1. Bubuka

This manual provides detailed instructions for the safe and efficient operation, setup, and maintenance of your VEVOR Continuous Bag Band Sealing Machine, Model 900MLP. This machine is designed for continuous sealing of various plastic bags and films, offering reliable performance for packaging needs. Please read this manual thoroughly before operating the machine to ensure proper usage and to prevent damage or injury.

2. Parentah Kasalametan

PERHATOSAN: Failure to follow these safety instructions may result in serious injury or damage to the equipment.

- Always ensure the machine is properly grounded before use.

- Ulah ngajalankeun mesin jeung leungeun baseuh atawa di damp kaayaan.

- Keep hands, hair, and loose clothing away from moving parts, especially the conveyor belt and sealing area.

- Disconnect power before performing any maintenance, cleaning, or when the machine is not in use.

- Do not attempt to modify the machine. Use only original VEVOR replacement parts.

- Pastikeun ventilasi anu cekap di sakitar mesin salami dioperasikeun.

- Jauhkeun barudak sareng tanaga anu henteu sah ti daérah operasi.

- The sealing bars become hot during operation. Avoid direct contact to prevent burns.

3. Produk Langkungview

3.1 Fitur konci

- Sealing gancang: High-power 600W design for stable, efficient sealing with durable carbon steel construction.

- Kasaluyuan Kantong Serbaguna: Adjustable sealing widths from 0.24 to 0.47 inches (6-12 mm) for various bag types.

- Fungsi Ningkatkeun: Supports embossing and alphanumeric printing (with optional rollers). Adjustable sealing speeds up to 0-52.49 ft/min (0-16 m/min).

- Asesoris lengkep: Includes toothed belts, Teflon belts, and a fuse for maintenance.

- Operasi gampang: Intuitive panel controls for adjusting parameters like temperature and speed.

3.2 Komponén

Familiarize yourself with the main components of the VEVOR Continuous Bag Band Sealing Machine:

- Panél kontrol: Contains power switch, heater switch, fan switch, speed knob, and digital temperature controller.

- Sabuk conveyor: Transports bags through the sealing process.

- Mékanisme Sealing: Includes heating and cooling elements for secure seals.

- Height Adjustment Knob: Allows adjustment of the sealing head height for different bag sizes.

- Embossing/Printing Rollers: (Optional/Included) For adding dates or codes to seals.

Figure 1: Control panel of the VEVOR Continuous Band Sealer, showing power, heater, fan switches, speed knob, and digital temperature controller.

Gambar 2: Internal view of the VEVOR Continuous Band Sealer, illustrating the heating and cooling elements for secure sealing.

4. Setélan

- Ngabongkar bungkusan: Cabut mesin sareng sadaya asesoris tina bungkusna kalayan ati-ati. Pariksa heula naha aya karusakan nalika pengiriman.

- panempatan: Place the machine on a stable, level surface capable of supporting its weight (approximately 26.12 lbs / 11.85 kg). Ensure sufficient space around the machine for operation and ventilation.

- Sambungan Daya: Connect the power cord to a grounded 110V AC outlet. Ensure the power switch on the control panel is in the OFF position before plugging in.

- Conveyor Belt adjustment: The conveyor belt is pre-installed. Ensure it runs smoothly and is properly aligned.

- Penyesuaian Jangkungna: Adjust the height of the sealing head using the adjustment knob to match the height of your bags. The bag height range is 4.72-9.65 inches (120-245 mm).

- Optional Embossing/Printing: If using embossing rollers, install them according to the separate instructions provided with the rollers.

Figure 3: The VEVOR Continuous Band Sealer shown with its included accessories, ready for setup.

5. Parentah Operasi

- Daya Hurung: Hurungkeun saklar daya utama dina panel kontrol.

- Setel Suhu: Use the digital temperature controller to set the desired sealing temperature. The temperature range is 32-572°F (0-300°C). The optimal temperature depends on the bag material and thickness. Start with a lower temperature and gradually increase if needed.

- Activate Heater and Fan: Turn on the HEATER switch. Allow the machine to preheat until the set temperature is reached (indicated on the digital display). Once the heater is on, also turn on the FAN switch to ensure proper cooling after sealing.

- Saluyukeun Speed: Use the SPEED knob to set the conveyor belt speed. The sealing speed can be adjusted from 0-52.49 ft/min (0-16 m/min). Adjust the speed based on the bag material and desired seal quality. Slower speeds generally result in stronger seals.

- Uji Segel: Before sealing actual products, perform test seals on empty bags to verify temperature and speed settings. Adjust as necessary to achieve a strong, consistent seal.

- Kantong pakan: Place the open end of the bag onto the conveyor belt, guiding it into the sealing mechanism. The machine will continuously feed and seal the bags.

- Operasi Monitor: Continuously monitor the sealing process to ensure consistent seal quality and proper bag feeding.

- Pareum listrik: After use, turn off the HEATER switch first. Allow the fan to run for a few minutes to cool down the sealing bars before turning off the FAN switch and then the main POWER switch. This extends the lifespan of the heating elements.

Video 1: Demonstration of the VEVOR Continuous Band Sealer in operation, showing bag feeding and sealing process.

Pidéo 2: Langkung lengkepnaview of the VEVOR Continuous Band Sealer's features and functionality.

6. Pangropéa

Pangropéa rutin mastikeun umur panjang sareng kinerja optimal mesin sealing anjeun.

- beberesih: Regularly clean the conveyor belt and sealing area to remove any plastic residue or debris. Use a dry cloth; do not use abrasive cleaners or solvents. Ensure the machine is unplugged and cooled down before cleaning.

- Teflon Belt Replacement: The Teflon belts (0.008 in/0.2 mm thickness, 0.59 in/15 mm width) are consumable parts and will wear out over time. Replace them when they show signs of wear, tearing, or reduced sealing quality. Refer to the included accessories for spare belts.

- Toothed Belt Inspection: Periodically inspect the toothed belts for wear or damage. Replace if necessary.

- Ngagantian sekering: If the machine loses power unexpectedly, check the fuse. Replace with the included spare fuse (if applicable) or a fuse of the same rating.

- Lubrication: Consult VEVOR support for any lubrication requirements.

Figure 4: Illustration of included consumables such as Teflon tape and an extra fuse, essential for maintenance.

7. Cara ngungkulan

| Masalah | Mungkin Cukang lantaranana | Solusi |

|---|---|---|

| Mesin teu hurung. | Teu aya catu daya; Sekring peupeus. | Check power cord connection and outlet. Replace fuse if blown. |

| Kualitas segel anu goréng (lemah atanapi teu lengkep). | Temperature too low; Speed too fast; Worn Teflon belt; Incorrect bag material. | Increase temperature; Decrease speed; Replace Teflon belt; Ensure bag material is suitable for heat sealing. |

| Kantong teu asup kalawan lancar. | Conveyor belt misalignment; Obstruction on belt; Incorrect bag height. | Check and adjust conveyor belt alignment; Remove any obstructions; Adjust sealing head height. |

| Overheating or burning of bags. | Temperature too high; Speed too slow. | Decrease temperature; Increase speed. |

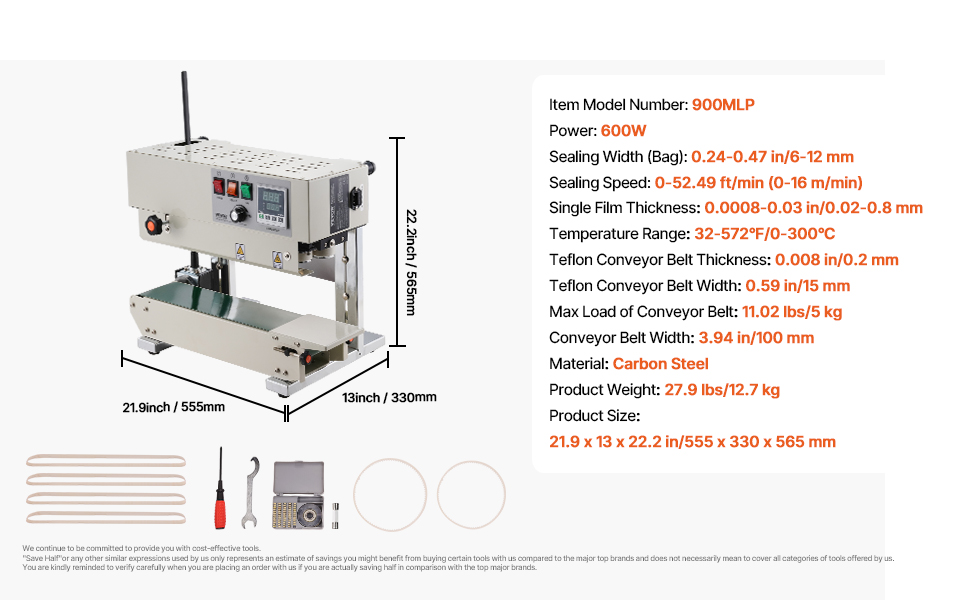

8. Spésifikasi

- Jumlah modél: 900MLP

- kakuatan: 600W

- Sealing Width (Bag): 0.24-0.47 di / 6-12 mm

- Bag Height: 4.72-9.65 di / 120-245 mm

- Laju Sealing: 0-52.49 ft/min (0-16 m/min)

- Single Film Thickness: 0.0008-0.03 di / 0.02-0.8 mm

- Rentang Suhu: 32-572 ° F / 0-300 ° C

- Teflon Conveyor Belt Thickness: 0.008 di / 0.2 mm

- Teflon Conveyor Belt Width: 0.59 di / 15 mm

- Max Load of Conveyor Belt: 11.02 pon / 5 kg

- Lebar Belt Conveyor: 3.94 di / 100 mm

- Bahan: Baja Karbon

- Beurat produk: 26.12 pon / 11.85 kg

- Ukuran produk: 21.85 x 12.99 x 22.24 inci / 555 x 330 x 565 mm

- Voltage: 110V

Figure 5: Dimensional drawing of the VEVOR Continuous Band Sealer, showing key measurements.

9. Garansi jeung Rojongan

Produk VEVOR dirancang pikeun daya tahan sareng kinerja. Kanggo inpormasi garansi, dukungan téknis, atanapi kanggo mésér suku cadang, mangga buka situs resmi VEVOR. website or contact VEVOR customer service. Please have your model number (900MLP) and purchase date available when contacting support.