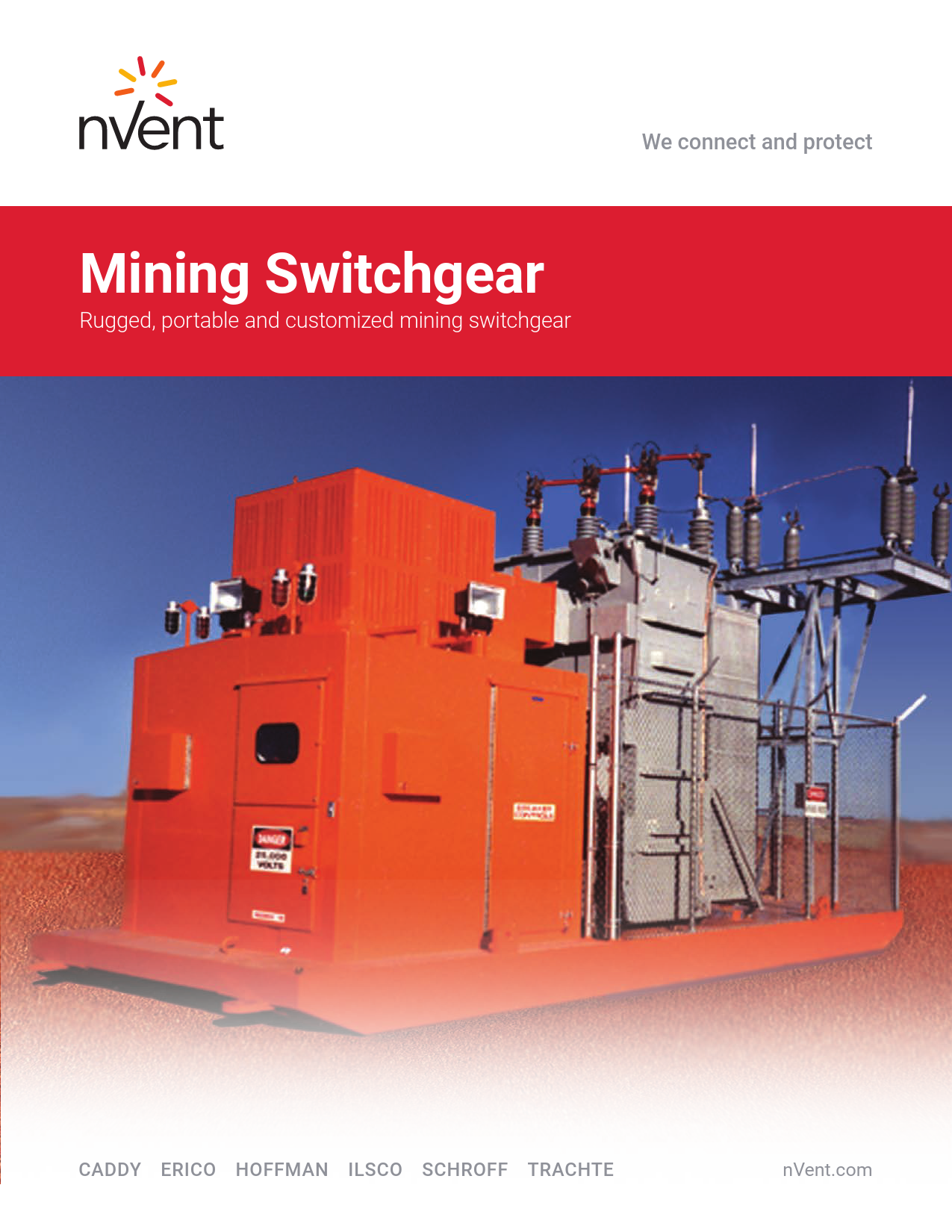

Reliable Switchgear Solutions Built for Tough Environments

Designed to withstand the harsh conditions found in mining applications, nVent provides a complete line of switchgear solutions. Featuring metal-clad and metal-enclosed designs engineered with an emphasis on safety, nVent switchgear supports drag lines and shovels for safe, efficient surface mining operations.

Industry Proven Designs

Backed by decades of manufacturing experience, nVent offers a complete line of custom-designed switchgear products for surface mining applications, utility distribution substations, generating stations, and industrial and commercial facilities. nVent delivers engineering and manufacturing capabilities that provide the highest combination of product quality, installation expertise, and reliable long-term product life – a unique, value-added benefits package unsurpassed in the industry.

The product line includes many proven designs. From these established solutions, nVent can incorporate special requirements to satisfy each project's specific needs. Through this approach, each customer receives custom-built equipment satisfying their unique requirements. The diverse product scope features RTU/SCADA/PLC integrated designs and ranges from small junction skids to complex trailer-mounted substations with walk-in enclosures.

Rugged. Portable. Customized.

When providing switchgear for the mining industry, rugged and durable construction is paramount. Equipment must withstand extreme temperatures, frequent transport, and harsh conditions. In such environments, your project requires more than switchgear – it demands proven “mine-duty” engineering.

nVent builds modular equipment that utilizes heavy-duty materials and an all-welded design. This industry-leading construction process ensures that customers can count on a solution that will prove both durable and reliable throughout its service life.

Skid-mounted units are constructed with 11 Ga. reinforced enclosures featuring doors with stainless steel hinges. This all-welded assembly is mounted to a heavy-duty skid featuring 1/4" deck plates, 1.5" towing eyes, 1" thick wear plates on runners and noses, and heavy-duty beams and channels. For blast protection of the transformer, 3/8" top and side steel plates are available on request.

Certified Quality and Safety

nVent is an ISO-9001 certified company that combines proven electrical expertise with an unmatched focus on safety. Personnel are safeguarded by the implementation of high voltage signs and metal safety barriers, door interlocks, ground monitors, and the use of fluidized epoxy bus insulation tested for use at voltages up to 38 kV.

At the project site, a team of MSHA certified field service technicians work to ensure the highest standard of safety is maintained.

Single Point of Contact

A dedicated project engineer is assigned who serves as the customer's single point of contact throughout the duration of the project. This person is solely responsible for the successful execution of job requirements and all communication with the customer. Your project engineer handles all aspects of design and manufacture of the equipment.

Additional Offerings Supporting the Mining Market

Substations

- Skid mounted

- Trailer mounted

- Sizes through 20 MVA

- Primary voltages through 138 kV

Switch Units

- Skid mounted

- Trailer mounted

- Voltages through 138 kV

Breaker Units

- Skid mounted

- Trailer mounted

- Voltages through 38 kV

Pump/Lighting Substations

- 150 kVA to 1500 kVA

- Dual primary voltage

- 480 V secondary

Junction Skids

- Voltages through 38 kV

Padmounted Switchgear

- Metal-clad through 38 kV

- Metal-enclosed through 38 kV

Ground Monitors

- Solid State

- Microprocessor technology

- Pilot wire version

- Pilot wireless version

- Retrofits existing nVent monitors

Support Structures

- Skid and Trailer mounted

- Voltages through 138 kV

- Galvanized, aluminum or painted

Mine-Duty Primary Substation

nVent manufactures customized portable and fixed electrical substations and a comprehensive line of metal-clad and metal-enclosed switchgear for the surface mining industry. nVent offers fully integrated, "smart" mine-duty switchgear with advanced protection and control features, monitoring/metering equipment, and SCADA Communication Capabilities.

The rugged and reliable mine-duty substations are characterized by an all-welded construction process. From a fully welded base assembly to heavy-duty 1.5" thick towing eyes, nVent provides durable solutions uniquely tailored to meet project requirements.

Most importantly, all designs are engineered with a focus on safety. nVent products adhere to the latest IEEE, ANSI, and MSHA standards and are serviced by a team of full-time MSHA certified technicians. Optional arc-flash energy calculations are supplied on request.

Safety Features

- Metal Barriers

- Door Interlocks

- Ground Monitors

- Field Service Supported By MSHA Certified Technicians

Diagram Description

The primary visual depicts a large, orange, ruggedized enclosure mounted on a heavy-duty skid, connected to a grey electrical transformer unit. The enclosure features multiple access doors with visible stainless steel hinges. Prominent warning labels state "DANGER HIGH VOLTAGE 25,000 VOLTS" (also in Spanish: "PELIGRO ALTO VOLTAJE 25000 VOLTIOS"). Key construction highlights include an 11 Ga. reinforced enclosure, an enclosure fully welded to the base, 1" thick wear plates on runners and noses, 1.5" towing eyes, and 1/4" deck plates. The base design is engineered for load spreading. The transformer unit is equipped with SCADA Communication Capabilities, offering serial & Ethernet ports, and can accommodate transformer sizes up to 20 MVA.