Bubuka

This manual provides essential information for the safe and effective operation, maintenance, and troubleshooting of your VEVOR MIG Welder. Please read this manual thoroughly before operating the machine to ensure proper usage and to prevent injury or damage.

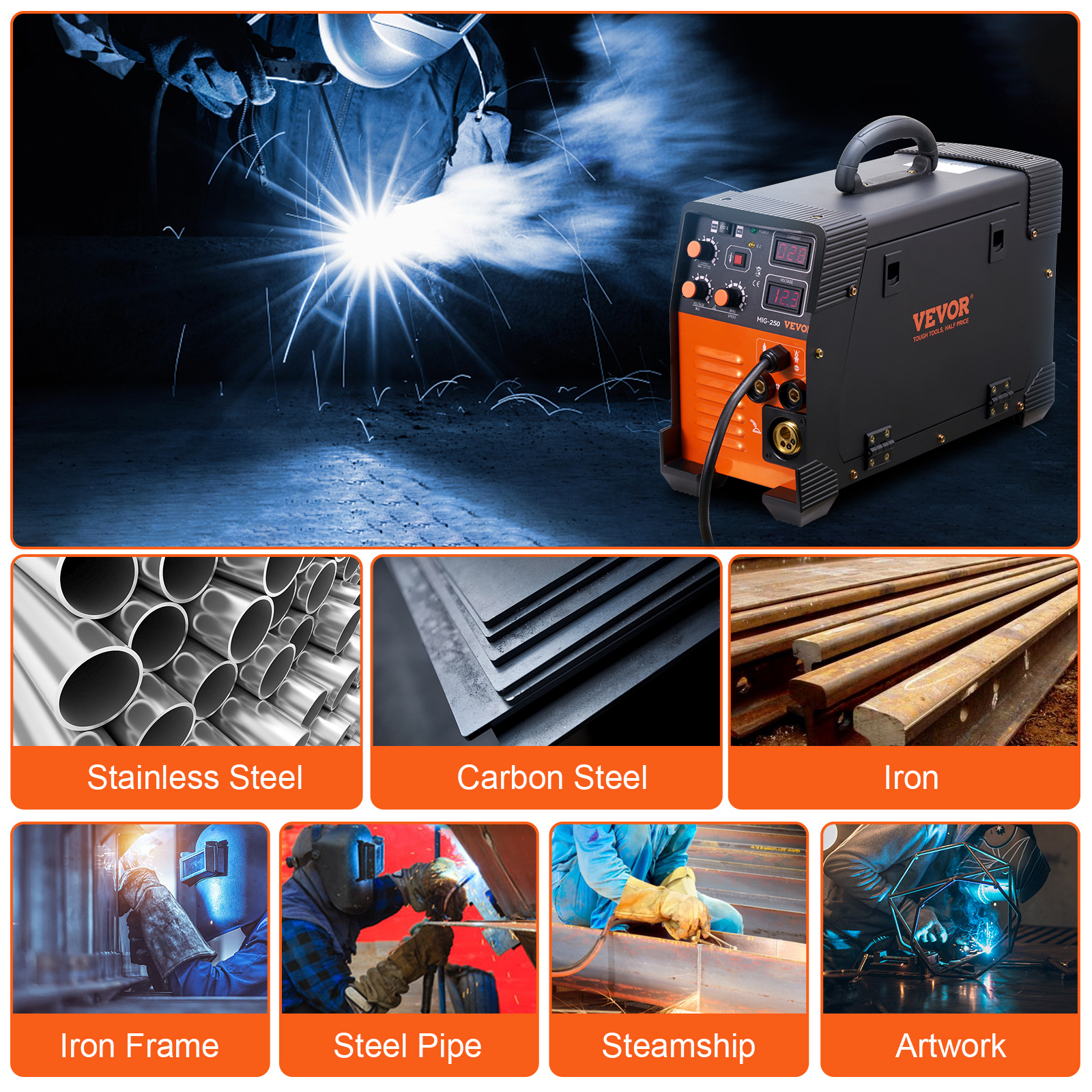

The VEVOR MIG Welder is a versatile 3-in-1 professional combo welder, integrating MIG, TIG, and MMA (Arc) welding functions. It features advanced IGBT inverter technology for stable arc and consistent weld beads, making it suitable for welding various materials including alloy, mild steel, stainless steel, copper, and cast iron. This machine is designed for a wide range of applications from home DIY to professional use.

Precautions Kasalametan

Utamakeun kasalametan nalika ngoperasikeun alat las. Gagal nuturkeun pedoman kaamanan tiasa nyababkeun tatu parah atanapi maot.

- Wear appropriate personal protective equipment (PPE), including a welding helmet, gloves, protective clothing, and safety shoes.

- Mastikeun ventilasi nyukupan pikeun nyegah inhaling haseup las.

- Jauhkeun bahan anu gampang kaduruk tina daérah las.

- Ulah noél bagian listrik hirup.

- Pastikeun mesin geus bener grounded.

- Pegatkeun sambungan kakuatan saméméh ngalakukeun sagala pangropéa atawa pangaluyuan.

- Do not operate the welder in wet conditions.

- Jauhkeun barudak sareng jalmi anu teu sah tina daérah pangelasan.

Eusi pakét

Saatos ngabongkar bungkusan, pariksa yén sadaya barang anu didaptarkeun di handap aya sareng henteu ruksak:

Figure 1: Included Accessories and Welder Unit

- 1 x MIG-250 3 In 1 Inverter Welding Machine

- 1 x Obor Las MIG

- 1 x Obor Las TIG

- 1 x Cables With Electrode Holder

- 1 x Cables With Earth Clamp

- 1 x 2M Argon Tube

- 1 x Welding Slag Hammer, Glasses and Brush

- 1 x 1KG Carbon Steel Gas Shielded Welding Wire (φ1.0)

- 1 x Accessories (various consumables)

- 1 x Manual Produk (dokumen ieu)

Note: Some accessories may be located inside the welder's side panel. Open the panel to retrieve them.

Produk Leuwihview

Familiarize yourself with the main components and controls of your VEVOR MIG Welder.

Figure 2: Front Panel Controls and Connections

- 1. Modes Switch: Milih antara modeu las MIG, MMA, sareng TIG.

- 2. Automatic Wire Feed Switch: Controls the wire feeding mechanism (for MIG mode).

- 3. Penyesuaian ayeuna: Adjusts the welding current (ampera).

- 4. Jilidtage Penyesuaian: Nyaluyukeun volum lastage.

- 5. Wire Speed Adjustment: Controls the speed of the welding wire feed (for MIG mode).

- 6. Current Display: Digital display showing the current welding amperage.

- 7. Jilidtage tampilan: Digital display showing the current welding voltage.

- 8. Conversion Cable: Used for connecting different welding accessories.

- 9. Positive Terminal: Connection point for the positive cable.

- 10. Negative Terminal: Connection point for the negative cable (earth clamp).

- 11. Torch Connector: Titik sambungan pikeun obor las.

Figure 3: Rear Panel Controls and Connections

- Saklar kakuatan: Turns the welder ON/OFF.

- Kakuatan Kabel: Connects the welder to the main power supply (220V).

- Air-duct: Ventilation for cooling the internal components.

Setup sareng Instalasi

Follow these steps to set up your welding machine safely and correctly.

- panempatan: Place the welder on a stable, level surface in a well-ventilated area, away from moisture and flammable materials. Ensure the air ducts are not obstructed.

- Sambungan Daya: Connect the power cable to a suitable 220V power outlet. Ensure the power supply matches the welder's requirements.

- Wire Spool Installation (MIG Mode):

- Open the side panel of the welder.

- Mount the appropriate wire spool (2.2 lbs or 11 lbs, 0.024", 0.031", or 0.039" flux-cored or solid wire) onto the wire feeder spindle.

- Thread the welding wire through the wire guide and into the wire feeder mechanism.

- Tutup panel samping.

Figure 4: Wire Spool and Automatic Wire Feed Installation

- Torch and Cable Connections:

- Connect the MIG welding torch, TIG welding torch, or electrode holder to the appropriate torch connector on the front panel, depending on the desired welding mode.

- Nyambungkeun bumi clamp cable to the negative terminal and the positive cable to the positive terminal.

- Securely attach the earth clamp kana workpiece atanapi las méja, mastikeun kontak listrik alus.

Figure 5: Welder with Accessories for Connection

- Gas Connection (for MIG/TIG with shielding gas):

- If using shielding gas (e.g., Argon/CO2 mix for steel, pure Argon for aluminum), connect the argon tube to the gas inlet on the welder and to your gas cylinder regulator.

- Ensure all gas connections are tight to prevent leaks.

Parentah Operasi

This section outlines the general operating procedures for the MIG, TIG, and MMA welding modes.

Léngkah-léngkah Operasi Umum:

- Pastikeun sadaya sambungan aman sareng leres pikeun prosés las anu dipilih.

- Turn on the main power switch on the rear panel of the welder.

- Select the desired welding mode (MIG, MMA, or TIG) using the Modes Switch on the front panel.

- Adjust the Current and Voltage according to the material thickness and welding process. Refer to welding charts for recommended settings.

- For MIG welding, adjust the Wire Speed.

- Put on all necessary PPE.

- Mimitian las.

- After welding, turn off the welder and disconnect from the power supply.

MIG Welding (Gas Metal Arc Welding)

MIG welding is suitable for various metals and offers high productivity. It can be performed with or without shielding gas (flux-cored wire typically does not require external gas).

- Flux-Cored Wire: If using flux-cored wire, external shielding gas is generally not required as the flux provides its own shielding.

- Kawat padat: If using solid wire, connect a suitable shielding gas (e.g., Argon/CO2 mix for steel, pure Argon for aluminum) to the welder.

- Adjust wire speed and voltage for optimal arc stability and bead appearance.

Figure 6: MIG Welding in Progress

TIG Welding (Gas Tungsten Arc Welding)

TIG welding provides precise, high-quality welds, especially for thin materials and exotic metals. It requires a separate TIG torch and shielding gas (typically pure Argon).

- Connect the TIG torch and ensure the gas supply is connected and flowing.

- Use a non-consumable tungsten electrode.

- Adjust current settings for precise control.

MMA Welding (Manual Metal Arc Welding / Stick Welding)

MMA welding is versatile and suitable for outdoor use and welding on rusty or dirty surfaces. It uses a consumable electrode (stick).

- Connect the electrode holder with the appropriate electrode.

- Adjust the current based on the electrode type and diameter.

Figure 7: Welder Setup for MIG, TIG, and MMA Modes

Pangropéa

pangropéa biasa ensures umur panjang tur operasi aman tina mesin las Anjeun.

- beberesih: Regularly clean the exterior of the machine with a dry cloth. Use compressed air to blow out dust from the air vents and internal components (ensure power is disconnected).

- Pamariksaan kabel: Periodically inspect all welding cables, torches, and connections for wear, damage, or loose connections. Replace damaged parts immediately.

- Wire Feeder (MIG): Clean the wire feeder rollers and guide tubes to ensure smooth wire feeding. Check for any debris or wire shavings.

- Electrode Holder/Torch: Clean the electrode holder and torch nozzles/contact tips regularly. Replace worn-out consumables.

- Panyimpenan: Simpen mesin las dina lingkungan anu garing sareng bersih nalika henteu dianggo.

Pamérésan masalah

Bagian ieu nyayogikeun solusi pikeun masalah umum anu anjeun tiasa patepang.

| Masalah | Mungkin Cukang lantaranana | Solusi |

|---|---|---|

| Mesin las teu bisa dihurungkeun. | No power supply; Power switch off; Faulty power cable. | Check power outlet; Ensure power switch is ON; Inspect/replace power cable. |

| Taya arc. | Kl bumi anu goréngamp connection; Incorrect welding mode; Faulty torch/electrode holder; Incorrect settings. | Ensure good earth connection; Select correct mode; Check torch/holder; Adjust current/voltage. |

| Kawat teu nyoco (MIG). | Wire tangled; Clogged liner; Incorrect wire speed; Drive roller pressure incorrect. | Untangle wire; Clean/replace liner; Adjust wire speed; Adjust drive roller pressure. |

| Overheat/Overload protection activated. | Excessive duty cycle; Obstructed air vents; High ambient temperature. | Allow machine to cool down; Clear air vents; Operate in cooler environment. |

| Poor weld quality (e.g., porosity, spatter). | Incorrect settings; Contaminated workpiece; Insufficient gas shielding (MIG/TIG); Worn consumables. | Adjust settings; Clean workpiece; Check gas flow/leaks; Replace contact tip/nozzle/tungsten. |

Figure 8: Built-in Protection Functions

spésifikasi

Detailed technical specifications for the VEVOR MIG-250 Welder.

| Fitur | Spésifikasi |

|---|---|

| Modél | MIG-250 |

| Jenis Welder | MIG/MMA/TIG (3-in-1) |

| Voltage | 220V |

| Kisaran ayeuna | 50-250A |

| Gelar panyalindungan | IP21S |

| Daya Input Dipeunteun | 5.6 KVA |

| Kawat Speed | 2.2-12 m / mnt |

| Ketebalan Kawat | 0.024'' & 0.031'' & 0.039'' / 0.6 mm & 0.8 mm & 1 mm |

| Kapasitas Beurat Kawat | 2.2 / 11 pounds |

| Dimensi produk | 18.1 x 7.5 x 13 inci / 46 x 19 x 33 cm |

| Beurat produk | 18.5 pon / 8.4 kg |

| Welded Material | Stainless Steel, Alloy Steel, Mild Steel, Copper |

| Sertifikasi | CE |

Figure 9: Portability of the Welder

Figure 10: Welder Dimensions

Tip pamaké

Based on common user experiences and best practices, consider the following tips for optimal performance:

- Setélan Latihan: Before starting a critical project, practice on scrap pieces of the same material and thickness to fine-tune your current, voltage, and wire speed settings.

- Kabersihan teh konci utama: Always ensure your workpiece is clean and free of rust, paint, or oil for the best weld quality and to minimize spatter.

- Consumable Management: Keep a supply of spare contact tips, nozzles, and electrodes. Replace them as soon as they show signs of wear to maintain consistent weld quality.

- Ventilasi: Even with flux-cored wire, good ventilation is crucial. Consider using a fume extractor or working in an open area.

- Duty Cycle Awareness: Pay attention to the welder's duty cycle. Overheating can occur if you weld continuously for too long. Allow the machine to cool down as needed.

Garansi sareng Rojongan

Kanggo inpormasi garansi, dukungan téknis, atanapi patarosan jasa, mangga tingal VEVOR resmi websitus atanapi ngahubungan layanan palanggan maranéhanana langsung. Simpen resi pameseran anjeun salaku bukti pameseran.