Danfoss DCR Filter Drier Shell Installation Guide

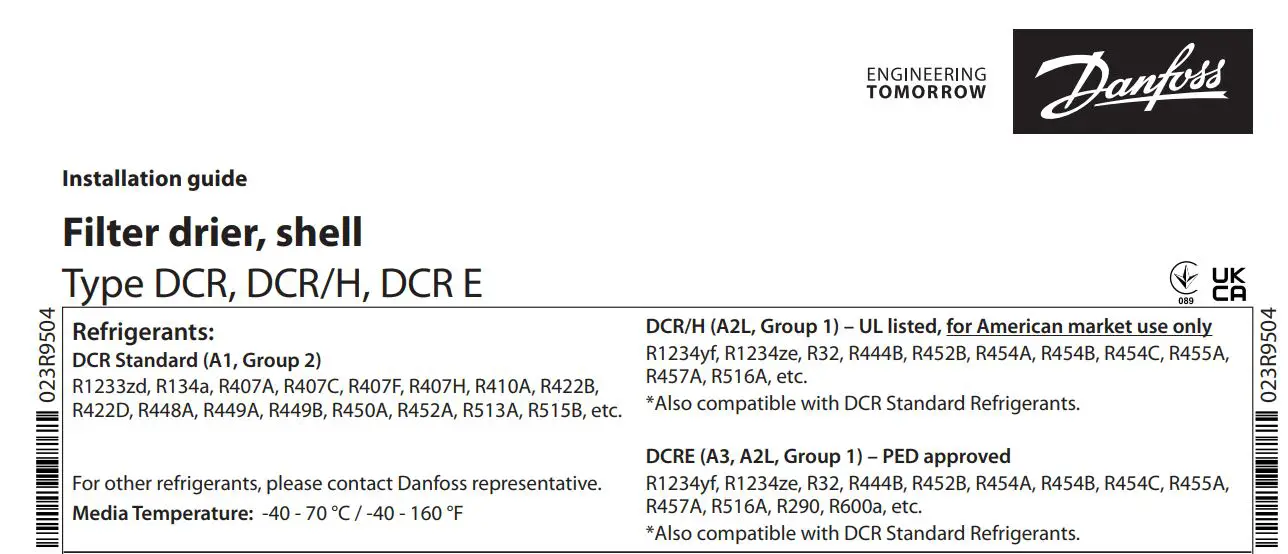

Design

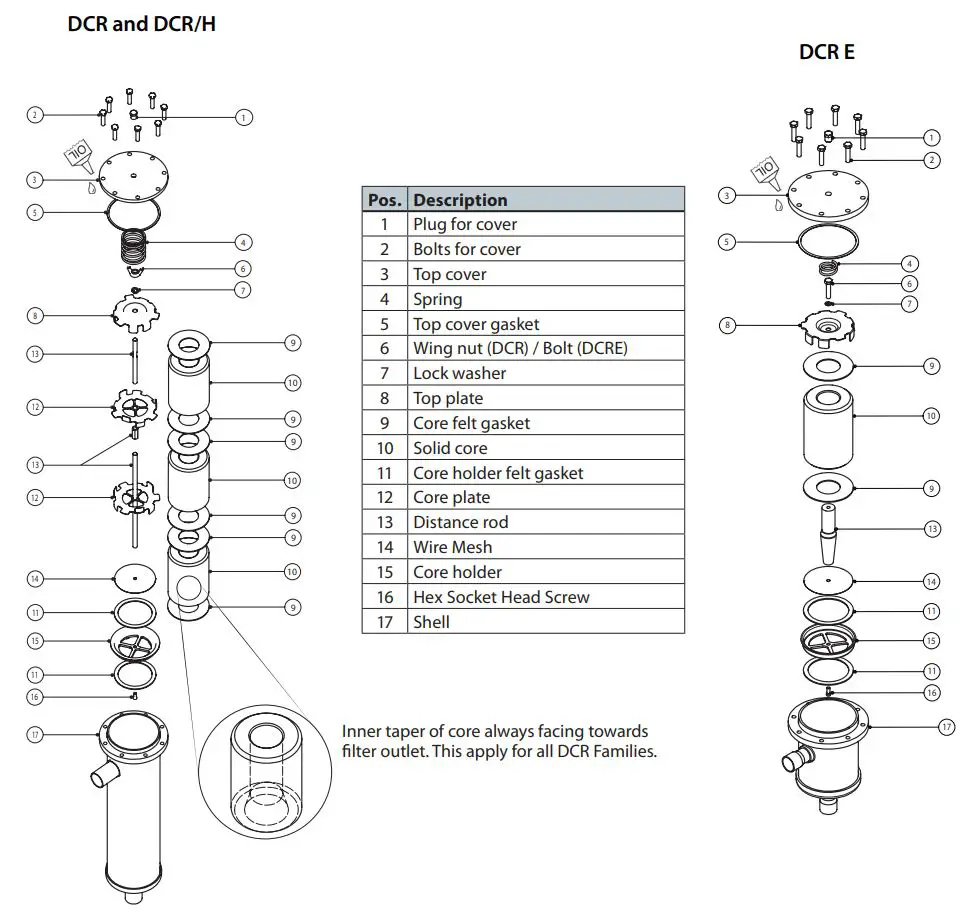

Installation

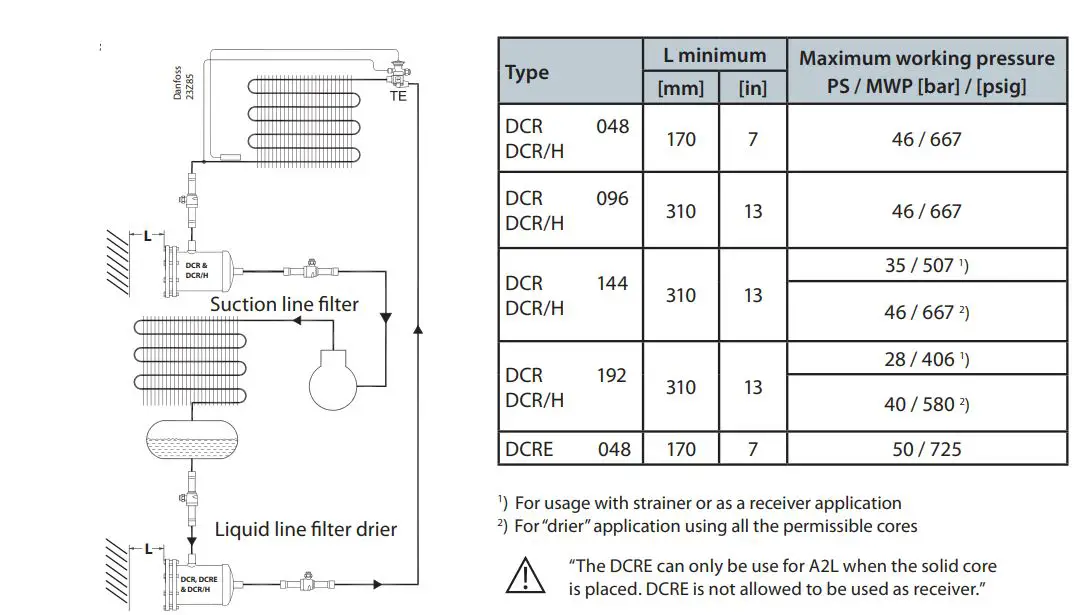

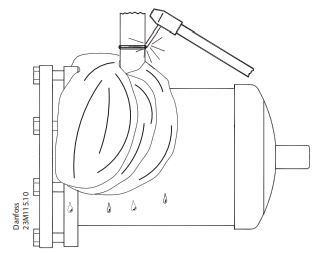

Brazing

Welding

Customer best practice will still be needed:

- Use wet wrap when installing.

- Braze the joints.

- Let them cool down.

- Clean the brazing /welding area after the installation (remove remaining flux with a brush).

- This is an important operation and needs to be done with great care to remove all remaining flux.

- Paint / Anti-corrosive needs to cover all open steel parts, areas where the black original paint has been burnt due to brazing and at least 3 cm approx. of the copper.

- Paint the joints twice.

⚠ Do not install gasket before soldering.

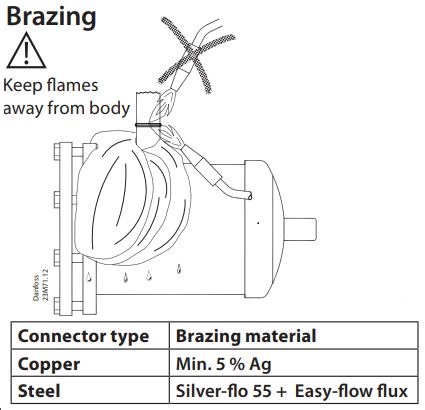

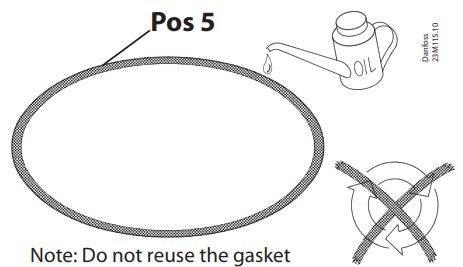

Note: Confirm correct top cover Gasket is selected.

There are 2 gaskets:

– DCR and DCR/H

– DCRE

Recommendation:

Apply a small amount of oil to the gasket before assembly. Preferably synthetic POE or PVE oil, although any general-purpose oil can be used.

Gasket

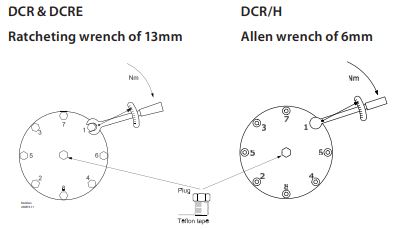

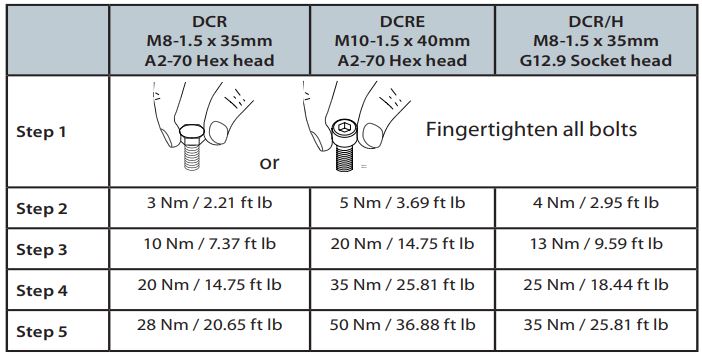

How to tighten the bolts

Optional Plug, recommended tightening torque: Plug: 1/4″ NPT: 50 Nm / 36.87 ft-lb applying 2 to 3 wraps of teflon tape.

The torque values mentioned only apply to bolts supplied by Danfoss.

* Each step must be applied following the sequence of the image. AN164986434975en-000702 | 2

Documents / Resources

|

Danfoss DCR Filter Drier Shell [pdf] Installation Guide 023R950 4, 23Z85, 23M71.12, 23M115.10, DCR Filter Drier Shell, DCR, Filter Drier Shell, Drier Shell, Shell |