TOPSIDE CREEPER

MODEL NO: SCRT01

1. Introduction

Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these instructions, and properly maintained, give you years of trouble-free performance.

IMPORTANT: Please read these instructions carefully. Note the safe operational requirements, warnings & cautions. Use the product correctly and with care for the purpose for which it is intended. Failure to do so may cause damage and/or personal injury and will invalidate the warranty. Keep these instructions safe for future use.

The Topside Creeper offers multi-height and angle adjustments for comfortable work on high-level engines in jeeps, pickups, trucks, SUVs, agricultural vehicles, and more. It features a 60mm deep foam, heavy vinyl-covered body pad, a heavy-duty steel framework with a powder coat finish for anti-scratch/rust resistance, and easy-rolling Ø75mm composite swivel castors (two lockable). Its folding design allows for easy transport and storing.

2. Safety

WARNING! Read and understand all instructions before assembling or using the creeper. Keep this manual for safety warnings, precautions, operating or maintenance instructions.

- [Prohibited Icon] DO NOT spend long periods on a creeper without regular breaks (tiredness is a risk).

- [Prohibited Icon] DO NOT use the creeper if contaminated, e.g. with wet paint, mud, oil or snow.

- [Prohibited Icon] DO NOT use the creeper outside in adverse weather conditions, such as strong wind or wet conditions.

- [Prohibited Icon] DO NOT modify the creeper design. Only qualified service personnel should maintain or repair the tool.

- [Prohibited Icon] DO NOT move a creeper while mounted on it.

- [Prohibited Icon] DO NOT stand or sit on the chest pad deck.

- [Prohibited Icon] DO NOT use the creeper to work over a running engine.

- [Prohibited Icon] DO NOT use the tool if any parts are damaged, broken or misplaced. Only qualified service personnel to maintain or repair the tool.

- [Prohibited Icon] DO NOT exceed the maximum load capacity of the creeper (150kg).

- [Checkmark Icon] Always ensure the height adjustment bar is securely fixed in one of the five position slots prior to using (refer to section 5.2 to adjust working height).

- [Checkmark Icon] Always lock castors before use.

- [Checkmark Icon] Lean your chest onto the deck cushion gently. Avoid causing a shock load by jumping or falling onto it.

- [Checkmark Icon] Prevent damage to the creeper when transporting, e.g. by fastening it. Ensure fasteners are suitably placed to prevent damage.

- [Checkmark Icon] Ensure the creeper is suitable for the task to be undertaken.

- [Checkmark Icon] For professional use, a risk assessment shall be carried out respecting the legislation in the country of use.

- [Checkmark Icon] When positioning the creeper, take into account the risk of collision with the creeper from pedestrians, vehicles or doors. Secure nearby doors (not fire exits) and windows in the work area where possible.

- [Checkmark Icon] Always lock castors before mounting.

- [Checkmark Icon] Keep work area clear, well lit, and free of distractions, and keep bystanders away from the work area.

- [Checkmark Icon] Wear suitable PPE for the task being carried out, i.e., safety goggles, gloves, work wear.

NOTE: The maximum capacity listed (150kg) includes the user, tools, equipment, and personal items.

2.1. Safety Symbols

WARNING: Falling from creeper. This warning sign shall appear on each marking on the creeper at the first place.

- [User Icon] Maximum number of users is 1.

- [Document Icon] Refer to instruction manual/booklet.

- [Inspect Icon] Inspect the creeper after delivery. Before every use, visually inspect the creeper to check it is not damaged and is safe to use. DO NOT use a damaged creeper.

- [Weight Icon] Maximum total load: 150 kg.

- [Prohibited Icon] DO NOT use creeper on uneven or unstable surfaces.

- [Descend Icon] DO NOT ascend or descend unless you are facing the creeper.

- [Grip Icon] Keep a secure grip on the creeper when ascending/descending. Maintain handhold whilst working from a creeper or take additional safety precautions if you cannot.

- [Sideways Load Icon] Avoid work that imposes a sideways load on the creeper, such as side-on drilling through solid materials.

- [Heavy Load Icon] DO NOT carry equipment which is heavy or difficult to handle when using a creeper.

- [Prohibited Icon] DO NOT overreach.

- [Prohibited Icon] DO NOT erect creeper on contaminated surfaces.

- WARNING: Electrical hazard. Identify any electrical risks in the work area, such as overhead lines or other exposed electrical equipment, and DO NOT use the creeper where electrical risks occur.

- [Non-conductive Icon] Use non-conductive materials for unavoidable live electrical work.

- [Prohibited Icon] DO NOT use the creeper as a bridge.

- [Stabilizer Bar Icon] If a creeper is delivered with stabilizer bars, the bars should be fixed by the user before the first use. This shall be described on the creeper and in the user instruction.

- [Prohibited Icon] DO NOT use creeper for tasks it is not intended for.

- [Professional/Domestic Icon] Creeper for professional and domestic use.

- [Prohibited Icon] DO NOT wear unsuitable footwear when working on creeper.

- [Fitness Icon] DO NOT use the creeper if you are not fit enough. Certain medical conditions or medication, alcohol, or drug abuse could make creeper use unsafe.

- WARNING: Open the creeper fully before use.

- [Restraint Device Icon] Use the creeper with restraint devices engaged only.

- [Leaning Icon] Standing creepers shall not be used as a leaning creeper unless it is designed to do so.

- [Step Icon] DO NOT stand on the top two steps/rungs of a standing creeper without a platform and a hand/knee rail.

- [Platform Icon] Horizontal surfaces which look like a platform but are not designed for standing on (e.g., a plastic work tray) shall be clearly indicated on their surface.

- [Step Off Icon] DO NOT step off the side of a standing creeper onto another surface.

- [Brake Icon] Use only when brake is activated.

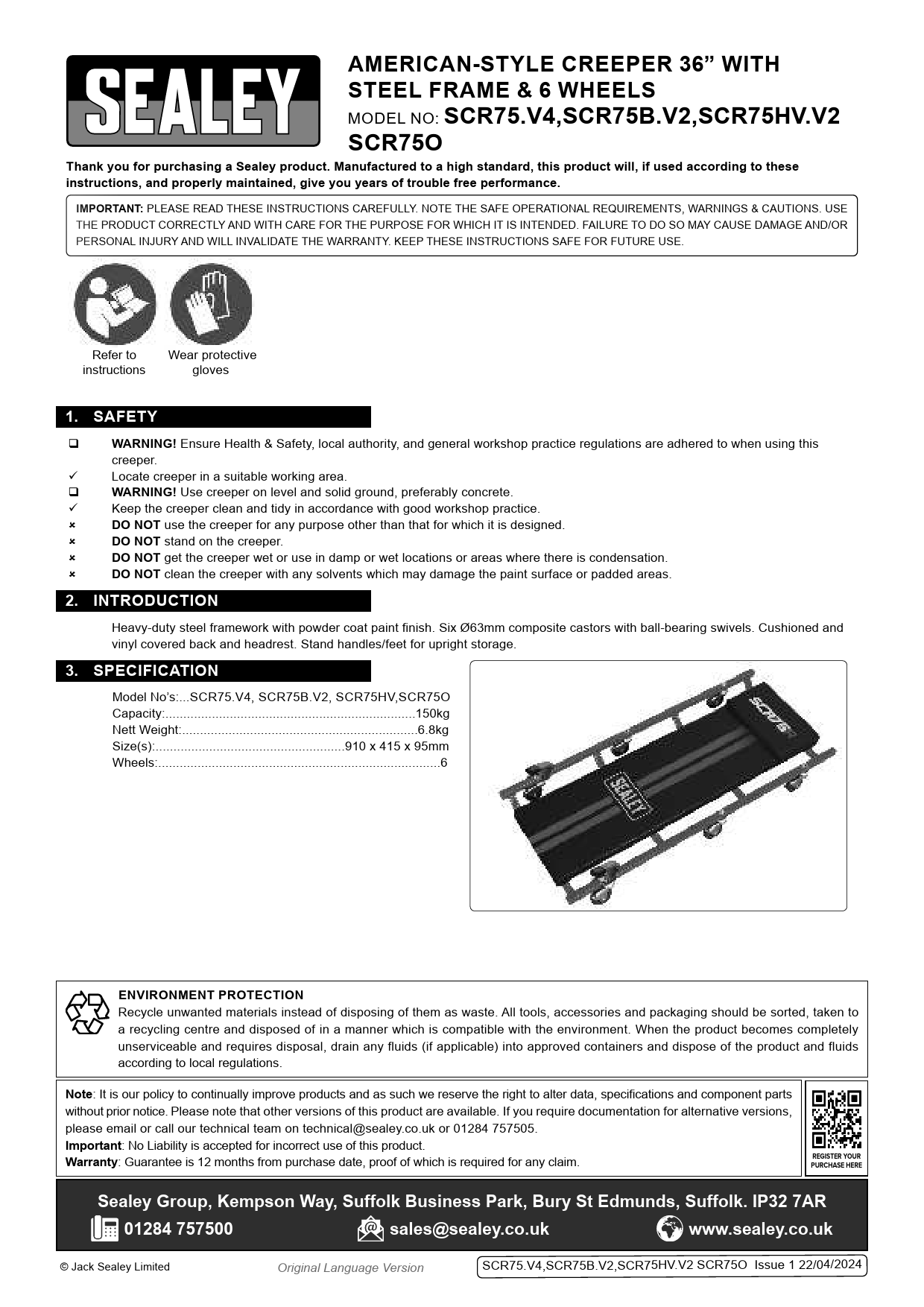

3. Specification

| Feature | Details |

|---|---|

| Model No. | SCRT01 |

| Capacity | 150kg |

| Net weight | 29kg |

| Size | L-1375, W-Front 775 x Rear 750, H-1190 - 1820mm |

4. Assembly

4.1. Remove the parts and accessories from the packaging and inspect for damage. Make sure that all items in the contents are included.

WARNING! DO NOT operate the tool if any part is missing. Replace the missing part before operating. Failure to do so could result in a malfunction and personal injury.

NOTE: Letter references in parenthesis (i.e. A) refer to the Parts Information.

4.2. Assemble the right and left legs (E & F) to the base frame (A). Insert the end of each leg into the base frame's openings and align the bolt holes. The height adjustment notches will be on the inside and the legs must angle outwards. Secure each leg with a frame bolt (N) and locknut (V). Insert two leg lock pins (M) and push ends down to secure the legs.

Diagram Description (Figure 1): Shows the base frame (A) with legs (E, F) being attached. Height adjustment notches (1-1) and locking pins (M) are indicated.

4.3. Attach the front castors (J) by inserting the stem of each castor through the end of each leg and securing it with a flange nut (U). Install rear locking castors (K) to the base frame in the same manner. Lock rear wheels in place for the remainder of the installation.

Diagram Description (Figure 2): Illustrates attaching front castors (J) with flange nuts (U) and rear locking castors (K) to the legs and base frame.

4.4. Install the ladder assembly (B) by inserting a frame bolt (N) through each side of the base frame and lower ladder assembly. Secure each bolt with a lock nut (V). Swing the ladder's angle support (3-1) into the height adjustment notches (3-2). Make sure the crossbar is firmly in place.

Diagram Description (Figure 3): Shows the ladder assembly (B) being attached to the base frame with bolts (N) and lock nuts (V). Angle support (3-1) and height adjustment notches (3-2) are highlighted.

4.5. Place the leg cross support (G) on both legs (E & F), aligning bolt holes. Insert cross support bolt (O) through each end of the leg cross support and leg. Slide a washer (T) over one bolt and secure with a lock nut (X). Repeat with the other cross support bolt.

4.6. Attach the height adjustment plate (Q). Match the angled opening with the adjustment notches. Insert a height adjustment plate bolt (R) through the bolt hole at each end of the plate. Secure each bolt with a locknut (W). Repeat on the other side.

Diagram Description (Figure 4): Depicts attaching the leg cross support (G) with bolts (O), washers (T), and lock nuts (X), and attaching the height adjustment plate (Q) with bolts (R) and lock nuts (W).

4.7. Attach the chest deck frame (C) to the top of the ladder assembly (B) using three chest frame bolts (P) and locknuts (X) on each side. Attach the chest deck pad (D) using two cross head screws (R) from underneath.

Diagram Description (Figure 5): Shows the chest deck frame (C) being attached to the ladder assembly (B) with bolts (P) and lock nuts (X). The chest deck pad (D) is attached with screws (R).

4.8. Place the pouch bracket (I) over the pouch (H) and align the screw holes. Insert a cross head screw (P) through the screw holes. Line up protruding screws with the holes in the deck frame's front panel. Secure the pouch to the deck frame with the screws.

Diagram Description (Figure 6): Illustrates attaching the pouch bracket (I) to the pouch (H) and then securing it to the deck frame with screws (P).

5. Operation

WARNING! Read and understand all instructions before assembling or using the creeper.

- [Prohibited Icon] DO NOT make any adjustment whilst anyone is mounted on the creeper.

- [Checkmark Icon] Undertake a risk assessment of the task and work area before commencing any task.

- [Checkmark Icon] Ensure the creeper is correctly and safely assembled and undamaged before use.

- WARNING! Keep hands and fingers clear while adjusting the height of the creeper pad.

- [Checkmark Icon] Position the creeper to enable safe access to the area of interest.

- [Checkmark Icon] Ensure bumper pads (item L) are placed over angle support arms and ladder assembly (item B) to prevent scuffing of the vehicle.

- [Checkmark Icon] Ensure castors are locked before using the creeper.

5.1. Adjusting Angle Lean-In

There are three different lean-in angles that allow the user to adjust positioning. This helps the user to maximize safety and productivity. To adjust angle lean-in:

- Lock castors (fig.2 - K) by pressing the lock tab with your foot on each of the locking castors.

- Push back on the climbing section (fig.3-1).

- Move the angle adjustment to one of the three notches located on the base.

5.2. Changing Working Height

The working height of the creeper is adjustable from 1190mm to 1820mm to suit work requirements.

- To change the working height, lock castors (fig.2 - K) by pressing the lock tab with your foot on each of the locking castors.

- Grasp a step within the sliding section with one hand while using the other hand to pull one of the spring-loaded locking pins outward. Rotate the pin so it does not slide back into the locking slot.

- Repeat step 5.2.3 on the other side of the sliding section to remove the second spring-loaded locking pin.

IMPORTANT: Firmly hold a step within the sliding section when the second spring-loaded locking pin is removed from the locked position. This prevents the sliding section from free-falling, which could cause serious personal injury.

- While holding a step within the sliding section with one hand, guide one of the spring-loaded locking pins into its corresponding hole in the outside rail.

- While holding the sliding section, move it up or down as needed until the locking pin drops into one of the height adjustment holes located in the side rails of the sliding section.

- Guide and insert the second spring-loaded locking pin through both the outside rail and the oval-shaped hole of the inside sliding section rail.

6. Maintenance

- Maintain the tool with care. A tool in good condition is efficient, easier to control, and will have fewer problems.

- Inspect the tool components periodically. Repair or replace damaged or worn components. Only use identical replacement parts when servicing.

- Maintain the tool's labels and name plates. These carry important information.

- WARNING! Only qualified service personnel should repair the tool. An improperly repaired tool may present a hazard to the user and/or others.

6.1. Cleaning

Wipe clean as needed. Use mild upholstery cleaner (not caustic) to clean the chest deck pad as needed.

6.2. Lubrication

[Prohibited Icon] DO NOT lubricate castors. This can damage the mechanism.

7. Storage

- Remove the leg lock pins from each leg. Hold the ladder when removing the second pin, as the base frame will fall to the floor. Store the pins in the creeper's pouch.

- Push the creeper's angle support arms back towards the creeper.

- Lift each leg up until it rests next to the creeper assembly.

- Store in a safe, dry location. Keep tools out of reach of children.

- Store the creeper vertically. Make sure the rear castors are locked once it is in place.

7.1. Removal from Storage

- Lower each leg.

- Pull the creeper's angle support arms forward to settle in a height adjustment notch.

- Remove the leg lock pins from the pouch.

- Lift the base frame and push the leg down until the bolt holes align. Push the leg lock pin through and turn the end down. Repeat with the other leg.

- Unlock the rear castors, and it is ready for use.

Environment Protection

Recycle unwanted materials instead of disposing of them as waste. All tools, accessories, and packaging should be sorted, taken to a recycling centre, and disposed of in a manner compatible with the environment. When the product becomes completely unserviceable and requires disposal, drain any fluids (if applicable) into approved containers and dispose of the product and fluids according to local regulations.

[QR Code Placeholder] REGISTER YOUR PURCHASE HERE

Notes and Warranty

Note: It is our policy to continually improve products and as such we reserve the right to alter data, specifications, and component parts without prior notice.

Important: No Liability is accepted for incorrect use of this product.

Warranty: Guarantee is 12 months from purchase date, proof of which is required for any claim.

Sealey Group, Kempson Way, Suffolk Business Park, Bury St Edmunds, Suffolk. IP32 7AR

01284 757500 | sales@sealey.co.uk | www.sealey.co.uk

File Info : application/pdf, 4 Pages, 871.73KB

DocumentDocumentReferences

Adobe PDF Library 17.0 Adobe InDesign 19.0 (Windows)Related Documents

|

Sealey SCRT01 Topside Engine Bay Creeper - User Manual and Safety Guide Comprehensive user manual and safety guide for the Sealey SCRT01 Topside Engine Bay Creeper. Learn about product features, assembly, operation, maintenance, and safety precautions for professional and domestic use. |

|

Sealey SCR75 Series American-Style Steel Creeper 36" with 6 Wheels - User Manual & Specifications Detailed instructions and specifications for the Sealey SCR75.V4, SCR75B.V2, SCR75HV.V2, and SCR750 American-Style 36-inch steel creeper. Includes safety guidelines, product introduction, and technical details for workshop use. |

|

Sealey SCR750 American-Style 36" Steel Frame Mechanic's Creeper - Manual & Specifications Official manual and specifications for the Sealey SCR750 American-Style 36" steel frame mechanic's creeper with 6 wheels. Includes safety guidelines, product details, and warranty information. |

|

Sealey SCR84.F Stand Handles for SCR84 - Installation and Safety Instructions Official instructions for Sealey SCR84.F Stand Handles for SCR84. Learn about safety, specifications, assembly, and maintenance for this garage workshop accessory. Includes product details and warranty information. |

|

Sealey ADT200 200kg Capacity Transmission Cradle: Instructions and Safety Guide Comprehensive instructions and safety guidelines for the Sealey ADT200 200kg capacity transmission cradle. Covers assembly, operation, specifications, and important safety warnings for proper use. |

|

Sealey SCR91 Mechanic's Detailing Utility Seat - Instructions and Guide Detailed instructions, safety guidelines, specifications, and assembly guide for the Sealey SCR91 Mechanic's Detailing Utility Seat. Learn how to use, assemble, and maintain your workshop seat. |

|

Sealey ES480D 450kg Folding 360° Rotating Engine Stand with Geared Handle Drive - User Manual Comprehensive user manual for the Sealey ES480D 450kg Folding 360° Rotating Engine Stand. Provides detailed instructions on safety, assembly, operation, storage, and maintenance for this workshop equipment. |

|

Sealey WF10Q 1 Tonne Quick Lift Folding Engine Crane: Instructions and Safety Guide Comprehensive instructions, safety guidelines, and maintenance procedures for the Sealey WF10Q 1 Tonne Quick Lift Folding Engine Crane. Learn about assembly, operation, troubleshooting, and technical specifications for safe workshop use. |