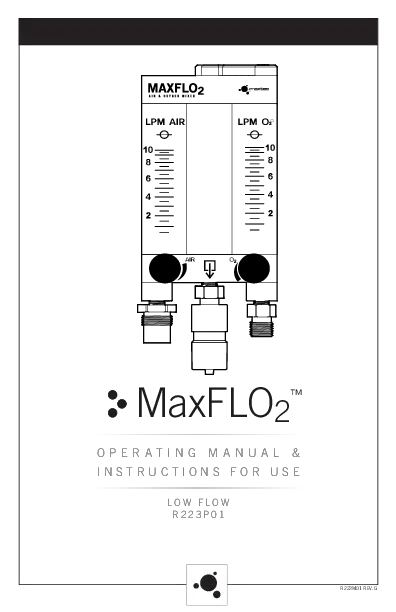

MaxFLO2™ Low Flow Air & Oxygen Mixer

OPERATING MANUAL & INSTRUCTIONS FOR USE

Model: R223P01

Document Revision: R223M01 REV. G

Manufacturer Information

Maxtec

2305 South 1070 West

Salt Lake City, Utah 84119

USA

TEL: (800) 748.5355

FAX: (801) 270.5590

EMAIL: sales@maxtec.com

WEBSITE: www.maxtec.com

Authorized Representative:

QNET BV

Kantstraat 19

NL-5076 NP Haaren

The Netherlands

[EC REP] [CE-0123]

Important Notes

NOTE: The MaxFLO2 is for use only by trained personnel. Before use, all individuals using the MaxFLO2 should become familiar with the information contained in this Operating Manual. Adherence to these instructions is necessary for safe, effective product performance. Thoroughly read all instructions and labelling provided with this device and any other equipment that will be used.

Indications for Use

The MaxFLO2 is designed to provide intermittent or continuous controlled flows of an air/oxygen gas mixture to infant, pediatric, and adult patients. The MaxFLO2 is intended to be used with a Maxtec Oxygen Analyzer as a spot checking device. The MaxFLO2 is a restricted medical device intended for use by qualified trained personnel under the direction of a physician in institutional environments where delivery and monitoring of air/oxygen mixtures are required.

Contraindications

The MaxFLO2 is not intended for use as a life support device.

Warranty

Under normal operating conditions, Maxtec warrants the MaxFLO2 to be free from defects of workmanship or materials for a period of 3 years from the date of shipment from Maxtec, provided that the unit is properly operated and maintained in accordance with Maxtec's operating instructions. Based on Maxtec product evaluation, Maxtec's sole obligation under the foregoing warranty is limited to making replacements, repairs, or issuing credit for equipment found to be defective. This warranty extends only to the buyer purchasing the equipment directly from Maxtec or through Maxtec's designated distributors and agents as new equipment.

Routine maintenance items are excluded from warranty. Maxtec and any other subsidiaries shall not be liable to the purchaser or other persons for incidental or consequential damages or equipment that has been subject to abuse, misuse, misapplication, alteration, negligence or accident.

These warranties are exclusive and in lieu of all other warranties, expressed or implied, including warranty of merchantability and fitness for a particular purpose.

⚠️ WARNINGS

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

- DO NOT use the MaxFLO2 in an MRI environment.

- DO NOT use the MaxFLO2 as a life support device.

- The MaxFLO2 DOES NOT CONTAIN AUDIBLE OR VISUAL ALARMS. Loss of a gas source or a drop of gas pressure below functional levels (25 PSI) is determined visually by monitoring individual gas flows.

- DO NOT use the MaxFLO2 to provide mixed gas to other devices which require a pressurized gas. The MaxFLO2 DOES NOT SUPPLY A PRESSURIZED GAS MIXTURE.

- DO NOT use the MaxFLO2 near any type of open flame.

- The MaxFLO2 is only for use with oxygen and medical air.

- Always operate the MaxFLO2 with clean, dry medical grade gases. Contaminates or moisture can cause defective operation. Oxygen should have a minimum dew point of -80°F (-62°C) or moisture content less than 7.9 ppm (0.0059 mg/L). Oxygen "purity" should be at least 99.6% and air used should be medical grade. Water vapor content must not exceed a dew point of 5°F (-15°C) below the lowest ambient temperature to which the delivery system is exposed. Particulate content must not exceed that which would be found immediately downstream of a 15 micron absolute filter. Refer to CGA commodity specifications G4.3 and G7.1 for more information. Water vapor content of medical air or oxygen supply to the MaxFLO2 must not exceed 5.63 x 10³ mg/m³ H₂O of non-condensable gas.

- The MaxFLO2 should only be used under proper supervision from a healthcare professional.

- Consult a physician for appropriate FiO₂ settings.

- The oxygen concentration selection table in this operating manual is provided only as a guideline for selecting oxygen concentration. Verify oxygen concentrations using an analyzer/monitor which can be calibrated.

- DO NOT autoclave or expose the MaxFLO2 to high temperatures (>65°C).

- DO NOT use ethylene oxide sterilization.

- DO NOT expose the MaxFLO2 to pressures greater than 100 PSI.

- DO NOT disconnect gas hoses from the MaxFLO2 while the device is under pressure.

? CAUTIONS

Indicates a potentially hazardous situation which, if not avoided, could result in minor or moderate injury and property damage.

- Use caution when using the MaxFLO2 in the presence of flammable anesthetics or in an atmosphere of flammable gases when the O₂ concentration exceeds 30%. Maxtec recommends following hospital anesthetic gas guidelines*.

- Before use on a patient, the oxygen concentration of the delivered gas should be checked at the setting intended for use.

- The MaxFLO2 is designed for use with a gas analyzer/monitor for continuous or intermittent gas analysis. Maxtec recommends use of an oxygen analyzer/monitor, which can be calibrated, whenever the MaxFLO2 is in use.

- Use caution when using the Mixed Gas Analysis Port to ensure the analyzer/ monitor does not become unintentionally or accidentally dislodged. The MaxFLO2 is optimized for use with flow diverters from Maxtec analyzers/monitors.

- Do not insert flow diverters into the Mixed Gas Analysis port which are not connected to an analyzer/monitor.

- Variations in inlet gas source pressure will change the flow rate of the affected gas and alter the percent of oxygen exiting the outlet.

- Excessive back pressure on the outlet will result in higher than indicated gas flow but will not result in inaccurate oxygen concentration.

- Use caution to ensure the mixed gas analysis port is clean and free of any foreign matter before each use.

- Maxtec recommends use of Maxtec analyzers/monitors which contain the Maxtec MAX-250 line of sensors. The use of analyzers/monitors with other brands or types of sensors may result in performance that does not conform to specifications found in Table 1 of Section 2.2 and information found in Section 12 of this operating manual.

- Clean the MaxFLO2 as recommended in section 5 of this operating manual. Excessive cleaning can cause residue buildup on critical components which can affect the performance of the MaxFLO2.

- Do not clean the MaxFLO2 with cleaning agents that contain phenols, ammonia chloride, or chloride compounds, or that contain more than 2% glutaraldehyde. These agents may damage the plastic components.

- Do not operate the MaxFLO2 at pressures below 25 PSIG (170kPaG) or above 75 PSIG (520kPaG).

- Mount the MaxFLO2 vertically and securely for correct performance. Check for proper function as outlined in section 3 of this operating manual prior to first use.

- Dropping the device may cause injury or device damage. If the MaxFLO2 is dropped, follow the procedures outlined in Section 3 of this operating manual for a performance check before re-using the device.

- An air inlet water filter is recommended for use with the MaxFLO2.

- Do not overtighten the flow adjustment valves.

- Use only Maxtec replacement parts. Failure to do so may seriously impair the performance of the MaxFLO2. Repair or alteration of the MaxFLO2 by anyone other than an authorized Maxtec service representative, could cause the product to fail to perform as designed.

- References: 1. New clinical guide to surgical fire prevention. Health Devices. 2009;38(10):314-332. 2. Accidents happen - an immediate action plan. The ECRI Institute website. Available at: https://www.ecri.org/Products/PatientSafetyQualityRiskManagement/CustomizedServices/Pages/Immediate_Action_Plan.aspx Accessed November 2, 2009.

? NOTES

Indicates supplemental information to assist in use of the device.

- There are no user serviceable components inside the MaxFLO2. All service should be referred to a Maxtec trained service technician or to Maxtec.

- The MaxFLO2 is tested for compliance with ISO 11195:1995, clause 6, and meets requirements regarding reverse gas flow as delivered.

- The MaxFLO2 has been cleaned and degreased for oxygen service prior to shipment. Any lubricants used are designed specifically for the application. Do not use anything other than Maxtec specified lubricants when servicing the MaxFLO2. Never use oils on the MaxFLO2.

- Users are advised to use pressure regulators set to 50 ± 5 PSIG (345 ± 35 kPaG) which display system pressure.

- All specifications assume the following standard environmental conditions unless otherwise specified: ambient and sample gas temperatures of 77°F (25°C), barometric pressure of 1 atm (101 kPa), ambient relative humidity of 50%, sample gas relative humidity of 0%.

1.0 System Overview

1.1 Description

The MaxFLO2 is a compact air/oxygen gas mixing device. The MaxFLO2 provides precise mixing of medical grade air and oxygen through two separate gas flowmeters controlled by two separate flow control knobs. The sum of each individual gas flow yields the total flow of gas, i.e. 5 LPM of oxygen and 8 LPM of air is a total flow of 13 LPM. Resulting oxygen concentration can be determined in several ways:

- With use of an oxygen analyzer/monitor mounted to the mixed gas analysis port.

- Referencing Table 1 in Section 2.2 of this Operating Manual.

Additional features and operational benefits include:

- Quick and easy intermittent or continuous oxygen measurements.

- No continuous bleed required, less wasted gas.

- Durable, compact design.

- Low maintenance.

1.2 Component Identification

Diagram showing the MaxFLO2 device with numbered components:

- 1: Medical Air Flowmeter

- 2: Medical Air Flow Adjustment Valve

- 3: Medical Air Gas Inlet

- 4: Male DISS Fitting

- 5: 22mm Male/15mm Female Conical Outlet Fitting

- 6: Oxygen Flow Meter

- 7: Oxygen Gas Inlet

- 8: Oxygen Flow Adjustment Valve

- 9: IV Pole Clamp

- 10: Mixed Gas Analysis Port

- 11: Mixed Gas Analysis Port Cover (Shown in open position)

1.3 Component Description

Oxygen Flowmeter: An acrylic flowmeter with a stainless steel float ball with black lettering on a white background designed specifically for the flow of oxygen.

Medical Air Flowmeter: An acrylic flowmeter with a stainless steel float ball with black lettering on a white background designed specifically for the flow of air.

Flow Control Valve: Valve controlling the flow of gas into the flowmeter.

Mixed Gas Outlet: A diameter indexed (DISS) oxygen fitting with a 22mm male/15mm female conical fitting.

Oxygen Gas Inlet: Fitting for connection of an oxygen inlet hose from the oxygen gas source.

Medical Air Gas Inlet: Fitting for connection of a medical air inlet hose from the medical air gas source.

Mixed Gas Analysis Port: Integrated port designed to divert a gas sample to an Analyzer/Monitor for intermittent or continuous gas sampling.

IV Pole Clamp: Clamp for securing the MaxFLO2 to a vertical pole.

1.4 Symbol Guide

The following symbols and safety labels are found on the MaxFLO2:

- ℹ️ Attention, consult accompanying documents

- [Manufacturer] Manufacturer

- SN Serial Number

- REF Catalog Number

- [Latex Free] Latex Free

- [EC REP] Authorized representative in the European Community

- [Rx Only] Federal law (USA) restricts this device to sale by or on order of a physician

- ⚠️ Warning

- Read Float Ball On Center

- LPM Liter per minute flow

- [Gas Inlet] Gas Inlet

- [Gas Outlet] Gas Outlet

- [Max Temperature] Maximum allowable temperature

- Pmax Maximum allowable pressure

- [Use No Oil] Use no oil

- [Do Not] Do Not

1.5 Operational Requirements

Pressurized Oxygen: For optimal performance the oxygen source must provide clean, dry, medical grade oxygen at a line pressure of 50 ± 5 PSIG (345 ± 35 kPaG).

Pressurized Medical Air: For optimal performance the air source must provide clean, dry, medical grade air at a line pressure of 50 ± 5 PSIG (345 ± 35 kPaG).

Note: Delivered gas characteristics are not affected by variations in input gas pressures.

⚙️ 2.0 Operating Instructions

2.1 Installation of MaxFLO2 to an IV Pole

Note: Prior to placing the MaxFLO2 into clinical use, the performance check described in Section 3 of this operating manual should be completed.

- Connect the 22mm Male/15mm Female conical outlet fitting to the male DISS fitting on the bottom of the device as seen in section 1.2 of this operating manual.

- The rear of the MaxFLO2 contains a pole clamp. Mount the unit securely to the pole via the pole clamp. When mounting ensure the pole sits in the curved groove of the clamp's arm. Tighten the screw clockwise until the unit is completely secure.

- The MaxFLO2 must be mounted in the vertical position for correct function of the air and oxygen flowmeters.

- Connect a pressure capable air source to the air inlet fitting and a pressure capable oxygen source to the oxygen inlet fitting.

- Connect the air and oxygen hoses to their respective gas sources.

- Connect appropriate tubing to the conical outlet fitting.

2.2 Setting Flow and Oxygen Concentration

- To increase the flow of air or oxygen turn the flow control knob of the desired gas counter-clockwise. Each flowmeter contains a float ball which indicates the flow rate when read against the flowmeter's scale. The float ball must be read at centerline while looking straight at the flowmeter.

- Table 1 (Oxygen Concentration) below, describes the required air/oxygen flow rates required to attain a desired FiO₂.

NOTE: For the Low Flow MaxFLO2, the maximum total flow at 21% O₂ or 100% O₂ is 10 LPM and the maximum total flow at 60% O₂ is 20 LPM.

TO SET FiO₂ and FLOW:

- Find correct total flow as illustrated in Table 1.

- Find closest FiO₂ corresponding to correct total flow as illustrated in Table 1.

- Set air flow as determined by medical air LPM of Table 1 by reading number at top of medical air LPM column.

- Set oxygen flow as determined by oxygen LPM of Table 1 by reading number at left of oxygen LPM row.

See example on pg. 4 of this operating manual.

| Oxygen (LPM) | Medical Air (LPM) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | |

| 0 | 21 | 21 | 21 | 21 | 21 | 21 | 21 | 21 | 21 | 21 | 21 |

| 1 | 100/61 | 47 | 41 | 37 | 34 | 32 | 31 | 30 | 29 | 28 | 21 |

| 2 | 100/74 | 61 | 53 | 47 | 44 | 41 | 39 | 37 | 35 | 34 | 21 |

| 3 | 100/80 | 68 | 61 | 55 | 51 | 47 | 45 | 43 | 41 | 39 | 21 |

| 4 | 100/84 | 74 | 66 | 61 | 56 | 53 | 50 | 47 | 45 | 44 | 21 |

| 5 | 100/87 | 77 | 70 | 65 | 61 | 57 | 54 | 51 | 49 | 47 | 21 |

| 6 | 100/89 | 80 | 74 | 68 | 64 | 61 | 57 | 55 | 53 | 51 | 21 |

| 7 | 100/90 | 82 | 76 | 71 | 67 | 64 | 61 | 58 | 56 | 54 | 21 |

| 8 | 100/91 | 84 | 78 | 74 | 70 | 66 | 63 | 61 | 58 | 56 | 21 |

| 9 | 100/92 | 86 | 80 | 76 | 72 | 68 | 65 | 63 | 61 | 58 | 21 |

| 10 | 100/93 | 87 | 82 | 77 | 74 | 70 | 67 | 65 | 63 | 61 | 21 |

2.3 Use of Mixed Gas Analysis Port

The mixed gas analysis port on the MaxFLO2 can be used to spot check or monitor oxygen concentrations being delivered from the device. The mixed gas analysis port contains a spring loaded valve which is opened on receipt of a standard 15mm flow diverter connected to an analyzer/monitor. The mixed gas analysis port is designed to support measurement of oxygen concentration without the need for continuous gas bleed. The valve automatically closes when the diverter is removed.

Use caution to ensure the mixed gas analysis port is clean and free of any foreign matter before each use. Always re-cover the port when the port is not in use with an oxygen analyzer/monitor.

- Slide the mixed gas analysis port cover to the side to expose the port. Insert the analyzer/monitor diverter completely into the port. A small gap may remain between the bottom of the diverter and the top of the MaxFLO2, this is normal. Note: the mixed gas analysis port contains a spring loaded valve. Diverters with improper fit may be pushed out of the port by the force of the spring. Use the diverter supplied with the MaxFLO2.

- Follow the manufacturer's recommended calibration procedures as outlined for your particular analyzer/monitor.

All Maxtec analyzers/monitors are designed to be calibrated at 100% O₂. Maxtec recommends for accuracy, that during calibration, oxygen flow be set as close to the desired total flow rate as possible. For example for a flow of 8 LPM of oxygen, and 4 LPM of air, calibrate using an oxygen flow of 10 LPM. Also, any downstream tubing or cannula must be connected to the Mixed Gas Outlet in order to induce the same amount of back pressure that will be seen during actual use.

✅ 3.0 Performance Check

The MaxFLO2 is designed for low maintenance operation. However, the following functional tests should be performed periodically in order to ensure proper function.

- Install the MaxFLO2 according to section 2.1 of this operating manual in order to conduct the performance check.

Warning: If the MaxFLO2 does not function as described in the following tests discontinue use of the device pending service by trained technicians or contact your Maxtec Distributor or Maxtec at: 2305 South 1070 West, Salt Lake City, UT 84119 (801) 266-5300 or (800) 748-5355

Gas supply functional testing procedure:

- Place a calibrated Analyzer/Monitor in the mixed gas analysis port and adjust both flowmeters to flow at 2 LPM. Observe gas flowing from mixed gas outlet and that the Analyzer/Monitor reads 57 - 64% O₂.

- Maintain both flowmeters at 2 LPM and disconnect 50 PSIG air source from the wall or regulator. Observe gas flowing from mixed gas outlet and that the Analyzer/Monitor reads 95 - 100% O₂.

- Reconnect 50 PSIG air source to the wall or regulator. Observe gas flowing from mixed gas outlet and that the Analyzer/Monitor reads 57 - 64% O₂.

- Maintain both flowmeters at 2 LPM and disconnect 50 PSIG oxygen source from the wall or regulator. Observe gas flowing from mixed gas outlet and that the Analyzer/Monitor reads 20.9 - 22% O₂.

- Reconnect 50 PSIG oxygen source to wall or regulator. Observe gas flowing from mixed gas outlet and that the Analyzer/Monitor reads 57 - 64% O₂.

Reverse flow functional testing procedure:

- Remove any Analyzer/Monitor from the mixed gas analysis port and ensure that the port is closed.

- Using air and oxygen cylinders with regulators, adjust both air and oxygen cylinder regulators to zero (0) PSIG.

- Remove the conical outlet fitting and cover and seal the male DISS fitting.

- Remove air inlet hose at air cylinder regulator and insert end into beaker of water.

- Fully open MaxFLO2 air and oxygen valves.

- Slowly raise pressure of oxygen cylinder regulator to 50 PSIG and return back to zero (0) PSIG while watching air hose end in beaker. Observe that no bubbles are escaping from submerged end of air hose during test.

- Ensure air inlet hose is completely dry and re-attach to air cylinder regulator.

- Remove oxygen inlet hose at oxygen cylinder regulator and insert end into beaker of water.

- Slowly raise pressure of air cylinder regulator to 50 PSIG and back to zero (0) while watching oxygen hose end in beaker. Observe that no bubbles are escaping from submerged end of oxygen hose during test.

- Ensure oxygen inlet hose is completely dry and re-attach to oxygen cylinder regulator.

- Uncover the DISS fitting and re-place the conical outlet fitting.

?️ 4.0 Troubleshooting

Problem: Gas leaking past flow control valve even though valve is closed.

Potential causes and solutions:

- Flow valve knob is over-tightened or the valve's internal stem may not be seated correctly. Turn the valve counter-clockwise to allow some flow then re-close the valve without undue force.

- Flow valve is contaminated or internal o-rings are worn or damaged. Contact your Maxtec distributor or Maxtec for repair.

Problem: Float ball is not stable and bobbles up and down.

Potential causes and solutions:

- Flow rate is outside flowmeter specifications. Reduce flow rate. (Occasional and intermittent bobbling is normal at flow rates between 80% and 100% of full scale.)

Problem: Flow exiting the MaxFLO2 is higher than the cumulative flow of both flowmeters.

Potential causes and solutions:

- Excessive backpressure is reducing sensitivity of flowmeters. Reduce the total flow rate and/or use less restrictive patient circuitry. Note: The FiO₂ readings from Table 1 (pg.3) will not be affected.

- Float ball is contaminated. Contact your Maxtec distributor or Maxtec for repair.

Problem: Analyzer/Monitor diverter is difficult to insert or does not remain inserted in Mixed Gas Analysis Port.

Potential causes and solutions:

- Diverter is the wrong size. Use diverter supplied by Maxtec, part number R110P10-001 as noted in section 10.2 of this operating manual.

? 5.0 Cleaning

Use caution to prevent any fluid from entering the MaxFLO2. Clean the exterior surface of the MaxFLO2 in accordance with institutional cleaning protocols. Dry completely before re-use.

- DO NOT soak or immerse the MaxFLO2 in fluid.

- DO NOT allow any fluid to enter the MaxFLO2.

- DO NOT autoclave or expose the MaxFLO2 to ethylene oxide sterilization.

- DO NOT use any solvent based cleaners on the MaxFLO2 or its' labels.

? 6.0 Service and Maintenance

Maxtec recommends the performance check listed in section 3 of this operating manual be conducted prior to placing the MaxFLO2 into clinical use and periodically thereafter. If the MaxFLO2 does not function as described in the performance check, discontinue use of the device pending service by trained technicians or contact your Maxtec distributor or Maxtec at: 2305 South 1070 West, Salt Lake City, UT 84119 (801) 266-5300 or (800) 748-5355

The MaxFLO2's flow adjustment valves should be replaced as needed with R219P33 from section 10.2 of this operating manual. The full MaxFLO2 device should be overhauled and serviced a minimum of every four (4) years with R219P33-002 to replace all o-rings and valves.

When using a medical grade air source, a watertrap/filter is recommended to be attached to the air inlet of the MaxFLO2 prior to use. Contaminants from gas sources may compromise the function of the MaxFLO2.

Store the MaxFLO2 in a clean, dry place when not in use.

? 7.0 Abbreviation Guide

| Abbreviation | Meaning |

|---|---|

| FiO₂ | Fraction concentration of inspired oxygen |

| °C | Degrees Celsius |

| °F | Degrees Fahrenheit |

| CGA | Compressed Gas Association |

| DISS | Diameter indexed safety system |

| O₂ | Oxygen |

| LPM | Liters per minute |

| atm | Standard atmosphere |

| PSIG | Pounds per square inch gauge |

| kPaG | Kilo-pascal gauge |

? 8.0 Specifications

| Specification | Value |

|---|---|

| Weight (unpackaged) | 2.4 lbs (1.1 kg) |

| Internal Filter (air and O₂ inlet) | 45 - 90 µm particulate |

| O₂ Concentration Adjustment Range | 21% - 100% O₂ |

| Accuracy of O₂ Concentration | +/- 5% of the indicated value |

| Gas Supply Pressure | 25 - 75 PSIG (170 - 520 kPaG) |

| Outlet Flow Range | 1 LPM (at 20.9% O₂ and 100% O₂) to 20 LPM (at 60% O₂) for low flow mixer |

| Optimal Working Pressure | 50 PSIG (345 kPaG) |

| Maximum Allowable Pressure | 100 PSIG (689 kPaG) |

| Temperature Range (Mixer only) | 59°F - 104°F (15°C - 40°C) |

| Maximum Allowable Temperature (Mixer only) | 150°F (65°C) |

| Relative Humidity Range | 0 - 95% non-condensing |

| Ambient Storage Conditions Temperature Range | 5°F - 122°F (-15°C - 50°C) |

? 9.0 Factors Influencing Calibration When Using the Mixed Gas Analysis Port

9.1 Flow Rate Effect

In order to get accurate readings from the mixed gas analysis port, for mixed gas concentrations, the total flow must be at least 2 LPM.

9.2 Temperature Effect

Readings from an oxygen analyzer/monitor will typically hold calibration and read correctly within ± 2% when in thermal equilibrium with their operating environment. Use caution to ensure the oxygen analyzer/monitor is thermally stable when calibrated to ensure optimal performance and accurate readings by the analyzer/monitor. Maxtec recommends the following:

- Allow adequate time for the sensor to equilibrate to a new ambient temperature.

- For best results, perform the calibration procedure at a temperature close to the temperature where analysis will occur.

9.3 Pressure Effect

Readings from an oxygen analyzer/monitor are proportional to the partial pressure of oxygen. The partial pressure is proportional to the absolute pressure at any given concentration. Thus the readings are proportional to the concentration if the pressure is held constant. Flow rate of a gas can affect the sensor calibration due to a change in pressure. Maxtec recommends the following:

- Calibrate analyzers/monitors used with the MaxFLO2 at as close to the same flow as possible as during normal operating conditions.

9.4 Humidity Effect

Humidity (non-condensing) has no effect on the performance of the MaxFLO2 other than diluting the gas.

- Use caution to avoid condensing humidity when in operation.

? 10.0 Spare Parts and Accessories

10.1 Included with Your Unit

| Part Number | Item |

|---|---|

| R223P01 | MaxFLO2, Low Flow |

| R219P31 | 22mm Male/15mm Female Conical Fitting, Low Flow |

| R110P10-001 | Flow Diverter |

| R223M01 | Operating Manual and Instructions for Use (English)* |

10.2 Spare Parts

| Part Number | Item |

|---|---|

| R110P10-001 | Flow Diverter |

| R219P31 | 22mm Male/15mm Female Conical Fitting, Low Flow |

| R219P33 | Low Flow Valve Replacement Kit |

| R219P33-002 | Low Flow Overhaul Kit |

10.3 Optional Accessories

| Part Number | Item |

|---|---|

| R217P62 | MaxO2+A (Handheld Oxygen Analyzer) |

| R217P72 | MaxO2+AE (Handheld Oxygen Analyzer) |

| R213P10 | OM-25AE (Oxygen Analyzer) |

| R213P05 | OM-25ME (Oxygen Monitor) |

| R125P03-002 | MAX-250E (Oxygen Sensor Medical) |

| R129P12 | 2' Blender Hose |

| R100P49-001 | SmartStack I.V. Stand (Single, Premium) |

| R206P75 | Pole Mount (For use with Analyzers/Monitors with external sensors) |

* An electronic version of this Operating Manual and Instructions for Use is available on-line at www.maxtec.com

? 11.0 Theory of Operation

11.1 Mixing Operation

The MaxFLO2 is designed to utilize two 50 PSIG (345 kPa) gas sources - medical grade air and oxygen (Figure 1, for reference only). The two gases enter through the air and oxygen inlet connectors located on the left and right side of the MaxFLO2 respectively. Each inlet connector incorporates a one-way check valve which prevents reverse gas flow from either the air or oxygen supply system in the event of a loss of pressure from either gas source. The check valves are followed by a 45-90 micron particulate filter. Once through the filters, each gas passes through a flow control valve and then into a non-pressure compensated flowmeter. The non-pressure compensated flowmeters display flow correctly by means of a float, regardless of the inlet pressure, due to flow being exhausted to atmosphere. Inlet pressures over 100 PSIG (690 kPa) risk damaging the mixer and/or causing injury and should never be surpassed. The flowmeters will continue to display the correct flow as long as no back pressure develops. The effects of backpressure are discussed and diagrammed in section 12.3 of this operating manual.

Figure 1: Mixing Diagram

Diagram illustrating the internal flow path of the MaxFLO2:

- Air enters through the Air Inlet, passes through the Air Flow Control Valve, and into the Air Flowmeter.

- Oxygen enters through the O₂ Inlet, passes through the O₂ Flow Control Valve, and into the Oxygen Flowmeter.

- Both gases are then combined at the top and exit through the Mixed Gas Outlet.

- Arrows indicate the direction of gas flow.

11.2 Mixed Gas Analysis Port and Sampling Chamber

After passing the flowmeters the air and oxygen gas sources are channeled to and combined together at the top of the mixer. Integral to the top of the mixer, and adjacent to the mixed gas analysis port, is a chamber designed to be accessed by the diverter of an oxygen analyzer/monitor through the mixed gas analysis port. The chamber of the mixed gas analysis port allows a sample of the mixed gas to be diverted towards the oxygen analzyer/monitor without the need for a continuous gas bleed. The mixed gas analysis port is sized for a 15mm diverter and contains a spring loaded, sealed plunger that opens on receipt of the diverter and automatically closes and seals on removal of the diverter.

11.3 Mixed Gas Outlet

A single gas outlet is located at the bottom of the MaxFLO2. The outlet is capable of delivering metered flows of 1 LPM (at 20.9% or 100% O₂) to 20 LPM (at 60% O₂) of mixed gas. The outlet is not intended to ever be sealed or occluded during normal use.

? 12.0 Flow Characteristics

12.1 Maximum Flow

The following diagram illustrates the maximum flow available to the Low Flow MaxFLO2 at any desired FiO₂. For maximum flow at values ≤ 60% O₂ set the air flowmeter to 10 LPM and adjust the oxygen flowmeter until the desired FiO₂ is attained. For maximum flow at values ≥ 60% O₂ set the oxygen flowmeter to 10 LPM and adjust the air flowmeter until the desired FiO₂ is attained.

Diagram: Maximum Flow vs. % Oxygen

A line graph showing Maximum Flow (LPM) on the Y-axis from 10 to 20, and % Oxygen on the X-axis from 20 to 100. The graph shows a curve peaking around 60% Oxygen, indicating the maximum achievable flow rate at different oxygen concentrations.

12.2 Minimum Flow

The following diagram illustrates the minimum flow available to the Low Flow MaxFLO2 at any desired FiO₂. For minimum flow at values ≤ 60% O₂ set the air flowmeter to 1 LPM and adjust the oxygen flowmeter until the desired FiO₂ is attained. For minimum flow at values ≥ 60% O₂ set the oxygen flowmeter to 1 LPM and adjust the air flowmeter until the desired FiO₂ is attained.

Diagram: Minimum Flow vs. % Oxygen

A line graph showing Minimum Flow (LPM) on the Y-axis from 1.0 to 2.0, and % Oxygen on the X-axis from 20 to 100. The graph shows a curve peaking around 60% Oxygen, indicating the minimum achievable flow rate at different oxygen concentrations.

12.3 Back Pressure Effect on Low Flow MaxFLO2

The following diagram shows the effect of backpressure on the Low Flow MaxFLO2's outlet port on actual flow rates.

1 PSIG = 6.9 kPag = 70 cm H₂O

3 PSIG = 20.9 kPag = 211 cm H₂O

6 PSIG = 41.4 kPag = 422 cm H₂O

Diagram: Actual Flow Rate vs. Set Flow Rate with Back Pressure

A line graph showing Actual Flow Rate (LPM) on the Y-axis from 0 to 30, and Set Flow Rate (LPM) on the X-axis from 0 to 20. Three distinct lines represent different back pressures: 1 psig, 3 psig, and 6 psig. The lines show that actual flow rate increases with set flow rate, and higher back pressure reduces the actual flow rate for a given set flow rate.