Danfoss MCB 103 Resolver Option Automation Drive

Product Information

Specifications

- Resolver Option MCB 103 for FC 360

- Used for interfacing the resolver motor feedback to the FC 360 frequency converters

- Resolver poles: 17-50 Poles – 2 * 2

- Vrms: *10.0 kHz

- Transformation ratio: Secondary input voltage Max. 4 Vrms

- Secondary load: App. 10 k

Product Usage Instructions

Safety Instructions

WARNING: DISCHARGE TIME

- Stop the motor.

- Disconnect AC mains, permanent magnet type motors, and remote DC-link power supplies, including battery back-ups, UPS, and DC-link connections to other frequency converters.

- Wait for the capacitors to discharge fully before performing any service or repair work. The waiting time is specified in Table 1.2.

Items Supplied

For J1-J5 enclosure types, a terminal cover must be ordered separately. For J6 and J7 enclosure types, no separate terminal covers are needed.

Mounting the Option

Mount the option according to the provided illustrations.

Electrical Installation

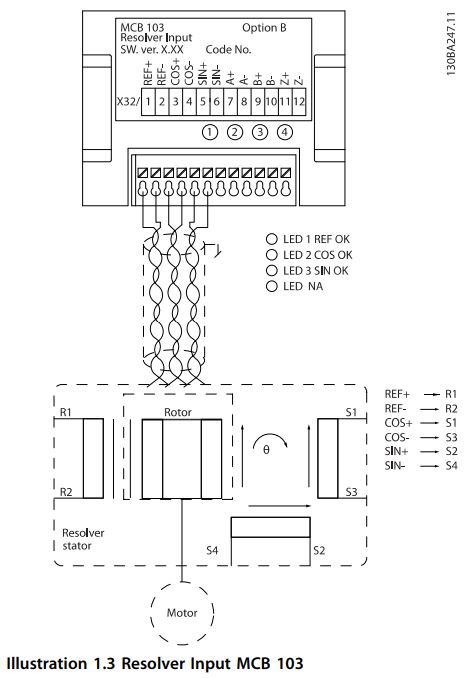

NOTICE: Always use screened motor cables and brake chopper cables. Separate resolver cables from motor cables. Connect the screen of the resolver cable to the de-coupling plate on the frequency converter side, and connect to the chassis (earth) on the motor side.

Ambient Working Temperature

Refer to Table 1.4 for the ambient working temperature at full load.

Resolver Option MCB 103 for FC 360 is used for interfacing the resolver motor feedback to FC 360 frequency converters.

| Resolver poles | 17-50 Poles: 2 *2 |

| Resolver input voltage | 17-51 Input Voltage: 2.0–8.0 Vrms *7.0

Vrms |

| Resolver input frequency | 17-52 Input Frequency: 2–15 kHz

*10.0 kHz |

| Transformation ratio | 17-53 Transformation Ratio: 0.1–1.1 *0.5 |

| Secondary input voltage | Max. 4 Vrms |

| Secondary load | App. 10 kΩ |

Safety Instructions

WARNING DISCHARGE TIME

The frequency converter contains DC-link capacitors, which can remain charged even when the frequency converter is not powered. Failure to wait the specified time after power has been removed before performing service or repair work could result in death or serious injury.

- Stop the motor.

- Disconnect AC mains, permanent magnet type motors, and remote DC-link power supplies, including battery back-ups, UPS, and DC-link connections to other frequency converters.

- Wait for the capacitors to discharge fully before performing any service or repair work. The duration of waiting time is specified in Table 1.2.

Voltage [V]

Minimum waiting time (minutes) 4 15 380-480 0.37-7.5 kW 11-75 kW High voltage may be present even when the warning LEDs are off!

Items Supplied

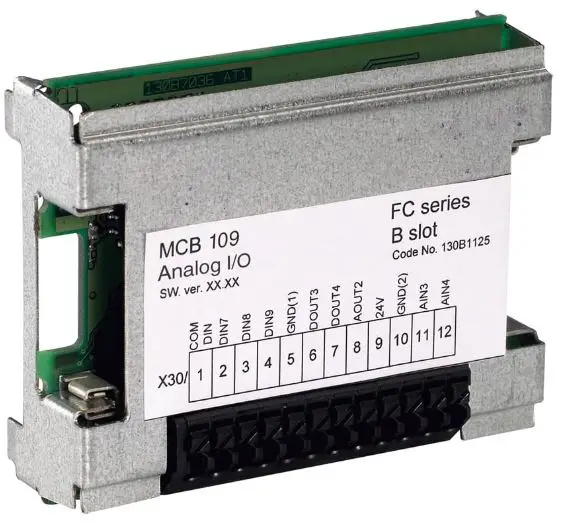

Resolver Option MCB 103

NOTICE

For J1-J5 enclosure types, a terminal cover must be ordered separately. For J6 and J7 enclosure types, no separate terminal covers are needed.

| Enclosure | Ordering number |

| J1 | 132B0263 |

| J2 | 132B0265 |

| J3 | 132B0266 |

| J4 | 132B0267 |

| J5 | 132B0268 |

Mounting the Option

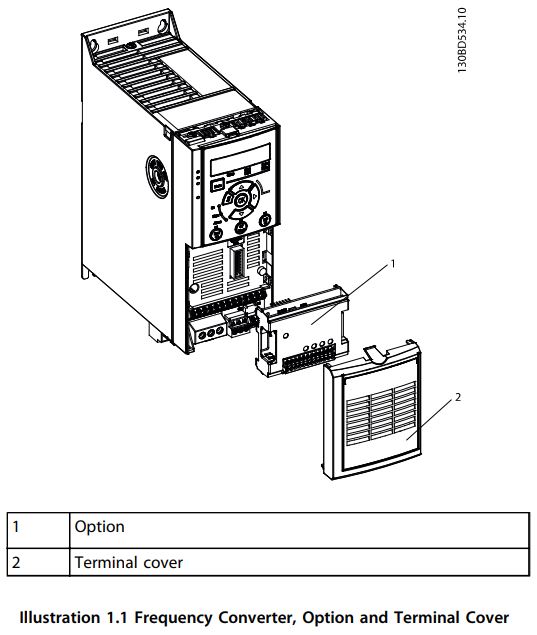

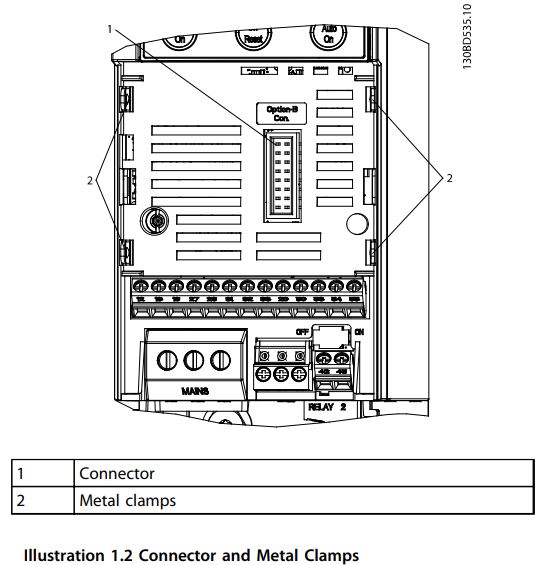

Mount the option according to Illustration 1.1 and Illustration 1.2.

Ambient Working Temperature

For ambient working temperature af full load, see Table 1.4.

| Without MCB | With MCB | |

| Standard Control Card | 45-50 °C* | 45 °C |

| Profibus or ProfiNet | 45 °C | 40 °C |

Some types can reach 50 °C, see VLT® AutomationDrive FC 360 Design Guide.

Electrical Installation

NOTICE

- Always use screened motor cables and brake chopper cables.

- Separate resolver cables from motor cables.

- Connect the screen of the resolver cable to the de-coupling plate on the frequency converter side, and connect to the chassis (earth) on the motor side.

ABOUT COMPANY

- Danfoss A/S

- Ulsnaes 1

- DK-6300 Graasten

- www.danfoss.com/drives

FAQ

What should I do if the warning LEDs are off but high voltage may still be present?

High voltage may still be present even when the warning LEDs are off. Follow safety protocols and refer to the provided instructions for proper discharge time before servicing or repair work.

Documents / Resources

|

Danfoss MCB 103 Resolver Option Automation Drive [pdf] Installation Guide MCB 103, MCB 103 Resolver Option Automation Drive, MCB 103, Resolver Option Automation Drive, Option Automation Drive, Automation Drive |