Danfoss Axispro Servo Performance Proportional Valve Owner’s Manual

The AxisPro™ proportional industrial valve is a cost-effective and reliable alternative to the traditional servo valve.

AxisPro,. four-way solenoid-operated proportional valves offer high dynamic performance which enables them to be used in closed loop motion control applications previously only possible using conventional servo valves. Compared to servo valves, AxisPro proportional valves offer excellent performance and better reliability at a significantly lower price point.

Servo valves: expensive with limited availability

Servo valves provide excellent accuracy and high repeatablllty. Servo valve technology has been in constant use for over 70 years. But servo valves are typically more expensive than other valves: they require elaborate production methods (Involving machining and assembllng two stages). And when placed into service, servo valves require sophisticated electronic control cards-adding additional costs. In addition, servo valves require use of a pilot-filter (typically) supplied by the manufacturer, which can become contaminated and require costly matntenance.

The new AxisPro … line of proportional directional valves provide a cost-effective alternative to tradlttonal nozzle-flapper servo valves. Proportional valves, like AxisPro, benefit from a simpler mechanical design that costs less to manufacture, while utilizing onboard integrated electronics and feedback to achieve servo-quality spool control performance. Plus, since the AxisPro power stage directly drives the spool, there Is Increased robustness to contamination (no need for pilot stage filtration to protect the fragile nozzle-flapper interface of a traditional servo valve).

Converting to AxisPro servo-performance valves: step-by-step

Note: This conversion process applies to A xis Pro Level 1 valves. Contact your Danfoss representative for information about converting to AxisPro Level 2 and Level 3 valves.

Converting to the AxisPro valve requires a simple six-step process:

Sotp 1. Determine maximum flow rate of the servo valve

Sotp 2. Choose the proper replacement AxisPro valve

sotp 3. Define parameters

Sotp 4. Determine where motion control is handled

Sotp 5. Mount AxisPro Valve

Sotp 6. W ire AxisPro Valve

You will find model codes, installation dimensions and other useful information in the appendix.

Step I: Determine maximum flow rate of the servo valve Maximum flow and pressure rating is typically listed as part of the model code and appears on the on the model code/serial number label (Figure 1).

Note:TheA xisPro valve is not recommended for pressure ratings higher than 350 bar.

Figure 1. Locate serial numberto determine flow rating.

Step 2: Choose the properAxisPro Replacement valve

Choose the proper AxisPro Level 1 replacement valve according to desired flow (note single-stage AxisPro valves have flows rated at 1000 psid pressure drop across the valve, i.e. 500 psi per metering edge):

Flow e: 10 gpm: choose the Danfoss KBS1-3

proportional directional valve Size D03 mounting pattern

Flow 10 gpm: choose the Danfoss KBS1-5 proportional directional valve Size D05 mounting pattern

To assist in choosing the right AxisPro model configuration, please refer to the appropriate AxisPro product catalogs.

Step 3: Define conditions, output and Electrical connections

- Define the AxisPro valve failsafe condition: Servo valves typically define the failsafe condition as all ports blocked in the neutral position. Because proportional valves are driven by a solenoid in only one direction, it is necessary to match the correct failsafe condition of the servo valve in the AxisPro valve. Choose the forced position as an all ports blocked position for the new AxisPro valve.

- Select the AxisPro valve spool and sleeve:Spool/sleeve settings will vary according to the flow rate of the valve.

Choose the correct flow when setting the valve by determining these parameters:

a. Symmetric vs. Asymmetric (valves are typically symmetric, but verify with your valve) Correct failsafe position

b. Select flow rate. Using the spool sleeve codes,

c. choose the correct flow rate that allows for at least the desired flow

Step 4: Determine where motion control is handled: PLC or card

Motion is typically controlled through the servo card or through the PLC.

If motion is controlled through the servo card, talk to your

Danfoss representative about using an AxisPro level 2 valve as a replacement valve

If motion is controlled through the PLC:

Ensure the PLC parameter scaling is equivalent to the AxisPro valve parameters

Verify that the PLC PID parameters are performing well/as expected

Step 5: Mount the AxisPro valve in place of the servo valve

1. Verify installation dimensions for desired AxisPro valve model code

a. AxisPro valves may require a larger size envelope than servo valves

b. Verify there is adequate space to accommodate the AxisPro valve by measuring space around the mounted servo valve (Figure 2)

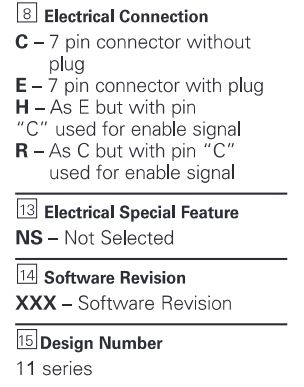

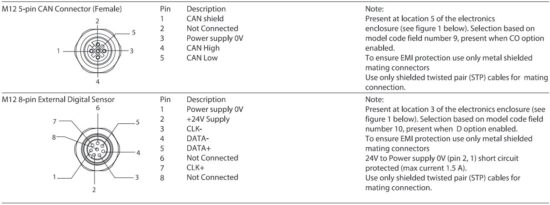

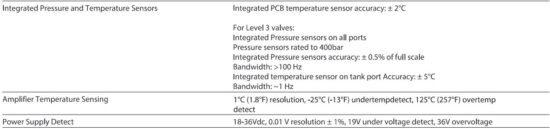

Model Code

To find available product configurations go to

www.danfoss.com

Installation dimensions

Mounting surfaces

Operating Data

Read More About This Manual & Download PDF:

Documents / Resources

|

Danfoss Axispro Servo Performance Proportional Valve [pdf] Owner's Manual Axispro Servo Performance Proportional Valve, Servo Performance Proportional Valve, Performance Proportional Valve, Proportional Valve, Valve |