Pickerbot Pro User Manual

Please note that images shown are for illustrative purposes only*.

Authors: Wayne Liu, Reilly Smithers

3 July 2024

SUMMARY

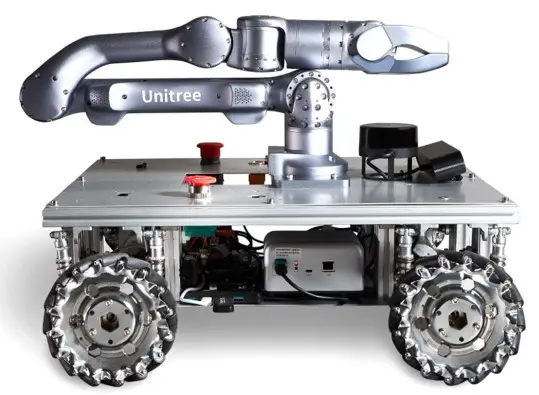

Pickerbot Pro is a versatile R&D robotics platform that can be used for a variety of applications, both outdoors such as agriculture, mining, and construction, and indoors, including robot-assisted logistics, search and rescue demonstrations, and mapping.

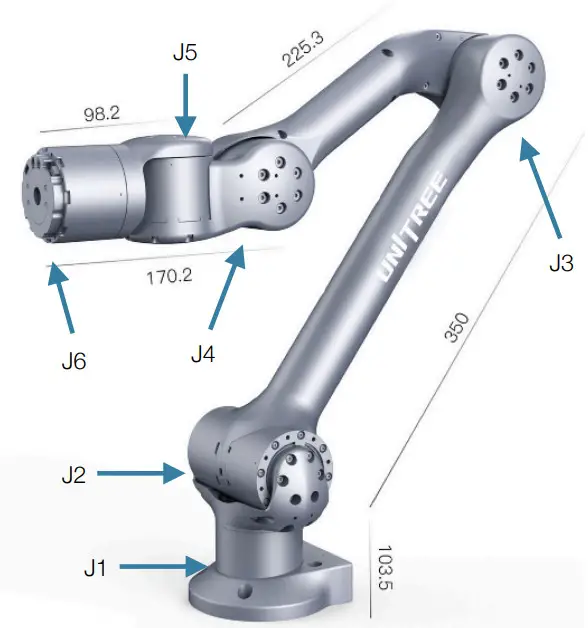

Featuring the Unitree Z1 Pro Robotic arm with a 740mm reach and 3kg payload capacity, the Pickerbot Pro offers impressive articulation with 6 degrees of freedom, along with force feedback and collision detection capabilities.

Powered by an NVIDIA Jetson Orin series single-board-computer (Nano or NX variant), it provides more advanced computer vision and machine-learning tasks with powerful graphics or parallel computing functionality using CUDA, whilst retaining a compact and lightweight design.

The Pickerbot Pro is equipped with an Orbbec 3D Astra camera, providing depth sensing, object tracking, and gesture recognition capabilities.

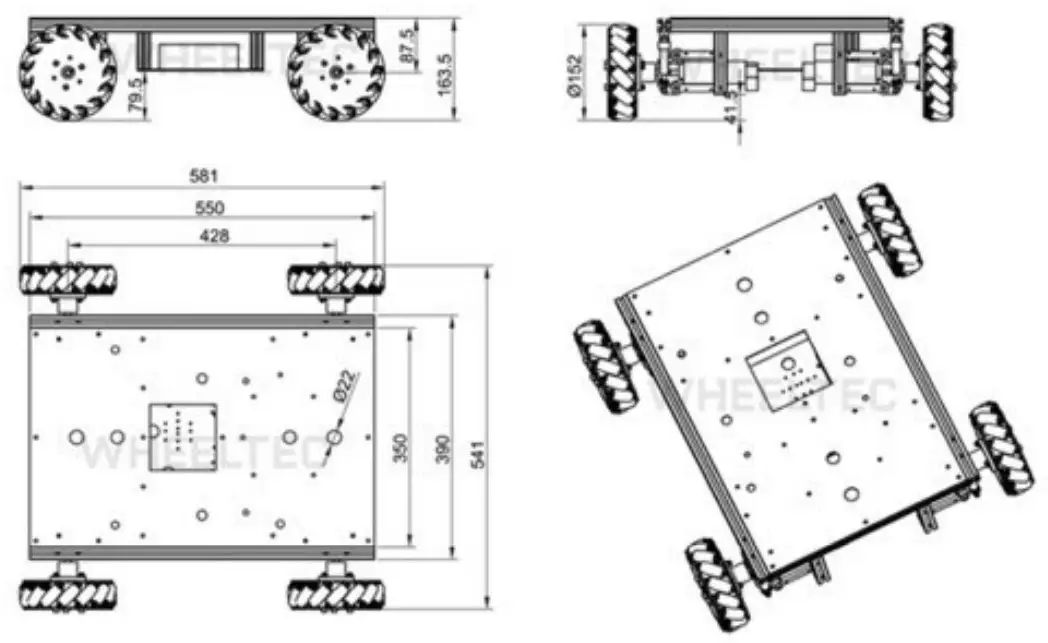

Built on a sturdy yet lightweight chassis, the Pickerbot Pro features a 4WD system with independent suspension for enhanced navigation across uneven terrain. Large mecanum wheels provide precise omnidirectional movement yet high grip.

Key components and hardware

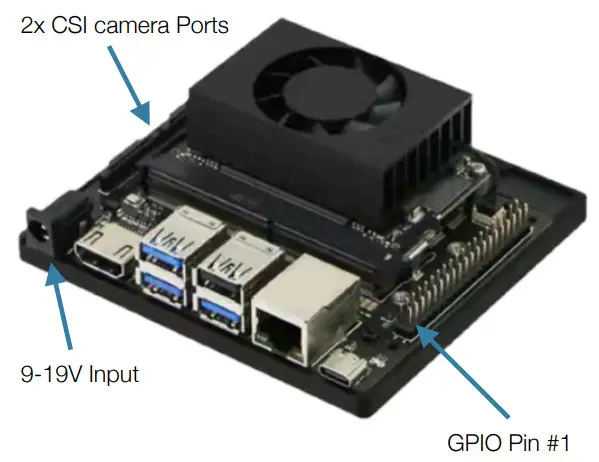

1.1 ROS 2 Controller: NVIDIA Jetson Orin (NX 8GB or Nano 4GB)

The onboard Jetson Orin single board computer provides powerful embedded computing to the Pickerbot Pro. It comes with a 128gb SSD, Intel Wireless card and onboard antennas, HDMI, four USB ports (3 of which are USB 3.0), Ethernet, and USB-C. A DC barrel jack to power the board, using between 9-19V. The onboard GPIO pins use the same basic layout as the popular Raspberry Pi single board computers, starting with Pin #1 on the outside row, adjacent to the Ethernet port. Likewise, two CSI camera connectors enable functionality with Raspberry Pi brand and similar small-form-factor cameras.

Pre-installed software includes ROS 2 Humble, Ubuntu 22.04, and NVIDIA Jetpack, enabling the full capability of the Orin platform.

Note: To maintain compatibility with the chassis controller and other robot components, we do not recommended flashing the Jetson Orin with different software. For more advanced use cases please contact Roboworks support.

1.2 Sensing System: LiDAR & Depth Camera

The Pickerbot Pro is equipped with a Leishen M10 LSLiDAR. With a 30m maximum detection range and 12Hz rotational scanning frequency, and a high signal-to-noise ratio, eliminating the need for additional filtering. It integrates seamlessly, providing excellent mapping and navigational capabilities.

Additionally, the Pickerbot Pro is equipped with an Orbbec Astra Depth Camera, which is an RGB depth camera. This camera is optimised for a range of uses including gesture control, skeleton tracking, 3D scanning, object detection and point cloud development with ROS 2.

| Depth Resolution | RGB Resolution | RGB Sense Angle | Depth FPS | RGB Framerate | Depth Framerate | Depth Range |

| 640×480 | 640×480 | 63.1×49.4° | 58×45.5° | 30fps | 30fps | 0.6~4m |

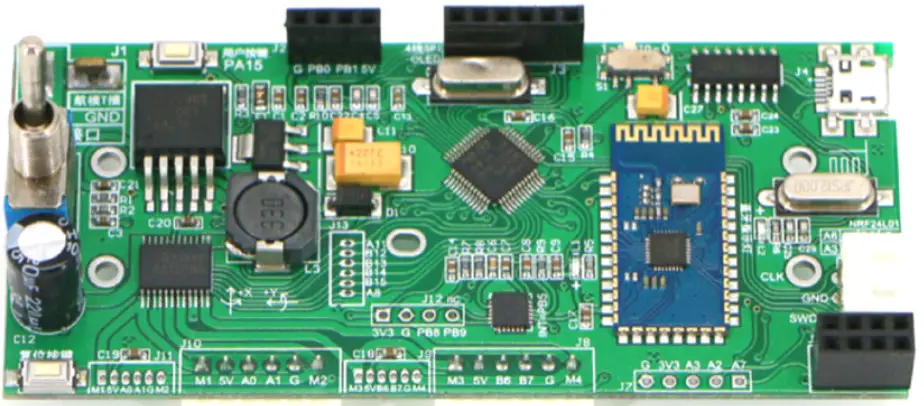

1.3 STM32 Control Board (Motor Control & IMU)

For chassis and motor control, Pickerbot Pro features an STM32 control board. This board ensures low power consumption, precise motor control, OLED readout displays for monitoring motors, and an inertial measurement unit (IMU). It can be configured for more specialised operation, or to enable encoder feedback to the Jetson Orin controller. Using the software packages Keil and FlyMCU for compilation and subsequent flashing of the STM32F103.

| STM32F103RC | Features |

| Core | ARM32-bit Cortex -M3 CPU Max speed of 72 MHz |

| Memories | 512 KB of Flash memory 64kB of SRAM |

| Clock, Reset and Supply Management | 2.0 to 3.6 V application supply and I/Os |

| Power | Sleep. Stop and Standby modes V supply for RTC and backup registers BAT |

| DMA | 12-channel DMA controller |

| Debug Mode | SWD and JTAG interfaces Cortex-M3 Embedded Trace Macrocell |

| I/O ports | 51 I/O ports (mappable on 16 external interrupt vectors and 5V tolerant) |

| Timers | 4×16-bit timers 2 x 16-bit motor control PWM timers (with emergency stop) 2 x watchdog timers (independent and Window) SysTick timer (24-bit downcounter) 2 x 16-bit basic timers to drive the DAC |

| Communication Interface | USB 2.0 full speed interface SDIO interface CAN interface (2.0B Active) |

1.4 Chassis Overview and Battery Options

The Pickerbot Pro is equipped with omnidirectional Mecanum wheels, each featuring 45-degree offset rollers that facilitate motion in all directions. It’s crucial to note that these wheels are supplied in pairs, with each pair having rollers oriented differently. During installation on the robot, ensure that diagonally opposing wheels have rollers pointing in the same direction. If the robot moves unexpectedly, simply reverse the pairs of wheels.

Considerations must be made when increasing battery capacity. The Pickerbot Pro comes standard with a 5000 mAh battery and can be upgraded to 10,000 or 20,000 mAh options for an additional cost. The 20,000 mAh battery is too large to fit within the chassis of the Pickerbot Pro and can only be installed on top of the robot chassis. Please refer to the table below for weight and size parameters.

| Battery parameter | Features | ||

| 5000mAh | 10000mAh | 20000mAh | |

| Battery Voltage | 22.2V | 22.2V | 22.2V |

| Size | 124*71*42mm | 124*71*71mm | 156*122*71mm |

| Power Charger | DC 5.5 Charging plug T-shaped discharge plug |

DC 5.5 Charging plug T-shaped discharge plug |

DC 5.5 Charging plug T-shaped discharge plug |

| Performance | 15A continuous d ischarge |

30A continuous discharge | 60A continuous discharge |

| Weight | 0.66kg | 1.25kg | 2.4kg |

1.5 Unitree Z1 Pro Robotic Arm

The Pickerbot Pro incorporates the Unitree Z1 Pro robotic arm, which provides impressive articulation with 6 degrees of freedom and a reach of 740mm. Please refer to the joint parameter table below for customising kinematics to meet with your specific requirements.

| Joint | Range of Motion | Max Speed | Max Torque |

| J1 | ±150° | 180°/s | 33N·m |

| J2 | 0—180° | 180°/s | 33N·m |

| J3 | -165°—0 | 180°/s | 33N·m |

| J4 | ±80° | 180°/s | 33N·m |

| J5 | ±85° | 180°/s | 33N·m |

| J6 | ±160 | 180°/s | 33N·m |

| Parameter | Z1 Pro |

| Weight | 4.5kg |

| Payload | 3kg |

| Reach | 740mm |

| Repeatability | ~0.1mm |

| Power Supply | 24V |

| Interface | Ethernet |

| Compatible operating system | Ubuntu |

| Maximum Power | 500W |

| Force Feedback | Yes |

Software and Getting Started

2.1 ROS 2 Quick Start

When the robot is first powered on, it is controlled by ROS by default. Meaning, the STM32 chassis controller board accepts commands from the ROS 2 Controller – The Jetson Orin.

Initial setup is quick and easy, from your host PC (Ubuntu Linux recommended) connect to the robot’s Wi-Fi hotspot. Password by default is “dongguan”.

Next, connect to robot using SSH via the Linux terminal, IP address is 192.168.0.100, default password is dongguan.

![]()

With terminal access to the robot, you can navigate to the ROS 2 workspace folder, under “wheeltec_ROS 2” Prior to running test programs, navigate to wheeltec_ROS 2/turn_on_wheeltec_robot/ and locate wheeltec_udev.sh – This script must be run, typically only once to ensure proper configuration of peripherals.

You are now able to test the robot’s functionality, to launch the ROS 2 controller functionality, run: “roslaunch turn_on_wheeltec_robot turn_on_wheeltec_robot.launch”

![]()

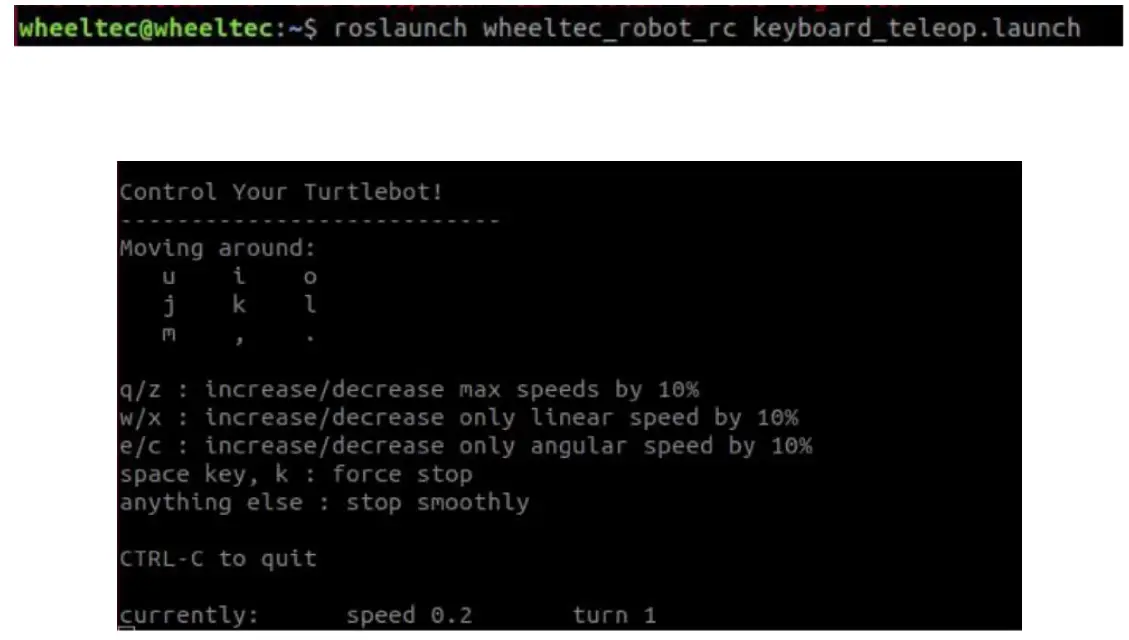

In a second terminal, you can use the keyboard_teleop node to validate chassis control, this is a modified version of the popular ROS 2 Turtlebot example. Type: “roslaunch wheeltec_robot_rc keyboard_teleop.launch”

2.2 Pre-installed ROS 2 Packages for the chassis

Below are the following user-oriented packages, whilst other packages may be present, these are dependencies only.

turn_on_wheeltec_robot

This package is crucial for enabling robot functionality, and communication with the chassis controller.

The primary script “turn_on_wheeltec_robot.launch” must be used upon each boot to configure ROS 2 and controller.

wheeltec_rviz2

Contains launch files to launch rviz with custom configuration for Pickerbot Pro.

wheeltec_robot_slam

SLAM Mapping and localisation package with custom configuration for Pickerbot Pro.

wheeltec_robot_rrt2

Rapidly exploring random tree algorithm – This package enables Pickerbot Pro to plan a path to it’s desired location, by launching exploration nodes.

wheeltec_robot_keyboard

Convenient package for validating robot functionality and controlling using the keyboard, including from remote host PC.

wheeltec_robot_nav2

ROS 2 Navigation 2 node package.

wheeltec_lidar_ROS 2

ROS 2 Lidar package for configuring Leishen M10/N10.

wheeltec_joy

Joystick control package, contains launch files for Joystick nodes.

simple_follower_ROS 2

Basic object and line following algorithms using either laser scan or depth camera.

ROS 2_astra_camera

Astra depth camera package with drivers and launch files.

Robotic arm integration

3.1 Robotic arm wiring components

Unitree Z1 Recommended Wiring

Below are the recommended wiring components for the Unitree Z1 arm. There should be an available female 2-pole dean connector on a breakout after the power switch. Connect the components in series. Ensure the connector +/GND connections match. The blade fuse holder should sit on the positive power line.

| Component | Quantity |

| Male deans style 2 pole connector | x1 |

| Male xt60 style 2 pole connector | x1 |

| Inline blade fuse holder | x1 |

| 14 AWG 2 core cable | x1 |

| 7.5 Blade fuse | x1 |

As the arm only has relative encoders it must be reset to the same position on every start-up. You may find it worthwhile attaching a switch in series in the cable to easily turn on and off the arm for resetting.

NOTE: Unitree documentation says the arm is rated for 20A. This is incorrect. A 10A SMD fuse is attached in series for each power supply. Using a 7.5A fuse will blow before the 10A SMD fuse and will be significantly easier to replace.

NOTE: Due to the extra weight of the unitree Z1 arm on the system the front springs are unable to support the arm. Drop-in 70mm*16mm compression springs can be found and used in place of the stock springs. Alternatively, large springs that encompass the shock can be used.

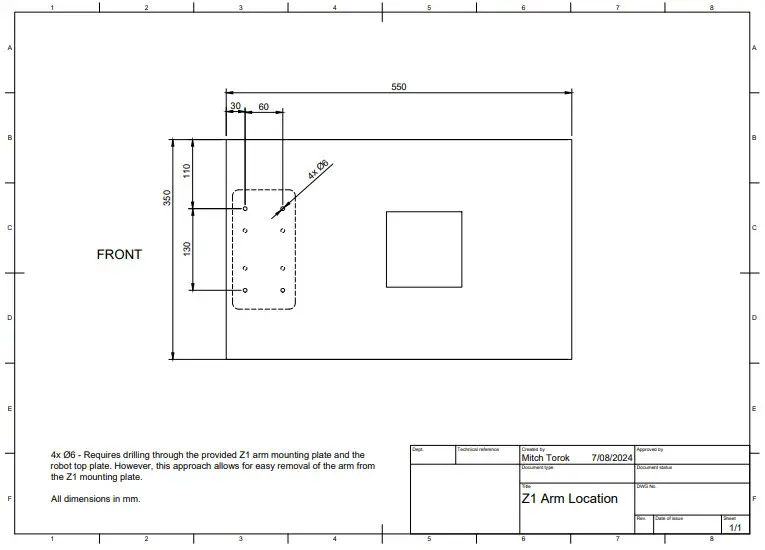

3.2 Robotic arm mounting drawings

3.3 Sample code for robotic arm

At the time of this User Manual is prepared, Unitree’s SDK for Z1 Pro only supports ROS 1 Melodic or Noetic.

The Pickerbot Pro product team has developed sample code in ROS 2 Humble compatible with the chassis.

The sample code to integrate the Z1 Pro robotic arm with the chassis can be found from the below GitHub respository:

https://github.com/roboworksdev/pickerbotproarm

www.roboworks.net

Copyright © 2024 Roboworks. All rights reserved.

Documents / Resources

|

ROBOWORKS Pickerbot Pro Pick and Drop Mobile Robot [pdf] User Manual Pickerbot Pro, Pickerbot Pro Pick and Drop Mobile Robot, Pick and Drop Mobile Robot, Drop Mobile Robot, Mobile Robot, Robot |