1. Product Overview

The JET BDB-1340A Belt Drive Bench Lathe is a precision machine designed for metalworking applications. It features an enclosed gearbox with helical cut gears for reduced noise and smooth operation. This model includes a sturdy stand for stability and comes equipped with various accessories to facilitate a wide range of machining tasks.

Key features include a full-length splash guard for protection, a quick-change gearbox for efficient threading, and precision tapered roller bearings supporting the spindle for consistent performance.

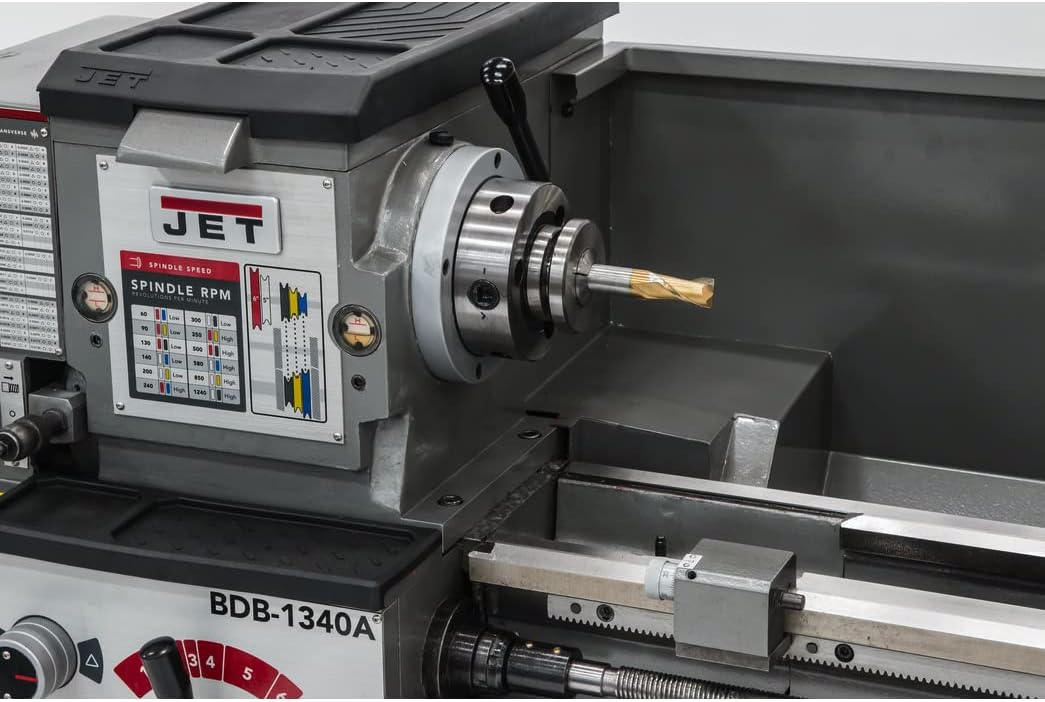

Figure 1: JET BDB-1340A Belt Drive Bench Lathe with Stand.

2. Setup and Installation

2.1 Unpacking and Inspection

Carefully unpack all components and inspect for any shipping damage. Ensure all listed components are present. The lathe and stand are heavy; use appropriate lifting equipment and techniques to prevent injury.

2.2 Assembly of Stand and Lathe

The CBS-1340A metal stand is designed to provide a stable base for the lathe. Assemble the stand according to the separate stand instructions, ensuring all fasteners are securely tightened. Once the stand is assembled, carefully lift and position the lathe onto the stand, aligning mounting holes. Secure the lathe to the stand using the provided hardware.

2.3 Electrical Connection

This lathe requires a 230V, 1-phase power supply. Ensure the electrical connection is performed by a qualified electrician and complies with all local electrical codes. The machine features low voltage motor controls for safety.

2.4 Leveling

After positioning the lathe, use a precision level to ensure the machine bed is perfectly level. Adjust the leveling feet on the stand as necessary to achieve optimal accuracy during operation.

Figure 2: Overall Dimensions of the Lathe (71" L x 32" W x 45" H).

3. Operating Instructions

3.1 Controls and Components Overview

Familiarize yourself with the main controls and components of the lathe before operation.

Figure 3: Key Components of the BDB-1340A Lathe.

- Spindle Speed Control: Adjust the spindle speed using the levers on the headstock. The lathe offers 12 spindle speeds ranging from 60 to 1,240 RPM.

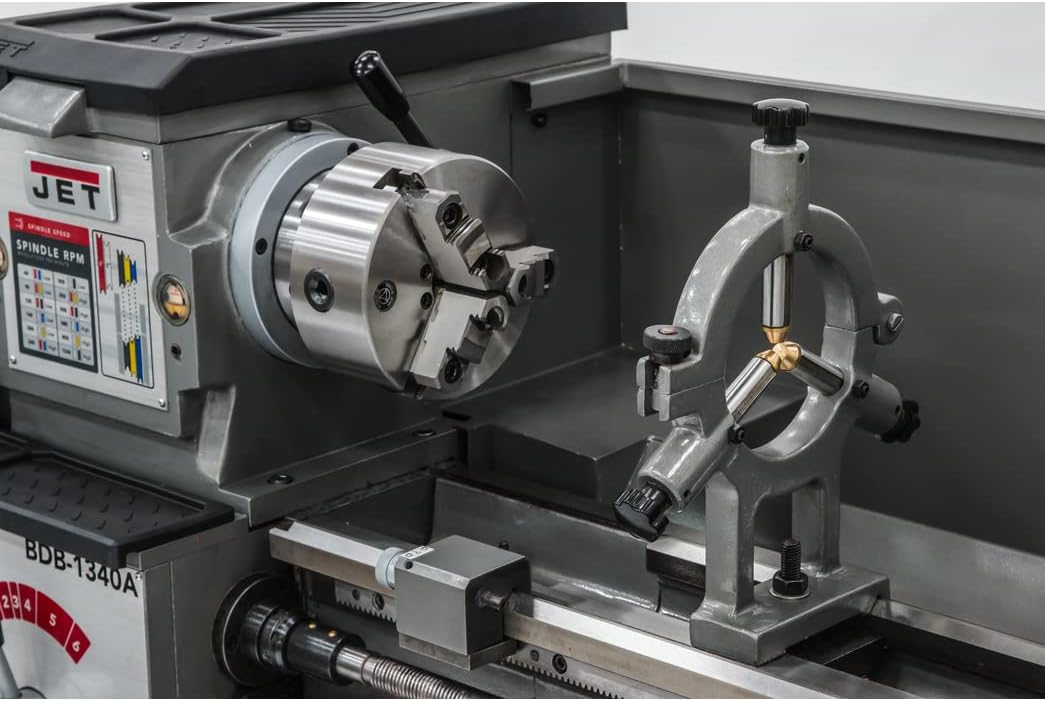

- Chucks: The lathe comes with a 6-inch 3-jaw direct mount scroll chuck with top reversing jaws and an 8-inch 4-jaw independent chuck. Select the appropriate chuck for your workpiece and secure it to the D1-4 spindle mount.

- Four-Way Tool Post: Mount cutting tools securely in the four-way tool post on the compound slide.

- Carriage Mounted Spindle Control Lever: This lever allows for convenient control of the spindle rotation from the carriage position.

- Full-Length Splash Guard: Provides protection from chips and coolant during operation.

Figure 4: Headstock and Spindle Area.

3.2 Workpiece Mounting

Securely mount the workpiece in the chosen chuck. For longer workpieces, utilize the steady rest or follow rest for additional support. The steady rest has a capacity of 2-5/8 inches, and the follow rest has a capacity of 2-3/4 inches.

Figure 5: Chuck and Steady Rest in Use.

3.3 Feeding and Threading

The lathe features independent leadscrew and feed rod for precise control. Automatic feeding and threading functions are fully interlocked for safety and ease of use. The quick-change gearbox allows for fast and easy gear changes for both inch (40 threads, 4 to 112 TPI) and metric (27 threads, 0.2 to 6) threading.

Figure 6: Carriage and Control Area.

3.4 Taper Turning

The tailstock may be offset for turning tapers, and it includes an inch/metric graduated quill for precise adjustments.

4. Maintenance

Regular maintenance is crucial for the longevity and optimal performance of your JET lathe.

- Cleaning: After each use, clean the machine thoroughly, especially the bedways, cross slide, and compound slide, to remove chips and coolant residue. The full-length splash guard helps contain debris.

- Lubrication: Refer to the lubrication chart (if available in the physical manual) for recommended lubrication points and intervals. Proper lubrication ensures smooth operation of moving parts and prevents premature wear.

- Inspection: Periodically inspect all belts, gears, and electrical connections for wear or damage. Ensure all fasteners are tight.

- Chuck Maintenance: Keep chuck jaws clean and lubricated. Store chucks properly when not in use.

5. Troubleshooting

This section provides general guidance for common issues. For complex problems, contact authorized service personnel.

- Machine Does Not Start:

- Check the main power connection and ensure the 230V supply is active.

- Verify that the emergency stop button is not engaged.

- Check for tripped circuit breakers or blown fuses.

- Excessive Noise or Vibration:

- Ensure the machine is properly leveled.

- Check for loose components or worn bearings.

- Verify that the workpiece is securely mounted and balanced.

- Inaccurate Cuts:

- Check for play in the slides (cross slide, compound slide) and adjust gibs if necessary.

- Ensure cutting tools are sharp and properly aligned.

- Verify that the tailstock is correctly aligned for non-tapered work.

6. Specifications

| Parameter | Value |

|---|---|

| Swing over bed | 13 inches |

| Swing over cross slide | 7-25/32 inches |

| Swing through gap | 18-3/4 inches |

| Length of gap | 8 inches |

| Distance between centers | 40 inches |

| Spindle bore | 1-3/8-inch |

| Spindle mount | D1-4 |

| Spindle taper with sleeve | MT-5 (MT-3) |

| Spindle speeds | 12; 60 to 1,240 RPM |

| Longitudinal feeds | 40; 0.0018 to 0.0374 IPR |

| Range of cross feeds | 0.0012 to 0.0345 IPR |

| Inch threads | 40; 4 to 112 TPI |

| Metric threads | 27; 0.2 to 6 |

| Maximum tool size | 5/8 x 5/8-inch |

| Compound slide travel | 2-11/16 inches |

| Cross slide travel | 6-5/16 inches |

| Carriage travel | 35 inches |

| Tailstock spindle travel | 3-3/4 inches |

| Taper in tailstock spindle | MT-3 |

| Steady rest capacity | 2-5/8 inches |

| Follow rest capacity | 2-3/4 inches |

| Width of bed | 7-3/8 inches |

| Overall dimensions (LxWxH) | 71 x 32 x 45 inches (with stand) |

| Motor | 2 HP, 1Ph, 230-volt only |

| Weight | 1,175 pounds |

6.1 Standard Equipment Included

- Coolant tray

- 6-inch 3-jaw direct mount scroll chuck with top reversing jaws

- 8-inch 4-jaw independent chuck

- 12-inch faceplate

- Four-way tool post

- Steady rest

- Follow rest

- Metric change gear

- Centers with headstock center sleeve

- Threading dial

- Micro Carriage Bed Stop

- Full Length Splash Guard

- Tolerance test certificate

- Tool box with tools

- CBS-1340A Stand

7. Warranty

The JET BDB-1340A Belt Drive Bench Lathe is backed by an industry-leading JET Two-Year Warranty. This warranty covers defects in materials and workmanship under normal use and service.

Figure 7: JET 2-Year Warranty.

For warranty service or repair, please contact one of JET's Authorized Service Centers located throughout the United States. These centers can assist with warranty repairs, parts acquisition, and routine maintenance.

8. Customer Support

For technical assistance, parts inquiries, or any questions regarding the operation and maintenance of your JET BDB-1340A Lathe, please contact JET customer support. Professional manuals are available to ensure optimal functioning and operation of your equipment.