Danfoss iC7 Series Automation Drive

Introduction

Purpose of the Operating Guide

This operating guide provides information for safe installation, commissioning, and operation of functional extensions used with iC7 drives.

This guide is intended for use by qualified personnel only. Read and follow the operating instructions to use the drive safely and professionally, and pay particular attention to the safety instructions and general warnings. Keep this operating guide available with the drive at all times.

Additional Resources

Additional resources are available to help understand the features, and safely install and operate the iC7 products:

- Safety guides, which provide important safety information related to installing iC7 drives.

- Installation guides, which cover the mechanical and electrical installation of drives, or functional extension options.

- Design guides, which provide technical information to understand the capabilities of the iC7 drives for integration into motor control and monitoring systems.

- Application guides, which provide instructions on setting up the drive for a specific end use.

- Supplemental publications, drawings, and manuals are available at www.danfoss.com.

Latest versions of Danfoss product manuals are available for download at http://drives.danfoss.com/downloads/portal/.

Version History

- This guide is regularly reviewed and updated. All suggestions for improvement are welcome.

- The original language of this guide is English.

Table 1: Version History

| Version | Remarks |

| AQ390830267692, version 0301 | Updates regarding electrical specifications and the default value and available selections of parameter P 9.6.6 BiSS/SSI Clock Rate. |

| AQ390830267692, version 0201 | Updates regarding Encoder/Resolver Option OC7M0 features. |

| AQ390830267692, version 0101 | First version. The information in this version is valid for Encoder/Resolver Option OC7M0 installed in iC7-Automation frequency converters. |

Safety

Safety Symbols

The following symbols are used in this guide:

DANGER

DANGER

Indicates a hazardous situation which, if not avoided, will result in death or serious injury. WARNING

WARNING

Indicates a hazardous situation which, if not avoided, could result in death or serious injury. CAUTION

CAUTION

Indicates a hazardous situation which, if not avoided, could result in minor or moderate injury. NOTICE

NOTICE

Indicates information considered important, but not hazard-related (for example, messages relating to property damage).

Safety and Installation Awareness

Before starting installation, read all safety guidelines and precautions related to installing functional extensions.

For more information on functional extension selection and functional extension slots in the drives, see the product-specific design guides. Supplemental information and other iC7 guides can be downloaded from www.danfoss.com/service-and-support.

Configuration

Configuration Overview

The parameters related to functional extensions are in parameter group 9, called I/O. Parameters are dependent on the mounting, and will appear in the parameter menu after the functional extension has been mounted and wired.

Encoder/Resolver Installation and Configuration

Encoder/Resolver Option OC7M0

The Encoder/Resolver option supports connecting various devices as speed/position feedback or reference. It also has a TTL encoder simulation output, which can be used to mirror the resolver input signal.

There are 4 channels (A, B, Z, and D) which can be configured in different combinations according to Table 2.

Table 2: Encoder/Resolver Option Configurations

| Device | Tracks |

| Incremental TTL/HTL | A and B |

| Incremental TTL/HTL with zero pulse | A, B, and Z |

| Resolver | A and B |

| Resolver with encoder mirror out | A and B + Z and D |

| SSI | Z and D |

| EnDat | Z and D |

| BiSS | Z and D |

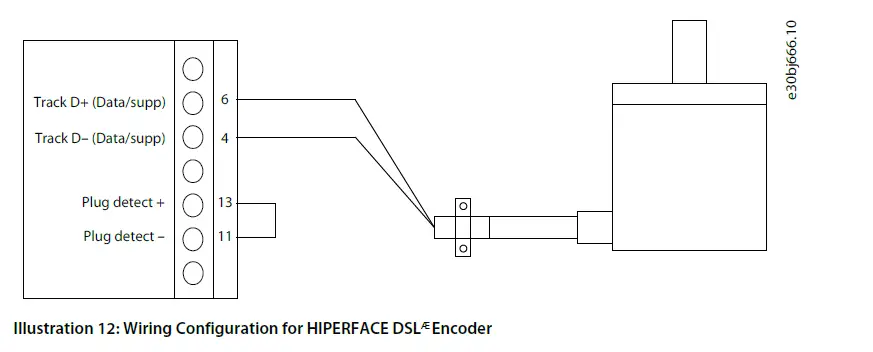

| HIPERFACE DSL | D |

Adjustable encoder voltage supply is available 5–24 V with the possibility of feedback enabling monitoring and compensation for cable voltage drop. The voltage level is set with parameter 9.4.4 Encoder supply voltage.

NOTICE

Setting the voltage too high can damage the connected encoder.

Resolver supply/excitation is available with adjustable voltage and frequency by parameters 9.7.1 Excitation Voltage and 9.7.2 Excitation Frequency.

Required Tools

- Torx 20 screwdriver for mounting EMC plate Slot C-E.

- Slotted screwdriver (maximum 3 mm) for releasing the spring-loaded terminals of the plug connector.

- Wire crimpers may be needed for certain encoder cable types.

Checking the Shipment

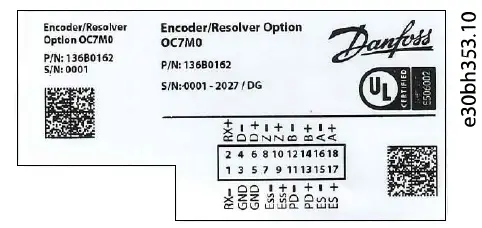

Make sure that the items supplied and the information on the product label correspond to the order confirmation. The product label is placed on the front and right side of the option casing.

Illustration 1: Example of a Product Label

The labels contain the following information:

- Product name, code number, and serial number

- Company name

- A 2D code which can be used to access detailed product information via MyDrive® tools.

- Compliance and approval markings

- Identification of I/O connections on the option

Items Supplied

The Encoder/Resolver OC7M0 option can be ordered as a preinstalled option by using the dedicated model code, or as a separate option for field mounting by using the code number.

When the option is not mounted at the factory, the following items are included in the shipment:

- Encoder/Resolver OC7M0.

- Option connector.

- Cable clamps.

- Screws.

- Operating guide.

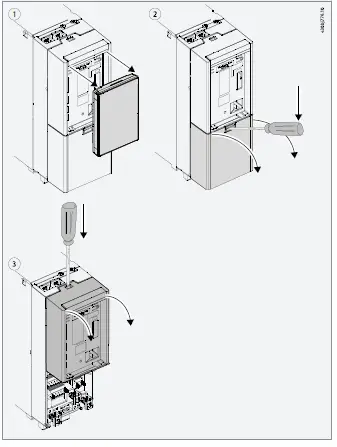

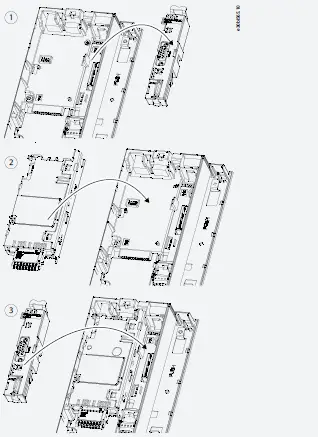

Installing Functional Extensions in Frequency Converters

The instructions in this chapter apply to frequency converters with an integrated control board.

DANGER

SHOCK HAZARD FROM THE AC DRIVE

Touching electrical parts of the drive can cause death or serious injury even after the equipment has been disconnected from AC power.

- Perform the following steps before touching any internal components:

- Disconnect the mains power.

- Disconnect the motor.

- Disconnect external connections to the DC terminals of the drive.

Wait for the capacitors to discharge fully. Refer to the label on the drive for the correct discharge time. Ensure that the DC-link capacitors have discharged fully by measuring the DC link with a voltage meter.

NOTICE

The Encoder/Resolver Option OC7M0 must be installed in option slot A.

- For more information on option slot locations in frequency converters, refer to the design guide.

- For information on slot identification in software, refer to the application guide.

- Remove the control panel, terminal cover, and control panel cradle.

- Remove the interface board, place the option board in the slot, and reinstall the interface board.

NOTICE

The interface boards are not interchangeable between drives.

The interface board must be reinstalled in the same drive it was removed from.

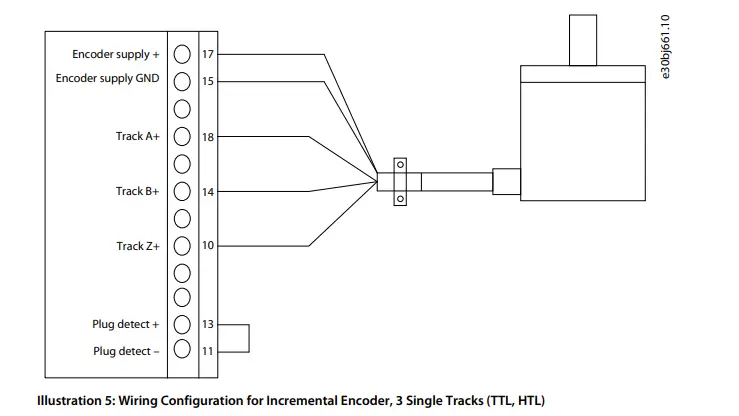

Pin Assignment for Encoder/Resolver OC7M0

The Plug detect feature, which monitors that pins 11 and 13 are connected, detects the unintentional disconnection of the plug connector.

NOTICE

If the Plug detect connection is missing while the interface is activated (parameter 9.4.1 Interface configuration ≠ “Disabled”), the drive generates a fault.

- The fault is generated only when switching to closed-loop operation, not when selecting an encoder.

- The plug connector is delivered without a connection between pin 11 and 13.

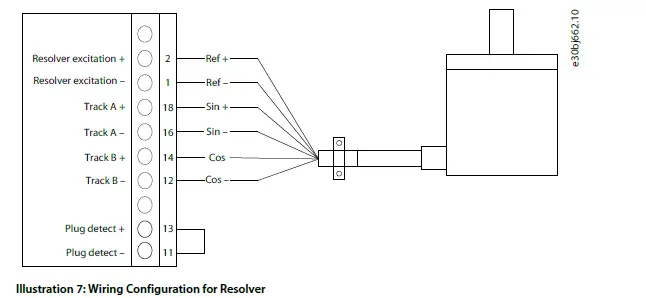

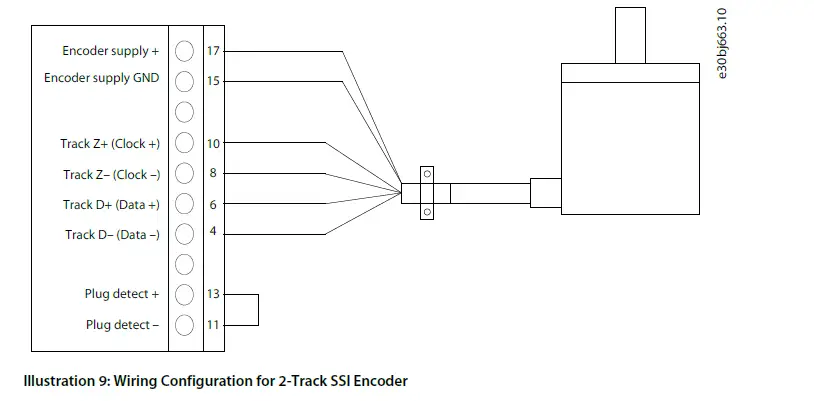

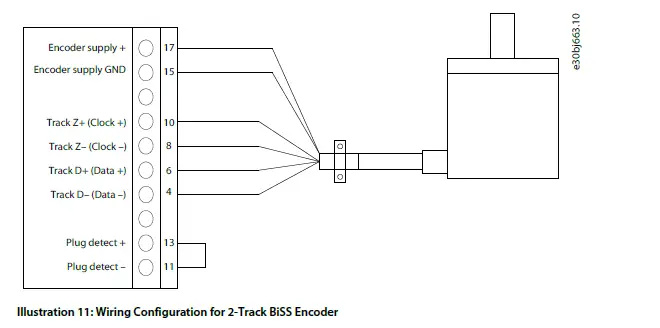

Table 3: Pin Assignment and Function for Encoder/Resolver Option OC7M0

| Numbering | Functions | Numbering | Functions |

| 1 | Resolver Excitation – | 2 | Resolver Excitation + |

| 3 | GND | 4 | Ch. D- (TTL, RS-485, HIPERFACE DSL®) |

| 5 | GND | 6 | Ch. D+ (TTL, RS-485, HIPERFACE DSL®) |

| 7 | Encoder Supply Sensor – | 8 | Ch. Z- (TTL, HTL, RS-485, R-) |

| 9 | Encoder Supply Sensor + | 10 | Ch. Z+ (TTL, HTL, RS-485, R+) |

| 11 | Plug Detect – (GND) | 12 | Ch. B- (TTL, HTL, RS-485, Analog B-) |

| 13 | Plug Detect + | 14 | Ch. B+ (TTL, HTL, RS-485, Analog B+) |

| 15 | Encoder Supply – (GND) | 16 | Ch. A- (TTL, HTL, RS-485, Analog A-) |

| 17 | Encoder Supply + | 18 | Ch. A+ (TTL, HTL, RS-485, Analog A+) |

Encoder/Resolver Option OC7M0 Specifications

NOTICE

Voltage can be up to 24 V. Setting the voltage too high can damage the connected encoder.

The voltage is configured in parameter 9.4.4 Encoder Supply Voltage. For details, refer to 4.9.1 Configuration (Menu Index 9.4).

Table 4: Electrical Specifications for Encoder/Resolver Option OC7M0

| Encoder supply voltage [V DC] | Maximum current [mA] |

| 24 | 125 |

| 15 | 150 |

| 12 | 150 |

| 8 | 225 |

| 5 | 300 |

If the available power is insufficient, it is possible to use an external power supply for the encoder.

Table 5: Device Type Specifications

| Device type | Specifications | Additional information(1) | |

| Data | Value | ||

| TTL (A, B, Z) | Signal level | 0–5 V | Differential signals are preferred, but single signals are also supported. The trigger threshold is 0.33–0.4 times the en- coder supply voltage. |

| Maximum resolution | 65535 | ||

| Maximum frequency | 10 MHz | ||

| Maximum cable length | Depends on signal frequency | ||

| HTL (A, B, Z) | Signal level | 0–24 V | |

| Maximum resolution | 65535 | ||

| Maximum frequency | 500 kHz | ||

| SSI | Maximum resolution | 31 bit | Only Gray code is supported as the data format. |

| Maximum data length | 63 bit | ||

| Maximum clock frequency | 2 MHz | ||

| EnDat | Maximum resolution | 31 bit | Both EnDat 2.1 and EnDat 2.2 are supported, but only with pure absolute channel, not with incremental channel. |

| Maximum data length | 63 bit | ||

| Maximum clock frequency | 8.33 MHz | ||

| HIPERFACE DSL® | Maximum resolution | 31 bit | Baud rate is fixed. |

| Maximum data length | 63 bit | ||

| Baud rate | 10 Mbps | ||

| BiSS | Maximum resolution | 31 bit | – |

| Maximum data length | 63 bit | ||

| Maximum clock frequency | 8.33 MHz | ||

| Resolver | Excitation voltage | 2–8 Vrms | – |

| Excitation frequency | 2–20 kHz | ||

| Maximum number of poles | 254 | ||

| Maximum input voltage | 8 Vrms | ||

| Maximum load | 100 mArms | ||

| Encoder simulation (TTL Output) | Voltage level | Minimum: 1.5 V

Typical: 2 V differential |

– |

| Device type | Specifications | Additional information(1) | |

| Data | Value | ||

| Maximum resolution | 65535 | ||

| Maximum frequency | 10 MHz | ||

| Maximum load | 60 mA | ||

1 The limitations described in this guide apply to the current software version.

Table 6: Cable Specifications for Encoder/Resolver Option OC7M0

| Cable type | Cross section [mm2 (AWG)] | Minimum stripping length [mm (in)] |

| Flexible/rigid wire without cable end sleeves | 0.2–1.5 (26–16) | 10 (0.4) |

| Flexible wire with cable end sleeves with collar | 0.2–0.75 (26–18) |

A standard RS485 interface supports cable lengths up to 1200 m (3940 ft) depending on signal frequency and cable type. Consult the documentation for the respective encoder or resolver for details on allowed cable length.

Setup and Connection Examples for Encoder/Resolver OC7M0

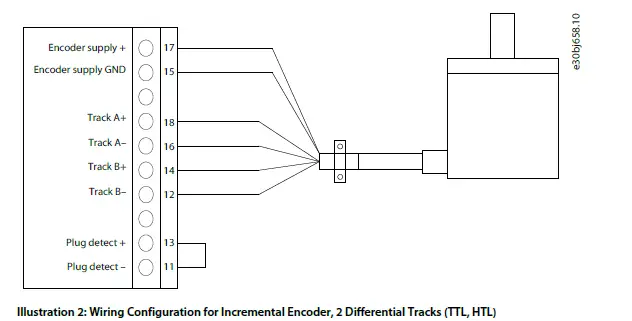

Incremental Encoder

With TTL and HTL incremental encoder, the actual position is 0 after power-up, and encoder pulses are counted to increment or decrement the actual position. For improved resolution with TTL and HTL encoders, both the positive and negative edge of A and B pulses are detected giving 4 quad counts per encoder pulse.

Table 7: Parameters for Incremental Encoder

| Parameter | Setting |

| 9.4.1 Interface configuration | Set according to the type of connected encoder. TTL/HTL with 2 tracks: Select [1] 2 track Incremental A, B.

TTL/HTL with 3 tracks: Select [3] 3 track Incremental A, B, Z. |

| 9.4.4 Encoder Supply Voltage | Set the appropriate supply voltage for the connected encoder.

NOTICE Voltage can be up to 24 V. Setting the voltage too high can damage the connected encoder. |

| 9.5.1 Resolution Device 1 | Set the resolution of the encoder in pulses per revolution. |

Two Incremental Encoders

It is possible to connect two 2-track incremental encoders where channel 1 (A, B) supports TTL and HTL, while channel 2 (Z, D) only supports TTL.

Table 8: Parameters for 2 Incremental Encoders

| Parameter | Setting |

| 9.4.1 Interface configuration | Select [5] 2 track Incremental A,B + 2 track incremental Z,D. |

| 9.4.4 Encoder Supply Voltage | Set the appropriate supply voltage for the connected encoders. If the power requirement exceeds the maximum power of the internal supply, the 2nd encoder may require external supply.

NOTICE |

| 9.5.1 Resolution Device 1 | Set the resolution of the encoder connected to A and B in pulses per revolution. |

| 9.5.2 Resolution Device 2 | Set the resolution of the encoder connected to Z and D in pulses per revolution. |

- Incremental encoder, 2 differential tracks (TTL, HTL)

- Incremental encoder, 2 differential tracks (only TTL on Z and D).

NOTICE

The incremental encoder connected to channels Z and D may require separate supply.

Resolver

With a resolver, the actual position is set to the absolute value within 1 resolver pole pair based on the analog value of the sine and cosine signals.

With a 2-pole resolver, this corresponds to the absolute position within 1 resolver revolution.

Table 9: Parameters for Resolver

| Parameter | Setting |

| 9.4.1 Interface configuration | Set to [7] Resolver A,B. |

| 9.7.1 Excitation Voltage | Set the excitation voltage according to the specification of the connected resolver. |

| 9.7.2 Excitation Frequency | Set the excitation frequency according to the specification of the connected resolver. |

| 9.7.3 Number of Poles | Set the number of poles of the connected resolver. |

Resolver with Mirror Out

When using a resolver, a TTL encoder signal can be generated to mirror the resolver signal. The mirroring enables transferring the shaft position to other devices for monitoring, or further control. The encoder output signal can be scaled by defining the number of pulses representing 1 rotation of the resolver.

Table 10: Parameters for Resolver with Mirror Out

| Parameter | Setting |

| 9.4.1 Interface Configuration | Set to [8] Resolver A,B + Mirror out Z,D. |

| 9.5.2 Resolution Channel 2 | Set the required number of pulses for the encoder output representing 1 rotation of the resolver. |

| 9.7.1 Excitation Voltage | Set the excitation voltage according to the specification of the connected resolver. |

| 9.7.2 Excitation Frequency | Set the excitation frequency according to the specification of the connected resolver. |

| 9.7.3 Number of Poles | Set the number of poles of the connected resolver. |

- Resolver

- Controller, or other device

SSI Encoder

Absolute position is read from the encoder and used to set the actual position after power-up.

Table 11: Parameters for SSI Encoder

| Parameter | Description |

| 9.4.1 Interface Configuration | Select [17] SSI Z,D. |

| 9.4.4 Encoder Supply Voltage | Set the appropriate supply voltage for the connected encoder.

NOTICE |

| 9.6.1 Resolution | Set the number of bits used for 1 revolution. |

| 9.6.2 Data Length | Set total number of bits used for position/angle + revolution count. |

| 9.6.6 BiSS/SSI Clock Rate | Sets the clock rate used for SSI or BiSS. |

EnDat Encoder

Absolute position is read from the encoder and used to set the actual position after power-up.

Table 12: Parameters for EnDat Encoder

| Parameter | Description |

| 9.4.1 Interface configuration | Select [22] EnDat Z,D. |

| 9.4.4 Encoder Supply Voltage | Set the appropriate supply voltage for the connected encoder.

NOTICE |

| 9.6.1 Resolution | Set the number of bits used for 1 revolution. |

| 9.6.2 Data Length | Set total number of bits used for position/angle + revolution count. |

| 9.6.3 EnDat Clock Rate | Set the rate for the clock signal according to the encoder specifications. |

BiSS Encoder

Absolute position is read from the encoder and used to set the actual position after power-up.

Table 13: Parameters for BiSS Encoder

Parameter Description

- 9.4.1 Interface configuration Select [29] BiSS Z,D.

- 9.4.4 Encoder Supply Voltage Set the appropriate supply voltage for the connected encoder.

NOTICE

Voltage can be up to 24 V. Setting the voltage too high can damage the connected encoder.

- 9.6.1 Resolution Set the number of bits used for 1 revolution.

- 9.6.2 Data Length Set total number of bits used for position/angle + revolution count.

- 9.6.6 BiSS/SSI Clock Rate Set the rate for the clock signal according to the encoder specifications.

HIPERFACE DSL

Absolute position is read from the encoder and used to set the actual position after power-up.

Table 14: Parameters for HIPERFACE DSL®

| Parameter | Description |

| 9.4.1 Interface configuration | Select [26] Hiperface DSL D. |

| 9.4.4 Encoder Supply Voltage | Set the appropriate supply voltage for the connected encoder.

NOTICE |

| 9.6.1 Resolution | Set the number of bits used for 1 revolution. |

| 9.6.2 Data Length | Set total number of bits used for position/angle + revolution count. |

Parameter Descriptions for Encoder/Resolver

Configuration (Menu Index 9.4)

Interface Configuration

Description: Select the required configuration of the interface consisting of 4 tracks A, B, Z, and D offering various combinations of 1 or 2 devices.

| Default Value: 0 [Disabled] | Parameter Type: Selection | Parameter Number: 4000 |

| Unit: – | Data Type: UINT | Access Type: Read/Write |

The following are the selections for the parameter:

| Selection number | Selection name |

| 0 | Disabled |

| 1 | 2 track incremental A,B |

| 3 | 3 track incremental A,B,Z |

| 5 | 2 track incremental A,B + 2 track incremental Z,D |

| 7 | Resolver A,B |

| 8 | Resolver A,B + mirror out Z,D |

| 9 | Resolver A,B + 2 track incremental Z,D |

| 17 | SSI Z,D |

| 19 | SSI Z,D + 2 track incremental A,B |

| Selection number | Selection name |

| 22 | EnDat Z,D |

| 23 | EnDat Z,D + 2 track incremental A,B |

| 26 | Hiperface DSL D |

| 27 | Hiperface DSL D + 2 track incremental A,B |

| 29 | BiSS Z,D |

| 30 | BiSS Z,D + 2 track incremental A,B |

Encoder Supply Voltage

Description: Set the supply voltage level according to the specification of the connected encoder.

| Default Value: 5 | Parameter Type: Range (3–24) | Parameter Number: 4002 |

| Unit: V | Data Type: UINT | Access Type: Read/Write |

Supply Sense

Description: Activate power supply cable drop compensation.

| Default Value: 0 | Parameter Type: Range (0–1) | Parameter Number: 4035 |

| Unit: – | Data Type: BOOL | Access Type: Read/Write |

Incremental Settings (Menu Index 9.5)

Resolution Channel 1

Description: Set the resolution of the incremental encoder connected to channel 1.

| Default Value: 1024 | Parameter Type: Range (1–65535) | Parameter Number: 4008 |

| Unit: – | Data Type: UINT | Access Type: Read/Write |

Resolution Channel 2

Description: Set the resolution of the incremental encoder connected to channel 2.

| Default Value: 1024 | Parameter Type: Range (1–65535) | Parameter Number: 4009 |

| Unit: – | Data Type: UINT | Access Type: Read/Write |

SSI/EnDat/BiSS/HIPERFACE Settings (Menu Index 9.6)

Resolution

Description: Number of bits used for 1 revolution.

| Default Value: 13 | Parameter Type: Range (1–31) | Parameter Number: 4010 |

| Unit: – | Data Type: UINT | Access Type: Read/Write |

Data Length

Description: Total number of bits used for position/angle + revolution count.

| Default Value: 25 | Parameter Type: Range (1–63) | Parameter Number: 4011 |

| Unit: – | Data Type: UINT | Access Type: Read/Write |

EnDat Clock Rate

Description: Set the Clock rate used for EnDat.

| Default Value: 0 [8.33 MHz] | Parameter Type: Selection | Parameter Number: 4036 |

| Unit: MHz | Data Type: UINT | Access Type: Read/Write |

The following are the selections for the parameter:

| Selection number | Selection name |

| 0 | 8.33 MHz |

| 6 | 4.16 MHz |

| 12 | 2.08 MHz |

| 13 | 1 MHz |

| 14 | 0.2 MHz |

| 15 | 0.1 MHz |

SSI Data Format

Description: Select the SSI data coding according to the specifications of the connected SSI encoder.

| Default Value: 1 [Gray](1) | Parameter Type: Selection | Parameter Number: 4034 |

| Unit: – | Data Type: BOOL | Access Type: Read/Write |

1 In this release, the value Gray is preselected and cannot be changed.

BiSS/SSI Clock Rate

Description: Sets the clock rate used for SSI or BiSS.

| Default Value: 18 [833 kHz] | Parameter Type: Selection | Parameter Number: 4037 |

| Unit: – | Data Type: UINT | Access Type: Read/Write |

The following are the selections for the parameter:

| Selection number | Selection name |

| 2 | 8.33 MHz |

| 3 | 6.25 MHz |

| 4 | 5.00 MHz |

| 5 | 4.16 MHz |

| 6 | 3.57 MHz |

| 7 | 3.13 MHz |

| 8 | 2.78 MHz |

| 9 | 2.50 MHz |

| 10 | 2.27 MHz |

| 11 | 2.08 MHz |

| 12 | 1.92 MHz |

| 13 | 1.79 MHz |

| 14 | 1.67 MHz |

| Selection number | Selection name |

| 15 | 1.56 MHz |

| 17 | 1.25 MHz |

| 18 | 833 kHz |

| 19 | 625 kHz |

| 20 | 500 kHz |

| 21 | 417 kHz |

| 22 | 357 kHz |

| 23 | 313 kHz |

| 24 | 278 kHz |

| 25 | 250 kHz |

| 26 | 227 kHz |

| 27 | 208 kHz |

| 28 | 192 kHz |

| 29 | 179 kHz |

| 30 | 167 kHz |

| 31 | 156 kHz |

Resolver (Menu Index 9.7)

Excitation Voltage

Description: Set the Excitation voltage according to the specifications of the connected resolver (RMS).

| Default Value: 5 | Parameter Type: Range (2–8) | Parameter Number: 4005 |

| Unit: V | Data Type: UINT | Access Type: Read/Write |

Excitation Frequency

Description: Set the Resolver excitation frequency according to the specifications of the connected resolver.

| Default Value: 5000 | Parameter Type: Range (2000–20000) | Parameter Number: 4004 |

| Unit: Hz | Data Type: UINT | Access Type: Read/Write |

Number of Poles

Description: Set the number of poles of the connected resolver.

| Default Value: 2 | Parameter Type: Range (2–254) | Parameter Number: 4003 |

| Unit: – | Data Type: USINT | Access Type: Read/Write |

- Danfoss A/S Ulsnaes 1

- DK-6300 Graasten

- drives.danfoss.com

Any information, including, but not limited to information on selection of product, its application or use, product design, weight, dimensions, capacity or any other technical data in product manuals, catalogues descriptions, advertisements, etc. and whether made available in writing, orally, electronically, online or via download, shall be considered informative, and is only binding if and to the extent, explicit reference is made in a quotation or order confirmation. Danfoss cannot accept any responsibility for possible errors in catalogues, brochures, videos and other material. Danfoss reserves the right to alter its products without notice. This also applies to products ordered but not delivered provided that such alterations can be made without changes to form, fit or function of the product. All trademarks in this material are property of Danfoss A/S or Danfoss group companies. Danfoss and the Danfoss logo are trademarks of Danfoss A/S. All rights reserved.

FAQ

Q: Where can I find additional resources for the iC7 drives?

A: Additional resources and guides can be downloaded from the official website at drives.danfoss.com.

Documents / Resources

|

Danfoss iC7 Series Automation Drive [pdf] User Guide iC7 Series Automation Drive, iC7 Series, Automation Drive, Drive |