Multilog WW

User Manual

This manual contains important safety and operating information. Please read, understand, and follow the instructions in the manual and also any documents shipped with the device.

MAN-147-0004-D March 2024

Introduction

The “Multilog2WW” device is multi-purpose data logger that can be built and configured to suit a specific application of the device; several versions are available within the logger family. Please contact your sales representative for help with selection of the appropriate model for your application.

HWM also provides a software tool, known as “IDT” (“Installation and Diagnostic Tool”) for logger setup and test. (See also section 1.6.)

Models Covered, Documentation and Support of Product

This user-guide covers the following model families:

| Model Number | Device Description |

|---|---|

| MP/*/*/* | Multilog2WW logger device. |

This user-guide should be read in conjunction with:

| Document Number | Document Description |

|---|---|

| MAN-147-0003 | Safety Warnings and Approvals Information (for Multilog2WW). |

| MAN-130-0017 | IDT (PC version) user-guide. |

| MAN-2000-0001 | IDT (app for mobile devices) user-guide. |

This user-guide provides details of the logger operation and how to install the product. Also refer to any user-guides or datasheets for sensors that are being used with the logger.

Read the relevant parts of the IDT user-guide for guidance on how to confirm settings or modify the set-up of your logger. This includes:

- Details of setup of sensor channels and making recordings of the data.

- Logger settings for the delivery of measurement data to a server.

- Logger setup for additional messaging features, such as alarms.

Note: The system periodically has new features and changes released, thus you may observe slight changes from the diagrams and features shown in this manual. Installed features and functionality can vary from device to device, therefore always refer to the menus and screens of any setup tool to determine which features are available on your logger device.

HWM provides support for logger devices by means of our customer support webpages: https://www.hwmglobal.com/help-and-downloads/

Should you have any questions that are not covered by this manual or online help, please contact the HWM Technical Support team on +44 (0) 1633 489479, or email cservice@hwm-water.com

Safety Considerations

Before continuing, carefully read and follow the information in the “Safety Warnings and Approvals Information” document supplied with the product. This provides general safety information.

Retain all documents for future reference.

Before using this product, make a risk assessment of the installation site and expected work activity. Ensure suitable protective clothing is worn and working practices are followed during installation and any maintenance.

WARNING: When this equipment is being used, installed, adjusted or serviced this must be undertaken by suitably qualified personnel familiar with the construction and operation of the equipment and the hazards of any utility network.

Operating Temperature

Use of Cellular Networks – Important Notes

Availability of SMS

Most Multilog2WW models include the ability to communicate to a server via use of the cellular data network. This is usually via the regular data network (which gives internet access). Alternatively, the SMS (Short Message Service) messaging can be used; in most cases this will be as a fall-back if the logger is temporarily unable to access the regular data network. If configured for SMS use, the logger uses the available 2G network.

Important: 2G (GPRS) services, which carry the SMS messaging system, are slowly being turned off around the globe. Once 2G is switched off, the SMS services available within the logger will no longer be able to function. Unless deactivated in the logger settings, the logger will continue to try, wasting battery power. Therefore, check with your cellular network operator for their switch off date before setting the logger to use the SMS backup service or any other feature requiring SMS use.

To deactivate the use of the SMS system, any related SMS settings must be removed (switched off or deleted). Refer to the IDT User Guide for details of SMS settings. Any modified settings must be saved to the logger.

Note: For use of SMS services, both the logger and the cellular network provider must support SMS. In addition, the SIM card fitted inside the logger must support SMS use. (Check with your SIM supplier if required).

Logger identity when using SMS

When using the cellular data network, the logger identity is included with the data within the message. However, when using the SMS system, the identity is the calling number (from the SIM card). Thus, when using any SMS services, these two numbers (IDT setting of logger telephone number and SIM telephone number) must match.

Viewing Data

To view logger data remotely, a viewing tool (website) is used. Various websites are available. Each website presents data associated with logger installation sites. The choice of website will depend on the type of sensors used and their application.

Data from your logger can also be viewed locally using IDT during a site visit.

Refer to the training materials available for your viewing tool and also the IDT user-guide for further information.

IDT – Software Tool (For Logger Programming And Tests)

A software tool, known as “IDT” (Installation and Diagnostic Tool), is available for checking or making adjustments to the logger setup and also for testing the logger operation on-site.

Choosing which version to use

The IDT software tool provides a user-interface to the logger. It can be used for checking or making adjustments to the logger settings and for testing the logger operation within its installed site. Prior to IDT being able to perform these functions, it has to ‘connect to’ the logger; this simply means that the two end devices (logger software and IDT software) are able to communicate with each other over a working communications path.

IDT is available in three versions:

- IDT for PCs having a Windows-operating system.

- IDT for mobile devices (phones and tablets) having an Android operating system.

- IDT for mobile devices (phones and tablets) having an (Apple) iOS system.

The latter two are referred to as the ‘IDT app’, whereas the first is referred to as ‘IDT (PC)’ or ‘IDT (Windows)’.

It is recommended to install and use the IDT app version whenever possible; it covers most types of HWM loggers. There are, however, a small number of situations where loggers or logger/sensor combinations that (at the time of writing) require the use of the IDT (PC) tool. Refer to section 8 for further details of which sensors or features require IDT (PC)

IDT (PC version)

Refer to the IDT (PC version) User-Guide (MAN-130-0017) for details of how to prepare your PC for communicating with the logger. The user-guide also gives details of how to use IDT with various logger settings.

IDT app (mobile device version)

Overview

Logger – Device Overview

Physical Features & Connector Identification

The Multilog2WW logger family is flexible in design and can be built to suit a variety of uses. An example is shown opposite.

Your logger may be different to the one illustrated; several models exist within the Multilog2WW family.

The loggers are of a waterproof construction and have waterproof connectors for attaching the sensors and antenna. The connectors can exit the unit via either the top or bottom of the case.

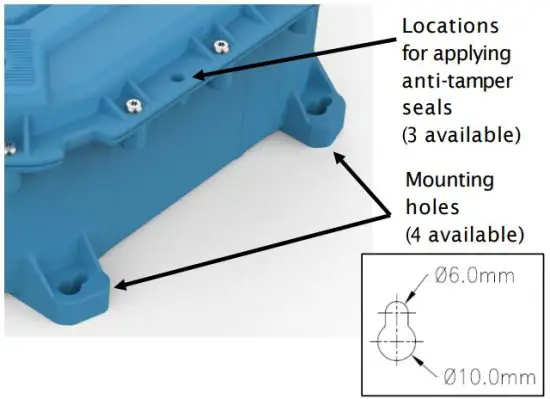

The logger includes 4 key-hole shaped mounting lugs, (spaced 300mm x 157mm apart). The logger may be fixed to a wall using flat-headed screws using the holes.

There are 3 additional holes passing through both sides of the case; these can be used for applications requiring anti-tamper seals to be applied.

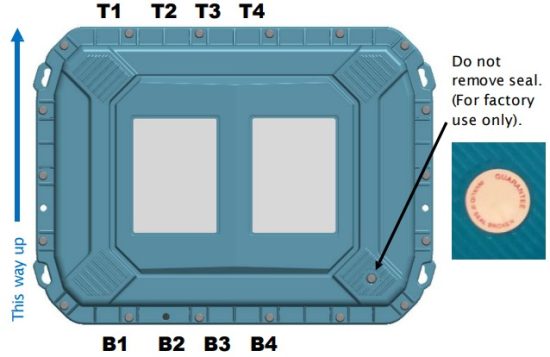

The top surface of the unit can be identified using the shape of the keyholes.

It can also be identified from one of the labels on the front of the unit.

The connector locations are identified as:

- T1, T2, T3, T4 (on the top surface) and

- B1, B2, B3, B4 (on the bottom surface).

A diagram showing the Multilog2WW logger. The top view highlights the keyhole mounting lugs and the “Top” surface. The side view shows three holes for anti-tamper seals and four keyhole mounting holes. A detailed diagram of the keyhole dimensions shows a 6.0mm diameter hole leading to a 10.0mm diameter wider section. A label on the front of the unit shows “HWM MultiLog 2 WW” with PN: MP/31RVQ0/1/UK15, SN: -13238, SMS, SIM, and CE2813 markings, along with connector labels T1, T2, T3, T4, B1, B2, B3, B4.

three holes for anti-tamper seals and four keyhole mounting holes. A detailed diagram of the keyhole dimensions shows a 6.0mm diameter hole leading to a 10.0mm diameter wider section. A label on the front of the unit shows “HWM MultiLog 2 WW” with PN: MP/31RVQ0/1/UK15, SN: -13238, SMS, SIM, and CE2813 markings, along with connector labels T1, T2, T3, T4, B1, B2, B3, B4.

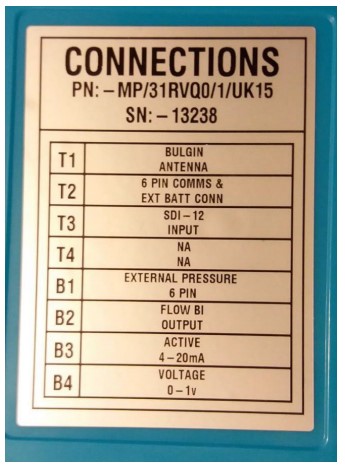

They appear in the sequence shown on the label and are discussed further (below).

Another label on the front of the logger shows the model number (part-number) of the unit. e.g., MP/31RVQ0/1/UK15 (shown opposite). It also shows the serial number. e.g., 13238 (shown opposite).

The label then shows a table which states the type of interface that is fitted at each of the positions.

The table shows:

- Antenna (connector type)

- Communications and external battery input

- Unused locations (labelled “NA” or blank)

- Sensor type that should be attached.

(or an electrical interface type if it is a multi-purpose interface).

Note: The table content will vary according to model (part-number) supplied.

All connector positions are shown opposite, although usually not all are used, depending on the model part number ordered. For optimal battery life, mount “this way up” as shown by the direction of the arrow in the diagram.

External Battery (Option)

Most Multilog2WW models have a connector that allows an External Battery to be connected. These provide the logger with additional power capacity.

An example is shown opposite.

Various battery capacities are available.

Always use HWM supplied batteries to ensure compatibility and safety. Ensure the cable supplied with the battery is suitable for the external power connector fitted to your logger.

(For situations where the use of an external battery is required, seek the advice of your HWM representative).

Logger Operation

The logger is powered by a non-rechargeable Lithium battery. The software is designed to minimize batteryuse and thereby prolong the expected battery life. However, battery life is also affected by user-programable settings. The user is advised to set the logger to keep tasks and sample frequencies to the minimum requirements of the intended use in order to manage battery power effectively.

Where supplied, the external battery power is used to extend the battery life of the system or for more frequent communications with the host server. The logger is normally shipped from the factory in an inactive state (referred to as “shipping mode”) to preserve the life of the battery.

When activated(see section 3), the logger will initially go into the state of “Waiting”(for a short time). Then it will go into the state of “Recording” and begin repetitive logging of measurements from the various sensors fittedto the unit, according to its configuration and settings.

The logger operates using two time periods, known as the “sample period” and the “log period”. It will sample the sensors at the sample rate to create temporary measurement samples; this is a repetitive background task. After taking several measurement samples, some statistical functions can be optionally applied to produce a datapointthat is logged (saved) at the log rate; these form the recorded (logged) measurements and are saved into an area of memory which is referred to as the “primary recording”.

The log period is always a multiple of the sample period.

If the logger has the feature enabled, it can also be set to occasionally save additional data into a “secondary recording” memory area (see section 2.4), (e.g., data sampled at a higher frequency, such as by using the “sample period” rather than the “log period”).

Note: This is not available on all supplied units and must be arranged through your sales representative before placing an order; it has implications concerning expected battery life of the unit.

The logger will also have daily tasks at set times, such as uploading its unsent data over the internet. When sending data, the logger waits to receive confirmation from the server that the data was receivedwithout error; If confirmation is not received, it will resend the data at the next call-in time.

The logger can be programmed to monitor data for certain patterns or conditions and can send a message if it should detect a match. Commonly, this is used for setting a condition that can be an indication of an “alarm”. The message can be sent to either the server (the usual destination) or another device۔

Enhanced Logging (Options)

Section 2.3 gave a description of logger operation that is available as standard on most Multilog2WW logger models; The logger normally samples data at the set sample period, and records datapoints at the set log period. However, certain models offer options for making additional recordings (of logged data) at higher-than-normal sampling rates. The additional data is recorded within the “secondary recording” memory area.

These features are sometimes referred to as “Enhanced Network” logging and “Pressure Transient” logging; Collectively they are referred to as “Fast Logging”.

Note: The feature can only be installed by the factory at the time of build. The options must therefore be specified at the time of ordering, along with the required maximum sampling rate.

Additional sampling has implications for power consumption and may require the use of external batteries to meet the required service life.

The fast-logging features of the logger can be disabled during logger setup. Where enabled, the logger has two strategies for dealing with memory becoming full. Either the fast logging will stop, or older data can be over-written. Make the selection you require during setup.

Not all sensor types are able to work at high sampling frequencies. The feature is therefore usually set to work with analogue sensors, such as a pressure transducer.

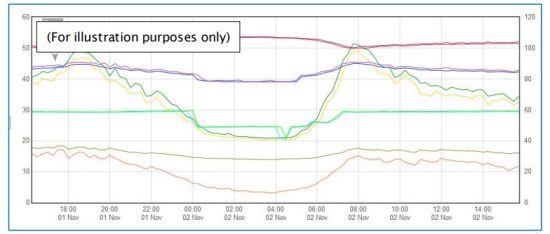

Fast logging is frequently used to monitor pressure fluctuations on the water supply network.

‘Enhanced Network’ logging and ‘Pressure Transient’ logging are mutually exclusive settings (only one can be used). Each has a different operation.

Enhanced Network Logging:

- This option allows certain events to create a secondary recording.

- The recording will be made at the background sampling rate.

- The recording can be a single channel or can include additional channels (if the sensor can cope with the speed).

- The maximum sampling rate is limited to a frequency of 1Hz.

Pressure Transient Logging:

- This option allows certain events to create a secondary recording.

- The logger has additional memory due to the amount of data required to be stored.

- The recording will be made at a sampling rate of 1Hz or one of a selection of higher frequencies, up to 25Hz.

- On Multilog2, up to two channels can be used. Each of these must be for a

- pressure sensor. The sensors must be allocated to channel 1, or channels 1 & 2.

- The recordings can be set to occur either at specific times or in response to various

- alarm events or a change in a Status Input (i.e., triggered by a switch output from external equipment).

Server Integration – Storing and Viewing Data

The logger includes an interface (referred to as a modem) that provides access to the internet via the cellular mobile communications network. A SIM card is used to give access of the network.

Measurement data is initially stored within the loggers, until the next call-in time. The data can then be uploaded to the server using an encrypted format. Typically, the server

used to receive and store the data will be a HWM Data Gate server, although other servers may be used in conjunction with HWM software.

The logger data may be viewed using a viewing portal which has access to the data stored on the server. (Refer to the relevant user guide for details of how your data viewing can be used to view the logger data).

DataGate Server / Data viewing portals

When integrated with HWM’s DataGate server, the logger’s measurement data can be stored centrally and made available to users via a viewing portal (website). The data storage server can handle receipt and storage of data from a single unit, or from an entire fleet of loggers.

Viewing Primary Recordings:

The data from your logger(s) can be viewed remotely / graphically by anyone authorized to do so, with a suitable user account (and password) using a standard web-browser.

HWM has a selection of websites that can be used to view logger data. The best choice of website depends upon the type of sensors used with the logger.

A website with a generic data viewer can show data graphically, but only for one logger at a time, installed on one site A website which can show a fleet of loggers, each having the same type of sensor, can often present data in a more meaningful way to the user, along with useful supplementary information (e.g., a map showing the logger locations). Thus, a website may give a picture of the current status of many sites at one time.

Refer to the IDT user guide or sensor user-guide for details of which viewing portal is most appropriate to use. Alternatively, discuss this issue with your HWM representative.

The DataGate server can also forward any alarms received from the logger to all users that have subscribed to them; one logger alarm message can therefore be distributed to multiple DataGate users.

DataGate can also (by arrangement with your sales representative) be used to export logger data to other servers.

Some administrative setup of the server and of the viewing portal is normally required to facilitate receiving, storing, and presenting logger data correctly. (Setup of and use of the DataGate system (or any other server) are not covered by this user guide).

Viewing Secondary Recordings:

For sites which have logger models with Fast logging included, secondary recordings

may have been made. These are also stored on the server.

Your data viewer will have a means of displaying secondary recordings. It may, for example, show a marker on the main trace to indicate the point where fast data is available (e.g., where a transient occurred). Click the marker to provide a close-up view of the transient.

Installation Accessories

Accessories (e.g., antenna) are available to suit various installation situations; discuss availability with your HWM representative.

Communications Interfaces And Programming Cable

To communicate with the Multilog2WW logger, a programming cable (e.g., CABA2093 or CABA6600) is required. This will include a USB-A end and also a connector for the logger side (usually a 6-pin connector that is water-tight when fitted). Certain models may require a cable with 10 pins; Use a programming cable that matches the connector of the logger. (Contact your HWM representative to discuss any programming cable requirements).

The interface for the communications cable

on Multilog2WW is normally positioned at location “T2” and is shared with the connector used for any external battery.

Where no external battery is connected, a straight cable is required. Attach the communications cable to the Comms interface.

Where an external battery is fitted, it is advisable to use the ‘Y-cable’ version of the programming cable, which is temporarily inserted between the battery and logger Comms connector. Its use is recommended due to some sensors requiring additional power that is provided by the external battery pack. Remember to re-connect any external battery when finished. Attach the Comms cable to the logger, and then complete the connection to the IDT host using one of the methods described in section 2.8.

Completing the Communications Path

For IDT to communicate with the logger,first select the appropriate cable and connect it to the COMMS connector of the logger, as described in section 2.7. The USB-A end of the programming cable should be used to connect to the IDT host by using one of the following methods:

IDT – used with a PC (& Windows)

Prior to use, the PC should have the IDT (PC version) programming tool installed.

The USB-A end should be plugged directly into a USB-A port of the PC (or to USB-B or USB-C port via a suitable adaptor). Refer to Figure 1.

Figure 1. Connection path when using IDT with a Windows-based PC

IDT app – used with a Mobile phone or Tablet / Bluetooth option

Certain mobile phone or tablet devices (which must be Android or iOS-based and support Bluetooth radio) are able to use this method. (For latest information about known compatible devices, contact your HWM representative).

Prior to use, the mobile device should have the IDT app software installed.

Figure 2. Connection path when using IDT app with a mobile device and the Bluetooth Interface Link

The connection path (refer to Figure 2) makes use of a communications adaptor known as the HWM “Bluetooth Interface Link”. Connect the logger end of the communications cable to the logger. Then the USB-A end of the communications cable should be plugged into the USB-A port of the Bluetooth Interface Link unit. The device should be turned on during use. The IDT app is required to be paired to the Bluetooth Interface Link unit prior to communication with the logger. The Bluetooth Interface Link handles protocol translations and flow control of messages between the logger (via the comms cable) and the radio link.

Activating the Logger and Communications Link

The communications interface is always monitored for activity and the logger will usually respond, unless it is busy communicating to the cellular network.

Logger Activation Process (For First-Time Use)

When shipped from the factory,the unit is in ‘shipping mode’ (deactivated; not logging or calling in). This mode is suitable for shipping or long-term storage. To use the logger, it must first be activated.

The process for doing this depends upon the logger setting for logging re-activation. Various setting options are available (specified time, upon connection of an external battery, upon the activation of a magnetic switch, ‘immediately’).

Most loggers are set to start ‘immediately’ upon having their settings read by IDT and then saved back to the unit.

Once activated, the logger will initially go into the state of ‘Waiting’ (for a short time).

Then it will enter a status of ‘recording’, where it is executing its repetitive logging functions.

The method depends on which version of IDT is being used:

- For IDT (PC), the user can do this manually (even if no program changes are required). (Refer to the IDT user-guide for the steps requiredto read the logger program and then to save it back to the unit using the ‘Setup Device’ button).

- For the IDT app, the user can also do this manually via a Start Device’ button. In addition, the app will check for potential issues whenever the user makes a controlled disconnection of the logger from the app, including a check for a logger that is not yet activated / recording.

Before leaving site, check that the logger has been correctly set up for logging, call-in tasks and that it is in a state of ‘Recording’ (logging). Refer to the IDT user-guide for guidance on how to check these points.

Interfaces and Sensors Supported

Note: Support for specific interfaces or functions vary and are dependent upon the model supplied.

Supported Interfaces

Pressure Inputs: Description

4-pin Connector External Pressure transducer

(Options: Standard or High Temperature or High accuracy).

6-pin Connector (As above. Includes ground screen).

(direct) Coupling Internal Pressure Transducer (Options: 20 bar, 30 bar).

Digital Pulse Inputs: Example Use (Bi Flow)

4-pin Connector 1 channel input (Pulses/Direction)

producing 1 logical channel output: “net flow”.

4-pin Connector 2 channel inputs (Forward & Reverse pulses)

combined to 1 logical channel output: “net flow”.

Example Use (Uni Flow)

4-pin Connector 2 x 1 channel input (Pulses)

producing 2 x 1 logical output channel outputs:

“unidirectional flow”.

Example Use (Status)

4-pin Connector 2 x 1 channel Status input

producing 2 x 1 logical channel output: “Status”.

Digital Outputs: Description

3-pin Connector 2 x Digital Output channel (configurable use).

Voltage inputs: Description

4-pin Connector Voltage Input (0-1V) ; passive

4-pin Connector Voltage Input (0-10V) ; passive

Current inputs: Description

4-pin Connector Current Input (4-20mA) ; passive

4-pin Connector Current Input (4-20mA) ; active

Temperature inputs: Description

4-pin Connector External Temperature Input (RTD)

6-pin Connector External Temperature Input (RTD) ; (includes ground screen)

Serial Comms inputs: Description

4-pin Connector Modbus

4-pin Connector SDI-12

Custom Sensor inputs: Description

4-pin Connector SonicSens2 (Ultrasound distance / depth sensor).

6-pin Connector SonicSens3 (Ultrasound distance / depth sensor).

4-pin Connector Raven Eye Interface (Modbus interface with power feed for a Radar Flow meter).

(Other Inputs)

Contact your sales rep for more information or to discuss your requirements.

For any given parameter, several sensors may be available with different types of electrical interface. Sensors provided by HWM will include a cable with a suitable connector for the supplied Multilog2WW.

Installation

Summary of Installation Steps

- Check that an assessment of the work has been done and that any safety measures are in place. (E.g., Safety precautions, protective clothing and/or equipment being used).

- Check the logger is suitable for use at the installation site. Check that you have the required sensors and antenna. Consider where the equipment is going to be located within the available space and that all cables and any hoses are of a suitable length.

- Check fittings are available to connect to any pressure measurement point.

- The logger, cables, and sensors should be kept away from sources of electrical interference such as motors or pumps.

- Cables and hoses should be routed and secured so as to not cause any hazards. Do not allow any equipment to rest on cables, connectors, or hoses as crush damage can result.

- Select the appropriate programming cable for the logger and attach it to the logger COMMS connector. Complete the connection path to the IDT host device (see sections 2.8.1 and 2.8.2). Use IDT to read the logger settings. (Refer to the IDT user-guide for guidance whenever needed).

- Update the logger firmware if required. (Refer to the IDT manual for guidance; consider downloading any existing data from the logger prior to upgrade).

- Use IDT to check or modify existing logger settings:

- Program a local time-zone into the logger (check or modify).

- Set the action or time when the Logger is to Start-up and begin recording (logging).

- Set timing intervals for making measurements (sample interval and log interval). They should be configured to suit your application’s specific logging requirements (minimize sampling rates to preserve battery life).

- Check / modify channel settings to produce measurement samples and the required datapoints from each interface.

- Configure the logger channel to match the sensor or other equipment that the logger connects to. (Check units of measure are correct, etc).

- Ensure the sensor is mapped to the correct output channel number; This is an identifier used when uploading the logged measurement data to the server. (i.e., Channel numbers must match between logger and DataGate).

- Apply any required statistical functions to the background measurement samples in order to produce logged data-points (saved values).

- Where required, undertake the setup of any additional options related to the channel. (E.g., add an initial meter reading, pulse replication setting, sensor calibration; these will be dependent on sensor and logger use). (Refer to the IDT user-guide for guidance details regarding and any additional setting options related to an interface).

- For pressure sensors, electrically attach them but expose the sensor to the local atmospheric pressure and re-zero them (using IDT) before commencing making a connection to the measurement point.

- Install (position and connect) the sensors at their measurement point.

- Bleed any connections to water.

- Where required, insulate any water-filled tubing connected to pressure transducers to protect them from frost. (Insulating pipe covers can be supplied upon request at additional cost or sourced locally from a hardware store).

- Ensure any electrical connections made on site are dry, durable and water-tight.

- Use IDT to:

- Test the logger and sensors are functioning correctly. (Some can be done pre-installation; others post installation).

- Setup the logger for any alarms. Consider the conditions for activating alarm messages and also the conditions for the alarm to clear.

- Check / modify the communications settings of device, as required:

- SIM settings (parameters for giving access to the cellular network).

- Modem settings (cellular network technology).

- Data delivery settings (server contact details).

- Call-in times and protocol settings.

- Verify any changes to settings have been saved prior to leaving site. Check that the logger is in a “recording” state.

- Install (position and connect) the antenna for server communications. Use IDT to test the cellular communications performance.

- Ensure details of the site of logger deployment are recorded. (The administration for the server could be handled by office staff, or the installer could use the HWM Deployment app).

Installing the Logger

The logger must be mounted in a suitable location where the sensors attached to it can reach their intended installation points. Position loggers, sensors, and antenna away from sources of electrical interference such and motors or pumps. Cables and hoses should be routed without causing any hazards. Do not allow any equipment to rest on hoses, cables or connectors as crush damage can result.

Wall mounting

Refer to the orientation shown in the diagram in section 2.1.1; The logger should be installed as shown for optimum battery performance.

Check for any access issues for using on-site communications (e.g., access to attach the comms cable).

The logger should be wall-mounted. Drill suitable fixings into location, ensuring they are able to bear the weight of the logger and any attached cables. Use the keyhole mounting holes to fix the logger in position. Anti-tamper seals can also be used if required to bear witness if anyone has interfered with the installation by disassembling the logger. (See diagram in in section 2.1.1.)

Ensure the antenna can be mounted in a suitable location where the radio signal will be of sufficient strength to call into the cellular network.

Electrical connections to the logger

When making electrical connections to the logger (e.g., attaching a connector for a sensor), ensure the connector is correctly fitted. Both parts of the connector should be dry and free of debris. The connectors are keyed (see opposite for examples) to ensure correct alignment of pins and receptacles. Align the sensor to the logger connector and push fully home. Then rotate the outer part of the sensor connector until it engages with the fastening mechanism and locks into place. The connector will then be secure and watertight.

When removing connections, follow the reverse steps of the procedure describe above. Always handle the connection by the connector; do not pull the cable as this could cause damage.

Route all cable so they do not cause any potential hazards and secure into place using suitable ties.

For antenna, follow the additional steps given in section 5.16.

Factory settings

Note: The logger will usually have settings pre-programmed by the factory prior to shipping. However, the installer has responsibility for confirming the settings are appropriate for use at the installed site.

If you have specific requirements this can be discussed with your HWM sales representative at the time of ordering the loggers.

Where required, IDT can be used to check or make any changes to the logger settings.

For most sensor interfaces, follow the general guidance within the IDT user-guide; the logger complies with the description and examples of setup provided therein. However, some HWM sensors require specialized setup screens or have their own userguide which provides further guidance.

Pressure Sensors

Re-zero Facility (for pressure relative to local atmosphere)

Pressure sensors supplied by HWM normally measure pressure relative to atmospheric pressure. Since there can be some variation in local atmospheric pressure (e.g., due to altitude), the loggers have a facility to re-zero the pressure sensor. This must be done with the sensor exposed to atmospheric air.

Prior to connecting the transducer to the actual measuring point, leave it exposed to air. Then “re-zero” the sensor using the method found in the IDT user-guide.

Pressure Sensor (Internal)

Note: Do not connect the sensor to the measurement point before going through the re-zero (to local atmospheric pressure) process, if required.

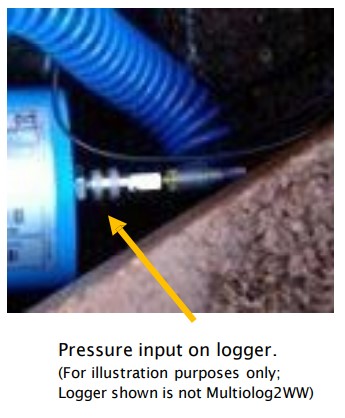

For an internal pressure transducer, simply connect the pressure to be measured via a suitable hose (with fittings) to the pressure sensor on the logger.

This interface is factory calibrated. No on-site calibration is required.

Note: Add insulation to the pipe and logger to prevent freezing. If the water in the hose or the logger itself freezes, there is a danger of permanent damage to the pressure transducer.

Pressure Sensor (External)

A pressure input may be presented as an electrical interface, using a 4-pin or 6-pin connector.

Cabled pressure sensors for the Multilog2WW are available from HWM. For most situations, sealed type pressure (or depth) sensors are used, and the sensor will be wired directly to the connector, as shown in the diagram below.

The logger temporarily applies power to the sensor just before (and during) making a measurement.

The logger interface will be labelled “Pressure (20 bar)” (or similar).

The pinout of the connectors are shown below.

| Logger bulkhead connector pinout : 4-pin External Pressure | |||

| A | B | C | D |

| V (+) ; (PWR) | V (+) ; (Signal) | V (-) ; (PWR) | V (-) ; (Signal) |

| Logger bulkhead connector pinout : 6-pin External Pressure | |||||

| A | B | C | D | E | F |

| V (+) ; (PWR) | V (+) ; (Signal) | V (-) ; (PWR) | V (-) ; (Signal) | GND / Screen | (not connected)

|

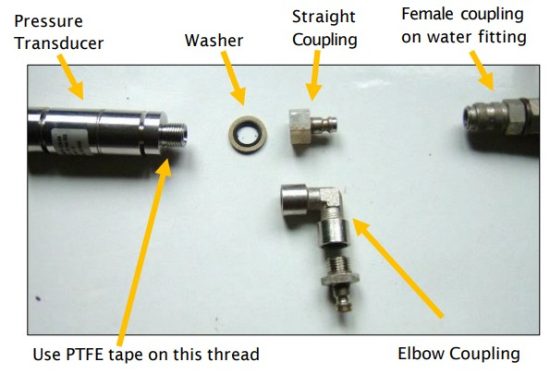

Where a pressure transducer has a threaded end for connection to the pressure measurem ent point, fittings may be required to modify the connection (e.g., a quickrelease connector for connection to a hose). Examples are shown below.

ent point, fittings may be required to modify the connection (e.g., a quickrelease connector for connection to a hose). Examples are shown below.

Assemble any fittings prior to connecting to the logger. Straight or elbow styles of coupling kits are available.

Confirm the logger has the appropriate interface for the pressure or depth sensor. Then connect the sensor to the relevant logger interface.

Note: Do not connect the sensor to the measurement point before going through the calibration process (see below) and then re-zero (to local atmospheric pressure).

For a pressure sensor, attach to the measurement point and (if applicable) bleed any connecting hose.

For a depth sensor, the sensor should be weighted down or mounted securely at the bottom of the water channel, using a fixture (e.g., a carrier plate or anchoring bracket) if required. The cable should also be secured in place to prevent moving water from acting on the cable to pull the sensor out of position or stress any connections.

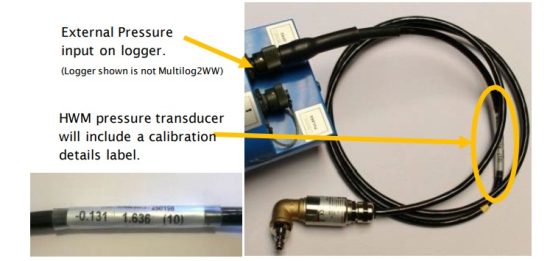

Calibration Process (using calibration values from the cable):

Prior to using the sensor, the logger and sensor pair must be calibrated to give correct readings.

This method can be used by an installer to pair and calibrate a pressure sensor to the logger.

HWM supplied pressure / depth sensors usually have calibration values shown on the cable (see example below). Use IDT to add the details from the calibration label on the cable into the logger using the guidance within the IDT user-guide.

The calibration process must occur before the re-zero of the pressure sensor.

After following the calibration process and re-zero process, the transducer can be located at (or fitted to) its measurement point.

The logger must be correctly set up to make measurements from the sensor. Refer to the IDT user-guide for further details.

Calibration Process (using applied pressures):

This method can be used by an authorized service center to pair and calibrate a pressure sensor to the logger.

The method consists of applying reference pressures to the transducer and building a table of calibration values.

Flow Sensor Input (Meter Pulse Collection)

Depending on the model supplied, the logger may have 0, to 6 Flow inputs. These are digital inputs, designed to sense the open or closed condition of a switch (activated by the installed meter). To use the flow channel(s) the logger must be set up (using IDT) to know what each meter pulse represents.

Explanation of Flow Channels & Input Signals

Flow of a fluid in a pipe is usually detected by a meter, which produces pulses related to the volume of fluid passing through it. There are several types of meters; some can detect both forward flow and reverse flow (bi-directional flow); some can detect flow in one direction only (uni-directional flow). There are therefore several ways of implementing the meter pulse output signals from a meter. Your logger must have the correctinterface and settings for the signaling from the meter to be compatible with it.

The Multilog2WW Flow inputs sometimes require two input signals in order to work with the meter-pulse signaling of certain meters. A pair of inputs can therefore sometimes be configured to operate as a single channel. Other meter types only require one signal, so the pair of inputs can operate as two separate channels. The pair of Flow signals can be labelled in one of the following ways:

| Alternative signal names | ||||

| Pair of FLOW signals | Flow Input 1 | Flow 1 | Pulses | Flow (Forward) |

| Flow Input 2 | Flow 2 | Direction | Flow (Reverse) | |

| Common | GND | |||

The labelling depends on the factory default for the configuration of the Flow channels on your logger model-number, but sometimes alternative types of configuration can be achieved by changing logger settings.

Where the logger is pre-configured by the factory to produce only 1 Flow channel (data point stream), the pair of inputs can be used in one of three different ways:

(1) Input 1 can be used with a Uni-directional meter (one which only measures forward flow / consumption).

For use in this configuration:

- Input 1 acts to collect meter pulses, and

- input 2 is usually left disconnected (or allocated to use as a ‘Tamper Alarm’, or used as a Status input).

(2) Inputs 1 and 2 can be used as a pair with a Bi-directional meter (one which can measure both forward and also reverse flow).

For use in this configuration:

- Input 1 acts to collect meter pulses, and

- input 2 is used for the flow direction indication from the meter (open = forward flow, closed = reverse flow).

(3) Inputs 1 and 2 can be used as a pair with a Bi-directional meter (one which can measure both forward and also reverse flow).

For use in this configuration:

- Input 1 acts to collect meter pulses (forward flow direction), and

- input 2 acts to collect meter pulses (reverse flow direction).

Where the logger is pre-configured by the factory to produce 2 Flow channels (datapoint streams), the pair of inputs can be used as 2 independent uni-directional Flow input channels (channels 1 and 2).

Each input can be used with a Uni-directional meter (one which only measures forward flow / consumption).

Via a Logger 4-pin Bulkhead Connector

Multilog2WW Flow signal inputs are presented on a 4-pin connector. Each connector has a pair of Flow signal inputs.

The pinout of this connector is shown below:

| Logger bulkhead connector pinout : 4-pin Flow Inputs | ||||

| Pin | A | B | C | D |

| Signal | (not connected) | Flow Input 1 | Flow_GND | Flow Input 2 |

Check the meter to which the logger is going to be connected and ensure its meter pulse signaling method is understood, along with the significance of each meter pulse. Connect the logger to the meter-pulse outputs of the meter using a suitable cable. If cables with bare tails have to be interconnected, refer to the guidance in section 5.5. Use IDT to complete the setup, ensuring the logger is correctly set to interpret the meter pulses. If the logger is required to keep track of the meter counter display, take an initial reading of the meter counter and program it into the logger. The logger uploads additional consumption regularly, so a meter reading can be made remotely.

Connecting Unterminated Cable Wires To Equipment

When using a cable that is unterminated, an installer will be required to make their own connection to the other equipment on site.

When making a connection to Multilog2WW you will normally need to splice the bare tails together. It is important that a waterproof connector housing is used, such as the “Tuff-Splice” enclosure available from HWM.

Note: Long data connections should always be made using screened cable. The use of screened cable will ensure maximum rejection of interference from outside sources. Always use a common ground point without creating ground loops.

Status Input

The Status Input pins are a re-purposed use of the Flow input electronics (see section 5.4)

A change in the software driver for the connector gives the input pins a different functionality.

The interface will be labelled as ‘Status’ or ‘Dual Status’.

The pinout of this connector is shown below:

| Logger bulkhead connector pinout : 4-pin Flow Inputs | ||||

| Pin | A | B | C | D |

| Signal | (not connected) | Flow Input 1 | Flow_GND | Flow Input 2 |

The Status Input signals can be configured for general-purpose use in detecting switch contacts. This has many uses.

- Detection of door / window / equipment-access openings for security purposes.

- A ‘spare’ pin on a flow channel can be used to generate a ‘tamper’ alarm in the event that the logger cable is cut or removed from the meter. (The meter must support this facility by providing a closed loop from the tamper input to the return pin, Status_GND).

Connect the logger to the external equipment using a suitable cable. If cables with bare tails have to be interconnected, refer to the guidance in section 5.5.

Use IDT to complete the setup, ensuring the logger is set to generate the desired alarm.

Outputs (Digital Switch: Open/Closed)

Multilog2WW Outputs are presented on a 3-pin connector.

Up to four outputs can be supported. Each connector has a pair of outputs.

The interface will be labelled as ‘Dual Output’.

The pinout of this connector is shown below:

| Logger bulkhead connector pinout : 3-pin Outputs | |||

| Pin | A | B | C |

| Signal | Output 1 | Output 2 | GND |

The logger does not supply any power to the output. The output takes the form of an electronic switch (transistor), which can either be open or closed. When closed, the current path or is between the output pin and ground.

The maximum rated voltage is 12V (D.C.)

The maximum rated current is 120mA.

A common use of the Output pins is for pulse replication (of meter pulses that are input to the Flow channels). Where this is implemented:

- Flow input 1 is replicated to Output 1

- Flow input 2 is replicated to Output 2

- Flow input 3 is replicated to Output 3

- Flow input 4 is replicated to Output 4

The Output signals may also be used to activate external equipment.

In order to use the outputs, a suitable cable is required (the exact requirements will depend on the equipment the logger is being used with; discuss with your HWM representative). If cables with bare tails need to be interconnected, refer to the guidance in section 5.5.

Use IDT to complete the setup, depending on your application for the output.

External Battery

The use of an external battery is optional for many installations but may be required to support the logger in order to obtain the required length of service.

For best battery life, orient the external battery in its preferred orientation (refer to the labelling on the battery). Batteries are heavy devices. When positioning the battery, check that it is not crushing any cables or tubes within the installation. Ensure the battery is secure in its installation position (so it cannot fall). Then connect it to the logger.

The logger connection for an external battery will be presented via a (6-pin or 10 pin) connector that is shared with the programming interface (labelled “COMMS”).

The cable that is used for interconnecting the external battery pack to the logger will only include the pins required for supply of power; pins assigned for communications purposes will not be fitted.

The external battery connection must be temporarily disconnected whenever a logger programming cable needs to be attached.

SONICSENS3 (Ultrasound Distance / Depth Sensor)

Where a SonicSens3 interface is available on your logger, it will have a 6-pin connector. The interface provides power and communications to the sensor, which measures distance to a fluid surface. By input of other parameters (e.g., distance from the bottom of the water channel) the logger can calculate water depth. It can also derive a variety of other measurements such as flow rates if situated near an open weir. Refer to the SonicSens-3 user-guide (MAN-153-0001) for instructions on how to install and setup the sensor for operation.

Note: Multilog2WW loggers are not of an intrinsically safe construction, and so cannot be used within an environment where a potentially explosive atmosphere may be present.

SONICSENS2 (Ultrasound Distance / Depth Sensor)

Where a SonicSens2 interface is available on your logger, it will have a 4-pin connector. The interface provides communications to the sensor, which measures distance to a fluid surface. By input of other parameters (e.g., distance from the bottom of the water channel) the logger can calculate water depth. It can also derive a variety of other measurements such as flow rates if situated near an open weir. Refer to the SonicSens-2 user-guide (MAN-115-0004) for instructions on how to install and setup the sensor for operation. Note: Multilog2WW loggers are not of an intrinsically safe construction, and so cannot be used within an environment where a potentially explosive atmosphere may be present.

Temperature Input (RTD – PT100)

The logger may be constructed with a 4-pin connector for connection of a temperature sensor. Typically, this will be a PT100 RTD sensor.

The logger interface will be labelled “TEMP” or similar).

The pinout of the connectors is shown below.

| Loggerbulkhead connectorpinout : 4-pin Temperature (RTD -PT100) | |||

| A | B | C | D |

| Temp_V + | Temp_S + | Temp_V – | Temp_S – |

| Loggerbulkhead connectorpinout : 4-pin Temperature (RTD -PT100) | |||||

| A | B | C | D | E | F |

| Temp_V + | Temp_S + | Temp_V – | Temp_S – | GND / Screen | (not connected) |

In order to use the temperature sensor, calibration of the input is required.

When ordered with a temperature sensor from HWM, the sensor will have the correct connector fitted for the Multilog2WW logger. The logger input will also be factory calibrated for use with the supplied sensor.

Analogue Voltage Input (0-1V, 0-10V)

The logger may be constructed with a 4-pin connector for connection of a sensor which employs an output voltage level as a method of signaling.

Both a 0-1V and a 0-10V input interfaces are available on Multilog2WW but must be specified at the time of ordering.

The logger does not provide power to the sensor; it must have its own source of power.

The pinout of this connector is shown below:

| Logger bulkhead connector pinout : Voltage Input 0-1V (& 0-10V) | ||||

| Pin | A | B | C | D |

| Signal | (not connected) | 0-10V + / 0-1V + | (not connected) | 0-10V – / 0-1V – |

A wide variety of sensors are available with this interface.

When ordered from HWM, the sensor will have the correct connector fitted for the Multilog2WW logger.

The installer will have to use IDT to confirm or adjust the settings of the logger to correctly scale and interpret the physical parameters the attached sensor is used to detect.

Analogue Current Input (4 to 20 mA)

The logger may be constructed with a 4-pin connector for connection of a sensor which employs an output current as a method of signaling.

Two interface types are available:

- Passive

- Active

4-20mA (Passive)

Where a “passive” 4-20mA interface is fitted, the logger does not provide power to the sensor; it must have its own source of power.

The logger interface will be labelled “4-20mA” (or similar).

The pinout of this connector is shown below:

| Logger bulkhead connector pinout : Current Input (4-20mA) | |||

| A | B | C | D |

| (not connected) | 4-20mA + | (not connected) | 4-20mA – |

A wide variety of sensors are available with this interface.

When ordered from HWM, the sensor will have the correct connector fitted for the Multilog2WW logger.

The installer will have to use IDT to confirm or adjust the settings of the logger to correctly scale and interpret the physical parameters the sensor is used to detect.

4-20mA (Active)

Where an “active” 4-20mA interface is fitted, the logger can provide power to a compatible sensor.

The logger interface will be labelled “4-20mA (Active)” (or similar).

The pinout of this connector is shown below:

| Logger bulkhead connector pinout : Current Input (4-20mA) | |||

| A | B | C | D |

| V+ (PWR) | 4-20mA + | GND (PWR) | 4-20mA – |

A wide variety of sensors are available with this interface. However, not all have the same power requirements. The connector is able supply up to 50mA of current. The output voltage is variable (from 6.8 V to 24.2 V, in 32 steps), and is able to be set using IDT.

To avoid damage: Prior to connecting the sensor, use IDT to ensure the correct output voltage for the sensor is set.

The logger does not supply continuous power to the interface, but only activates it for a short time whilst making a measurement. IDT gives access to controls to set the amount of time the sensor has power applied prior to and during measurement. The installer can set these to allow for any initialization or settling time the sensor requires.

When ordered from HWM, the sensor will have the correct connector fitted for the Multilog2WW logger.

The installer will have to use IDT to confirm or adjust the settings of the logger to correctly scale and interpret the physical parameters the sensor is used to detect.

The interface can also be used with sensors having their own source of power.

Serial Input (SDI-12 Interface)

The logger may be constructed with a 4-pin connector for connection to equipment which employs the SDI-12 method of signaling; this is a serial data interface. The external equipment drives any sensor electronics; one or multiple sensors may be attached to it.

The logger does not provide power to the SDI-12 interface. The attached equipment / sensor must have its own source of power.

The logger interface will be labelled “SDI-12” (or similar).

The pinout of the connector is shown below:

| Logger bulkhead connector pinout : SDI-12 | |||

| A | B | C | D |

| SDI-12_Data | (RS485, Unused) |

Comms_GND | (RS485, Unused) |

A wide variety of sensors are available with this interface. When ordered from HWM, the sensor will have the correct connector fitted for the Multilog2WW logger. During installation and setup, refer to the user-guide of the equipment that is being attached.

Note: Ensure the attached sensor has the SDI-12 protocol selected, otherwise communications will fail.

Using the SDI-12 protocol, the logger can make a request for a measurement to the attached equipment. The attached equipment responds when the measurement has been obtained.

The sensor equipment will have an address that the logger must use when communicating with it. Obtaining data begins by the logger requesting a measurement (sending an “M” command or a “C” command).

Some sensor equipment will send multiple items of measurement data as a block (e.g., one piece of equipment may include several sensors). The setup of the logger can include an index to select the required data from the block.

The installer will have to use IDT to confirm or adjust the settings of the logger to request the required measurement data from the sensor. Setup of the logger should include the relevant addresses, commands, and indexes that are required to start the measurement and then select the specific data item required.

The installer is required to correctly scale and interpret the physical parameters the sensor is used to detect.

Serial Input (RS485 / Modbus) Interface

The logger may be constructed with a 4-pin connector for connection of a sensor which

employs the RS-485/MODBUS method of signaling; this is a serial data interface.

(There are two size options used for the connector).

During installation and setup, refer to the user-guide of the equipment that is being

attached.

Note: Ensure the attached sensor has the RS485/MODBUS protocol selected, otherwise

communications will fail.

Two types of MODBUS interface are available:

• Passive.

• Active.

For a Passive interface, the logger does not provide power to the sensor; it must have its

own source of power.

For an Active interface, the logger provides temporary power to the sensor, just before (and during) the measurement cycle.

The port type (active or passive) can be determined by inspection as to whether (or not) there is a voltage output control shown within IDT. In addition, the connector label will

indicate ‘MODBUS’ or ‘POWERED MODBUS’.

A wide variety of sensors are available with this interface. When ordered from HWM, the sensor will have the correct connector fitted for the Multilog2WW logger. In addition,

the sensor type will have been tested with the logger to confirm compatibility for use to obtain certain measurements. However, this may require selecting a specific driver

for the sensor within IDT.

The Multilog2WW operates as the master device when using the Modbus protocol. It sends setup instructions and other information to the attached sensor equipment

(which operates in slave mode). The protocol includes the ability to address each register in order to read and (depending on the attached unit) write to the registers.

Measurement results are made available to the logger by reading them from specific registers in the sensor equipment over the Modbus link.

The sensor equipment will have an address that the logger must use to identify it when communicating. The setup of the logger should therefore include the sensor address as

well as the register access details (function code, start register address).

The quantity of registers to be read will depend on the format of the data within the sensor registers. The logger can handle multiple formats of numeric data (e.g., 16-bit signed, 16-bit unsigned, float, double); however, the expected data format must be specified in the logger setup; this will ensure that the required number of registers are read and that the data is correctly interpreted by the logger. The read data can then be used to obtain the channel data points.

When setting the logger for use with your sensor, usually the “generic” settings are suitable. However, some modification of the logger operation is required for certain

types of sensor equipment in order to get the best out of them. IDT provides a control to select specific sensors from a list. Once chosen, the logger will handle any

peculiarities of the behavior of the sensor, its protocol, or additional needs for the measurement being taken (e.g., additional exchanges of information between the logger and the sensor equipment).

Refer to the IDT user-guide regarding how to set up the RS485 / Modbus interface. This must be read in conjunction with the user-guide of the equipment that is being

attached; this will provide information on the measurements available from the sensor equipment registers (and the numeric format of the data), and how to initiate register

reads to obtain the required data.

The installer should use IDT to confirm or adjust the settings of the logger that request the required measurement data from the sensor. Then use IDT to correctly scale and interpret the physical parameters the sensor is used to detect.

RS485 / MODBUS (Passive)

The logger interface will be labelled “MODBUS” (or similar).

The pinout of this connector is shown below:

| Logger bulkhead connector pinout : RS485 / MODBUS (passive) | |||

| A | B | C | D |

| (SDI-12, Unused) |

RS485_A | Comms_GND | RS485_B |

A wide variety of sensors are available with this interface.

When ordered from HWM, the sensor will have the correct connector fitted for the Multilog2WW logger. In addition, the sensor type will have been tested with the logger to confirm compatibility for use to obtain certain measurements. However, this may require selecting a specific driver for the sensor within IDT.

The installer should use IDT to confirm or adjust the settings of the logger to request the required measurement data from the sensor. Then use IDT to correctly scale and interpret the physical parameters the sensor is used to detect.

RS485 / MODBUS (Active)

The logger interface will be labelled “POWERED MODBUS” (or similar).

Note: When supplied with (and configured for) a known sensor, the logger MODBUS interface may alternatively be labelled so as to identify the sensor itself.

Examples are:

• Raven Eye

The pinout of this connector is shown below:

| Logger bulkhead connector pinout : RS485 / MODBUS (passive) | |||

| A | B | C | D |

| V+ (PWR) | RS485_A | GND | RS485_B |

For an ‘Active’ interface, the logger usually provides temporary power to the sensor, just before (and during) the measurement cycle. The sensor used must be compatible with the logger power supply to the interface (voltage and current output). It also has to be compatible with the timing of the power activation and any exchange of messages. Consult your HWM representative for advice on sensor compatibility or if you have any specific sensor requirements. A wide variety of sensors are available with this interface. However, not all have the same power requirements.

To avoid damage, check the sensor is compatible with the logger power supply range and use IDT to check that the logger power settings have already been correctly set prior to connection.

- The interface is able supply up to 50mA of current.

- The output voltage can be set using IDT (from 6.8 V to 24.2 V, in 32 steps).

IDT gives access to controls to set the amount of time the sensor has power applied prior to and during measurement. The installer can set these to allow for any initialization or settling time the sensor requires.

When ordered from HWM, the sensor will have the correct connector fitted for the Multilog2WW logger. In addition, the sensor type will have been tested with the logger to confirm compatibility for use to obtain certain measurements. However, this may require selecting a specific driver for the sensor within IDT.

The installer should use IDT to confirm or adjust the settings of the logger to request the required measurement data from the sensor. Then use IDT to correctly scale and interpret the physical parameters the sensor is used to detect.

Installing the Antenna and Testing Cellular Communications

An antenna should be selected to suit the available space in the chamber, allowing some space for it to be re-positioned (if required). Only use HWM-provided antenna with your logger, to ensure the radio interface meets approvals requirements (safety, etc).

The Multilog2WW logger uses a plastic style antenna connector.

Prior to connecting the antenna, remove the protective cap and ensure that the connector is dry and clear of dirt and debris; trapped moisture or contaminants can impair the antenna performance. Clean if necessary.

Insert the antenna connector into the logger connection and then (first ensuring the thread is correctly engaged) carefully tighten the plastic threaded nut to secure the antenna to the logger connector.

The nut on the antenna should be finger tight.

No sharp bends should exist at the cable ends, or in the routing of the antenna cable.

To avoid risk of crush damage to the antenna cable, check that no equipment is placed onto it.

Similarly, cable ties fixing the cable in place should not be too tight.

The antenna should not be bent to fit the installation; if it is too big for the chamber, use a smaller type of HWM approved

antenna. When positioning the antenna, ensure that the radiating end of the antenna does not touch or go close to a metal surface. The radiating element of the antenna should ideally be positioned in free air (free from obstructions).

Try to avoid placing the antenna in a location where it can be flooded. If this is unavoidable, then place it where the risk is at its minimum.

For equipment that is installed in a chamber below ground level, the antenna should be placed above ground level if possible. Where this is not possible, position it near to the top of the chamber.

IDT should be used to check that the logger can connect to the cellular network and that the antenna is in the optimal position for the site.

• Choose a suitable antenna for the installation and decide on its initial position.

• Determine the network technology being used and the appropriate signal quality limits that should be used (refer to the IDT user-guide).

• Perform Network Signal tests to confirm the logger connects to the mobile network and find the best location of the antenna.

• Perform test calls to confirm the logger can communicate with the Data Gate server via the internet and (if required / available) SMS.

(Details of use of IDT for making these tests are provided in the IDT app user-guide).

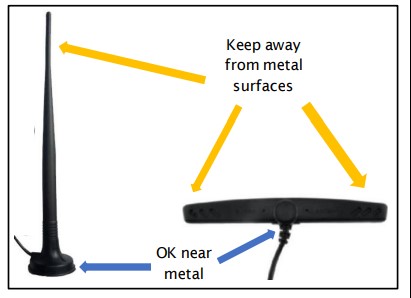

Trouble-shoot a test-call failure if required, following the advice in the IDT app user guide. Further information is given in the HWM Antenna Installation Guide (MAN-072-0001), and on the webpage https://www.hwmglobal.com/antennas-support/ Keep away from metal surfaces OK near metal No sharp bends OK Some general advice is given below:

Monopole Antenna

For most installations, a monopole antenna will give acceptable performance. Installation Considerations:

- The antenna has a magnetic base to be used for mounting.

- For optimum performance, the antenna requires a “ground plane” (metal surface). Consider installing a metal bracket made of a ferrous material to attach the magnetic base of the antenna if space allows or signal strength is marginal.

- When installing the antenna in large underground chambers it should be positioned close to the surface.

- Ensure that any chamber lid will not interfere with the antenna or cables when being opened/closed.

- This antenna is vertically polarized, it should always be installed in the vertical orientation.

- Never bend the radiating element of the antenna.

- The antenna can also be attachedto an installationbracket mounted to an existing marker post.

- Where an antenna is held in place by magnets, ensure the weight of any cables does not excessively load the magnet so as to detach it from the installed location.

- Do not allow any equipment to rest on the antenna connector as crush damage to the connector or antenna cable can result.

For other antenna options and additional installation guidelines, refer to the documents available on the support webpage: https://www.hwmglobal.com/antennas-support/ Troubleshooting a Call Test failure There are a number of reasons why a Call test may fail.

The following points should be checked before calling HWM support for assistance: –

| Possible Problem | Solution |

| Network Busy due to excessive traffic. Commonly occurs around schools and at peak travel times. | Retry the test after a few minutes. |

| Network signal not available at your location. Not all Cell masts carry data traffic | Relocate the logger to an area that has a data service or change to a different network provider |

| Network signal not strong enough. For 2G, 3G, you need a CSQ (reported by the Call test) of at least 8 for reliable communications. For 4G networks, check the RSRP and RSRQ values are suitable, as described in the IDT user guide | Relocate the antenna if possible or try alternative antenna configurations. |

| APN settings incorrect. | Check with your network operator that you have the correct settings for your SIM. |

If you continue to experience problems with communication, you may need to check the network coverage in your location.

Troubleshooting

Any issues should consider all parts of the system (IDT, the user, the logger, sensors, the cellular network, and the server).

General checks:

Initial checks to be made during a site visit include:

- Check if the version of IDT you are using (IDT app for mobile devices / IDT for Windows PC) supports the features and sensors you are using; refer to section 8.

- Check that the latest version of IDT is being used.

- Check that the logger being used has the latest software (IDTwill offer to upgrade if required).

- Check the battery voltage of logger is good (using the IDT Hardware Test).

- Check the cable and connectors between sensors and the logger are in an OK condition, with no damage or water ingress.

The logger does not appear to be able to communicate with IDT:

- Check the communications path from the IDT host device to the logger is complete. (See section 2.8.)

- If using the direct cable connection method with IDT (PC),the logger may have shut down the connection to IDT due to is not being used for several minutes. Re-read the logger settings into IDT. Any previously unsaved settings will have been lost.

- If using the IDT app, the permission to use the cable may have expired. Detach the USB-A end of the programming cable and re-attach a few seconds later. Give permission to use the cable and then re-read the logger settings into IDT. Any previously unsaved settings will have been lost.

The data from the logger does not appear on the server:

- Check the settings for the SIM card to access the mobile data network.

- Ensure the logger uses the correct data destination URL and port-number for your server.

- Check call-in times have been set.

- Check antenna is attached and in an OK condition.

Check signal quality and strength parameters are suitable. Re-locate the antenna, if required, or try an alternative type of antenna. - Make a Call Test and confirm OK.

- Ensure your server is correctly configured to receive and present the data.

Maintenance, Service and Repair

Unauthorized servicing will void the warranty and any potential liability for HWM-Water Ltd.

Cleaning

Note the safety warnings that are applicable to cleaning. The unit may be cleaned using a mild cleaning solution and a damp soft cloth. Always keep connectors free of dirt and moisture.

Replaceable Parts

Antenna

• Only use antenna recommended and provided by HWM.

For details of antenna options and part-numbers to order, refer to the following link: https://www.hwmglobal.com/antennas-support/ (or consult your HWM representative).

Batteries

- Only use batteries and parts recommended and provided by HWM.

- Batteries are only replaceable by a HWM approved service center or relevantly trained technician. Contact your HWM representative for more details if required.

- Batteries can be returned to HWM for disposal. To arrange the return, complete the on-line RMA (Returned Materials Authorization) form: https://www.hwmglobal.com/hwm-rma/

Refer to the Safety Warnings and Approvals Information for guidelines of the packing requirements.

SIM-card

- SIM-cards are replaceable by a HWM approved service center or relevantly trained technician.

- Only use consumable parts recommended and provided by HWM.

Return of Product for Service or Repair

When returning product for investigation or repair, be sure to follow the instructions of your distributor to document why the product is being returned and provide contact details.

If returning to HWM, this can be done by completing the on-line RMA form:

https://www.hwmglobal.com/hwm-rma/

Prior to shipping, put the equipment into Shipping mode (refer to the IDT user-guide for instructions). Refer to the Safety Warnings and Approvals Information for guidelines of the packing requirements.

If soiled, ensure the unit is cleaned with a mild cleaning solution and soft brush, disinfected, and dried prior to shipment.

Appendix 1: Systems and Features Requiring IDT (PC)

Historically, setup of Multilog2WW loggers was undertaken using the IDT (PC/Windows) tool. Setup of most Multilog2WW logger functions for Pressure and Flow channels and the most commonly used alarm types has recently been introduced to the IDT (mobile app) tool. However, the IDT (mobile app) does not yet support some situations.

The following logger/sensor combinations require IDT (PC) for setup:

- Multilog2WW using a SonicSens2 sensor.

- Multilog2WW using a SonicSens3 sensor.

- Multilog2WW using a RS485/MODBUS sensor.

- Multilog2WW using an SDI-12 sensor.

The following logger features require IDT (PC) for setup:

- Update of firmware of logger or attached sensors.

- Fast logging features (Pressure Transient, Enhanced Network logging).

- Flow Rate (when calculated from flow velocity, channel depth, channel geometry).

- Profile Alarm.

- Tamper Alarm.

Fluid Conservation Systems

1960 Old Gatesburg Road

Suite 150

State College PA, 16803

800-531-5465

www.fluidconservation.com

©HWM-Water Limited. This document is the property of HWM-Water Ltd. and must not be copied or disclosed to a third party without the permission of the company. All images, text and designs are protected by international and UK copywrite law and remain the property of HWM-Water. It is against the law to copy or use any of the content from the HWM website or literature without the written consent of HWM-Water. HWM-Water Ltd reserve the right to vary the specification.

MAN-147-0004-D

Documents / Resources

|

FCS MAN-147-0004 Multilog WW Evice Is Multi Purpose Data Logger [pdf] User Manual MAN-147-0004 Multilog WW Evice Is Multi Purpose Data Logger, MAN-147-0004, Multilog WW Evice Is Multi Purpose Data Logger, Evice Is Multi Purpose Data Logger, Multi Purpose Data Logger, Purpose Data Logger, Data Logger |