing the remote again during its travel will have no effect. Once it reaches the Open position, pressing the remote will command the door to close.

In ‘Open/Stop/Close’ mode pressing the remote button when the door is closed, the door will open to the chosen limit setting. Should you press the remote again during the Open cycle, the door wil stop. If it is pressed again, it will close from the stopped position. In either mode, if the remote is pressed while the door is closing, it will reverse.

In either mode, if the remote is pressed while the door is closing, it will reverse.

OPEN LIMIT SWITCH

If choosing to use a Switch (limit, proximity, reed, etc) to signal the door’s fully open position for encoder reset (connecting to H1 & H2 in junction box), set this selection to YES. USING A SWITCH STILL REQUIRES INSTALLATION OF LIMIT BRACKETS AS A SAFETY REDUNDANCY IN CASE OF SWITCH FAILURE.

If choosing to use a Switch (limit, proximity, reed, etc) to signal the door’s fully open position for encoder reset (connecting to H1 & H2 in junction box), set this selection to YES. USING A SWITCH STILL REQUIRES INSTALLATION OF LIMIT BRACKETS AS A SAFETY REDUNDANCY IN CASE OF SWITCH FAILURE.

CLOSE RAMP-UP TIME On the Close cycle, from the open position, you can adjust the amount of time that it takes the door to accelerate from its resting position to its full speed. This is particularly beneficial when using standard lift doors and/or large drums, or when the unit is mounted on a balanced rolling steel door. This can be adjusted in 0.5s increments from 0.5 to 3.0 Seconds. Factory Default is 1.0s

On the Close cycle, from the open position, you can adjust the amount of time that it takes the door to accelerate from its resting position to its full speed. This is particularly beneficial when using standard lift doors and/or large drums, or when the unit is mounted on a balanced rolling steel door. This can be adjusted in 0.5s increments from 0.5 to 3.0 Seconds. Factory Default is 1.0s

MOTION DETECT TIME As an added safety feature, the encoder monitors the rotation of the shaft. Should it detect no motion where there should be motion, the system will halt the cycle command, and show a fault display of ‘NO MOTION DETECTED’. The allowable delay before this fault is recognized by the system can be adjusted from 0.2s to 0.6s, but should not be altered from the Factory Default setting of 0.3s unless instructed to do so by technical support personnel.

As an added safety feature, the encoder monitors the rotation of the shaft. Should it detect no motion where there should be motion, the system will halt the cycle command, and show a fault display of ‘NO MOTION DETECTED’. The allowable delay before this fault is recognized by the system can be adjusted from 0.2s to 0.6s, but should not be altered from the Factory Default setting of 0.3s unless instructed to do so by technical support personnel.

BALANCE CHECK Once selected from the menu, the door will automatically run through one full close/open cycle (after an encoder reset). It will then report on the screen values representing the force required to open and to close the door. The difference in these numbers represents the imbalance, and adjustments to the spring tension should be made accordingly. Run this feature again to verify proper adjustment.

Once selected from the menu, the door will automatically run through one full close/open cycle (after an encoder reset). It will then report on the screen values representing the force required to open and to close the door. The difference in these numbers represents the imbalance, and adjustments to the spring tension should be made accordingly. Run this feature again to verify proper adjustment.

FACTORY RESET This setting allows for a reset of all menu options to the factory default recommended for sectional doors. These are the Factory Settings:

This setting allows for a reset of all menu options to the factory default recommended for sectional doors. These are the Factory Settings:

STARTUP MENU

Closing Timer: ……………………………………………….. OFF

Voltage Range: ………………………………………………. 208V-240V

Door Limits Setup: ……………………………………….. 4 Rotations – Must be Re-Programmed by Installer

Open Speed: ………………………………………………….. 3

Close Speed: …………………………………………………. 3

ADVANCED SETUP MENU

Reversing Timer: ……………………………………… 1.0 Seconds

PWM Frequency: …………………………………… 12 kHz

Dynamic Brake: ………………………………………… OFF

Opening Force: …………………………………………. 10

Closing Force: ……………………………………………… 2

Open Slow Speed: ……………………………………… Normal

Close Slow Speed: ……………………………………. Normal

Close Rampdown: …………………………………… Auto

Open Rampdown: ……………………………. Auto

Open Limit Options – Push Button:……………………. Set Limit

Open Limit Options – Remote Radio:………………….. Set Limit

Output Relay:…………………………………. Energized When Open

Red Flashing: ……………………………………………. OFF

Advanced Red: ………………………. OFF

Advanced Red: ……………………………….. Open/Close

Maintenance Schedule: ……………………….. 250,000 Cycles

Open Limit Switch: ………………………………………. No

Close Ramp-Up Time ……………………………… 1.0 Seconds

Motion Detect Time………………………………….. 0.3 Seconds

After performing factory reset (if deemed necessary), adjust settings as required, and re-program limit settings and perform calibration thereafter.

EXITING ADVANCED MENU – CALIBRATION & TESTING To exit from the ADVANCED MENU, press and release the STOP button while ADVANCED MENU appears on the LCD. This will bring you back to the STARTUP MENU. Press and release the STOP button again to exit all menus and to test the changed settings. If, while you were in the ADVANCED MENU and have saved changes to the PWM Frequency, Open Rampdown or Close Rampdown you will be required to do a quick system calibration. Screen prompts will provide real-time instruction on calibration requirements. See Page 21 for more detailed informaiton on Calibration.

To exit from the ADVANCED MENU, press and release the STOP button while ADVANCED MENU appears on the LCD. This will bring you back to the STARTUP MENU. Press and release the STOP button again to exit all menus and to test the changed settings. If, while you were in the ADVANCED MENU and have saved changes to the PWM Frequency, Open Rampdown or Close Rampdown you will be required to do a quick system calibration. Screen prompts will provide real-time instruction on calibration requirements. See Page 21 for more detailed informaiton on Calibration.

Once Calibration is completed or if it was not required, the system will run a quick diagnostic, and the LCD should indicate current door postion (Open, Closed or Stopped). It is now that testing of any of the changed settings can commence.

PATENTED BATTERY BACKUP – POWER OUTAGE OPERATION

The Pulse is factory equipped with a patented battery backup system and it is automatically activated during a power outage. This battery backup even works if there is board damage occuring due to external forces such as lightning or impact.

During a power outage, simply push and hold the OPEN button in order to open the door, and push and hold the CLOSE button in order close the door – the door will respond accordingly, but note that speeds will be reduced.

Limits are not active, and it is important to release the button as soon as the door reaches the appropriate position.

All safety devices will also be disabled during a battery backup operation and any personnel operating the door should maintain a clear line of sight with the doorway in order to reduce the risk of possible door impact with personnel or equipment, and to ensure the door operates safely.

NOTE: WHEN USING BATTERY BACKUP, LIMITS ARE NOT ENGAGED. YOU MUST RELEASE THE BUTTON AT THE APPROPRIATE TIME, OR RISK TRIGGERING THE CIRCUIT BREAKER. DO NOT HOLD THE OPEN OR CLOSE BUTTON ANY LONGER THAN NECESSARY.

To enable/test battery backup functionality when the power is available, disconnect power to the operator. In case the batteries are fully drained or missing, the base of the motor is also equipped with a 3/8” ratchet entry. TURN OFF POWER TO THE OPERATOR (even if the power seems out), secure a crankshaft, socket wrench or power drill with 3/8” ratchet head (not included) inside the ratchet entry and rotate it in the appropriate direction in order to open or close the door. Turn on the power once manual operation is no longer required.

NOTE ON BATTERIES

Provided lead-acid batteries are 2 x 12V connected in series to provide 24Vdc. The controller provides a monitored trickle charger in order to maintain the batteries’ life. Should the batteries be fully drained and no longer accept a charge, please replace them with equivalent batteries, and dispose of the expired units according to local environmental regulations. NEVER remove the provided jumper between the batteries unless in the process of replacement, and be sure to re-connect in the event battery replacement is required.

WEATHER-RESISTANT APPLICATIONS

iControls recommends an available upgrade for all Weather Resistant applications. Standard Pulse Operator Motors are rated IP44, and could be vulnerable to water ingress. Furthermore, reflective photo-eye sensors have a tendency to be detrimentally affected by condensation on the reflector, preventing reliable operation in such conditions.

iControls offers a cost-effective weather-resistant upgrade that seals ingress points on the motor junction box, and includes a NEMA 4X thru-beam sensor in place of a reflective photo-eye. Please contact iControls for details and pricing.

PULSE OPERATOR COMPONENTS

TROUBLE SHOOTING GUIDE

| SYMPTOM | PROBABLE CAUSE | SUGGESTED ACTION |

| NO DISPLAY AT THE LCD PANEL | NO POWER. | Check power is on at circuit breaker, disconnect switch, and check wiring connections. |

| Check fuse (refer to fuse specs in the installation instructions) in the junction box. | ||

| LOOSE CONNECTION(S). | Check connections in the J/box (near operator) and control panel; check that the ribbon cable to LCD display is firmly connected at both ends. | |

| VOLTAGE DROP IN WIRING BETWEEN OPERATOR JUNCTION BOX TO CONTROL PANEL. | Check voltage between terminal +24 and COM, if no power or Pulse voltage is less than 23V, check wiring between Junction box (near operator)

and control panel. |

|

| LCD PANEL ASSEMBLY. | If 24Vdc is detected and ribbon cable is connected then replacement of LCD panel assembly may be required. | |

| CONTROL PANEL CIRCUIT BOARD. | Disconnect +24V wire (from the J/box) in the control panel, check voltage between disconnected wire and COM terminal, if voltage is 24Vdc then replacement of control panel circuit board may be required. | |

| DOOR STOPS AT RANDOM (DOES NOT RECOGNIZE LIMITS) POSITION. | ENCODER ISSUE POSSIBLE | Contact Toll-Free Number for assistance: 1-833-785-7332 |

| DOOR CONSTANTLY STOPS SHORT OF CLOSE POSITION | DOOR MAY BE OUT OF BALANCE. | Run Balance Check from Advanced Menu. |

| DOOR REVERSES BEFORE REACHING CLOSE POSITION OR AS SOON AS THE CLOSE BUTTON IS RELEASED | PHOTO-EYE/REFLECTOR/ THRU-BEAM SENSOR MISALIGNED/OBSTRUCTED/ MISWIRED. | Clean, re-align and/or clear obstruction in front of the sensors/reflector. Re-check wiring as shown in Diagram 1 on Page 13. Ensure a rope or weather-stripping is not causing interference. |

| FORCE MONITORING IS TOO SENSITIVE | Adjust the Closing Force to a less sensitive setting in the Advanced Menu. 1 is most sensitive, and 20 is least sensitive. | |

| THIRD PARTY REVERSING DEVICES MALFUNCTIONING. | Disconnect third party reversing devices, install jumper between reversing input terminal 3 and +24 and test again. Reconnect reversing devices one at a time to isolate the defected device, (refer to page 11-17 In the installation manual). | |

| ‘DOOR IS STOPPED’ MESSAGE ON LCD PANEL | OBSTRUCTION OR DOOR JAMMED DUE TO OBSTRUCTION. | Remove obstruction or free up the door, disconnect (turn off) the AC power and test operate the door under batterY power. |

| PUSHER SPRINGS MAY BE PREVENTING DOOR FROM REACHING THE OPEN LIMITS. | Remove Pusher Springs and install upper limit brackets supplied with operator or reset OPEN limit so that Pusher Spring are not engaged. | |

| ENCODER MALFUNCTION | Contact Toll-Free Number for assistance: 1-833-785-7332 | |

| DOOR MOVES FEW INCHES AFTER OPEN/CLOSE COMMAND AND STOPS | JUMPER BETWEEN THE ‘S’ AND ‘+24’ TERMINAL HAS BEEN REMOVED. | If no push-button station has been wired in its place, re-install the jumper. |

| THE REMOTE PUSH BUTTON DOES NOT HAVE THE NC (NORMALLY CLOSED) CONTACT FOR THE STOP BUTTON. | Replace the push button station (or the contact for the STOP button) for one that has an NC contact on the STOP button. | |

| REMOTE PUSH BUTTON STATION WIRED INCORRECTLY. | Check and correct wiring as necessary. | |

| DOOR DOES NOT CLOSE ON REMOTE OR CLOSE TIMER | PUSHER SPRINGS MAY BE PREVENTING DOOR TO OPEN FULLY TO THE OPEN LIMIT (SCREEN READS ‘DOOR IS STOPPED’) . | Remove pusher springs and replace with supplied Limit Brackets; or adjust Set Open Limit so that it does not engage pusher springs and set all activation devices to open the door to Set Limit. |

| CLOSE TIMER NOT SET APPROPRIATELY. | Reset Close Timer, (refer to Pg 18 in the installation manual). | |

| NO FUNCTIONAL REVERSING DEVICE IN R1 OR R2 TERMINAL | Ensure that 1 appropriate and functional device is installed in at least one of these terminals. If installed, check wiring and alignment and test functionality | |

| DOOR DOES NOT WORK ON BATTERY POWER | CIRCUIT BREAKER BLOWN | Re-activate circuit breaker by pressing reset button. |

| BATTERIES MAY BE DRAINED, OR DEAD OR

DEFECTIVE CONTROL BOARD. |

Check batteries voltage, if low let them charge for 24 hours with AC power ON. Replace batteries if still not charged. Replace control board if the batteries are fully charged and door is balanced. | |

| DOOR OUT OF BALANCE. | Run Balance Check from Advanced Menu. | |

| THE POWER MAY BE STILL BE ON. | Ensure the main power to the unit is off. | |

| FORCE MONITOR- ING CONSTANTLY TRIGGERED | CLOSING FORCE IS NOT SET PROPERLY | Adjust the Closing and/or Opening Force. Directions are shown on Pages 21-22. Increase or decrease based on door weight/ side and application of the door |

PULSE OPERATOR REPLACEMENT PARTS

| REPLACEMENT PART DESCRIPTION | Pulse 500-100 | Pulse 500-125 | Pulse 750-100 | Pulse 750-125 | Pulse 1000 |

| Motor | PDC-500-1800 | PDC-500-1800 | PDC-750-1800 | PDC-750-1800 | PDC-P1000-1800 |

| Motor Brush Set (2) | PDC-BRUSH | PDC-BRUSH | PDC-BRUSH | PDC-BRUSH | PDC-BRUSH |

| Gearbox | PDC-GB50/1/30 | PDC-GB75/1.25/40 | PDC-GB50/1/30 | PDC-GB75/1.25/40 | PDC-GB75/1.25/40 |

| Lower Control Board | PCBA-PC7 | PCBA-PC7 | PCBA-PC7 | PCBA-PC7 | PCBA-PC7 |

| Upper Drive Board | PCBA-PD7 | PCBA-PD7 | PCBA-PD7 | PCBA-PD7 | PCBA-PD7 |

| Torque Arm | PDC-TQA-50 | PDC-TQA-75 | PDC-TQA-50 | PDC-TQA-75 | PDC-TQA-75 |

| Torque Arm Bracket | PDC-TQB-50 | PDC-TQB-75 | PDC-TQB-50 | PDC-TQB-75 | PDC-TQB-75 |

| Limit Brackets w/ Hardware | PDC-LMTBKT | PDC-LMTBKT | PDC-LMTBKT | PDC-LMTBKT | PDC-LMTBKT |

| Shaff Collar | PDC-COL-1.0 | PDC-COL-1.25 | PDC-COL-1.0 | PDC-COL-1.25 | PDC-COL-1.25 |

| Shaff Key | PDC-KEY-3 | PDC-KEY-3 | PDC-KEY-3 | PDC-KEY-3 | PDC-KEY-3 |

| Encoder | PDC-ENCD50 | PDC-ENCD75 | PDC-ENCD50 | PDC-ENCD75 | PDC-ENCD75 |

| Battery (single piece) | PCB-BAT-5A | PCB-BAT-5A | PCB-BAT-7A | PCB-BAT-7A | PCB-BAT-9A |

| Battery Set | PCB-BAT-5A2 | PCB-BAT-5A2 | PCB-BAT-7A2 | PCB-BAT-7A2 | PCB-BAT-9A2 |

| Reflective Photo Eye Set | RPE-100SET | RPE-100SET | RPE-100SET | RPE-100SET | RPE-1000SET |

| Photo-Eye Sensor Only | RPE-100 | RPE-100 | RPE-100 | RPE-100 | RPE-100 |

| Photo-Eye Bracket | RPESTB-BRKT | RPESTB-BRKT | RPESTB-BRKT | RPESTB-BRKT | RPESTB-BRKT |

| Photo-Eye Reflector | RPE-RFLC | RPE-RFLC | RPE-RFLC | RPE-RFLC | RPE-RFLC1000 |

| Control Panel Enclosure | PCBA/ENC- | PCBA/ENC- | PCBA/ENC- | PCBA/ENC- | PCBA/ENC- |

| (Complete) | PC7/500 | PC7/500 | PC7/750 | PC7/750 | PC7/1000 |

| Control Panel (no board) | PCB-ENC-500 | PCB-ENC-500 | PCB-ENC-750 | PCB-ENC-750 | PCB-ENC-750 |

| Ribbon Cable | PCB-RIBCAB-1 | PCB-RIBCAB-2 | PCB-RIBCAB-1 | PCB-RIBCAB-2 | PCB-RIBCAB-2 |

| Push Button | PCB-PB1 | PCB-PB1 | PCB-PB1 | PCB-PB1 | PCB-PB1 |

Remote Radio Transmitter/Receiver Wiring Diagram/Instructions

Remote Radio Transmitter/Receiver Wiring Diagram/Instructions

Wiring Receiver to Pulse Operator:

Wiring Receiver to Pulse Operator:

Single Channel:

If using only one button on the transmitter to operate the door, wire per the left diagram above to the REMOTE CONTROL terminals on the Pulse Operator Control Board. Once installed and properly paired with the transmitter (see opposite side for mating instructions), the programmed button will either open or close the door, depending on door position. If the reversing timer is engaged on your Pulse Operator, the programmed button will open the door only. Note that all 3 buttons on the transmitter can be programmed to operate the same door, or individually programmed to different receivers to operate 3 separate doors.

Dual Channel:

If using one button on the transmitter to open and another to close the door, wire per the right diagram above to the PUSH BUTTON STATION terminals on the Pulse Operator Control Board. Once correctly installed and paired with the transmitter (see opposite side for pairing instructions), each programmed button will perform its assigned function.

Remote Radio Transmitter/Receiver Pairing Instructions

Mating RXTA-100 Receiver to TXTA-100 Transmitter

Mating RXTA-100 Receiver to TXTA-100 Transmitter

Proceed only if receiver has been wired properly and power is on.

Single Channel:

- Press the ‘leam’ button beside the S1 mark on the receiver until the corresponding L1 LED turns on. Do not press/program the S2 button for single channel use.

- Press and hold the desired button on the transmitter until the L1 LED flashes 4 times to indicate successful pairing. Release button.

- Press programmed button on transmitter for verification-L1 LED should illuminate.

- Repeat this step with all buttons on the transmitter (pairing with S1), if used only for this receiver.

Dual Channel:

- Press the ‘learn” button beside the S1 mark on the receiver until the corresponding L1 LED turns on.

- Press and hold the desired ‘OPEN’ button on the transmitter until the L1 LED flashes 4 times to indicate. successful pairing. Release button.

- Press programmed button on transmitter for verification-L1 LED should illuminate.

- Press the ‘learn’ button beside the S2 mark on the receiver until the corresponding L2 LED turns on.

- Press and hold the desired ‘CLOSE’ button on the transmitter until the L2 LED flashes 4 times to indicate successful pairing. Release button.

- Press programmed button on transmitter for verification-L2 LED should illuminate.

PULSE 500+ WARRANTY

Coverage

Pulse 500-1000 Operators are fully warrantied for a period of 2 years or 1,000,000 cycles (whichever comes first) from their purchase date. This warranty i s i nclusive of, and l imited to, a ll component and manufacturing defects only, and does not cover possible failure due to external forces including irregularities caused by impact, improper installation and/or connection, voltage surges and any and all other user and/or environmentally caused failures. This warranty is valid for replacement or repair of defective product only, and does not include any labour incurred for the removal or installation of defective part(s), re-installation of replacement/repaired product, shipping charges for the return of the product, or other possible costs related to the inoperability of the operator.Coverage does not extend to maintenance of Motor Brushes which should be replaced every 200,000 cycles. Software reliability and performance is also covered under our warranty, but does not include software updates, upgrades and/or custom modifications unless so authorized in writing by iControls.

Claims

Before making a warranty claim, please call Pulse Tech Support at 1-833-785-7332 and ask for troubleshooting assistance. DO NOT REMOVE THE PRODUCT , until so authorized.

Note

Upon request, iControls can also provide field assistance (additional fees may apply) and/or advice with installation, troubleshooting, product enhancement or improvement of our product. Under the terms of this limited warranty, for any operator components that are found to be defective upon inspection by authorized iControls personnel, iControls will replace/repair the defective operator components. Labour charges for installation or repairs shall be the responsibility of the customer and must be performed by an authorized iControls Dealer where available. This warranty applies only to operators that are professional installed by an authorized iControls dealer and done so within the guidelines of the installation manual. In the case that one of the operator model or part is discontinuedor becomes obsolete, iControls reserves the right to replace the product with a suitable alternative.

iControls shall not be liable for any consequential or incidental damages. All other warranties, express or implied, including any warranty of merchantability, are hereby expressly excluded. Some jurisdictions do not allow the exclusion or limitation of consequential or incidental damages, so the above limitation or exclusion may not apply to you. This warranty gives you specific legal rights, and you may also have other rights which vary from jurisdiction to jurisdiction. To make a claim under these warranties,

contact iControls.

For more information, please contact www.devancocanada.com or call toll free at 1-855-931-3334

Documents / Resources

|

Controls Pulse Series Controller Pulse Red [pdf] Owner's Manual Pulse Series Controller Pulse Red, Pulse Series, Controller Pulse Red, Pulse Red, Red |