Fronius RI MOD Compact Com Module

Specifications

- Product Name: RI FB PRO/i RI MOD/i CC Ethernet/IP-2P

- Vendor: Fronius International GmbH

- Device Type: Communication adapter

- Product Code: 0320hex (800dez)

- Image Type: Standard Image

- Instance Type: Producing Instance

- Consuming Instance: Consuming Instance

- Instance Name: Fronius-FB-Pro-EtherNetIP(TM)

Product Usage Instructions

Setting the IP Address of the Bus Module

The IP address of the bus module can be set using the DIP switches on the interface:

- Set the IP address within the range of 192.168.0.xx (where xx corresponds to DIP switch positions from 1 to 63).

- DIP switch settings and corresponding IP addresses:

| DIP Switch | IP Address |

|---|---|

| OFF OFF OFF OFF OFF OFF ON | 1 |

| OFF OFF OFF OFF OFF ON OFF | 2 |

| OFF OFF OFF OFF OFF ON ON | 3 |

| ON ON ON ON ON OFF | 62 |

| ON ON ON ON ON ON | 63 |

Data Types and Signal Mapping

The product uses the following data types:

- UINT16 (Unsigned Integer) – Range: 0 to 65535

- SINT16 (Signed Integer) – Range: -32768 to 32767

Address mapping for input and output signals:

| Address | Type | Description |

|---|---|---|

| 0-7 | BIT Signal | Signal Mapping Details |

General

Safety

WARNING!

Danger from incorrect operation and work that is not carried out properly. This can result in serious personal injury and damage to property.

- All the work and functions described in this document must only be carried out by technically trained and qualified personnel.

- Read and understand this document in full.

- Read and understand all safety rules and user documentation for this equip-ment and all system components.

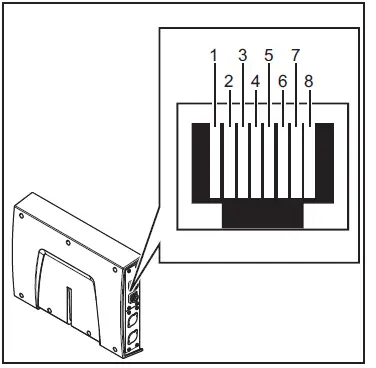

Connections and Displays

| 1 | TX+ |

| 2 | TX- |

| 3 | RX+ |

| 6 | RX- |

| 4,5,7, | Not normally used; to ensure- |

| 8 | re signal completeness, the |

| se pins must be Intercon- | |

| nected and, after passing | |

| through a filter circuit, must | |

| terminate at the ground | |

| conductor (PE). |

RJ45 connection

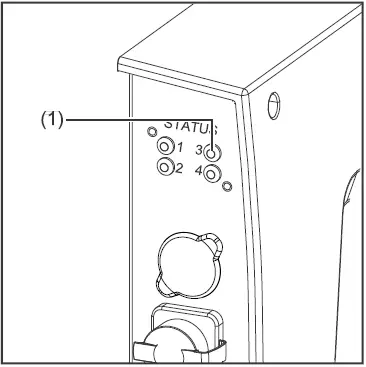

| (1) LED MS – Module status |

| Off:

No supply voltage |

| Lights up green:

Controlled by a master |

| Flashes green (once):

Master not configured or master idle |

| Lights up red:

Major error (exception state, serious fault, …) |

| Flashes red:

Correctable error |

| (2) LED NS – Network status |

| Off:

No supply voltage or no IP address |

| Lights up green:

Online, one or more connections established (CIP category 1 or 3) |

| Flashes green:

Online, no connection is established |

| Lights up red:

Double IP address, serious error |

| Flashes red:

Overrun of time for one or more connections (CIP category 1 or 3) |

Data Transfer Properties

Transfer technology

- Ethernet

Medium

- When selecting the cables and plugs, the ODVA recommendation for the plan-ning and installation of EtherNet/IP systems must be observed. The EMC tests were carried out by the manufacturer with the cable IE-C5ES8VG0030M40M40-F.

Transmission speed

- 10 Mbit/s or 100 Mbit/s

Bus connection

- RJ-45 Ethernet / M12

Configuration Parameters

- In some robot control systems, it may be necessary to state the configuration parameters described here so that the bus module can communicate with the robot.

| Parameter | Value | Description |

| Vendor ID | 0534hex (1332dec) | Fronius International GmbH |

| Device Type | 000Chex (12dec) | Communication adapter |

| Product Code | 0320hex (800dec) | Fronius FB Pro Ethernet/IP-2-Port |

Product Name Fronius-FB-Pro-EtherNetIP(TM)

|

Image Type |

Instance Type |

Instance Name |

Instance Description |

Instance Number |

Size [Byt e] |

| Standard Image | Produ- coming Instance | Input Data Standard | Data from power source to robot | 100 | 40 |

|

Image Type |

Instance Type |

Instance Name |

Instance Description |

Instance Number |

Size [Byt e] |

| Con- summing Instance | Output Data Standard | Data from robot to power source | 150 | 40 | |

| Economy Image | Produ- coming Instance | Input Data Standard | Data from power source to robot | 101 | 16 |

| Con- summing Instance | Output Data Standard | Data from robot to power source | 151 | 16 |

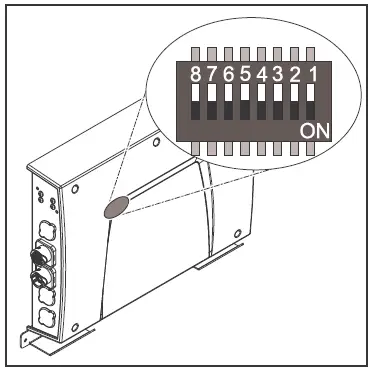

Setting the Bus Module IP Address

Setting the Bus Module IP Address You can set the bus module IP address as follows:

- Using the DIP switch in the interface within the range defined by 192.168.0.xx (xx = DIP switch setting = 1 to 63)

- All positions are set to the OFF position at the factory. In this case, the IP address must be set on the website of the welding machine

- On the website of the welding machine (if all positions of the DIP switch are set to the OFF position)

The IP address is set using DIP switch positions 1 to 6. The configuration is carried out in binary format. This results in a configuration range of 1 to 63 in decimal format.

| Example for setting the IP address of the bus module using the DIP switch in the interface: | ||||||||

| Dip switch | ||||||||

| 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | IP address |

| – | – | OFF | OFF | OFF | OFF | OFF | ON | 1 |

| – | – | OFF | OFF | OFF | OFF | ON | OFF | 2 |

| – | – | OFF | OFF | OFF | OFF | ON | ON | 3 |

| – | – | ON | ON | ON | ON | ON | OFF | 62 |

| – | – | ON | ON | ON | ON | ON | ON | 63 |

Instructions for setting the IP address on the website of the welding machine:

Note down the IP address of the welding machine used:

- On the welding machine control panel, select “Defaults”

- On the welding machine control panel, select “System”

- On the welding machine control panel, select “Information”

- Note down the displayed IP address (example: 10.5.72.13)

Access the website of the welding machine in the internet browser:

- Connect the computer to the network of the welding machine

- Enter the IP address of the welding machine in the search bar of the internet browser and confirm

- Enter the standard user name (admin) and password (admin)

- The website of the power source is displayed

Set the bus module IP address:

- On the power welding machine, select the “RI FB PRO/i” tab

- Enter the desired IP address for the interface under “Module configuration”. For example: 192.168.0.12

- Select “Set configuration”

- Select “Restart module”

- The set IP address is applied

Input and output signals

Data types

The following data types are used:

- UINT16 (Unsigned Integer)

- The whole number in the range from 0 to 65535

- SINT16 (Signed Integer)

- The whole number ranges from -32768 to 32767

Conversion examples:

- for a positive value (SINT16) e. g. desired wire speed x factor 12.3 m/min x 100 = 1230dec = 04CEhex

- for a negative value (SINT16) e. g. arc correction x factor -6.4 x 10 = -64dec = FFC0hex

Availability of input signals

The input signals listed below are available from firmware V2.0.0 of the RI FB PRO/i onwards.

Input signals (from robot to power source)

|

Address |

Signal |

Activity/data type |

Range |

Factor | Process image | ||||

|

Relative |

Absolu- te | Standard | Economy | ||||||

| WORD | BYTE | BIT |

BIT |

||||||

|

0 |

0 |

0 | 0 | Welding Start | Increa- sing |

ü |

ü |

||

| 1 | 1 | Robot ready | High | ||||||

| 2 | 2 | Working mode Bit 0 | High |

See table Value Range for Working Mode on page 35 |

|||||

| 3 | 3 | Working mode Bit 1 | High | ||||||

| 4 | 4 | Working mode Bit 2 | High | ||||||

| 5 | 5 | Working mode Bit 3 | High | ||||||

| 6 | 6 | Working mode Bit 4 | High | ||||||

| 7 | 7 | — | |||||||

|

1 |

0 | 8 | Gas on | Increa- sing | |||||

| 1 | 9 | Wire forward | Increa- sing | ||||||

| 2 | 10 | Wire backward | Increa- sing | ||||||

| 3 | 11 | Error quit | Increa- sing | ||||||

| 4 | 12 | Touch sensing | High | ||||||

| 5 | 13 | Torch blow out | Increa- sing | ||||||

| 6 | 14 | Processing selection Bit 0 | High | See table Value range Process li- ne selection on page 36 | |||||

|

7 |

15 |

Processing selection Bit 1 |

High |

||||||

|

Address |

Signal |

Activity/data type |

Range |

Factor | Process image | ||||

|

Relative |

Absolu- te | Standard | Economy | ||||||

| WORD | BYTE | BIT |

BIT |

||||||

|

1 |

2 |

0 | 16 | Welding simulation | High |

ü |

ü |

||

|

1 |

17 |

Welding process MIG/MAG: 1)

Synchro pulse on |

High |

||||||

| Welding process WIG: 2)

TAC on |

High |

||||||||

|

2 |

18 |

Welding process WIG: 2)

Cap shaping |

High |

||||||

| 3 | 19 | — | |||||||

| 4 | 20 | — | |||||||

| 5 | 21 | Booster manual | High | ||||||

| 6 | 22 | Wire brake on | High | ||||||

| 7 | 23 | Torchbody Xchange | High | ||||||

|

3 |

0 | 24 | — | ||||||

| 1 | 25 | Teach mode | High | ||||||

| 2 | 26 | — | |||||||

| 3 | 27 | — | |||||||

| 4 | 28 | — | |||||||

| 5 | 29 | Wire since start | Increa- sing | ||||||

| 6 | 30 | Wire sense break | Increa- sing | ||||||

| 7 | 31 | — | |||||||

|

Address |

Signal |

Activity/data type |

Range |

Factor | Process image | ||||

|

Relative |

Absolu- te | Standard | Economy | ||||||

| WORD | BYTE | BIT |

BIT |

||||||

|

2 |

4 |

0 | 32 | TWIN mode Bit 0 | High | See table Value Range for TWIN Mode on page 36 |

ü |

ü |

|

|

1 |

33 |

TWIN mode Bit 1 |

High |

||||||

| 2 | 34 | — | |||||||

| 3 | 35 | — | |||||||

| 4 | 36 | — | |||||||

|

5 |

37 |

Documentation mode |

High |

See table Value Range for Docu- mentation Mode on page 36 | |||||

| 6 | 38 | — | |||||||

| 7 | 39 | — | |||||||

|

5 |

0 | 40 | — | ||||||

| 1 | 41 | — | |||||||

| 2 | 42 | — | |||||||

| 3 | 43 | — | |||||||

| 4 | 44 | — | |||||||

| 5 | 45 | — | |||||||

| 6 | 46 | — | |||||||

| 7 | 47 | Disable process-controlled correction | High | ||||||

|

Address |

Signal |

Activity/data type |

Range |

Factor | Process image | ||||

|

Relative |

Absolu- te | Standard | Economy | ||||||

| WORD | BYTE | BIT |

BIT |

||||||

|

3 |

6 |

0 | 48 | — |

ü |

ü |

|||

| 1 | 49 | — | |||||||

| 2 | 50 | — | |||||||

| 3 | 51 | — | |||||||

| 4 | 52 | — | |||||||

| 5 | 53 | — | |||||||

| 6 | 54 | — | |||||||

| 7 | 55 | — | |||||||

|

7 |

0 | 56 | ExtInput1 => OPT_Output 1 | High | |||||

| 1 | 57 | ExtInput2 => OPT_Output 2 | High | ||||||

| 2 | 58 | ExtInput3 => OPT_Output 3 | High | ||||||

| 3 | 59 | ExtInput4 => OPT_Output 4 | High | ||||||

| 4 | 60 | ExtInput5 => OPT_Output 5 | High | ||||||

| 5 | 61 | ExtInput6 => OPT_Output 6 | High | ||||||

| 6 | 62 | ExtInput7 => OPT_Output 7 | High | ||||||

| 7 | 63 | ExtInput8 => OPT_Output 8 | High | ||||||

| 4 | 8-

9 |

0–7 | 64–79 | Welding characteristic- / Job number | UINT16 | 0 to 1000 | 1 | ü | ü |

|

5 |

10 – 11 |

0-7 |

80-95 |

Welding process MIG/MAG: 1)

Constant Wire:

Wire feed speed command value |

SINT16 |

-327,68 to 327,67 [m/min] |

100 |

ü |

ü |

| Welding process WIG: 2)

Main- / Hotwire current command value |

UINT16 |

0 to 6553,5 [A] |

10 |

||||||

| For job-mode:

Power correction |

SINT16 |

-20,00 to

20,00 [%] |

100

|

||||||

|

Address |

Signal |

Activity/data type |

Range |

Factor | Process image | ||||

|

Relative |

Absolu- te | Standard | Economy | ||||||

| WORD | BYTE | BIT |

BIT |

||||||

|

6 |

12 – 13 |

0-7 |

96-111 |

Welding process MIG/MAG: 1)

Arclength correction |

SINT16 |

-10,0 to

10,0 [Schritte] |

10 |

ü |

ü |

| Welding process

MIG/MAG Standard-Manuel:

Welding voltage |

UINT16 |

0,0 to

6553,5 [V] |

10 |

||||||

| Welding process WIG: 2)

Wire feed speed command value |

SINT16 |

-327,68 to 327,67 [m/min] |

100 |

||||||

| For job-mode:

Arclength correction |

SINT16 |

-10,0 to

10,0 [Schritte] |

10 |

||||||

| Welding process Constant Wire:

Hotwire current |

UINT16 |

0,0 to

6553,5 [A] |

10 |

||||||

|

7 |

14 – 15 |

0-7 |

112-127 |

Welding process MIG/MAG: 1)

Pulse-/dynamic correction |

SINT16 |

-10,0 to

10,0 [steps] |

10 |

ü |

ü |

| Welding process

MIG/MAG Standard-Manuel:

Dynamic |

UINT16 |

0,0 to

10,0 [steps] |

10 |

||||||

| Welding process WIG: 2)

Wire correction |

SINT16 |

-10,0 to

10,0 [steps] |

10 |

||||||

|

8 |

16 – 17 |

0-7 |

128-143 |

Welding process MIG/MAG: 1)

Wire retract correction |

UINT16 |

0,0 to

10,0 [steps] |

10 |

ü |

|

| Welding process WIG: 2)

Wire retract end |

UINT16 |

OFF, 1 to

50 [mm] |

1 |

||||||

|

9 |

18

– 19 |

0-7 |

144-159 |

Welding speed |

UINT16 |

0,0 to

1000,0 [cm/min] |

10 |

ü |

|

|

Address |

Signal |

Activity/data type |

Range |

Factor | Process image | ||||

|

Relative |

Absolu- te | Standard | Economy | ||||||

| WORD | BYTE | BIT |

BIT |

||||||

|

10 |

20 – 21 |

0-7 |

160-175 |

Process controlled correction |

See table Value range for Process controlled correction on page 36 |

ü |

|||

|

11 |

22

– 23 |

0-7 |

176-191 |

Welding process WIG: 2)

Wire positioning start |

ü |

||||

|

12 |

24

– 25 |

0-7 |

192-207 |

— |

ü |

||||

|

13 |

26

– 27 |

0-7 |

208-223 |

— |

ü |

||||

|

14 |

28

– 29 |

0-7 |

224-239 |

— |

ü |

||||

|

15 |

30

– 31 |

0-7 |

240-255 |

Wire forward / backward length |

UINT16 |

OFF / 1 to 65535 [mm] |

1 |

ü |

|

|

16 |

32

– 33 |

0-7 |

256-271 |

Wire sense edge detection |

UINT16 |

OFF / 0,5

to 20,0 [mm] |

10 |

ü |

|

|

17 |

34

– 35 |

0-7 |

272-287 |

— |

ü |

||||

|

18 |

36

– 37 |

0-7 |

288-303 |

— |

ü |

||||

|

19 |

38

– 39 |

0-7 |

304-319 |

Seam number |

UINT16 |

0 to

65535 |

1 |

ü |

|

- MIG/MAG Puls-Synergic, MIG/MAG Standard-Synergic, MIG/MAG Stan- dard-Manuel, MIG/MAG PMC, MIG/MAG, LSC

- WIG cold wire, WIG hotwire

Value Range for Working Mode

| Bit 4 | Bit 3 | Bit 2 | Bit 1 | Bit 0 | Description |

| 0 | 0 | 0 | 0 | 0 | Internal parameter selection |

| 0 | 0 | 0 | 0 | 1 | Special 2-step mode characteristics |

| 0 | 0 | 0 | 1 | 0 | Job mode |

| Bit 4 | Bit 3 | Bit 2 | Bit 1 | Bit 0 | Description |

| 0 | 1 | 0 | 0 | 0 | 2-step mode characteristics |

| 0 | 1 | 0 | 0 | 1 | 2-step MIG/MAG standard manual |

| 1 | 0 | 0 | 0 | 0 | Idle Mode |

| 1 | 0 | 0 | 0 | 1 | Stop coolant pump |

| 1 | 1 | 0 | 0 | 1 | R/L-Measurement |

Value range for operating mode

Value Range for Documentation Mode

| Bit 0 | Description |

| 0 | Seam number of welding machine (internal) |

| 1 | Seam number of robots (Word 19) |

The value range for documentation mode

The value range for Process control-led correction

|

Process |

Signal |

Activity/data type |

Value range configuration range |

Unit |

Factor |

|

PMC |

Arc length stabilizer |

SINT16 |

-327.8 to +327.7

0.0 to +5.0 |

Volts |

10 |

The value range for documentation mode

The value range for Process control-led correction

|

Process |

Signal |

Activity/data type |

Value range configuration range |

Unit |

Factor |

|

PMC |

Arc length stabilizer |

SINT16 |

-327.8 to +327.7

0.0 to +5.0 |

Volts |

10 |

The value range for process-dependent correction

Value range Process line selection

| Bit 1 | Bit 0 | Description |

| 0 | 0 | Process line 1 (default) |

| 0 | 1 | Process line 2 |

| 1 | 0 | Process line 3 |

| 1 | 1 | Reserved |

Value range for process line selection

Value Range for TWIN Mode

| Bit 1 | Bit 0 | Description |

| 0 | 0 | TWIN Single mode |

| 0 | 1 | TWIN Lead mode |

| 1 | 0 | TWIN Trail mode |

| 1 | 1 | Reserved |

The value range for the TWIN mode

Availability of the output signals

The output signals listed below are available from firmware V2.0.0 of the RI FB PRO/i onwards.

Output Signals (from Power Source to Robot)

|

Address |

Signal |

Activity/data type |

Range |

Factor |

Process image | ||||

| relative | absolute | Standard | Economy | ||||||

| WORD | BYTE | BIT |

BIT |

||||||

|

0 |

0 |

0 | 0 | Heartbeat Powersource | High/Low | 1 Hz |

ü |

ü |

|

| 1 | 1 | Power source ready | High | ||||||

| 2 | 2 | Warning | High | ||||||

| 3 | 3 | Process active | High | ||||||

| 4 | 4 | Current flow | High | ||||||

| 5 | 5 | Arc stable- / touch signal | High | ||||||

| 6 | 6 | Main current signal | High | ||||||

| 7 | 7 | Touch signal | High | ||||||

|

1 |

0 |

8 |

Collision box active |

High |

0 = collision- on or cable break | ||||

| 1 | 9 | Robot Motion Release | High | ||||||

| 2 | 10 | Wire stick workpiece | High | ||||||

| 3 | 11 | — | |||||||

| 4 | 12 | Short circuit contact tip | High | ||||||

| 5 | 13 | Parameter selection in- eternally | High | ||||||

| 6 | 14 | Characteristic number valid | High | ||||||

| 7 | 15 | Torch body gripped | High | ||||||

|

Address |

Signal |

Activity/data type |

Range |

Factor |

Process image | ||||

| relative | absolute | Standard | Economy | ||||||

| WORD | BYTE | BIT |

BIT |

||||||

|

1 |

2 |

0 | 16 | Command value out of range | High |

ü |

ü |

||

| 1 | 17 | Correction out of range | High | ||||||

| 2 | 18 | — | |||||||

| 3 | 19 | Limitsignal | High | ||||||

| 4 | 20 | — | |||||||

| 5 | 21 | — | |||||||

| 6 | 22 | Main supply status | Low | ||||||

| 7 | 23 | — | |||||||

|

3 |

0 | 24 | Sensor status 1 | High |

See table Assign- ment of Sensor Sta- uses 1–4 on page 40 |

||||

| 1 | 25 | Sensor status 2 | High | ||||||

| 2 | 26 | Sensor status 3 | High | ||||||

| 3 | 27 | Sensor status 4 | High | ||||||

| 4 | 28 | — | |||||||

| 5 | 29 | — | |||||||

| 6 | 30 | — | |||||||

| 7 | 31 | — | |||||||

|

2 |

4 |

0 | 32 | — |

ü |

ü |

|||

| 1 | 33 | — | |||||||

| 2 | 34 | — | |||||||

| 3 | 35 | Safety status Bit 0 | High | See table Value ran- ge Safety status on page 41 | |||||

| 4 | 36 | Safety status Bit 1 | High | ||||||

| 5 | 37 | — | |||||||

| 6 | 38 | Notification | High | ||||||

| 7 | 39 | System not ready | High | ||||||

|

5 |

0 | 40 | — | ||||||

| 1 | 41 | — | |||||||

| 2 | 42 | — | |||||||

| 3 | 43 | — | |||||||

| 4 | 44 | — | |||||||

| 5 | 45 | — | |||||||

| 6 | 46 | — | |||||||

| 7 | 47 | — | |||||||

|

Address |

Signal |

Activity/data type |

Range |

Factor |

Process image | ||||

| relative | absolute | Standard | Economy | ||||||

| WORD | BYTE | BIT |

BIT |

||||||

|

3 |

6 |

0 | 48 | Process Bit 0 | High |

See table Value Range for Process Bit on page 41 |

ü |

ü |

|

| 1 | 49 | Process Bit 1 | High | ||||||

| 2 | 50 | Process Bit 2 | High | ||||||

| 3 | 51 | Process Bit 3 | High | ||||||

| 4 | 52 | Process Bit 4 | High | ||||||

| 5 | 53 | — | |||||||

| 6 | 54 | Touch signal gas nozzle | High | ||||||

| 7 | 55 | TWIN synchronization active | High | ||||||

|

7 |

0 | 56 | ExtOutput1 <= OPT_In- put1 | High | |||||

| 1 | 57 | ExtOutput2 <= OPT_In- put2 | High | ||||||

| 2 | 58 | ExtOutput3 <= OPT_In- put3 | High | ||||||

| 3 | 59 | ExtOutput4 <= OPT_In- put4 | High | ||||||

| 4 | 60 | ExtOutput5 <= OPT_In- put5 | High | ||||||

| 5 | 61 | ExtOutput6 <= OPT_In- put6 | High | ||||||

| 6 | 62 | ExtOutput7 <= OPT_In- put7 | High | ||||||

| 7 | 63 | ExtOutput8 <= OPT_In- put8 | High | ||||||

| 4 | 8-

9 |

0-7 | 64-79 | Welding voltage | UINT16 | 0.0 to

655.35 [V] |

100 | ü | ü |

|

5 |

10

– 11 |

0-7 |

80-95 |

Welding current |

UINT16 |

0.0 to 6553.5 [A] |

10 |

ü |

ü |

|

6 |

12

– 13 |

0-7 |

96-111 |

Wire feed speed |

SINT16 |

-327.68 to

327.67 [m/ min] |

100 |

ü |

ü |

|

7 |

14

– 15 |

0-7 |

112-127 |

Actual real value for seam tracking |

UINT16 |

0 to

6.5535 |

10000 |

ü |

ü |

|

8 |

16

– 17 |

0-7 |

128-143 |

Error number |

UINT16 |

0 to

65535 |

1 |

ü |

|

|

9 |

18

– 19 |

0-7 |

144-159 |

Warning number |

UINT16 |

0 to

65535 |

1 |

ü |

|

|

Address |

Signal |

Activity/data type |

Range |

Factor |

Process image | ||||

| relative | absolute | Standard | Economy | ||||||

| WORD | BYTE | BIT |

BIT |

||||||

|

10 |

20

– 21 |

0-7 |

160-175 |

Motor current M1 |

SINT16 |

-327.68 to

327.67 [A] |

100 |

ü |

|

|

11 |

22

– 23 |

0-7 |

176-191 |

Motor current M2 |

SINT16 |

-327.68 to

327.67 [A] |

100 |

ü |

|

|

12 |

24

– 25 |

0-7 |

192-207 |

Motor current M3 |

SINT16 |

-327.68 to

327.67 [A] |

100 |

ü |

|

|

13 |

26

– 27 |

0-7 |

208-223 |

— |

ü |

||||

|

14 |

28

– 29 |

0-7 |

224-239 |

— |

ü |

||||

|

15 |

30

– 31 |

0-7 |

240-255 |

— |

ü |

||||

|

16 |

32

– 33 |

0-7 |

256-271 |

Wire position |

SINT16 |

-327.68 to

327.67 [mm] |

100 |

ü |

|

|

17 |

34

– 35 |

0-7 |

272-287 |

— |

ü |

||||

|

18 |

36

– 37 |

0-7 |

288-303 |

— |

ü |

||||

|

19 |

38

– 39 |

0-7 |

304-319 |

— |

ü |

||||

Assignment of Sensor Statuses 1–4

| Signal | Description |

| Sensor status 1 | OPT/i WF R wire end (4,100,869) |

| Sensor status 2 | OPT/i WF R wire drum (4,100,879) |

| Sensor status 3 | OPT/i WF R ring sensor (4,100,878) |

| Sensor status 4 | Wire buffer set CMT TPS/I (4,001,763) |

Assignment of sensor statuses

Value range Safety status

| Bit 1 | Bit 0 | Description |

| 0 | 0 | Reserve |

| 0 | 1 | Hold |

| 1 | 0 | Stop |

| 1 | 1 | Not installed / active |

Value Range for Process Bit

| Bit 4 | Bit 3 | Bit 2 | Bit 1 | Bit 0 | Description |

| 0 | 0 | 0 | 0 | 0 | No internal parameter selection or process |

| 0 | 0 | 0 | 0 | 1 | MIG/MAG pulse synergic |

| 0 | 0 | 0 | 1 | 0 | MIG/MAG standard synergic |

| 0 | 0 | 0 | 1 | 1 | MIG/MAG PMC |

| 0 | 0 | 1 | 0 | 0 | MIG/MAG LSC |

| 0 | 0 | 1 | 0 | 1 | MIG/MAG standard manual |

| 0 | 0 | 1 | 1 | 0 | Electrode |

| 0 | 0 | 1 | 1 | 1 | TIG |

| 0 | 1 | 0 | 0 | 0 | CMT |

| 0 | 1 | 0 | 0 | 1 | Constantine |

| 0 | 1 | 0 | 1 | 0 | ColdWire |

| 0 | 1 | 0 | 1 | 1 | DynamicWire |

Value Range for Process Bit

Value Range for Function Status

| Bit 1 | Bit 0 | Description |

| 0 | 0 | Inactive |

| 0 | 1 | Idle |

| 1 | 0 | Finished |

| 1 | 1 | Error |

The value range for function status

- spareparts.fronius.com

- At www.fronius.com/contact you will find the contact details of all Fronius subsidiaries and Sales & Service Partners.Frequently Asked Questions

How do I troubleshoot LED status indications?

If the LED MS is lit red, it indicates a main error. If it blinks red, it signifies a fixable error. For LED NS, a red light could indicate a double IP address or a severe network error.

What are the default configuration parameters for the bus module?

The default configuration parameters include Vendor ID: 0534hex, Device Type: Communication adapter, Product Code: 0320hex, Product Name: Fronius FB Pro Ethernet/IP-2-Port.

Documents / Resources

|

Fronius RI MOD Compact Com Module [pdf] Instruction Manual RI MOD Compact Com Module, RI MOD, Compact Com Module, Com Module, Module |