EVCO c-pro 3 Kilo Programmable Control

Specifications

- Brand: EVCO S.p.A.

- Product Code: 104CP3NKIE203

- Type: Programmable controllers

- Communication Ports: RS-485, CAN, USB, Ethernet

- Power Supply: 24 VAC/DC

Product Usage Instructions

Introduction

- The c-pro 3 NODE kilo is a range of programmable controllers designed for applications in the refrigeration and air conditioning sectors. These controllers offer a wide range of inputs and outputs, allowing for a flexible and expandable control devices network.

Description

- The c-pro 3 NODE kilo IoT has a modern and compact design, suitable for various applications in the HVAC industry.

Size and Installation

- Size: The device occupies 8 DIN modules and can be installed on a DIN rail measuring 35.0 x 7.5 mm or 35.0 x 15.0 mm.

- Installation: To install the device, follow the provided drawings and instructions. Make sure to remove any extractable screw terminal blocks before mounting on the DIN rail.

Electrical Connection

- Connectors: The device features specific connectors for power supply and communication ports. Ensure proper connection according to the provided diagrams.

- Power Supply: The device requires a 24 VAC/DC power supply. Pay attention to polarity when connecting in direct current mode.

IMPORTANT

Read this document carefully before installing and using the device and follow all the additional information; keep this document close to the device for future consultations.

For further information consult the hardware manual.

![]() The device must be disposed according to the local legislation about the collection for electrical and electronic equipment.

The device must be disposed according to the local legislation about the collection for electrical and electronic equipment.

INTRODUCTION

c-pro 3 NODE kilo is a range of programmable controllers for applications in refrigeration and air conditioning sectors. The controllers have a considerable number of inputs and outputs; they allow to realize a flexible, modular and expandable control devices network.The variety of available communication ports (RS-485, CAN, USB and Ethernet) and supported communication protocols make easier the integration of the devices in systems. The application software can be realized through the UNI-PRO 3 development environment for programmable controllers. For information on the use of the BACnet communication protocol please consult the PICS.

The actual UNI-PRO 3.13 version implements a BACnet® standardized device profile B-ASC, which doesn’t require the managing of Scheduler and Calendar objects, instead required for the B-AAC profile.

DESCRIPTION

The following drawing shows the aspect of the devices.

The following chart shows the meaning of the parts of the devices.

| Part | Meaning |

| 1 | digital outputs K1 and K2 |

| 2 | digital outputs K3, K4, K5 and K6 |

| 3 | digital output K7 |

| 4 | MODBUS TCP, Web Server Ethernet port |

| 5 | display and keyboard (not available in the blind

versions) |

| 6 | digital inputs |

| 7 | analog outputs |

| 8 | USB port |

| 9 | analog inputs |

| 10 | micro-switch to plug in the CANBUS CAN port line termination, the MODBUS master/slave RS-485 port line termination and the MODBUS

slave RS-485 port line termination |

| 11 | MODBUS slave RS-485 port, MODBUS master/

slave RS-485 port and CANBUS CAN port |

| 12 | power supply |

| 13 | signalling LEDs |

SIZE AND INSTALLATION

Size

The following drawing shows the size of the devices (8 DIN modules); size is in mm (in).

Installation

Installation is on DIN rail 35.0 x 7.5 mm (1.377 x 0.295 in) or 35.0 x 15.0 mm (1.377 x 0.590 in), into a switch-board.

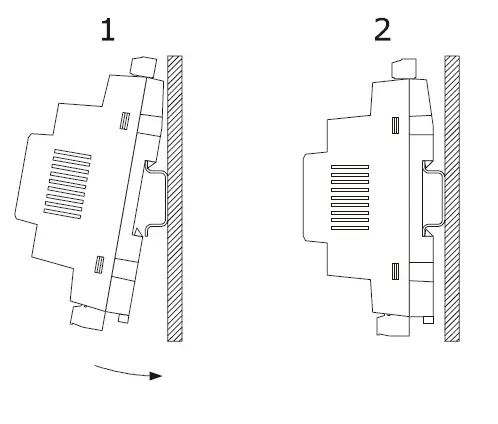

To install the devices operate as shown in the following drawing.

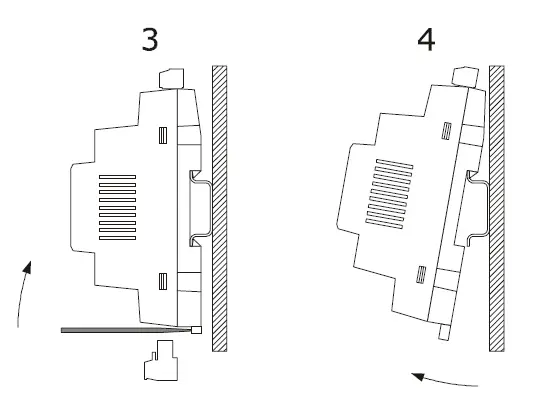

To remove the devices remove possible extractable screw ter-minal blocks plugged at the bottom first, then operate on the DIN rail clips with a screwdriver as shown in the following drawing.

To install the devices again press the DIN rail clips to the end first.

Additional information for the installation

- make sure the working conditions of the device (operating temperature, operating humidity, etc.) are in the limits indicated; look at chapter “TECHNICAL DATA”

- do not install the device close to heating sources (heaters, hot air ducts, etc.), devices having big magnetos (big speakers, etc.), locations subject to direct sunlight, rain, humidity, dust, mechanical vibrations or bumps

- according to the safety legislation, the protection against possible contacts with the electrical parts must be ensured by a correct installation of the device; all the parts which ensure the protection must be fixed so that you can not remove them if not by using a tool.

ELECTRICAL CONNECTION

Connectors

The following drawing shows the connectors of the devices.

Meaning of connectors

The following charts show the meaning of the connectors of the devices.

For further information look at chapter “TECHNICAL DATA”.

POWER

Power supply device (24 VAC/DC not isolated).

If the device is powered in direct current, it will be necessary to respect the polarity of the power supply voltage.

If the device is connected to a devices network, it will be necessary:

- the power supply of the devices making the network is galvanically isolated one another

- the phase supplying the device is the same supplying all the devices making the network.

| Part | Meaning |

| AC/+ | power supply device:

|

| AC/- | power supply device:

|

ANALOG INPUTS

Analog inputs.

| Part | Meaning |

| GND | ground analog inputs |

| AI1 | analog input 1, which can be set via configuration

parameter for PTC, NTC, Pt 1000 probes, 0-20 mA, 4-20 mA, 0-5 V ratiometric or 0-10 V transducers |

| AI2 | analog input 2, which can be set via configuration

parameter for PTC, NTC, Pt 1000 probes, 0-20 mA, 4-20 mA, 0-5 V ratiometric or 0-10 V transducers |

| AI3 | analog input 3, which can be set via configuration

parameter for PTC, NTC, Pt 1000 probes, 0-20 mA, 4-20 mA, 0-5 V ratiometric or 0-10 V transducers |

| AI4 | analog input 4, which can be set via configuration

parameter for PTC, NTC or Pt 1000 probes |

| AI5 | analog input 5, which can be set via configuration

parameter for PTC, NTC or Pt 1000 probes |

| AI6 | analog input 6, which can be set via configuration

parameter for PTC, NTC or Pt 1000 probes |

| GND | ground analog inputs |

| +5V | power supply 0-5 V ratiometric transducers (5 VDC) |

| VS | power supply 0-20 mA, 4-20 mA and 0-10 V transducers (12 VDC) |

DIGITAL INPUTS

Digital inputs.

| Part | Meaning |

| DI1 | digital input 1 (24 VAC/DC, 50/60 Hz or 2 KHz

optoisolated); the frequency can be set with the development environment UNI-PRO 3 |

| DI2 | digital input 2 (24 VAC/DC, 50/60 Hz or 2 KHz

optoisolated); the frequency can be set with the development environment UNI-PRO 3 |

| DI3 | digital input 3 (24 VAC/DC, 50/60 Hz optoisolated) |

| DI4 | digital input 4 (24 VAC/DC, 50/60 Hz optoisolated) |

| DI5 | digital input 5 (24 VAC/DC, 50/60 Hz optoisolated) |

| COM | common digital inputs |

ANALOG OUTPUTS

Analog outputs.

| Part | Meaning |

| GND | ground analog outputs |

| AO1 | analog output 1, which can be set via configuration

parameter for PWM or 0-10 V |

| AO2 | analog output 2, which can be set via configuration

parameter for PWM or 0-10 V |

| AO3 | analog output 3, which can be set via configuration

parameter for 0-20 mA, 4-20 mA or 0-10 V |

DIGITAL OUTPUTS

Digital outputs.

| Part | Meaning |

| CO1 | common digital output 1 |

| NO1 | normally open contact digital output 1

according to the model: – 3 res. A @ 250 VAC electromechanical relay – 24 VAC/DC, 600 mA max. command for solid state relay |

| CO2 | common digital output 2 |

| NO2 | normally open contact digital output 2

according to the model: – 3 res. A @ 250 VAC electromechanical relay – 24 VAC/DC, 600 mA max. command for solid state relay |

| CO3-6 | common digital outputs 3… 6 |

| NO3 | normally open contact digital output 3 (3 res. A @

250 VAC electromechanical relay) |

| NO4 | normally open contact digital output 4 (3 res. A @

250 VAC electromechanical relay) |

| NO5 | normally open contact digital output 5 (3 res. A @

250 VAC electromechanical relay) |

| NO6 | normally open contact digital output 6 (3 res. A @

250 VAC electromechanical relay) |

| CO7 | common digital output 7 |

| NO7 | normally open contact digital output 7 (3 res. A @

250 VAC electromechanical relay) |

| NC7 | normally closed contact digital output 7 |

CAN/RS-485

MODBUS slave RS-485 port, MODBUS master/slave RS-485 port and CAN CANBUS port.

The communication protocol of the MODBUS master/slave RS-485 port can be set with the development environment UNI-PRO 3.

| Part | Meaning |

| CAN+ | positive pole CANBUS CAN port |

| CAN- | negative pole CANBUS CAN port |

| GND | ground MODBUS slave RS-485 port, MODBUS mas-

ter/slave RS-485 port and CAN CANBUS port |

| A1/+ | positive pole MODBUS master/slave RS-485 port |

| B1/- | negative pole MODBUS master/slave RS-485 port |

| A2/+ | positive pole MODBUS slave RS-485 port |

| B2/- | negative pole MODBUS slave RS-485 port |

USB

USB port.

ETHERNET

MODBUS TCP, Web Server Ethernet port.

Plugging in the CANBUS CAN port line termination

To plug in the CANBUS CAN port line termination, position micro-switch 3 on position ON.

Plugging in the MODBUS master/slave RS-485 port line termination

To plug in the MODBUS master/slave RS-485 port line termination, position micro-switch 2 on position ON.

Plugging in the MODBUS slave RS-485 port line termination

To plug in the MODBUS slave RS-485 port line termination, position micro-switch 1 on position ON.

Polarizing the MODBUS master/slave RS-485 port

The polarization of the MODBUS master/slave RS-485 port can be set via configuration parameter.

Polarizing the MODBUS slave RS-485 port

The devices are not able to polarize the MODBUS slave RS-485 port; the polarization must be done by another de-vice.

Additional information for electrical connection

- do not operate on the terminal blocks of the device using electrical or pneumatic screwers

- if the device has been moved from a cold location to a warm one, the humidity could condense on the inside; wait about an hour before supplying it

- make sure the power supply voltage, the electrical frequency and the electrical power of the device correspond to those of the local power supply; look at chapter “TECHNICAL DATA”

- disconnect the power supply of the device before servicing it

- connect the device to a RS-485 devices network using a twisted pair

- connect the device to a CAN devices network using a twisted pair

- position the power cables as far away as possible from the signal cables

- do not use the device as safety device

- for the repairs and for information about the device please contact the EVCO sales network.

SIGNALINGS

Signalings

| LED | Meaning |

| ON | LED power supply

if it is lit, the device will be powered if it is out, the device will not be powered |

| RUN | LED run

if it is lit, the application software will be compiled and running in release modality if it flashes slowly, the application software will be compiled and running in debug modality if it flashes quickly, the application software will be compiled, running in debug modality and stopped in a breakpoint if it is out: – the device will not be compatible with the application software – the device will not be enabled to work with the special ABL (Application Block Libraries) |

|

LED system alarm

if it is lit, an alarm system not resettable via application software will be running if it flashes slowly, a system alarm with automatic reset will be running if it flashes very slowly, an access to the external FLASH memory will be running if it flashes quickly, a system alarm with manual reset will be running if it is out, no alarm system will be running |

| CAN | LED CANBUS CAN communication

if it is lit, the device will be configured to communicate via CANBUS CAN with another device but the communication will not have been set up if it flashes slowly, the CANBUS CAN communication will have been set up but it will not be completely correct if it flashes quickly, the CANBUS CAN communication will have been set up and will be correct if it is out, no CANBUS CAN communication will be running |

| L1 | LED auxiliary

the operation of this LED can be set with the development environment UNI-PRO 3 |

TECHNICAL DATA

Technical data

- Purpose of control: operating control device. Construction of control: incorporated electronic device.

- Box: self-extinguishing grey.

- Heat and fire resistance category: D.

- Size: 142.0 x 128.0 x 60.0 mm (5.590 x 5.039 x 2.362 in; W x H x D); 8 DIN modules.

- Size refers to the device with the extractable screw terminal blocks properly plugged.

- Method of mounting control: on DIN rail 35.0 x 7.5 mm (1.377 x 0.295 in) or 35.0 x 15.0 mm (1.377 x 0.590 in).

Degree of protection

- IP20 on the whole

- IP40 the front.

Connections

- only male removable screw connection terminal blocks with pitch 3.5 mm (0.137 in) for conductors up to 1.5 mm² (0.0028 in²): power supply, analog inputs, digital inputs, analog outputs, MODBUS slave RS-485 port, MODBUS master/slave RS-485 port and CANBUS CAN port

- only male removable screw connection terminal blocks with pitch 5.0 mm (0.196 in) for conductors up to 2.5 mm² (0.0038 in²): digital outputs

- A type USB connector: USB port

- RJ45 F telephone connector: MODBUS TCP, Web Server Ethernet port.

The maximum lengths allowed for the connecting cables are the following:

- power supply: 100 m (328 ft)

- analog inputs: 100 m (328 ft)

- power supply transducers: 100 m (328 ft)

- digital inputs: 100 m (328 ft)

- PWM analog outputs: 1 m (3.280 ft)

- 0-20 mA, 4-20 mA and 0-10 V analog outputs: 100 m (328 ft)

- digital outputs (electromechanical relays): 100 m (328 ft)

- digital outputs (command for solid state relays): 100 m (328 ft)

- MODBUS slave RS-485 port and MODBUS master/slave RS-485 port: 1,000 m (3,280 ft); also look at MODBUS specifications and implementation guides manual available on http://www.modbus.org/specs.php

CANBUS CAN port:

- 1,000 m (3,280 ft) with baud rate 20,000 baud

- 500 m (1,640 ft) with baud rate 50,000 baud

- 250 m (820 ft) with baud rate 125,000 baud

- 50 m (164 ft) with baud rate 500,000 baud according to the factory setting the device automatically detects the baud rate of the other elements making the network, on condition that it is one of those listed before; on afterwards set manually the baud rate to the same value of that of the other elements

USB port: 1 m (3.280 ft).

To wire the device one suggests using the connecting kit CJAV31 (to order separately): only female removable screw connection terminal blocks with pitch 3.5 mm (0.137 in) for conductors up to 1.5 mm² (0.0028 in²) and only fe-male removable screw connection terminal blocks with pitch 5.0 mm (0.196 in) for conductors up to 2.5 mm² (0.0038 in²).

To program the device one suggests using the connecting cables 0810500018 or 0810500020 (to order separately): the cable 0810500018 is 2.0 m (6.561 ft) long, the cable 0810500020 is 0.5 m (1.640 ft) long.

Operating temperature:

- from -10 to 55 °C (from 14 to 131 °F) for the built-in versions

- from -20 to 55 °C (from -4 to 131 °F) for the blind versions.

Storage temperature: from -25 to 70 °C (from -13 to 158 °F).

Operating humidity: from 10 to 90% of relative humidity not condensing.

Control pollution situation: 2.

Environmental conformity:

- RoHS 2011/65/CE

- WEEE 2012/19/EU

- REACH regulation (CE) n. 1907/2006.

EMC conformity:

- EN 60730-1

- IEC 60730-1.

Power supply:

- 24 VAC (+10 % -15 %), 50/60 Hz (±3 Hz), 20 V A max. not isolated

- 20… 40 VDC, 12 W max. not isolated supplied by a class 2 circuit.

Protect the power supply with a 2 A-T 250 V fuse.

If the device is powered in direct current, it will be necessary to respect the polarity of the power supply voltage.

Rated impulse voltage: 4 KV.

Overvoltage category: III.

Class and structure of software: A.

Real time clock: incorporated (with lithium primary battery).

Battery range in absence of power supply: 5 years @ 25 °C (77 °F).

Drift: ≤ 30 s/month @ 25 °C (77 °F).

Analog inputs: 5 inputs:

- 3 which can be set via configuration parameter for PTC, NTC or Pt 1000 probes

- 3 which can be set via configuration parameter for PTC, NTC, Pt 1000 probes, 0-20 mA, 4-20 mA, 0-5 V ratiometric or 0-10 V transducers

Power supply 0-5 V ror 0-10 V ratiometric transducers: 5 VDC (+0 %, -12 %), 60 mA max.

Power supply 0-20 mA, 4-20 mA and 0-10 V transducers: 12 VDC (±10 %), 120 mA max.

The maximum current which can be supplied on the whole from the two power supply is 120 mA.

PTC analog inputs (990 Ω @ 25 °C, 77 °F)

- Kind of sensor: KTY 81-121.

- Working range: from -50 to 150 °C (from -58 to 302 °F).

- Accuracy: ±0.5 % of the full scale.

- Resolution: 0.1 °C.

- Conversion time: 100 ms.

- Protection: none.

NTC analog inputs (10 KΩ @ 25 °C, 77 °F)

- Kind of sensor: ß3435.

- Working range: from -40 to 120 °C (from -58 to 248 °F).

- Accuracy:

- ±0.5 % of the full scale from -40 to 100 °C

- ±1 °C from -50 to -40 °C and from 100 to 120 °C.

- Resolution: 0.1 °C.

- Conversion time: 100 ms.

- Protection: none.

NTC analog inputs (10 KΩ @ 25 °C, 77 °F)

- Kind of sensor: NTC type 2.

- Working range: from -40 to 86 °C (from -40 to 186 °F).

- Accuracy: ±1 °C.

- Resolution: 0.1 °C.

- Conversion time: 100 ms.

- Protection: none.

NTC analog inputs (10 KΩ @ 25 °C, 77 °F)

- Kind of sensor: NTC type 3.

- Working range: from -40 to 86 °C (from -40 to 186 °F).

- Accuracy: ±1 °C

- Resolution: 0.1 °C.

- Protection: none..

Pt 1000 analog inputs (1 KΩ @ 0 °C, 32 °F)

- Working range: from -100 to 400 °C (from -148 to 752 °F).

- Accuracy:

- ±0.5 % of the full scale from -100 to 200 °C

- ±2 °C from 200 to -400 °C.

- Resolution: 0.1 °C.

- Conversion time: 100 ms

- Protection: none.

0-20 mA and 4-20 mA analog inputs

- Input resistance: ≤ 200 Ω.

- Accuracy: ±0.5 % of the full scale.

- Resolution: 0.01 mA.

- Conversion time: 100 ms.

- Protection: none; the maximum current allowed on each input is 25 mA.

0-5 V ratiometric and 0-10 V analog inputs

- Input resistance: ≥ 10 KΩ.

- Accuracy: ±0.5 % of the full scale.

- Resolution: 0.01 V.

- Conversion time: 100 ms.

- Protection: none.

Digital inputs: 5 inputs (which can be set with the development environment UNI-PRO 3 for NO or NC contact):

- 2 at 24 VAC/DC, 50/60 Hz or 2 KHz optoisolated; the frequency can be set with the development environment UNI-PRO 3

- 3 at 24 VAC/DC, 50/60 Hz.

24 VAC/DC, 50/60 Hz digital inputs

- Power supply:

- 24 VAC (±15 %), 50/60 Hz (±3 Hz)

- 24 VDC (+66 %, -16 %).

- Input resistance: ≥ 10 KΩ.

- Protection: none.

24 VAC/DC, 2 KHz digital inputs

- Power supply:

- 24 VAC (±15 %), 50/60 Hz (±3 Hz)

- 24 VDC (+66 %, -16 %).

- Input resistance: ≥ 10 KΩ.

- Protection: none.

Analog outputs: 3 outputs:

- 2 which can be set via configuration parameter for PWM or 0-10 V

- 1 which can be set via configuration parameter for 0-20 mA, 4-20 mA or 0-10 V.

PWM analog outputs

- Power supply: 10 VDC (+16 %, -25 %), 10 mA max.

- Frequency: 0… 2 KHz.

- Duty: 0… 100 %.

- Protection: none.

0-20 mA and 4-20 mA analog outputs

- Input resistance: 40… 300 Ω.

- Accuracy: ±3 % of the full scale.

- Resolution: 0.05 mA.

- Conversion time: 1 s.

- Protection: none.

0-10 V analog outputs

- Input resistance: 1 KΩ.

- Accuracy: ±3 % of the full scale.

- Resolution:

- +2 %, -5 % of the full scale for loads having impedance from 1 to 5 KΩ

- ±2 % of the full scale for loads having impedance > 5 KΩ.

Digital outputs: 7 outputs:

- according to the model:

- six 3 res. A @ 250 VAC SPST electromechanical relays (K1… K6)

- two 24 VAC/DC, 600 mA max. commands for solid state relay (K1 and K2) and four 3 res. A @ 250 VAC SPST electromechanical relays (K3… K6)

- one 3 res. A @ 250 VAC SPDT electromechanical relay (K7).

The device ensures a double insulation among each connector of the digital outputs and the remaining parts of the device.

Type 1 or type 2 actions: type 1.

Additional features of type 1 or type 2 action: C.

Displays: according to the model:

- none (blind version)

- 4+4 digits custom display (built-in LED version)

- 128 x 64 pixel single colour LCD graphic display (built-in LCD version).

Communication ports: 5 ports:

- 1 RS-485 port with MODBUS slave communication protocol

- 1 RS-485 port with MODBUS master/slave, BACnet MS/TP communication protocol (which can be set with the development environment UNI-PRO 3)

- 1 CAN port with CANBUS communication protocol

- 1 USB port

- 1 Ethernet port with MODBUS TCP, Web Server, BACnet IP communication protocol.

The actual UNI-PRO 3.13 version implements a BACnet® standardized device profile B-ASC, which doesn’t require the managing of Scheduler and Calendar objects, instead required for the B-AAC profile.

- CPU: 200 MHz.

- RAM: 512 kB.

- Program memory: 2 MB.

- External FLASH: 32 MB.

- Memory for Web Server: 8 MB.

- Datalog memory: 8 MB.

More Info

EVCO S.p.A.

Via Feltre 81, 32036 Sedico (BL) ITALY

- phone: +39 0437 8422

- fax: +39 0437 83648

- email: info@evco.it

- web: www.evco.it

FAQs

- Q: How do I dispose of the device?

- A: The device must be disposed of following local legislation for electrical and electronic equipment disposal.

- Q: What communication protocols are supported?

- A: The c-pro 3 NODE kilo supports communication protocols such as RS-485, CAN, USB, and Ethernet for seamless integration into systems.

Documents / Resources

|

EVCO c-pro 3 Kilo Programmable Control [pdf] Instruction Manual c-pro 3 Kilo Programmable Control, c-pro 3, Kilo Programmable Control, Programmable Control, Control |