Danfoss X-Gate Gateway Solution

Equipment

This guide focuses at the current moment on the integration of the AK2 controller via CAN bus to the X-Gate. For the integration of the X-Gate with a BMS, PLC, SCADA, etc., please refer to the User Guide.

This guide also does not cover how to obtain the ED3/ED4 file.

What is needed

- X-Gate + power supply 24V AC/DC

- AK-PC 78x family (080Z0192) + power supply 24 AC/DC

- Display MMIGRS2 (080G0294) + ACCCBI Cable Telephone (080G0076)

- Cables for the wiring

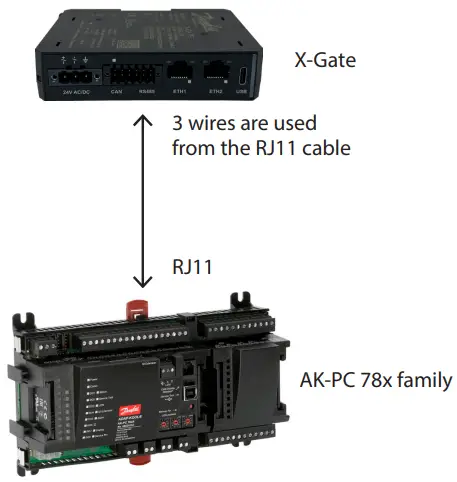

Wiring with the MMIGRS2

General overview

2a. Connection between AK-PC 78x family and MMIGRS2

CANH-R connection should be done only on the first and last element of the network. AK-PC 78x is terminated internally and the last element of the network will be the X-Gate therefore do not terminate the display. Also do not connect a separate power supply for the display. Supply comes directly from the controller via cable.

2b. Connection between MMIGRS2 and X-Gate

Terminate the CANH-R on the X-Gate. Do not connect a separate power supply for the display.

Wiring without the MMIGRS2 (direct)

Terminate the CANH-R on the X-Gate. Do not connect a separate power supply for the display.

Skip chapter 4 if the MMIGRS2 is not being used.

Settings in MMIGRS2

Required App version: 3.29 or higher and BIOS: 1.17 or higher.

Depending on the configuration of AK-PC 78x, the main screen will appear slightly different. To access the MMIGRS2 display settings, simultaneously press ![]() the and the

the and the ![]() for a few seconds.

for a few seconds.

The BIOS displays “MCX:001” in the top right corner, indicating the CAN address of AK-PC 78x. The “50K” displayed represents the CAN baud rate.

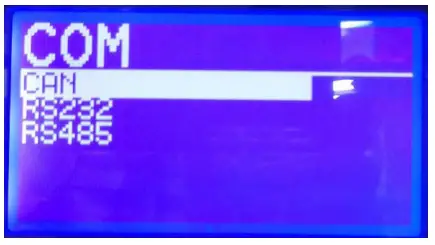

These are the default settings, and no changes are needed. If for some reason you are seeing something different you can check the following settings:

- under “COM Selection,” choose “CAN” from the available options: CAN, RS232, and RS485

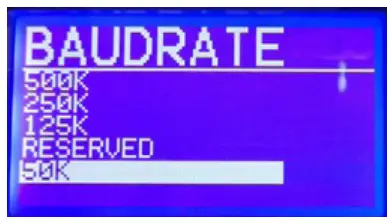

- Back in the BIOS menu: Press the down arrow to access the CAN settings. These settings control various aspects of CAN communication: Node ID, Baud Rate, Active Nodes, Diagnostics, and LSS.

- In Node ID you can select the CAN address for the display itself which is as default 126. In Baud rate we need to select 50K:

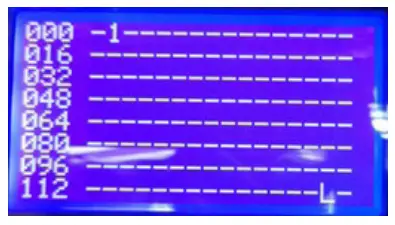

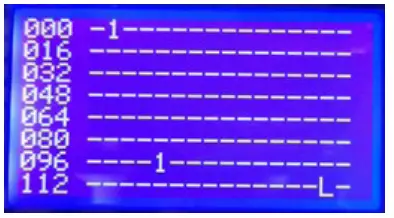

- under “Active Nodes,” you can see the connected devices:

Before the X-Gate configuration

After the X-Gate configuration

Settings in X-Gate

Access you X-Gate and log in using your credentials (default user: admin; password: PASS).

- Ensure that you have version 5.22 or higher:

- Go to Files and upload the CDF file (or ED3/ED4) for the pack controller:

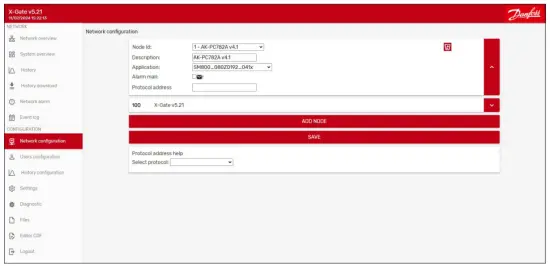

- Go to “Network Configuration” and add a node with the following settings:

- Node ID: 1

- Description: (Enter a descriptive name – this field cannot be blank)

- Application: Select the appropriate CDF file.

- Protocol Address: Leave empty.

- In the Network Overview, access the X-Gate settings by pressing the arrow next to it:

- Go to Client fieldbus and enable CAN bus (G36):

- Go to “Supervisor Settings” from the Main Menu and verify that the CAN Baud Rate (SU4) is set to 50kbps.

- Go to the Network Overview, it can take 1-2 minutes to load the page. The question mark symbol next to the AK-PC 78x should now be replaced with an arrow, indicating a successful connection:

- Go to the Pack Controller settings. You should see various values displayed. Note that some values might appear as “NaN” if the corresponding functions are not used in the Pack Controller.

Glossary of terms

| ED3/ED4 | These les are used to store conjuration settings, and other information for Danfoss devices. They are essential for maintaining and updating Danfoss equipment, ensuring that the devices operate efficiently and according to the latest speciation’s. |

| CDF (Conjuration Description File) | CDF is used to store conjuration settings and parameters for controllers. |

| BMS (Building Management System) | A BMS, also known as a Building Automation System (BAS), is a control system used in buildings to manage and monitor the building’s mechanical and electrical equipment. |

| PLC (Programmable Logic Controller) | A PLC is an industrial digital computer designed for the control and automation of manufacturing processes, such as assembly lines, robotic devices, or any activity that requires high reliability, ease of programming, and process fault diagnosis. |

| Scada (Supervisory Control and Data Acquisition) | Scada is a system used for remote monitoring and control of industrial processes. It gathers real-time data from remote locations to control equipment and conditions |

Any information, including, but not limited to information on selection of product, its application or use, product design, weight, dimensions, capacity or any other technical data in product manuals, catalogues descriptions, advertisements, etc. and whether made available in writing, orally, electronically, online or via download, shall be considered informative, and is only binding if and to the extent, explicit reference is made in a quotation or order confirmation. Danfoss cannot accept any responsibility for possible errors in catalogues, brochures, videos and other material. Danfoss reserves the right to alter its products without notice. This also applies to products ordered but not delivered provided that such alterations can be made without changes to form, fit or function of the product.

All trademarks in this material are property of Danfoss A/S or Danfoss group companies. Danfoss and the Danfoss logo are trademarks of Danfoss A/S. All rights reserved.

CUSTOMER SUPPORT

Danfoss A/S

Climate Solutions danfoss.com +45 7488 2222

Danfoss | Climate Solutions |

2025.01

AQ510212057350en-000101 | 8

Documents / Resources

|

Danfoss X-Gate Gateway Solution [pdf] Instruction Manual AQ510212057350en-000101, 080Z0192, 080G0294, X-Gate Gateway Solution, X-Gate, Gateway Solution, Solution |