CC1312PSIP

CC1312PSIP

SWRS293 – MAY 2023

CC1312PSIP SimpleLink™ Sub-1-GHz Wireless System-in-Package

Features

Wireless microcontroller

- Powerful 48-MHz Arm ® Cortex ® TI Co nfid -M4F processor

- 352KB flash program memory

- 256KB of ROM for protocols and library functions

- 8KB of cache SRAM

- 80KB of ultra-low leakage SRAM with parity for high-reliability operation

- Dynamic multiprotocol manager (DMM) driver

- Programmable radio includes support for 2(G)FSK, 4-(G)FSK, MSK, OOK, IEEE 802.15.4 PHY and MAC

- Supports over-the-air upgrade (OTA) Ultra-low power sensor controller

- Autonomous MCU with 4KB of SRAM

- Sample, store, and process sensor data

- Fast wake-up for low-power operation

- Software defined peripherals; capacitive touch, flow meter,

LCD Low power consumption - MCU consumption: – 2.9 mA active mode, CoreMark ®

– 60 μA/MHz running CoreMark®

– 0.9 μA standby mode, RTC, 80KB RAM

– 0.1 μA shutdown mode, wake-up on pin - Ultra low-power sensor controller consumption:

– 30 μA in 2-MHz mode

– 808 μA in 24-MHz mode - Radio Consumption:

– 5.8-mA RX at 868 MHz

– 28.7-mA TX at +14 dBm at 868 MHz

Wireless protocol support - Wi-SUN®

- mioty®

- Wireless M-Bus

- SimpleLink™ TI 15.4-stack

- 6LoWPAN

- Proprietary systems High-performance radio

- –119 dBm for 2.5-kbps long-range mode

- –108 dBm at 50 kbps, 802.15.4, 868 MHz

Regulatory compliance - Pre-certified for:

– FCC CFR47 Part 15 - Suitable for systems targeting compliance with:

– ETSI EN 300 220 Receiver Cat. 1.5 and 2, EN 303 131, EN 303 204

– ARIB STD-T108

MCU peripherals - Digital peripherals can be routed to 30 GPIOs

- Four 32-bit or eight 16-bit general-purpose timers

- 12-bit ADC, 200 kSamples/s, 8 channels

- 8-bit DAC

- Two comparators

- Programmable current source

- Two UART, two SSI, I

- Real-time clock (RTC)

- Integrated temperature and battery monitor

Security enablers - AES 128- and 256-bit cryptographic accelerator

- ECC and RSA public key hardware accelerator

- SHA2 Accelerator (full suite up to SHA-512)

- True random number generator (TRNG)

Development tools and software - LP-CC1312PSIP Development Kit

- SimpleLink™ CC13xx and CC26xx Software

Development Kit (SDK) - SmartRF™ Studio for simple radio configuration

- Sensor Controller Studio for building low-power sensing applications

- SysConfig system configuration tool

Operating range - 1.8-V to 3.8-V single supply voltage

- –40 to +105°C (+14 dBm PA)

All necessary components integrated - 48-MHz crystal: RF accuracy ±10 ppm

- 32-kHz crystal: RTC accuracy ±50 ppm

- DC/DC converter components and decoupling capacitors

- RF front-end components with 50-Ohm output

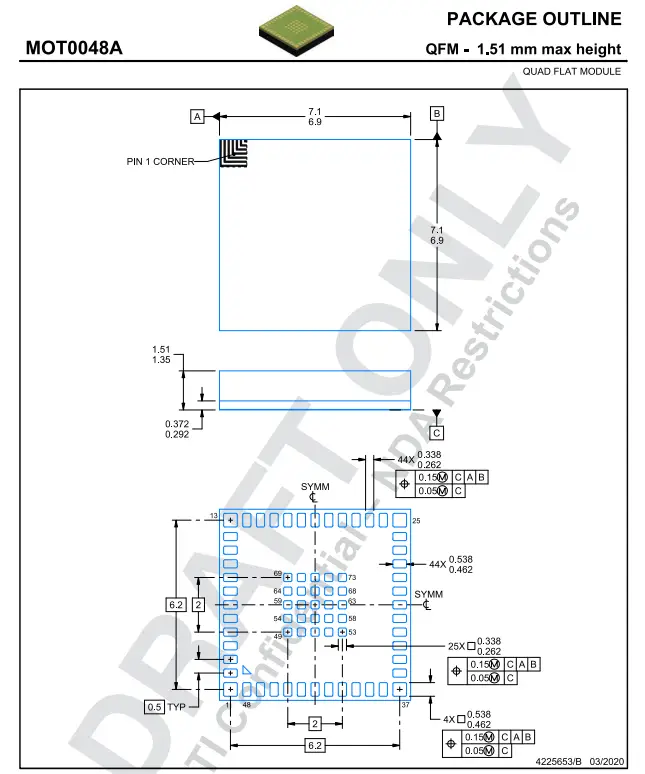

Package - 7-mm × 7-mm MOT (30 GPIOs)

- Pin-to-pin compatible with CC2652RSIP and CC2652PSIP

- RoHS-compliant package

![]() IMPORTANT NOTICE at the end of this data sheet addresses availability, warranty, changes, use in safety-critical applications, intellectual property matters and other important disclaimers. ADVANCE INFORMATION for preproduction products; subject to change without notice.

IMPORTANT NOTICE at the end of this data sheet addresses availability, warranty, changes, use in safety-critical applications, intellectual property matters and other important disclaimers. ADVANCE INFORMATION for preproduction products; subject to change without notice.

Applications

- 868 and 902 to 928 MHz ISM and SRD systems 1 with down to 4 kHz of receive bandwidth

- Building automation

– Building security systems – motion detector, electronic smart lock, door and window sensor, garage door system, gateway

– HVAC – thermostat, wireless environmental sensor, HVAC system controller, gateway

– Fire safety system – smoke and heat detector, fire alarm control panel (FACP)

– Video surveillance – IP network camera

– Elevators and escalators – elevator main control panel for elevators and escalators - Grid infrastructure

– Smart meters – water meter, gas meter, electricity meter, and heat cost allocators

– Grid communications – wireless communications – long-range sensor applications

– EV Charging infrastructure – AC charging (pile) station

– Other alternative energy – energy harvesting - Industrial transport – asset tracking

- Factory automation and control

- Medical

- Communication equipment

– Wired networking – wireless LAN or Wi-Fi access points, edge router

Description

The SimpleLink ™ CC1312PSIP device is a System-in-Package (SiP) Sub-1 GHz wireless module supporting IEEE 802.15.4, IPv6-enabled smart objects (6LoWPAN), mioty, proprietary systems, including the TI 15.4-Stack. The CC1312PSIP microcontroller (MCU) is based on an Arm M4F main processor and optimized for low-power wireless communication and advanced sensing in grid infrastructure, building automation, retail automation and medical applications. The CC1312PSIP has a low sleep current of 0.9 μA with RTC and 80KB RAM retention. In addition to the main Cortex® M4F processor, the device also has an autonomous ultra-low power Sensor Controller CPU with fast wake-up capability. As an example, the sensor controller is capable of 1-Hz ADC sampling at average 1-μA system current.

The CC1312PSIP has Low SER (Soft Error Rate) FIT (Failure-in-time) for long operational lifetime. Always-on SRAM parity minimizes risk for corruption due to potential radiation events. Consistent with many customers’ 10 to 15 years or longer life cycle requirements, TI has a product life cycle policy with a commitment to product longevity and continuity of supply including dual sourcing of key components in the SIP. The CC1312PSIP device is part of the SimpleLink™ MCU platform, which consists of Wi-Fi®, Bluetooth® Low Energy, Thread, Zigbee, Wi-SUN®, Amazon Sidewalk, mioty, Sub-1 GHz MCUs, and host MCUs. CC1312PSIP is part of a portfolio that includes pin-compatible 2.4-GHz SIPs for easy adaption of a wireless product to multiple communication standards. The common SimpleLink™CC13xx and CC26xx Software Development Kit (SDK) and SysConfig system configuration tool supports migration between devices in the portfolio. A comprehensive number of software stacks, application examples and SimpleLink Academy training sessions are included in the SDK. For more information, visit wireless connectivity.

| PART NUMBER | PACKAGE | BODY SIZE (NOM) |

| CC1312PSIPMOT | QFM | 7.00 mm × 7.00 mm |

(1) For the most current part, package, and ordering information for all available devices, see the Package Option Addendum in Mechanical, Packaging, and Orderable Information, or see the TI website.

1 See RF Core for additional details on supported protocol standards, modulation formats, and data rates.

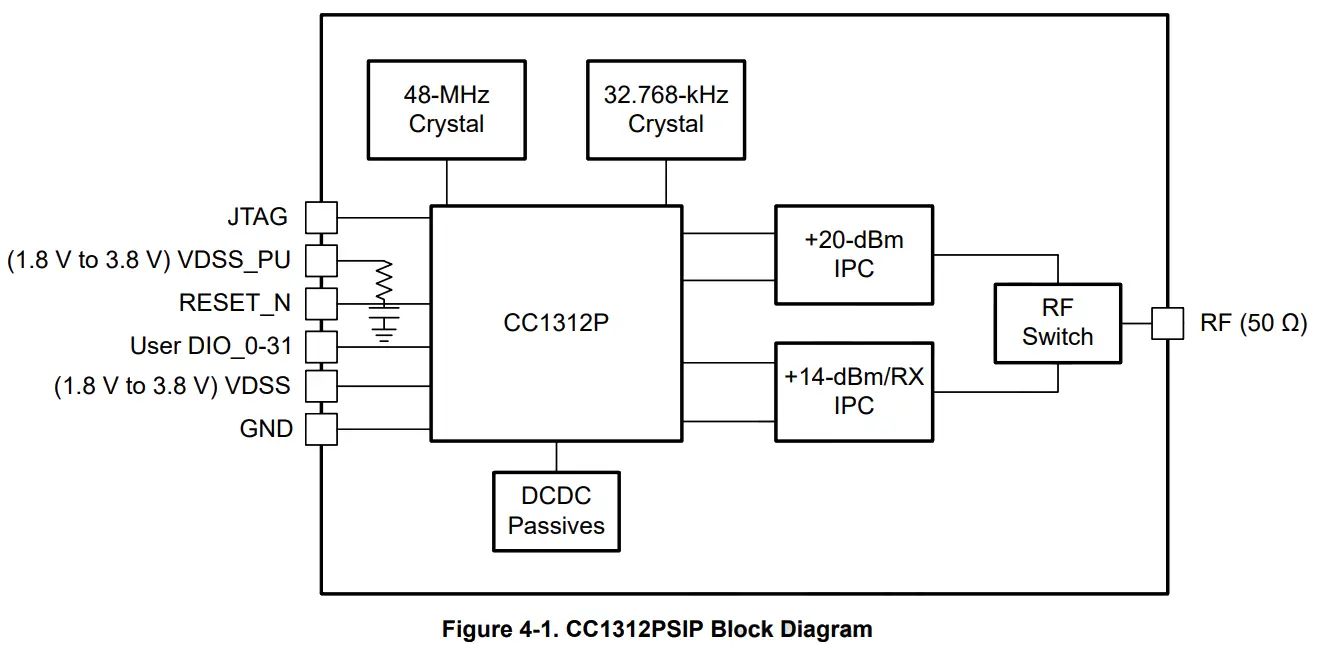

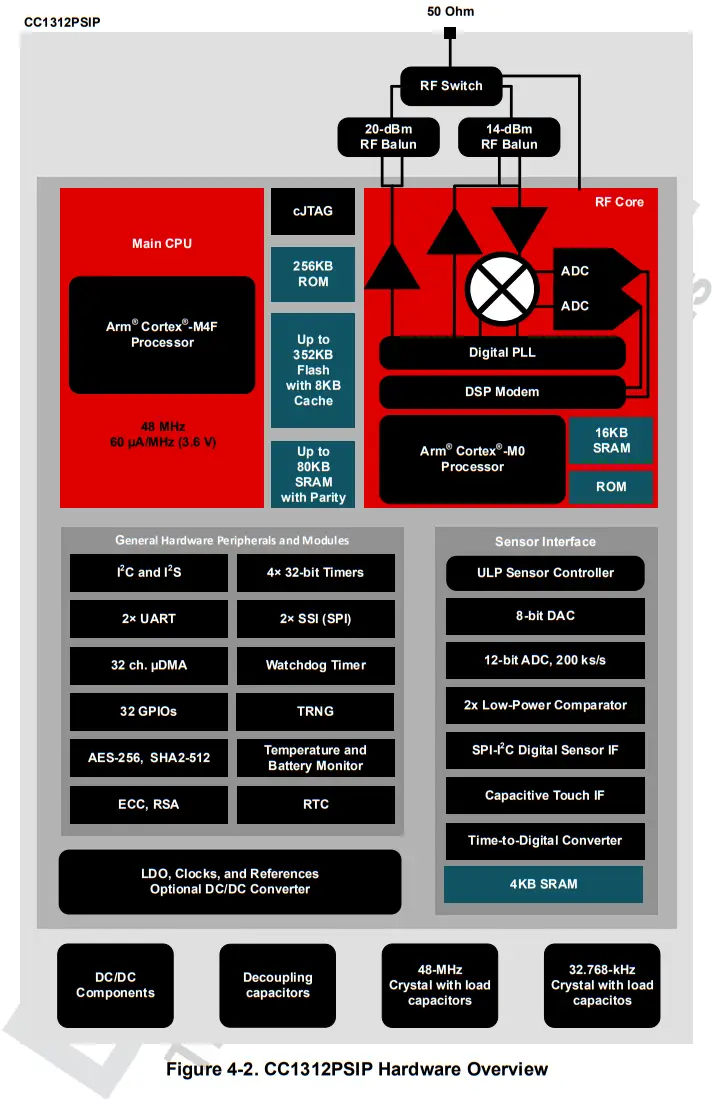

Functional Block Diagram

Revision History

NOTE: Page numbers for previous revisions may differ from page numbers in the current version.

| DATE | REVISION | NOTES |

| May-23 | * | Initial Release |

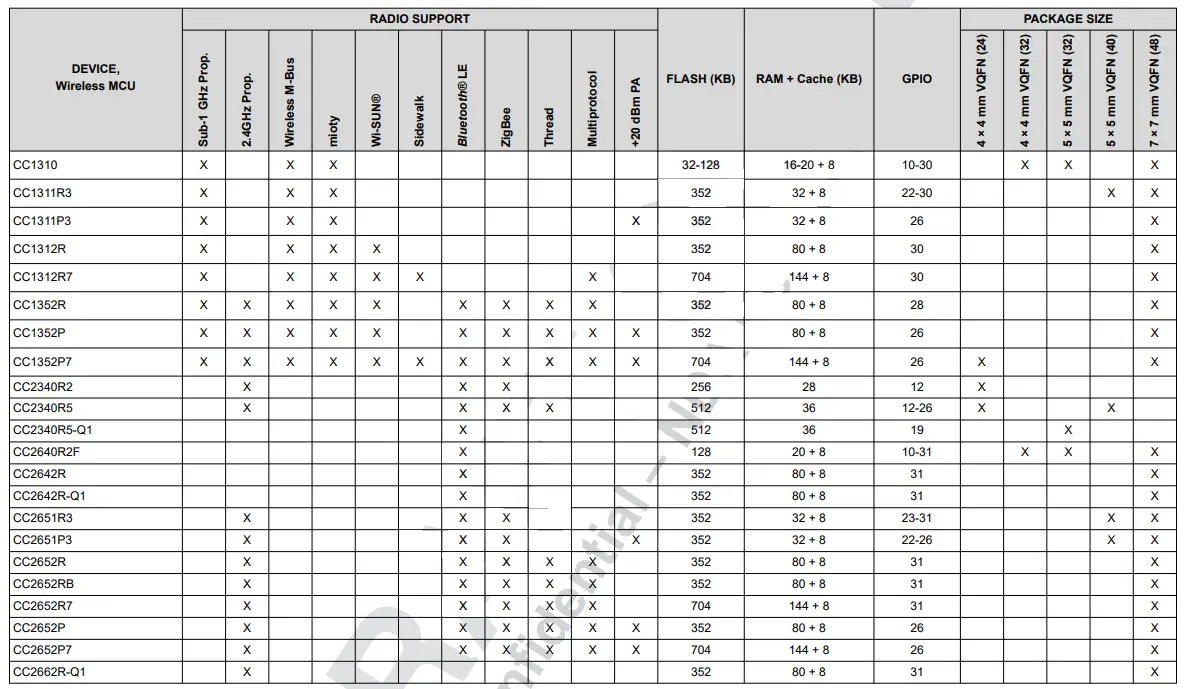

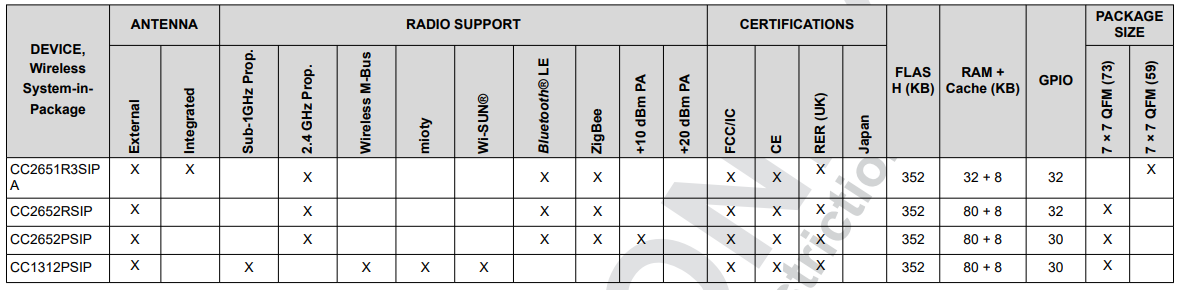

Device Comparison

Pin Configuration and Functions

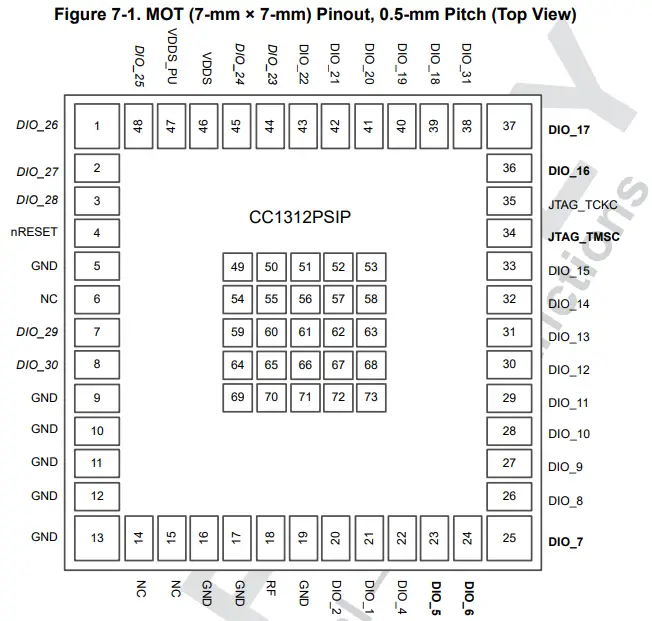

7.1 Pin Diagram – MOT Package (Top View)

Figure 7-1. MOT (7-mm × 7-mm) Pinout, 0.5-mm Pitch (Top View)

The following I/O pins marked in Figure 7-1 in bold have high-drive capabilities:

- Pin 23, DIO_5

- Pin 24, DIO_6

- Pin 25, DIO_7

- Pin 34, JTAG_TMSC

- Pin 36, DIO_16

- Pin 37, DIO_17

The following I/O pins marked in Figure 7-1 in italics have analog capabilities:

- Pin 1, DIO_26

- Pin 2, DIO_27

- Pin 3, DIO_28

- Pin 7, DIO_29

- Pin 8, DIO_30

- Pin 44, DIO_23

- Pin 45, DIO_24

- Pin 48, DIO_25

7.2 Signal Descriptions – MOT Package

Table 7-1. Signal Descriptions – SIP Package

| PIN | I/O | TYPE |

DESCRIPTION |

|

| NAME |

NO. |

|||

| NC | 14 | I/O | Digital | No Connect |

| DIO_1 | 21 | I/O | Digital | GPIO |

| DIO_10 | 28 | I/O | Digital | GPIO |

| DIO_11 | 29 | I/O | Digital | GPIO |

| DIO_12 | 30 | I/O | Digital | GPIO |

| DIO_13 | 31 | I/O | Digital | GPIO |

| DIO_14 | 32 | I/O | Digital | GPIO |

| DIO_15 | 33 | I/O | Digital | GPIO |

| DIO_16 | 36 | I/O | Digital | GPIO, JTAG_TDO, high-drive capability |

| DIO_17 | 37 | I/O | Digital | GPIO, JTAG_TDI, high-drive capability |

| DIO_18 | 39 | I/O | Digital | GPIO |

| DIO_19 | 40 | I/O | Digital | GPIO |

| DIO_2 | 20 | I/O | Digital | GPIO |

| DIO_20 | 41 | I/O | Digital | GPIO |

| DIO_21 | 42 | I/O | Digital | GPIO |

| DIO_22 | 43 | I/O | Digital | GPIO |

| DIO_23 | 44 | I/O | Digital or Analog | GPIO, analog capability |

| DIO_24 | 45 | I/O | Digital or Analog | GPIO, analog capability |

| DIO_25 | 48 | I/O | Digital or Analog | GPIO, analog capability |

| DIO_26 | 1 | I/O | Digital or Analog | GPIO, analog capability |

| DIO_27 | 2 | I/O | Digital or Analog | GPIO, analog capability |

| DIO_28 | 3 | I/O | Digital or Analog | GPIO, analog capability |

| DIO_29 | 7 | I/O | Digital or Analog | GPIO, analog capability |

| NC | 15 | I/O | Digital | No Connect |

| DIO_30 | 8 | I/O | Digital or Analog | GPIO, analog capability |

| PIO_31 | 38 | I/O | Digital | Supports only peripheral functionality. Does not support general purpose I/O functionality. |

| DIO_4 | 22 | I/O | Digital | GPIO |

| DIO_5 | 23 | I/O | Digital | GPIO, high-drive capability |

| DIO_6 | 24 | I/O | Digital | GPIO, high-drive capability |

| DIO_7 | 25 | I/O | Digital | GPIO, high-drive capability |

| DIO_8 | 26 | I/O | Digital | GPIO |

| DIO_9 | 27 | I/O | Digital | GPIO |

| GND | 5 | — | — | GND |

| GND | 9 | — | — | GND |

| GND | 10 | — | — | GND |

| GND | 11 | — | — | GND |

| GND | 12 | — | — | GND |

| GND | 13 | — | — | GND |

| GND | 16 | — | — | GND |

| GND | 17 | — | — | GND |

| GND | 19 | — | — | GND |

| GND | 49-73 | — | — | GND |

7.3 Connections for Unused Pins and Modules

Table 7-2. Connections for Unused Pins

| PIN | I/O | TYPE |

DESCRIPTION |

|

|

NAME |

NO. |

|||

| NC | 6 | — | — | No Connect |

| nRESET | 4 | I | Digital | Reset, active low. Internal pullup resistor and internal 100 nF to VDDS_PU |

| RF | 18 | — | RF | 50 ohm RF port |

| JTAG_TCKC | 35 | I | Digital | JTAG_TCKC |

| JTAG_TMSC | 34 | I/O | Digital | JTAG_TMSC, high-drive capability |

| VDDS | 46 | — | Power | 1.8-V to 3.8-V main SIP supply |

| VDDS_PU | 47 | — | Power | Power to reset internal pullup resistor |

Specifications

8.1 Absolute Maximum Ratings

over operating free-air temperature range (unless otherwise noted)(1) (2)

|

|

MIN | MAX |

UNIT |

||

| VDDS(3) | Supply voltage | –0.3 | 4.1 | V | |

| Voltage on any digital pin(4) | –0.3 | VDDS + 0.3, max 4.1 | V | ||

| Vin | Voltage on ADC input | Voltage scaling enabled | –0.3 | VDDS |

V |

| Voltage scaling disabled, internal reference | –0.3 | 1.49 | |||

| Voltage scaling disabled, VDDS as reference | –0.3 | VDDS / 2.9 | |||

| 10 | dBm | ||||

| Tstg | Storage temperature | –40 | 150 | °C | |

- Operation outside the Absolute Maximum Ratings may cause permanent device damage. Absolute Maximum Ratings do not imply functional operation of the device at these or any other conditions beyond those listed under Recommended Operating Conditions. If used outside the Recommended Operating Conditions but within the Absolute Maximum Ratings, the device may not be fully functional, and this may affect device reliability, functionality, performance, and shorten the device lifetime

- All voltage values are with respect to ground, unless otherwise noted.

- VDDS_DCDC, VDDS2 and VDDS3 must be at the same potential as VDDS.

- Including analog capable DIOs.

8.2 ESD Ratings

| VALUE | UNIT | ||||

| VESD | Electrostatic discharge | Human body model (HBM), per ANSI/ESDA/JEDEC JS-001(1) | All pins | ±1000 | V |

| Charged device model (CDM), per ANSI/ESDA/JEDEC JS-002(2) | All pins | ±500 | V | ||

- JEDEC document JEP155 states that 500-V HBM allows safe manufacturing with a standard ESD control process.

- JEDEC document JEP157 states that 250-V CDM allows safe manufacturing with a standard ESD control process.

8.3 Recommended Operating Conditions

over operating free-air temperature range (unless otherwise noted)

|

|

MIN | MAX |

UNIT |

|

| Operating ambient temperature(1) (2) | –40 | 105 | °C | |

| Operating supply voltage (VDDS) | 1.8 | 3.8 | V | |

| Operating supply voltage (VDDS), boost mode | VDDR = 1.95 V +14 dBm RF output sub-1 GHz power amplifier | 2.1 | 3.8 | V |

| Rising supply voltage slew rate | 0 | 100 | mV/µs | |

| Falling supply voltage slew rate | 0 | 20 | mV/µs | |

(1) Operation at or near maximum operating temperature for extended durations will result in a reduction in lifetime.

(2) For thermal resistance characteristics refer to .

8.4 Power Supply and Modules

over operating free-air temperature range (unless otherwise noted)

|

PARAMETER |

MIN | TYP | MAX |

UNIT |

|

| VDDS Power-on-Reset (POR) threshold | 1.1 – 1.55 | V | |||

| VDDS Brown-out Detector (BOD) (1) | Rising threshold | 1.77 | V | ||

| VDDS Brown-out Detector (BOD), before initial boot (2) | Rising threshold | 1.70 | V | ||

| VDDS Brown-out Detector (BOD) (1) | Falling threshold | 1.75 | V | ||

(1) For boost mode (VDDR =1.95 V), TI drivers software initialization will trim VDDS BOD limits to maximum (approximately 2.0 V)

(2) Brown-out Detector is trimmed at initial boot, value is kept until device is reset by a POR reset or the RESET_N pin

8.5 Power Consumption – Power Modes

When measured on the CC1312PSIP-EM reference design with Tc = 25 °C, VDDS = 3.6 V with DC/DC enabled unless otherwise noted.

|

PARAMETER |

TEST CONDITIONS | TYP | UNIT | |

|

Core Current Consumption |

||||

| Icore | Reset | Reset. RESET_N pin asserted or VDDS below power-on-reset threshold (4) | 36 | µA |

| Shutdown | Shutdown. No clocks running, no retention | 150 | nA | |

| Standby with cache retention | RTC running, CPU, 80KB RAM and (partial) register retention. RCOSC_LF | 0.9 | µA | |

| RTC running, CPU, 80KB RAM and (partial) register retention XOSC_LF | 1.0 | |||

| Standby with cache retention | RTC running, CPU, 80KB RAM and (partial) register retention XOSC_LF | 2.8 | µA | |

| RTC running, CPU, 80KB RAM and (partial) register retention XOSC_LF | 2.9 | |||

| Idle | Supply Systems and RAM powered RCOSC_HF | 590 | µA | |

| Icore | Active | MCU running CoreMark at 48 MHz RCOSC_HF | 2.89 | mA |

| Peripheral Current Consumption | ||||

| Iperi | Peripheral power domain | Delta current with domain enabled | 82 | µA |

| Serial power domain | Delta current with domain enabled | 5.5 | ||

| RF Core | Delta current with power domain enabled, clock enabled, RF core idle | 179 | ||

| µDMA | Delta current with clock enabled, module is idle | 54 | ||

| Timers | Delta current with clock enabled, module is idle(3) | 68 | ||

| I2C | Delta current with clock enabled, module is idle | 8.2 | ||

| I2S | Delta current with clock enabled, module is idle | 22 | ||

| SSI | Delta current with clock enabled, module is idle(2) | 70 | ||

| UART | Delta current with clock enabled, module is idle(1) | 141 | ||

| CRYPTO (AES) | Delta current with clock enabled, module is idle | 21 | ||

| PKA | Delta current with clock enabled, module is idle | 71 | ||

| TRNG | Delta current with clock enabled, module is idle | 30 | ||

| Sensor Controller Engine Consumption | ||||

| ISCE | Active mode | 24 MHz, infinite loop | 808 | µA |

| Low-power mode | 2 MHz, infinite loop | 30.1 | ||

- Only one UART running

- Only one SSI running

- Only one GPTimer running

- CC1312PSIP integrates a 100 kΩ pull-up resistor on nRESET

8.6 Power Consumption – Radio Modes

When measured on the CC1312PSIP-EM reference design with Tc = 25 °C, VDDS = 3.6 V with DC/DC enabled unless otherwise noted.

Using boost mode (increasing VDDR up to 1.95 V), will increase system current by 15% (does not apply to TX +14 dBm setting where this current is already included).

Relevant Icore and Iperi currents are included in below numbers.

|

PARAMETER |

TEST CONDITIONS | TYP |

UNIT |

|

| Radio receive current, 868 MHz | 5.8 | mA | ||

| Radio transmit current Regular PA | 0 dBm output power setting 868 MHz | 9.4 | mA | |

| +10 dBm output power setting 868 MHz | 17.3 | mA | ||

| Radio transmit current Boost mode, regular PA | +14 dBm output power setting 868 MHz | 28.7 | mA | |

8.7 Nonvolatile (Flash) Memory Characteristics

Over operating free-air temperature range and VDDS = 3.0 V (unless otherwise noted)

| PARAMETER | TEST CONDITIONS | MIN | TYP | MAX |

UNIT |

| Flash sector size | 8 | KB | |||

| Supported flash erase cycles before failure, single-bank(1) (5) | 30 | k Cycles | |||

| Supported flash erase cycles before failure, single sector(2) | 60 | k Cycles | |||

| Maximum number of write operations per row before sector erase(3) | 83 | Write Operations | |||

| Flash retention | 105 °C | 11.4 | Years at 105°C | ||

| Flash sector erase current | Average delta current | 10.7 | mA | ||

| Flash sector erase time(4) | Zero cycles | 10 | ms | ||

| 30k cycles | 4000 | ms | |||

| Flash write current | Average delta current, 4 bytes at a time | 6.2 | mA | ||

| Flash write time(4) | 4 bytes at a time | 21.6 | µs | ||

- A full bank erase is counted as a single erase cycle on each sector.

- Up to 4 customer-designated sectors can be individually erased an additional 30k times beyond the baseline bank limitation of 30k cycles

- Each wordline is 2048 bits (or 256 bytes) wide. This limitation corresponds to sequential memory writes of 4 (3.1) bytes minimum per write over a whole wordline. If additional writes to the same wordline are required, a sector erase is required once the maximum number of write operations per row is reached.

- This number is dependent on Flash aging and increases over time and erase cycles

- Aborting flash during erase or program modes is not a safe operation.

8.8 Thermal Resistance Characteristics

| THERMAL METRIC | PACKAGE | UNIT | |

| MOT (SIP) | |||

| 73 PINS | |||

| RθJA | Junction-to-ambient thermal resistance | 48.7 | °C/W(1) |

| RθJC(top) | Junction-to-case (top) thermal resistance | 12.4 | °C/W(1) |

| RθJB | Junction-to-board thermal resistance | 32.2 | °C/W(1) |

| ψJT | Junction-to-top characterization parameter | 0.40 | °C/W(1) |

| ψJB | Junction-to-board characterization parameter | 32.0 | °C/W(1) |

(1) °C/W = degrees Celsius per watt.

8.9 RF Frequency Bands

Over operating free-air temperature range (unless otherwise noted).

| PARAMETER | MIN | TYP | MAX | UNIT |

| Frequency band | 863 | 930 | MHz |

8.10 861 MHz to 1054 MHz – Receive (RX)

When measured on the CC1312PSIP-EM reference design with Tc = 25 °C, VDDS = 3.0 V with DC/DC enabled and high power PA connected to VDDS unless otherwise noted.

All measurements are performed at the antenna input with a combined RX and TX path, except for high power PA which is measured at a dedicated antenna connection. All measurements are performed conducted.

|

PARAMETER |

TEST CONDITIONS | MIN | TYP | MAX | UNIT |

|

General Parameters |

|||||

| Digital channel filter programmable receive bandwidth | 4 | 4000 | kHz | ||

| Data rate step size | 1.5 | bps | |||

| Spurious emissions 25 MHz to 1 GHz | 868 MHz Conducted emissions measured according to ETSI EN 300 220 | < -57 | dBm | ||

| Spurious emissions 1 GHz to 13 GHz | < -47 | dBm | |||

| 802.15.4, 50 kbps, ±25 kHz deviation, 2-GFSK, 100 kHz RX Bandwidth | |||||

| Sensitivity | BER = 10–2, 868 MHz | –108 | dBm | ||

| Saturation limit | BER = 10–2, 868 MHz | 10 | dBm | ||

| Selectivity, ±200 kHz | BER = 10–2, 868 MHz(1) | 44 | dB | ||

| Selectivity, ±400 kHz | BER = 10–2, 868 MHz(1) | 48 | dB | ||

| Blocking, ±1 MHz | BER = 10–2, 868 MHz(1) | 57 | dB | ||

| Blocking, ±2 MHz | BER = 10–2, 868 MHz(1) | 62 | dB | ||

| Blocking, ±5 MHz | BER = 10–2, 868 MHz(1) | 68 | dB | ||

| Blocking, ±10 MHz | BER = 10–2, 868 MHz(1) | 76 | dB | ||

| Image rejection (image compensation enabled) | BER = 10–2, 868 MHz(1) | 39 | dB | ||

| RSSI dynamic range | Starting from the sensitivity limit | 95 | dB | ||

| RSSI accuracy | Starting from the sensitivity limit across the given dynamic range | ±3 | dB | ||

| 802.15.4, 100 kbps, ±25 kHz deviation, 2-GFSK, 137 kHz RX Bandwidth | |||||

| Sensitivity 100 kbps | 868 MHz, 1% PER, 127 byte payload | -101 | dBm | ||

| Selectivity, ±200 kHz | 868 MHz, 1% PER, 127 byte payload. Wanted signal at -96 dBm | 38 | dB | ||

| Selectivity, ±400 kHz | 868 MHz, 1% PER, 127 byte payload. Wanted signal at -96 dBm | 45 | dB | ||

| Co-channel rejection | 868 MHz, 1% PER, 127 byte payload. Wanted signal at -79 dBm | -9 | dB | ||

| 802.15.4, 200 kbps, ±50 kHz deviation, 2-GFSK, 311 kHz RX Bandwidth | |||||

| Sensitivity | BER = 10–2, 868 MHz | –103 | dBm | ||

| Sensitivity | BER = 10–2, 915 MHz | –103 | dBm | ||

| Selectivity, ±400 kHz | BER = 10–2, 915 MHz. Wanted signal 3 dB above sensitivity limit. | 41 | dB | ||

| Selectivity, ±800 kHz | BER = 10–2, 915 MHz. Wanted signal 3 dB above sensitivity limit. | 47 | dB | ||

| Blocking, ±2 MHz | BER = 10–2, 915 MHz. Wanted signal 3 dB above sensitivity limit. | 55 | dB | ||

| Blocking, ±10 MHz | BER = 10–2, 915 MHz. Wanted signal 3 dB above sensitivity limit. | 67 | dB | ||

| 802.15.4, 500 kbps, ±190 kHz deviation, 2-GFSK, 655 kHz RX Bandwidth | |||||

| Sensitivity 500 kbps | 916 MHz, 1% PER, 127 byte payload | -90 | dBm | ||

| Selectivity, ±1 MHz | 916 MHz, 1% PER, 127 byte payload. Wanted signal at -88 dBm | 11 | dB | ||

| Selectivity, ±2 MHz | 916 MHz, 1% PER, 127 byte payload. Wanted signal at -88 dBm | 43 | dB | ||

| Co-channel rejection | 916 MHz, 1% PER, 127 byte payload. Wanted signal at -71 dBm | -9 | dB | ||

|

SimpleLink™ Long Range 2.5 kbps or 5 kbps (20 ksym/s, 2-GFSK, ±5 kHz Deviation, FEC (Half Rate), DSSS = 1:2 or 1:4, 34 kHz RX Bandwidth |

|||||

| Sensitivity | 2.5 kbps, BER = 10–2, 868 MHz | -119 | dBm | ||

| Sensitivity | 5 kbps, BER = 10–2, 868 MHz | -117 | dBm | ||

| Saturation limit | 2.5 kbps, BER = 10–2, 868 MHz | 10 | dBm | ||

| Selectivity, ±100 kHz | 2.5 kbps, BER = 10–2, 868 MHz(1) | 49 | dB | ||

| Selectivity, ±200 kHz | 2.5 kbps, BER = 10–2, 868 MHz(1) | 50 | dB | ||

| Selectivity, ±300 kHz | 2.5 kbps, BER = 10–2, 868 MHz(1) | 51 | dB | ||

| Blocking, ±1 MHz | 2.5 kbps, BER = 10–2, 868 MHz(1) | 63 | dB | ||

| Blocking, ±2 MHz | 2.5 kbps, BER = 10–2, 868 MHz(1) | 68 | dB | ||

| Blocking, ±5 MHz | 2.5 kbps, BER = 10–2, 868 MHz(1) | 78 | dB | ||

| Blocking, ±10 MHz | 2.5 kbps, BER = 10–2, 868 MHz(1) | 87 | dB | ||

When measured on the CC1312PSIP-EM reference design with Tc = 25 °C, VDDS = 3.0 V with DC/DC enabled and high power PA connected to VDDS unless otherwise noted.

All measurements are performed at the antenna input with a combined RX and TX path, except for high power PA which is measured at a dedicated antenna connection. All measurements are performed conducted.

| PARAMETER | TEST CONDITIONS | MIN TYP MAX | UNIT |

| Image rejection (image compensation enabled) | 2.5 kbps, BER = 10–2, 868 MHz(1) | 45 | dB |

| RSSI dynamic range | Starting from the sensitivity limit | 97 | dB |

| RSSI accuracy | Starting from the sensitivity limit across the given dynamic range | ±3 | dB |

|

Wireless M-Bus |

|||

| Receiver sensitivity, wM-BUS C-mode, 100 kbps ±45 kHz | Receiver Bandwidth 236 kHz, BER 1% | -104 | dBm |

| Receiver sensitivity, wM-BUS T-mode, 100 kbps ±50 kHz | Receiver Bandwidth 236 kHz, BER 1% | -103 | dBm |

| Receiver sensitivity, wM-BUS S2-mode, 32.768 kbps ±50 kHz | Receiver Bandwidth 196 kHz, BER 1% | -109 | dBm |

| Receiver sensitivity, wM-BUS S1-mode, 32.768 kbps ±50 kHz | Receiver Bandwidth 311 kHz, BER 1% | -107 | dBm |

|

OOK, 4.8 kbps, 39 kHz RX Bandwidth |

|||

| Sensitivity | BER = 10–2, 868 MHz | -112 | dBm |

| Sensitivity | BER = 10–2, 915 MHz | -112 | dBm |

|

Narrowband, 9.6 kbps ±2.4 kHz deviation, 2-GFSK, 868 MHz, 17.1 kHz RX Bandwidth |

|||

| Sensitivity | 1% BER | -118 | dBm |

| Adjacent Channel Rejection | 1% BER. Wanted signal 3 dB above the ETSI reference sensitivity limit (-104.6 dBm). Interferer ±20 kHz | 39 | dB |

| Alternate Channel Rejection | 1% BER. Wanted signal 3 dB above the ETSI reference sensitivity limit (-104.6 dBm). Interferer ±40 kHz | 40 | dB |

| Blocking, ±1 MHz | 1% BER. Wanted signal 3 dB above the ETSI reference sensitivity limit (-104.6 dBm). | 65 | dB |

| Blocking, ±2 MHz | 69 | dB | |

| Blocking, ±10 MHz | 85 | dB | |

|

1 Mbps, ±350 kHz deviation, 2-GFSK, 2.2 MHz RX Bandwidth |

|||

| Sensitivity | BER = 10–2, 868 MHz | -94 | dBm |

| Sensitivity | BER = 10–2, 915 MHz | -93 | dBm |

| Blocking, +2 MHz | BER = 10–2, 915 MHz. Wanted signal 3 dB above sensitivity limit. | 44 | dB |

| Blocking, -2 MHz | BER = 10–2, 915 MHz. Wanted signal 3 dB above sensitivity limit. | 27 | dB |

| Blocking, +10 MHz | BER = 10–2, 915 MHz. Wanted signal 3 dB above sensitivity limit. | 59 | dB |

| Blocking, -10 MHz | BER = 10–2, 915 MHz. Wanted signal 3 dB above sensitivity limit. | 54 | dB |

|

Wi-SUN, 2-GFSK |

|||

| Sensitivity | 50 kbps, ±12.5 kHz deviation, 2-GFSK, 866.6 MHz, 68 kHz RX BW, 10% PER, 250 byte payload | -104 | dBm |

| Selectivity, -100 kHz, 50 kbps, ±12.5 kHz deviation, 2-GFSK, 866.6 MHz | 50 kbps, ±12.5 kHz deviation, 2-GFSK, 68 kHz RX Bandwidth, 866.6 MHz, 10% PER, 250 byte payload. Wanted signal 3 dB above sensitivity level | 32 | dB |

| Selectivity, +100 kHz, 50 kbps, ±12.5 kHz deviation, 2-GFSK, 866.6 MHz | 33 | dB | |

| Selectivity, ±100 kHz, 50 kbps, ±12.5 kHz deviation, 2-GFSK, 866.6 MHz | 30 | dB | |

| Selectivity, -200 kHz, 50 kbps, ±12.5 kHz deviation, 2-GFSK, 866.6 MHz | 36 | dB | |

| Selectivity, +200 kHz, 50 kbps, ±12.5 kHz deviation, 2-GFSK, 866.6 MHz | 38 | dB | |

| Selectivity, ±200 kHz, 50 kbps, ±12.5 kHz deviation, 2-GFSK, 866.6 MHz | 37 | dB | |

| Sensitivity | 50 kbps, ±25 kHz deviation, 2-GFSK, 98 kHz RX Bandwidth,918.2 MHz, 10% PER, 250 byte payload | -104 | dBm |

When measured on the CC1312PSIP-EM reference design with Tc = 25 °C, VDDS = 3.0 V with DC/DC enabled and high power PA connected to VDDS unless otherwise noted. All measurements are performed at the antenna input with a combined RX and TX path, except for high power PA which is measured at a dedicated antenna connection. All measurements are performed conducted.

| PARAMETER | TEST CONDITIONS | MIN TYP MAX |

UNIT |

| Selectivity, -200 kHz, 50 kbps, ±25 kHz deviation, 2-GFSK, 918.2 MHz | 50 kbps, ±25 kHz deviation, 2-GFSK, 98 kHz RX Bandwidth, 918.2 MHz, 10% PER, 250 byte payload. Wanted signal 3 dB above sensitivity level | 34 | dB |

| Selectivity, +200 kHz, 50 kbps, ±25 kHz deviation, 2-GFSK, 918.2 MHz | 35 | dB | |

| Selectivity, ±200 kHz, 50 kbps, ±25 kHz deviation, 2-GFSK, 918.2 MHz | 34 | dB | |

| Selectivity, -400 kHz, 50 kbps, ±25 kHz deviation, 2-GFSK, 918.2 MHz | 40 | dB | |

| Selectivity, +400 kHz, 50 kbps, ±25 kHz deviation, 2-GFSK, 918.2 MHz | 40 | dB | |

| Selectivity, ±400 kHz, 50 kbps, ±25 kHz deviation, 2-GFSK, 918.2 MHz | 40 | dB | |

| Sensitivity | 100 kbps, ±25 kHz deviation, 2-GFSK, 866.6 MHz, 135 kHz RX BW, 10% PER, 250 byte payload | -102 | dBm |

| Sensitivity | 100 kbps, ±25 kHz deviation, 2-GFSK, 918.2 MHz, 135 kHz RX BW, 10% PER, 250 byte payload | -101 | dBm |

| Selectivity, -200 kHz, 100 kbps, ±25 kHz deviation, 2-GFSK, 866.6 MHz | 100 kbps, ±25 kHz deviation, 2-GFSK, 135 kHz RX Bandwidth, 866.6 MHz, 10% PER, 250 byte payload. Wanted signal 3 dB above sensitivity level | 37 | dB |

| Selectivity, +200 kHz, 100 kbps, ±25 kHz deviation, 2-GFSK, 866.6 MHz | 38 | dB | |

| Selectivity, ±200 kHz, 100 kbps, ±25 kHz deviation, 2-GFSK, 866.6 MHz | 37 | dB | |

| Selectivity, -400 kHz, 100 kbps, ±25 kHz deviation, 2-GFSK, 866.6 MHz | 45 | dB | |

| Selectivity, +400 kHz, 100 kbps, ±25 kHz deviation, 2-GFSK, 866.6 MHz | 45 | dB | |

| Selectivity, ±400 kHz, 100 kbps, ±25 kHz deviation, 2-GFSK, 866.6 MHz | 45 | dB | |

| Sensitivity | 100 kbps, ±50 kHz deviation, 2-GFSK, 920.9 MHz, 196 kHz RX BW, 10% PER, 250 byte payload | -100 | dBm |

| Selectivity, -400 kHz, 100 kbps, ±50 kHz deviation, 2-GFSK, 920.9 MHz | 100 kbps, ±50 kHz deviation, 2-GFSK, 196 kHz RX Bandwidth, 920.9 MHz, 10% PER, 250 byte payload. Wanted signal 3 dB above sensitivity level | 40 | dB |

| Selectivity, +400 kHz, 100 kbps, ±50 kHz deviation, 2-GFSK, 920.9 MHz | 40 | dB | |

| Selectivity, ±400 kHz, 100 kbps, ±50 kHz deviation, 2-GFSK, 920.9 MHz | 40 | dB | |

| Selectivity, -800 kHz, 100 kbps, ±50 kHz deviation, 2-GFSK, 920.9 MHz | 46 | dB | |

| Selectivity, +800 kHz, 100 kbps, ±50 kHz deviation, 2-GFSK, 920.9 MHz | 52 | dB | |

| Selectivity, ±800 kHz, 100 kbps, ±50 kHz deviation, 2-GFSK, 920.9 MHz | 48 | dB | |

| Sensitivity | 150 kbps, ±37.5 kHz deviation, 2-GFSK, 918.4 MHz, 273 kHz RX BW, 10% PER, 250 byte payload | -96 | dBm |

| Selectivity, -400 kHz, 150 kbps, ±37.5 kHz deviation, 2-GFSK, 918.4 MHz | 150 kbps, ±37.5 kHz deviation, 2-GFSK, 273 kHz RX Bandwidth, 918.4 MHz, 10% PER, 250 byte payload. Wanted signal 3 dB above sensitivity level | 41 | dB |

| Selectivity, +400 kHz, 150 kbps, ±37.5 kHz deviation, 2-GFSK, 918.4 MHz | 42 | dB | |

| Selectivity, -800 kHz, 150 kbps, ±37.5 kHz deviation, 2-GFSK, 918.4 MHz | 46 | dB | |

| Selectivity, +800 kHz, 150 kbps, ±37.5 kHz deviation, 2-GFSK, 918.4 MHz | 49 | dB | |

| Sensitivity | -96 | dBm |

When measured on the CC1312PSIP-EM reference design with Tc = 25 °C, VDDS = 3.0 V with DC/DC enabled and high power PA connected to VDDS unless otherwise noted.

All measurements are performed at the antenna input with a combined RX and TX path, except for high power PA which is measured at a dedicated antenna connection. All measurements are performed conducted.

| PARAMETER | TEST CONDITIONS | MIN TYP MAX |

UNIT |

| Selectivity, -400 kHz, 150 kbps, ±37.5 kHz deviation, 2-GFSK, 920.9 MHz | 150 kbps, ±37.5 kHz deviation, 2-GFSK, 273 kHz RX Bandwidth, 920.9 MHz, 10% PER, 250 byte payload. Wanted signal 3 dB above sensitivity level | 40 | dB |

| Selectivity, +400 kHz, 150 kbps, ±37.5 kHz deviation, 2-GFSK, 920.9 MHz | 42 | dB | |

| Selectivity, ±400 kHz, 150 kbps, ±37.5 kHz deviation, 2-GFSK, 920.9 MHz | 40 | dB | |

| Selectivity, -800 kHz, 150 kbps, ±37.5 kHz deviation, 2-GFSK, 920.9 MHz | 46 | dB | |

| Selectivity, +800 kHz, 150 kbps, ±37.5 kHz deviation, 2-GFSK, 920.9 MHz | 49 | dB | |

| Selectivity, ±800 kHz, 150 kbps, ±37.5 kHz deviation, 2-GFSK, 920.9 MHz | 46 | dB | |

| Sensitivity | 200 kbps, ±50 kHz deviation, 2-GFSK, 918.4 MHz, 273 kHz RX BW, 10% PER, 250 byte payload | -97 | dBm |

| Selectivity, -400 kHz, 200 kbps, ±50 kHz deviation, 2-GFSK, 918.4 MHz | 200 kbps, ±50 kHz deviation, 2-GFSK, 273 kHz RX Bandwidth, 918.4 MHz, 10% PER, 250 byte payload. Wanted signal 3 dB above sensitivity level | 40 | dB |

| Selectivity, +400 kHz, 200 kbps, ±50 kHz deviation, 2-GFSK, 918.4 MHz | 43 | dB | |

| Selectivity, ±400 kHz, 200 kbps, ±50 kHz deviation, 2-GFSK, 918.4 MHz | 41 | dB | |

| Selectivity, -800 kHz, 200 kbps, ±50 kHz deviation, 2-GFSK, 918.4 MHz | 46 | dB | |

| Selectivity, +800 kHz, 200 kbps, ±50 kHz deviation, 2-GFSK, 918.4 MHz | 50 | dB | |

| Selectivity, ±800 kHz, 200 kbps, ±50 kHz deviation, 2-GFSK, 918.4 MHz | 48 | dB | |

| Sensitivity | 200 kbps, ±100 kHz deviation, 2-GFSK, 920.8 MHz, 273 kHz RX BW, 10% PER, 250 byte payload | -96 | dBm |

| Selectivity, -600 kHz, 200 kbps, ±100 kHz deviation, 2-GFSK, 920.8 MHz | 200 kbps, ±100 kHz deviation, 2-GFSK, 273 kHz RX Bandwidth, 920.8 MHz,, 10% PER, 250 byte payload. Wanted signal 3 dB above sensitivity level | 43 | dB |

| Selectivity, +600 kHz, 200 kbps, ±100 kHz deviation, 2-GFSK, 920.8 MHz | 47 | dB | |

| Selectivity, ±600 kHz, 200 kbps, ±100 kHz deviation, 2-GFSK, 920.8 MHz | 44 | dB | |

| Selectivity, -1200 kHz, 200 kbps, ±100 kHz deviation, 2-GFSK, 920.8 MHz | 51 | dB | |

| Selectivity, +1200 kHz, 200 kbps, ±100 kHz deviation, 2-GFSK, 920.8 MHz | 54 | dB | |

| Selectivity, ±1200 kHz, 200 kbps, ±100 kHz deviation, 2-GFSK, 920.8 MHz | 51 | dB | |

| Sensitivity | 300 kbps, ±75 kHz deviation, 2-GFSK, 917.6 MHz, 576 kHz RX BW, 10% PER, 250 byte payload | -94 | dBm |

| Selectivity, -600 kHz, 300 kbps, ±75 kHz deviation, 2-GFSK, 917.6 MHz | 300 kbps, ±75 kHz deviation, 2-GFSK, 576 kHz RX Bandwidth, 917.6 MHz,, 10% PER, 250 byte payload. Wanted signal 3 dB above sensitivity level | 27 | dB |

| Selectivity, +600 kHz, 300 kbps, ±75 kHz deviation, 2-GFSK, 917.6 MHz | 45 | dB | |

| Selectivity, ±600 kHz, 300 kbps, ±75 kHz deviation, 2-GFSK, 917.6 MHz | 35 | dB | |

| Selectivity, -1200 kHz, 300 kbps, ±75 kHz deviation, 2-GFSK, 917.6 MHz | 46 | dB | |

| Selectivity, +1200 kHz, 300 kbps, ±75 kHz deviation, 2-GFSK, 920.8 MHz | 50 | dB | |

| Selectivity, ±1200 kHz, 300 kbps, ±75 kHz deviation, 2-GFSK, 917.6 MHz | 48 | dB | |

|

WB-DSSS, 240/120/60/30 kbps (480 ksym/s, 2-GFSK, ±195 kHz Deviation, FEC (Half Rate), DSSS = 1/2/4/8, 622 kHz RX BW) |

|||

| Sensitivity | 240 kbps, DSSS = 1, BER = 10–2, 915 MHz | -101 | dBm |

| Sensitivity | 120 kbps, DSSS = 2, BER = 10–2, 915 MHz | -103 | dBm |

When measured on the CC1312PSIP-EM reference design with Tc = 25 °C, VDDS = 3.0 V with DC/DC enabled and high power PA connected to VDDS unless otherwise noted.

All measurements are performed at the antenna input with a combined RX and TX path, except for high power PA which is measured at a dedicated antenna connection. All measurements are performed conducted.

| PARAMETER | TEST CONDITIONS | MIN TYP MAX |

UNIT |

| Sensitivity | 60 kbps, DSSS = 4, BER = 10–2, 915 MHz | -105 | dBm |

| Sensitivity | 30 kbps, DSSS = 8, BER = 10–2, 915 MHz | -106 | dBm |

| Blocking ±1 MHz | 240 kbps, DSSS = 1, BER = 10–2, 915 MHz | 49 | dB |

| Blocking ±2 MHz | 240 kbps, DSSS = 1, BER = 10–2, 915 MHz | 53 | dB |

| Blocking ±5 MHz | 240 kbps, DSSS = 1, BER = 10–2, 915 MHz | 58 | dB |

| Blocking ±10 MHz | 240 kbps, DSSS = 1, BER = 10–2, 915 MHz | 67 | dB |

(1) Wanted signal 3 dB above the reference sensitivity limit according to ETSI EN 300 220 v. 3.1.1

8.11 861 MHz to 1054 MHz – Transmit (TX)

Measured on the CC1312PSIP-EM reference design with Tc = 25 °C, VDDS = 3.0 V with DC/DC enabled and high power PA connected to VDDS using 2-GFSK, 50 kbps, ±25 kHz deviation unless otherwise noted. All measurements are performed at the antenna input with a combined RX and TX path, except for high power PA which is measured at a dedicated antenna connection. All measurements are performed conducted. (1)c

|

PARAMETER |

TEST CONDITIONS | MIN | TYP | MAX |

UNIT |

|

|

General parameters |

||||||

| Max output power, boost mode Regular PA | VDDR = 1.95 V Minimum supply voltage (VDDS ) for boost mode is 2.1 V 915 MHz | 14 | dBm | |||

| Max output power, Regular PA | 868 MHz and 915 MHz | 12.4 | dBm | |||

| Output power programmable range Regular PA | 868 MHz and 915 MHz | 34 | dB | |||

| Output power variation over temperature Regular PA | +10 dBm setting Over recommended temperature operating range | ±2 | dB | |||

| Output power variation over temperature Boost mode, regular PA | +14 dBm setting Over recommended temperature operating range | ±1.5 | dB | |||

|

Spurious emissions and harmonics |

||||||

| Spurious emissions (excluding harmonics) Regular PA (2) | 30 MHz to 1 GHz | +14 dBm setting ETSI restricted bands | < -54 | dBm | ||

| +14 dBm setting ETSI outside restricted bands | < -36 | dBm | ||||

| 1 GHz to 12.75 GHz (outside ETSI restricted bands) | +14 dBm setting measured in 1 MHz bandwidth (ETSI) | < -30 | -35 | dBm | ||

| Spurious emissions out- of-band Regular PA, 915 MHz (2) | 30 MHz to 88 MHz (within FCC restricted bands) | +14 dBm setting | < -56 | dBm | ||

| 88 MHz to 216 MHz (within FCC restricted bands) | +14 dBm setting | < -52 | dBm | |||

| 216 MHz to 960 MHz (within FCC restricted bands) | +14 dBm setting | < -50 | dBm | |||

| 960 MHz to 2390 MHz and above 2483.5 MHz (within FCC restricted band) | +14 dBm setting | <-42 | dBm | |||

| 1 GHz to 12.75 GHz (outside FCC restricted bands) | +14 dBm setting | < -40 | -44 | dBm | ||

| Spurious emissions out- of-band Regular PA, 920.6/928 MHz (2) | Below 710 MHz (ARIB T-108) | +14 dBm setting | < -36 | dBm | ||

| 710 MHz to 900 MHz (ARIB T-108) | +14 dBm setting | < -55 | dBm | |||

| 900 MHz to 915 MHz (ARIB T-108) | +14 dBm setting | < -55 | dBm | |||

| 930 MHz to 1000 MHz (ARIB T-108) | +14 dBm setting | < -55 | dBm | |||

| 1000 MHz to 1215 MHz (ARIB T-108) | +14 dBm setting | < -45 | dBm | |||

| Above 1215 MHz (ARIB T-108) | +14 dBm setting | < -30 | dBm | |||

| Harmonics Regular PA | Second harmonic | +14 dBm setting, 868 MHz | < -30 | dBm | ||

| +14 dBm setting, 915 MHz | < -30 | |||||

| Third harmonic | +14 dBm setting, 868 MHz | < -30 | dBm | |||

| +14 dBm setting, 915 MHz | < -42 | |||||

| Fourth harmonic | +14 dBm setting, 868 MHz | < -30 | dBm | |||

| +14 dBm setting, 915 MHz | < -30 | |||||

| Fifth harmonic | +14 dBm setting, 868 MHz | < -30 | dBm | |||

| +14 dBm setting, 915 MHz | < -42 | |||||

Measured on the CC1312PSIP-EM reference design with Tc = 25 °C, VDDS = 3.0 V with DC/DC enabled and high power PA connected to VDDS using 2-GFSK, 50 kbps, ±25 kHz deviation unless otherwise noted. All measurements are performed at the antenna input with a combined RX and TX path, except for high power PA which is measured at a dedicated antenna connection. All measurements are performed conducted.(1)

| PARAMETER | TEST CONDITIONS | MIN TYP MAX |

UNIT |

|

|

Adjacent Channel Power |

||||

| Adjacent channel power, regular 14 dBm PA | Adjacent channel, 20 kHz offset. 9.6 kbps, h=0.5 | 12.5 dBm setting. 868.3 MHz. 14 kHz channel BW | -24 | dBm |

| Alternate channel power, regular 14 dBm PA | Alternate channel, 40 kHz offset. 9.6 kbps, h=0.5 | 12.5 dBm setting. 868.3 MHz. 14 kHz channel BW | -31 | dBm |

(1) Some combinations of frequency, data rate and modulation format requires use of external crystal load capacitors for regulatory compliance. More details can be found in the device errata.

(2) Suitable for systems targeting compliance with EN 300 220, EN 303 131, EN 303 204, FCC CFR47 Part 15, ARIB STD-T108.

8.12 861 MHz to 1054 MHz – PLL Phase Noise Wideband Mode

When measured on the reference design with Tc = 25 °C, VDDS = 3.0 V.

| PARAMETER | TEST CONDITIONS | MIN | TYP | MAX |

UNIT |

| Phase noise in the 868- and 915-MHz bands 20 kHz PLL loop bandwidth | ±10 kHz offset | –74 | dBc/Hz | ||

| ±100 kHz offset | –97 | dBc/Hz | |||

| ±200 kHz offset | –107 | dBc/Hz | |||

| ±400 kHz offset | –113 | dBc/Hz | |||

| ±1000 kHz offset | –120 | dBc/Hz | |||

| ±2000 kHz offset | –127 | dBc/Hz | |||

| ±10000 kHz offset | –141 | dBc/Hz | |||

8.13 861 MHz to 1054 MHz – PLL Phase Noise Narrowband Mode

When measured on the reference design with Tc = 25 °C, VDDS = 3.0 V.

| PARAMETER | TEST CONDITIONS | MIN | TYP | MAX |

UNIT |

| Phase noise in the 868- and 915-MHz bands 150 kHz PLL loop band with | ±10 kHz offset | –93 | dBc/Hz | ||

| ±100 kHz offset | –93 | dBc/Hz | |||

| ±200 kHz offset | –95 | dBc/Hz | |||

| ±400 kHz offset | –104 | dBc/Hz | |||

| ±1000 kHz offset | –121 | dBc/Hz | |||

| ±2000 kHz offset | –130 | dBc/Hz | |||

| ±10000 kHz offset | –140 | dBc/Hz | |||

8.14 Timing and Switching Characteristics

8.14.1 Reset Timing

| PARAMETER | MIN | TYP | MAX |

UNIT |

| RESET_N low duration | 1 | µs | ||

8.14.2 Wakeup Timing

Measured over operating free-air temperature with VDDS = 3.0 V (unless otherwise noted). The times listed here do not include software overhead.

| PARAMETER | TEST CONDITIONS | MIN | TYP | MAX | UNIT |

| MCU, Reset to Active(1) | 850 – 4000 | µs | |||

| MCU, Shutdown to Active(1) | 850 – 4000 | µs | |||

| MCU, Standby to Active | 165 | µs | |||

| MCU, Active to Standby | 39 | µs | |||

Measured over operating free-air temperature with VDDS = 3.0 V (unless otherwise noted). The times listed here do not include software overhead.

| PARAMETER | TEST CONDITIONS | MIN TYP MAX |

UNIT |

| MCU, Idle to Active | 15 | µs |

(1) The wakeup time is dependent on remaining charge on VDDR capacitor when starting the device, and thus how long the device has been in Reset or Shutdown before starting up again. The wake up time increases with a higher capacitor value.

8.14.3 Clock Specifications

8.14.3.1 48 MHz Crystal Oscillator (XOSC_HF) and RF frequency accuracy

The module contains a 48 MHz crystal that is connected to the oscillator. During the production test of the module, the internal capacitor array loading the crystal is adjusted to minimize the crystal frequency error. The production test is also minimizing the RF frequency error at room temperature by adjusting the RF frequency word (PLL). This initial correction of the RF frequency is used in software (if enabled) to compensate the RF frequency based on the estimated temperature drift of the crystal. Measured on a Texas Instruments reference design with Tc = 25 °C, VDDS = 3.0 V, unless otherwise noted.

|

|

PARAMETER | MIN | TYP | MAX |

UNIT |

| Crystal frequency | 48 | MHz | |||

| Crystal oscillator start-up time(2) | 200 | µs | |||

| 48 MHz initial frequency accuracy at 25° | -5 | 2 | 5 | ppm | |

| 48 MHz frequency stability, temperature drift -40° to 105° | -16 | 18 | ppm | ||

| Crystal aging, 5 years | -2 | 2 | ppm | ||

| Crystal aging, 10 years | -4 | 2 | ppm | ||

| RF Frequency accuracy including internal software compensated temperature drift, excluding aging, -40° to 65°. Based on estimated crystal drift across temperature from the manufacturer’s crystal specification. | -10 | 10 | ppm | ||

- Probing or otherwise stopping the crystal while the DC/DC converter is enabled may cause permanent damage to the device.

- Start-up time using the TI-provided power driver. Start-up time may increase if driver is not used.

8.14.3.2 48 MHz RC Oscillator (RCOSC_HF)

Measured on a Texas Instruments reference design with Tc = 25 °C, VDDS = 3.0 V, unless otherwise noted.

| MIN | TYP | MAX |

UNIT |

|

| Frequency | 48 | MHz | ||

| Uncalibrated frequency accuracy | ±1 | % | ||

| Calibrated frequency accuracy(1) | ±0.25 | % | ||

| Start-up time | 5 | µs | ||

- Accuracy relative to the calibration source (XOSC_HF)

8.14.3.3 2 MHz RC Oscillator (RCOSC_MF)

Measured on a Texas Instruments reference design with Tc = 25 °C, VDDS = 3.0 V, unless otherwise noted.

| MIN | TYP | MAX | UNIT | |

| Calibrated frequency | 2 | MHz | ||

| Start-up time | 5 | µs | ||

8.14.3.4 32.768 kHz Crystal Oscillator (XOSC_LF) and RTC accuracy

The module contains a 32 kHz crystal that is connected to the oscillator. During the production test of the module, the RTC (Real Time Clock) derived from the 32 kHz crystal oscillator is calibrated at roome tempertaure. This is done to minimize the RTC error caused by the initial error of the 32 kHz crystal. This initial correction of the RTC is used in software (if enabled) to compensate the RTC based on the estimated temperature drift of the crystal. Measured on a Texas Instruments reference design with Tc = 25 °C, VDDS = 3.0 V, unless otherwise noted.

|

|

MIN | TYP | MAX |

UNIT |

|

| Crystal frequency | 32.768 | kHz | |||

| Initial frequency accuracy at 25° | -20 | 20 | ppm | ||

| 32kHz crystal aging, first year | -3 | 3 | ppm | ||

| Real Time Clock (RTC) accuracy using temperature compensation for the 32kHz xtal (if enabled in software), excluding aging, -40° to 105° degrees. Based on estimated crystal drift across temperature from the manufacturer’s crystal specification. | -100 | 50 | ppm | ||

| Real Time Clock (RTC) accuracy using temperature compensation for the 32kHz xtal (if enabled in software), excluding aging, -40° to 65° degrees. Based on estimated crystal drift across temperature from the manufacturer’s crystal specification. | -50 | 50 | ppm | ||

8.14.3.5 32 kHz RC Oscillator (RCOSC_LF)

Measured on a Texas Instruments reference design with Tc = 25 °C, VDDS = 3.0 V, unless otherwise noted.

| MIN | TYP | MAX |

UNIT |

||

| Frequency | 32.8 | kHz | |||

| Calibrated RTC variation(1) |

Calibrated periodically against XOSC_HF(2) | ±600(3) | ppm | ||

| Temperature coefficient | 50 | ppm/°C | |||

- When using RCOSC_LF as source for the low frequency system clock (SCLK_LF), the accuracy of the SCLK_LF-derived Real Time Clock (RTC) can be improved by measuring RCOSC_LF relative to XOSC_HF and compensating for the RTC tick speed. This functionality is available through the TI-provided Power driver.

- TI driver software calibrates the RTC every time XOSC_HF is enabled.

- Some device’s variation can exceed 1000 ppm. Further calibration will not improve variation.

8.14.4 Synchronous Serial Interface (SSI) Characteristics

8.14.4.1.1 Synchronous Serial Interface (SSI) Characteristics over operating free-air temperature range (unless otherwise noted)

8.14.4.1.1 Synchronous Serial Interface (SSI) Characteristics over operating free-air temperature range (unless otherwise noted)

| PARAMETER NO. | PARAMETER | MIN | TYP | MAX | UNIT | |

| S1 | tclk_per | SSIClk cycle time | 12 | 65024 | System Clocks (2) | |

| S2(1) | tclk_high | SSIClk high time | 0.5 | tclk_per | ||

| S3(1) | tclk_low | SSIClk low time | 0.5 | tclk_per | ||

- Refer to SSI timing diagrams , and .

- When using the TI-provided Power driver, the SSI system clock is always 48 MHz.

8.14.5 UART

8.14.5.1 UART Characteristics

over operating free-air temperature range (unless otherwise noted)

| PARAMETER | MIN | TYP | MAX | UNIT |

| UART rate | 3 | MBaud | ||

8.15 Peripheral Characteristics

8.15.1 ADC

8.15.1.1 Analog-to-Digital Converter (ADC) Characteristics

Tc = 25 °C, VDDS = 3.0 V and voltage scaling enabled, unless otherwise noted. (1)

Performance numbers require use of offset and gain adjustments in software by TI-provided ADC drivers.

| PARAMETER | TEST CONDITIONS | MIN | TYP | MAX |

UNIT |

|

| Input voltage range | 0 | VDDS | V | |||

| Resolution | 12 | Bits | ||||

| Sample Rate | 200 | ksps | ||||

| Offset | Internal 4.3 V equivalent reference(2) | ±2 | LSB | |||

| Gain error | Internal 4.3 V equivalent reference(2) | ±7 | LSB | |||

| DNL(4) | Differential nonlinearity | >–1 | LSB | |||

| INL | Integral nonlinearity | ±4 | LSB | |||

| ENOB | Effective number of bits | Internal 4.3 V equivalent reference(2), 200 kSamples/s, 9.6 kHz input tone |

9.8 | Bits | ||

| Internal 4.3 V equivalent reference(2), 200 kSamples/s, 9.6 kHz input tone, DC/DC enabled |

9.8 | |||||

| VDDS as reference, 200 kSamples/s, 9.6 kHz input tone | 10.1 | |||||

| Internal reference, voltage scaling disabled, 32 samples average, 200 kSamples/s, 300 Hz input tone |

11.1 | |||||

| Internal reference, voltage scaling disabled, 14-bit mode, 200 kSamples/s, 600 Hz input tone (5) | 11.3 | |||||

| Internal reference, voltage scaling disabled, 15-bit mode, 200 kSamples/s, 150 Hz input tone (5) | 11.6 | |||||

| THD | Total harmonic distortion | Internal 4.3 V equivalent reference(2), 200 kSamples/s, 9.6 kHz input tone | –65 | dB | ||

| VDDS as reference, 200 kSamples/s, 9.6 kHz input tone | –70 | |||||

| Internal reference, voltage scaling disabled, 32 samples average, 200 kSamples/s, 300 Hz input tone | –72 | |||||

| SINAD, SNDR | Signal-to-noise and distortion ratio | Internal 4.3 V equivalent reference(2), 200 kSamples/s, 9.6 kHz input tone | 60 | dB | ||

| VDDS as reference, 200 kSamples/s, 9.6 kHz input tone | 63 | |||||

| Internal reference, voltage scaling disabled, 32 samples average, 200 kSamples/s, 300 Hz input tone | 68 | |||||

| SFDR | Spurious-free dynamic range | Internal 4.3 V equivalent reference(2), 200 kSamples/s, 9.6 kHz input tone | 70 | dB | ||

| VDDS as reference, 200 kSamples/s, 9.6 kHz input tone | 73 | |||||

| Internal reference, voltage scaling disabled, 32 samples average, 200 kSamples/s, 300 Hz input tone | 75 | |||||

| Conversion time | Serial conversion, time-to-output, 24 MHz clock | 50 | Clock Cycles | |||

| Current consumption | Internal 4.3 V equivalent reference(2) | 0.40 | mA | |||

| Current consumption | VDDS as reference | 0.57 | mA | |||

| Reference voltage | Equivalent fixed internal reference (input voltage scaling enabled). For best accuracy, the ADC conversion should be initiated through the TI-RTOS API in order to include the gain/ offset compensation factors stored in FCFG1 | 4.3(2) (3) | V | |||

| Reference voltage | Fixed internal reference (input voltage scaling disabled). For best accuracy, the ADC conversion should be initiated through the TI-RTOS API in order to include the gain/offset compensation factors stored in FCFG1. This value is derived from the scaled value (4.3 V) as follows: Vref = 4.3 V × 1408 / 4095 | 1.48 | V | |||

| Reference voltage | VDDS as reference, input voltage scaling enabled | VDDS | V | |||

| Reference voltage | VDDS as reference, input voltage scaling disabled | VDDS / 2.82(3) | V | |||

Tc = 25 °C, VDDS = 3.0 V and voltage scaling enabled, unless otherwise noted. (1)

Performance numbers require use of offset and gain adjustments in software by TI-provided ADC drivers.

| PARAMETER | TEST CONDITIONS | MIN TYP MAX |

UNIT |

|

| Input impedance | 200 kSamples/s, voltage scaling enabled. Capacitive input, Input impedance depends on sampling frequency and sampling time | >1 | MΩ | |

- Using IEEE Std 1241-2010 for terminology and test methods

- Input signal scaled down internally before conversion, as if voltage range was 0 to 4.3 V

- Applied voltage must be within Absolute Maximum Ratings at all times

- No missing codes

- ADC_output = Σ(4 n samples ) >> n, n = desired extra bits

8.15.2 DAC

8.15.2.1 Digital-to-Analog Converter (DAC) Characteristics

Tc = 25 °C, VDDS = 3.0 V, unless otherwise noted.

|

PARAMETER |

TEST CONDITIONS | MIN | TYP | MAX | UNIT | |

|

General Parameters |

||||||

| Resolution | 8 | Bits | ||||

|

VDDS |

Supply voltage | Any load, any VREF, pre-charge OFF, DAC charge-pump ON | 1.8 | 3.8 |

V |

|

| External Load(4), any VREF, pre-charge OFF, DAC charge-pump OFF | 2.0 | 3.8 | ||||

| Any load, VREF = DCOUPL, pre-charge ON | 2.6 | 3.8 | ||||

| FDAC | Clock frequency | Buffer ON (recommended for external load) | 16 | 250 |

kHz |

|

| Buffer OFF (internal load) | 16 | 1000 | ||||

| Voltage output settling time | VREF = VDDS, buffer OFF, internal load | 13 | 1 / FDAC | |||

| VREF = VDDS, buffer ON, external capacitive load = 20 pF(3) | 13.8 | |||||

| External capacitive load | 20 | 200 | pF | |||

| External resistive load | 10 | MΩ | ||||

| Short circuit current | 400 | µA | ||||

| ZMAX | Max output impedance Vref = VDDS, buffer ON, CLK 250 kHz | VDDS = 3.8 V, DAC charge-pump OFF | 50.8 | kΩ | ||

| VDDS = 3.0 V, DAC charge-pump ON | 51.7 | |||||

| VDDS = 3.0 V, DAC charge-pump OFF | 53.2 | |||||

| VDDS = 2.0 V, DAC charge-pump ON | 48.7 | |||||

| VDDS = 2.0 V, DAC charge-pump OFF | 70.2 | |||||

| VDDS = 1.8 V, DAC charge-pump ON | 46.3 | |||||

| VDDS = 1.8 V, DAC charge-pump OFF | 88.9 | |||||

|

Internal Load – Continuous Time Comparator / Low Power Clocked Comparator |

||||||

| DNL | Differential nonlinearity | VREF = VDDS, load = Continuous Time Comparator or Low Power Clocked Comparator FDAC = 250 kHz | ±1 | LSB(1) | ||

| Differential nonlinearity | VREF = VDDS, load = Continuous Time Comparator or Low Power Clocked Comparator FDAC = 16 kHz | ±1.2 | ||||

| Offset error(2) Load = Continuous Time Comparator | VREF = VDDS = 3.8 V | ±0.64 | LSB(1) | |||

| VREF = VDDS= 3.0 V | ±0.81 | |||||

| VREF = VDDS = 1.8 V | ±1.27 | |||||

| VREF = DCOUPL, pre-charge ON | ±3.43 | |||||

| VREF = DCOUPL, pre-charge OFF | ±2.88 | |||||

| VREF = ADCREF | ±2.37 | |||||

| Offset error(2) Load = Low Power Clocked Comparator | VREF = VDDS= 3.8 V | ±0.78 | LSB(1) | |||

| VREF = VDDS = 3.0 V | ±0.77 | |||||

| VREF = VDDS= 1.8 V | ±3.46 | |||||

| VREF = DCOUPL, pre-charge ON | ±3.44 | |||||

| VREF = DCOUPL, pre-charge OFF | ±4.70 | |||||

| VREF = ADCREF | ±4.11 | |||||

| Max code output voltage variation(2) Load = Continuous Time Comparator | VREF = VDDS = 3.8 V | ±1.53 | LSB(1) | |||

| VREF = VDDS = 3.0 V | ±1.71 | |||||

| VREF = VDDS= 1.8 V | ±2.10 | |||||

| VREF = DCOUPL, pre-charge ON | ±6.00 | |||||

| VREF = DCOUPL, pre-charge OFF | ±3.85 | |||||

| VREF = ADCREF | ±5.84 | |||||

Tc = 25 °C, VDDS = 3.0 V, unless otherwise noted.

|

PARAMETER |

TEST CONDITIONS | MIN TYP MAX |

UNIT |

|

| Max code output voltage variation(2) Load = Low Power Clocked Comparator | VREF = VDDS= 3.8 V | ±2.92 | LSB(1) | |

| VREF =VDDS= 3.0 V | ±3.06 | |||

| VREF = VDDS= 1.8 V | ±3.91 | |||

| VREF = DCOUPL, pre-charge ON | ±7.84 | |||

| VREF = DCOUPL, pre-charge OFF | ±4.06 | |||

| VREF = ADCREF | ±6.94 | |||

| Output voltage range(2) Load = Continuous Time Comparator | VREF = VDDS = 3.8 V, code 1 | 0.03 | V | |

| VREF = VDDS = 3.8 V, code 255 | 3.62 | |||

| VREF = VDDS= 3.0 V, code 1 | 0.02 | |||

| VREF = VDDS= 3.0 V, code 255 | 2.86 | |||

| VREF = VDDS= 1.8 V, code 1 | 0.01 | |||

| VREF = VDDS = 1.8 V, code 255 | 1.71 | |||

| VREF = DCOUPL, pre-charge OFF, code 1 | 0.01 | |||

| VREF = DCOUPL, pre-charge OFF, code 255 | 1.21 | |||

| VREF = DCOUPL, pre-charge ON, code 1 | 1.27 | |||

| VREF = DCOUPL, pre-charge ON, code 255 | 2.46 | |||

| VREF = ADCREF, code 1 | 0.01 | |||

| VREF = ADCREF, code 255 | 1.41 | |||

| Output voltage range(2) Load = Low Power Clocked Comparator | VREF = VDDS = 3.8 V, code 1 | 0.03 | V | |

| VREF = VDDS= 3.8 V, code 255 | 3.61 | |||

| VREF = VDDS= 3.0 V, code 1 | 0.02 | |||

| VREF = VDDS= 3.0 V, code 255 | 2.85 | |||

| VREF = VDDS = 1.8 V, code 1 | 0.01 | |||

| VREF = VDDS = 1.8 V, code 255 | 1.71 | |||

| VREF = DCOUPL, pre-charge OFF, code 1 | 0.01 | |||

| VREF = DCOUPL, pre-charge OFF, code 255 | 1.21 | |||

| VREF = DCOUPL, pre-charge ON, code 1 | 1.27 | |||

| VREF = DCOUPL, pre-charge ON, code 255 | 2.46 | |||

| VREF = ADCREF, code 1 | 0.01 | |||

| VREF = ADCREF, code 255 | 1.41 | |||

|

External Load |

||||

|

INL |

Integral nonlinearity |

VREF = VDDS, FDAC = 250 kHz | ±1 |

LSB(1) |

| VREF = DCOUPL, FDAC = 250 kHz | ±2 | |||

| VREF = ADCREF, FDAC = 250 kHz | ±1 | |||

| DNL | Differential nonlinearity | VREF = VDDS, FDAC = 250 kHz | ±1 | LSB(1) |

| Offset error | VREF = VDDS= 3.8 V | ±0.40 | LSB(1) | |

| VREF = VDDS= 3.0 V | ±0.50 | |||

| VREF = VDDS = 1.8 V | ±0.75 | |||

| VREF = DCOUPL, pre-charge ON | ±1.55 | |||

| VREF = DCOUPL, pre-charge OFF | ±1.30 | |||

| VREF = ADCREF | ±1.10 | |||

| Max code output voltage variation | VREF = VDDS= 3.8 V | ±1.00 | LSB(1) | |

| VREF = VDDS= 3.0 V | ±1.00 | |||

| VREF = VDDS= 1.8 V | ±1.00 | |||

| VREF = DCOUPL, pre-charge ON | ±3.45 | |||

| VREF = DCOUPL, pre-charge OFF | ±2.10 | |||

| VREF = ADCREF | ±1.90 | |||

| Output voltage range Load = Low Power Clocked Comparator |

VREF = VDDS = 3.8 V, code 1 | 0.03 | V |

- 1 LSB (VREF 3.8 V/3.0 V/1.8 V/DCOUPL/ADCREF) = 14.10 mV/11.13 mV/6.68 mV/4.67 mV/5.48 mV

- Includes comparator offset

- A load > 20 pF will increases the settling time

- Keysight 34401A Multimeter

8.15.3 Temperature and Battery Monitor

8.15.3.1 Temperature Sensor

Measured on a Texas Instruments reference design with Tc = 25 °C, VDDS = 3.0 V, unless otherwise noted.

| PARAMETER | TEST CONDITIONS | MIN | TYP | MAX |

UNIT |

| Resolution | 2 | °C | |||

| Accuracy | -40 °C to 0 °C | ±5.0 | °C | ||

| Accuracy | 0 °C to 105 °C | ±3.5 | °C | ||

| Supply voltage coefficient(1) | 3.6 | °C/V | |||

- The temperature sensor is automatically compensated for VDDS variation when using the TI-provided temperature driver.

8.15.3.2 Battery Monitor

Measured on a Texas Instruments reference design with T = 25 °C, unless otherwise noted.

|

PARAMETER |

TEST CONDITIONS | MIN | TYP | MAX |

UNIT |

| Resolution | 25 | mV | |||

| Range | 1.8 | 3.8 | V | ||

| Integral nonlinearity (max) | 23 | mV | |||

| Accuracy | VDDS = 3.0 V | 22.5 | mV | ||

| Offset error | -32 | mV | |||

| Gain error | -1 | % | |||

8.15.4 Comparators

8.15.4.1 Low-Power Clocked Comparator

T = 25 °C, V = 3.0 V, unless otherwise noted.

| PARAMETER | TEST CONDITIONS | MIN | TYP | MAX |

UNIT |

| Input voltage range | 0 | VDDS | V | ||

| Clock frequency | SCLK_LF | ||||

| Internal reference voltage(1) | Using internal DAC with VDDS as reference voltage, DAC code = 0 – 255 | 0.024 – 2.865 | V | ||

| Offset | Measured at VDDS / 2, includes error from internal DAC | ±5 | mV | ||

| Decision time | Step from –50 mV to 50 mV | 1 | Clock Cycle | ||

(1) The comparator can use an internal 8 bits DAC as its reference. The DAC output voltage range depends on the reference voltage selected. See

8.15.4.2 Continuous Time Comparator

Tc = 25°C, VDDS = 3.0 V, unless otherwise noted.

| PARAMETER | TEST CONDITIONS | MIN | TYP | MAX |

UNIT |

| Input voltage range(1) | 0 | VDDS | V | ||

| Offset | Measured at VDDS / 2 | ±5 | mV | ||

| Decision time | Step from –10 mV to 10 mV | 0.70 | µs | ||

| Current consumption | Internal reference | 8.0 | µA | ||

- The input voltages can be generated externally and connected throughout I/Os or an internal reference voltage can be generated using the DAC

8.15.5 Current Source

8.15.5.1 Programmable Current Source

Tc = 25 °C, VDDS = 3.0 V, unless otherwise noted.

| PARAMETER | TEST CONDITIONS | MIN | TYP | MAX |

UNIT |

| Current source programmable output range (logarithmic range) | 0.25 – 20 | µA | |||

| Resolution | 0.25 | µA | |||

8.15.6 GPIO

8.15.6.1 GPIO DC Characteristics

Measurements CBSed to PG2.1:

|

PARAMETER |

TEST CONDITIONS | MIN | TYP | MAX |

UNIT |

|

TA = 25 °C, VDDS = 1.8 V |

|||||

| GPIO VOH at 8 mA load | IOCURR = 2, high-drive GPIOs only | 1.56 | V | ||

| GPIO VOL at 8 mA load | IOCURR = 2, high-drive GPIOs only | 0.24 | V | ||

| GPIO VOH at 4 mA load | IOCURR = 1 | 1.59 | V | ||

| GPIO VOL at 4 mA load | IOCURR = 1 | 0.21 | V | ||

| GPIO pullup current | Input mode, pullup enabled, Vpad = 0 V | 73 | µA | ||

| GPIO pulldown current | Input mode, pulldown enabled, Vpad = VDDS | 19 | µA | ||

| GPIO low-to-high input transition, with hysteresis | IH = 1, transition voltage for input read as 0 → 1 | 1.08 | V | ||

| GPIO high-to-low input transition, with hysteresis | IH = 1, transition voltage for input read as 1 → 0 | 0.73 | V | ||

| GPIO input hysteresis | IH = 1, difference between 0 → 1and 1 → 0 points | 0.35 | V | ||

|

TA = 25 °C, VDDS = 3.0 V |

|||||

| GPIO VOH at 8 mA load | IOCURR = 2, high-drive GPIOs only | 2.59 | V | ||

| GPIO VOL at 8 mA load | IOCURR = 2, high-drive GPIOs only | 0.42 | V | ||

| GPIO VOH at 4 mA load | IOCURR = 1 | 2.63 | V | ||

| GPIO VOL at 4 mA load | IOCURR = 1 | 0.40 | V | ||

|

TA = 25 °C, VDDS = 3.8 V |

|||||

| GPIO pullup current | Input mode, pullup enabled, Vpad = 0 V | 282 | µA | ||

| GPIO pulldown current | Input mode, pulldown enabled, Vpad = VDDS | 110 | µA | ||

| GPIO low-to-high input transition, with hysteresis | IH = 1, transition voltage for input read as 0 → 1 | 1.97 | V | ||

| GPIO high-to-low input transition, with hysteresis | IH = 1, transition voltage for input read as 1 → 0 | 1.55 | V | ||

| GPIO input hysteresis | IH = 1, difference between 0 → 1and 1 → 0 points | 0.42 | V | ||

| TA = 25 °C | |||||

| VIH | Lowest GPIO input voltage reliably interpreted as a High |

0.8*VDDS | V | ||

| VIL | Highest GPIO input voltage reliably interpreted as a Low |

0.2*VDDS | V | ||

8.16 Typical Characteristics

All measurements in this section are done with Tc = 25 °C and VDDS = 3.0 V, unless otherwise noted. See Recommended Operating Conditions for device limits. Values exceeding these limits are for reference only.

8.16.1 MCU Current

8.16.2 RX Current

8.16.2 RX Current

8.16.3 TX Current

Table 8-1. Typical TX Current and Output Power

| CC1312PSIP at 915 MHz, VDDS = 3.0 V (Measured on LP-EM-CC1312PSIP) | |||

|

txPower |

TX Power Setting (SmartRF Studio) | Typical Output Power [dBm] |

Typical Current Consumption [mA] |

| 0x013F | 14 | 13.8 | 34.6 |

| 0x823F | 12.5 | 12.2 | 24.9 |

| 0x7828 | 12 | 11.8 | 23.5 |

| 0x7A15 | 11 | 10.9 | 21.6 |

| 0x4C0D | 10 | 10.1 | 20.0 |

| 0x400A | 9 | 9.5 | 19.1 |

| 0x449A | 8 | 8.1 | 17.1 |

| 0x364D | 7 | 6.8 | 15.3 |

| 0x2892 | 6 | 6.3 | 14.8 |

| 0x20DC | 5 | 4.9 | 13.7 |

| 0x28D8 | 4 | 4 | 12.6 |

| 0x1C46 | 3 | 3.7 | 11.7 |

| 0x18D4 | 2 | 2.8 | 11.5 |

| 0x16D1 | 1 | 0.8 | 10.6 |

| 0x16D0 | 0 | 0.3 | 10.3 |

| 0x0CCB | -3 | -3.4 | 8.6 |

| 0x0CC9 | -5 | -5.4 | 7.9 |

| 0x08C7 | -7 | -8 | 7.3 |

| 0x0AC5 | -10 | -11.7 | 6.6 |

| 0x08C3 | -15 | -17.1 | 5.9 |

| 0x08C2 | -20 | -20.9 | 5.6 |

8.16.4 RX Performance

8.16.5 TX Performance

8.16.5 TX Performance

8.16.6 ADC Performance

8.16.6 ADC Performance

Detailed Description

9.1 Overview

Section 4 shows the core modules of the CC1312PSIP device.

9.2 System CPU

-M4F system CPU, which runs the

application and the higher layers of radio protocol stacks.

The CC1312PSIP SimpleLink ™ Wireless MCU contains an Arm Cortex

The system CPU is the foundation of a high-performance, low-cost platform that meets the system requirements of minimal memory implementation, and low-power consumption, while delivering outstanding computational performance and exceptional system response to interrupts.

Its features include the following:

- ARMv7-M architecture optimized for small-footprint embedded applications

- Arm Thumb -2 mixed 16- and 32-bit instruction set delivers the high performance expected of a 32-bit Arm core in a compact memory size

- Fast code execution permits increased sleep mode time

- Deterministic, high-performance interrupt handling for time-critical applications

- Single-cycle multiply instruction and hardware divide

- Hardware division and fast digital-signal-processing oriented multiply accumulate

- Saturating arithmetic for signal processing

- IEEE 754-compliant single-precision Floating Point Unit (FPU)

- Memory Protection Unit (MPU) for safety-critical applications

- Full debug with data matching for watchpoint generation

– Data Watchpoint and Trace Unit (DWT)

– JTAG Debug Access Port (DAP)

– Flash Patch and Breakpoint Unit (FPB) - Trace support reduces the number of pins required for debugging and tracing

– Instrumentation Trace Macrocell Unit (ITM)

– Trace Port Interface Unit (TPIU) with asynchronous serial wire output (SWO) - Optimized for single-cycle flash memory access

- Tightly connected to 8-KB 4-way random replacement cache for minimal active power consumption and wait states

- Ultra-low-power consumption with integrated sleep modes

- 48 MHz operation

- 1.25 DMIPS per MHz

9.3 Radio (RF Core)

The RF Core is a highly flexible and future proof radio module which contains an Arm Cortex-M0 processor that interfaces the analog RF and base-band circuitry, handles data to and from the system CPU side, and assembles the information bits in a given packet structure. The RF core offers a high level, command-based API to the main CPU that configurations and data are passed through. The Arm Cortex-M0 processor is not programmable by customers and is interfaced through the TI-provided RF driver that is included with the SimpleLink Software Development Kit (SDK).

The RF core can autonomously handle the time-critical aspects of the radio protocols, thus offloading the main CPU, which reduces power and leaves more resources for the user application. Several signals are also available to control external circuitry such as RF switches or range extenders autonomously.

The various physical layer radio formats are partly built as a software defined radio where the radio behavior is either defined by radio ROM contents or by non-ROM radio formats delivered in form of firmware patches with the SimpleLink SDKs. This allows the radio platform to be updated for support of future versions of standards even with over-the-air (OTA) updates while still using the same silicon.

Note

Not all combinations of features, frequencies, data rates, and modulation formats described in this chapter are supported. Over time, TI can enable new physical radio formats (PHYs) for the device and provides performance numbers for selected PHYs in the data sheet. Supported radio formats for a specific device, including optimized settings to use with the TI RF driver, are included in the SmartRF Studio tool with performance numbers of selected formats found in the Specifications section.

9.3.1 Proprietary Radio Formats

The CC1312PSIP radio can support a wide range of physical radio formats through a set of hardware peripherals combined with firmware available in the device ROM, covering various customer needs for optimizing towards parameters such as speed or sensitivity. This allows great flexibility in tuning the radio both to work with legacy protocols as well as customizing the behavior for specific application needs.

Table 9-1 gives a simplified overview of features of the various radio formats available in ROM. Other radio formats may be available in the form of radio firmware patches or programs through the Software Development Kit (SDK) and may combine features in a different manner, as well as add other features.

Table 9-1. Feature Support

|

Feature |

Main 2-(G)FSK Mode | High Data Rates | Low Data Rates |

SimpleLink™ Long Range |

| Programmable preamble, sync word, and CRC | Yes | Yes | Yes | No |

| Programmable receive bandwidth | Yes | Yes | Yes (down to 4 kHz) | Yes |

| Data / Symbol rate(3) | 20 to 1000 kbps | ≤ 2 Msps | ≤ 100 ksps | ≤ 20 ksps |

| Modulation format | 2-(G)FSK | 2-(G)FSK 4-(G)FSK | 2-(G)FSK 4-(G)FSK | 2-(G)FSK |

| Dual Sync Word | Yes | Yes | No | No |

| Carrier Sense (1) (2) | Yes | No | No | No |

| Preamble Detection(2) | Yes | Yes | Yes | No |

| Data Whitening | Yes | Yes | Yes | Yes |

| Digital RSSI | Yes | Yes | Yes | Yes |

| CRC filtering | Yes | Yes | Yes | Yes |

| Direct-sequence spread spectrum (DSSS) | No | No | No | 1:2 1:4 1:8 |

| Forward error correction (FEC) | No | No | No | Yes |

| Link Quality Indicator (LQI) | Yes | Yes | Yes | Yes |

- Carrier Sense can be used to implement HW-controlled listen-before-talk (LBT) and Clear Channel Assessment (CCA) for compliance with such requirements in regulatory standards. This is available through the CMD_PROP_CS radio API.

- Carrier Sense and Preamble Detection can be used to implement sniff modes where the radio is duty cycled to save power.

- Data rates are only indicative. Data rates outside this range may also be supported. For some specific combinations of settings, a smaller range might be supported.

9.4 Memory

The up to 352-KB nonvolatile (Flash) memory provides storage for code and data. The flash memory is in-system programmable and erasable. The last flash memory sector must contain a Customer Configuration section (CCFG) that is used by boot ROM and TI provided drivers to configure the device. This configuration is done through the ccfg.c source file that is included in all TI provided examples.

The ultra-low leakage system static RAM (SRAM) is split into up to five 16-KB blocks and can be used for both storage of data and execution of code. Retention of SRAM contents in Standby power mode is enabled by default and included in Standby mode power consumption numbers. Parity checking for detection of bit errors in memory is built-in, which reduces chip-level soft errors and thereby increases reliability. System SRAM is always initialized to zeroes upon code execution from boot.

To improve code execution speed and lower power when executing code from nonvolatile memory, a 4-way nonassociative 8-KB cache is enabled by default to cache and prefetch instructions read by the system CPU.

The cache can be used as a general-purpose RAM by enabling this feature in the Customer Configuration Area (CCFG).

There is a 4-KB ultra-low leakage SRAM available for use with the Sensor Controller Engine which is typically used for storing Sensor Controller programs, data and configuration parameters. This RAM is also accessible by the system CPU. The Sensor Controller RAM is not cleared to zeroes between system resets.

The ROM includes a TI-RTOS kernel and low-level drivers, as well as significant parts of selected radio stacks, which frees up flash memory for the application. The ROM also contains a serial (SPI and UART) bootloader that can be used for initial programming of the device.

9.5 Sensor Controller

The Sensor Controller contains circuitry that can be selectively enabled in both Standby and Active power modes. The peripherals in this domain can be controlled by the Sensor Controller Engine, which is a proprietary power-optimized CPU. This CPU can read and monitor sensors or perform other tasks autonomously; thereby significantly reducing power consumption and offloading the system CPU.

The Sensor Controller Engine is user programmable with a simple programming language that has syntax similar to C. This programmability allows for sensor polling and other tasks to be specified as sequential algorithms rather than static configuration of complex peripheral modules, timers, DMA, register programmable state machines, or event routing.

The main advantages are:

- Flexibility – data can be read and processed in unlimited manners while still ensuring ultra-low power

- 2 MHz low-power mode enables lowest possible handling of digital sensors

- Dynamic reuse of hardware resources

- 40-bit accumulator supporting multiplication, addition and shift

- Observability and debugging options

Sensor Controller Studio is used to write, test, and debug code for the Sensor Controller. The tool produces C driver source code, which the System CPU application uses to control and exchange data with the Sensor Controller. Typical use cases may be (but are not limited to) the following:

- Read analog sensors using integrated ADC or comparators

- Interface digital sensors using GPIOs, SPI, UART, or I2 C are bit-banged)

- Capacitive sensing

- Waveform generation

- Very low-power pulse counting (flow metering) Key scan

The peripherals in the Sensor Controller include the following:

- The low-power clocked comparator can be used to wake the system CPU from any state in which the comparator is active. A configurable internal reference DAC can be used in conjunction with the comparator.

The output of the comparator can also be used to trigger an interrupt or the ADC. - Capacitive sensing functionality is implemented through the use of a constant current source, a time-to-digital converter, and a comparator. The continuous time comparator in this block can also be used as a higher accuracy alternative to the low-power clocked comparator. The Sensor Controller takes care of baseline tracking, hysteresis, filtering, and other related functions when these modules are used for capacitive sensing.

- The ADC is a 12-bit, 200-ksamples/s ADC with eight inputs and a built-in voltage reference. The ADC can be triggered by many different sources including timers, I/O pins, software, and comparators.

- The analog modules can connect to up to eight different GPIOs

- Dedicated SPI master with up to 6 MHz clock speed

The peripherals in the Sensor Controller can also be controlled from the main application processor.

9.6 Cryptography

The CC1312PSIP device comes with a wide set of modern cryptography-related hardware accelerators, drastically reducing code footprint and execution time for cryptographic operations. It also has the benefit of being lower power and improves availability and responsiveness of the system because the cryptography operations runs in a background hardware thread.

Together with a large selection of open-source cryptography libraries provided with the Software Development Kit (SDK), this allows for secure and future proof IoT applications to be easily built on top of the platform. The hardware accelerator modules are:

- True Random Number Generator (TRNG) module provides a true, nondeterministic noise source for the purpose of generating keys, initialization vectors (IVs), and other random number requirements. The TRNG is built on 24 ring oscillators that create unpredictable output to feed a complex nonlinear-combinatorial circuit.

- Secure Hash Algorithm 2 (SHA-2) with support for SHA224, SHA256, SHA384, and SHA512

- Advanced Encryption Standard (AES) with 128 and 256 bit key lengths

- Public Key Accelerator – Hardware accelerator supporting mathematical operations needed for elliptic curves up to 512 bits and RSA key pair generation up to 1024 bits.

Through use of these modules and the TI provided cryptography drivers, the following capabilities are available for an application or stack:

- Key Agreement Schemes

– Elliptic curve Diffie–Hellman with static or ephemeral keys (ECDH and ECDHE)

– Elliptic curve Password Authenticated Key Exchange by Juggling (ECJ-PAKE) - Signature Generation

– Elliptic curve Diffie-Hellman Digital Signature Algorithm (ECDSA) - Curve Support

– Short Weierstrass form (full hardware support), such as: - NIST-P224, NIST-P256, NIST-P384, NIST-P521

- Brainpool-256R1, Brainpool-384R1, Brainpool-512R1

- secp256r1

– Montgomery form (hardware support for multiplication), such as: - Curve25519

- SHA2 based MACs

– HMAC with SHA224, SHA256, SHA384, or SHA512 - Block cipher mode of operation

– AESCCM

– AESGCM

– AESECB

– AESCBC

– AESCBC-MAC - True random number generation

Other capabilities, such as RSA encryption and signatures as well as Edwards type of elliptic curves such as Curve1174 or Ed25519, can also be implemented using the provided hardware accelerators but are not part of the TI SimpleLink SDK for the CC1312PSIP device.

9.7 Timers

A large selection of timers are available as part of the CC1312PSIP device. These timers are:

- Real-Time Clock (RTC)

A 70-bit 3-channel timer running on the 32 kHz low frequency system clock (SCLK_LF)

This timer is available in all power modes except Shutdown. The timer can be calibrated to compensate for frequency drift when using the LF RCOSC as the low frequency system clock. If an external LF clock with frequency different from 32.768 kHz is used, the RTC tick speed can be adjusted to compensate for this.

When using TI-RTOS, the RTC is used as the base timer in the operating system and should thus only be accessed through the kernel APIs such as the Clock module. The real time clock can also be read by the Sensor Controller Engine to timestamp sensor data and also has dedicated capture channels. By default, the RTC halts when a debugger halts the device. - General Purpose Timers (GPTIMER)