WATERLEESS M Series Multi Function Machines

Specifications

- Model: M SERIES R-454B

- Configurations: WG2AD (Forced air/heating/cooling with domestic water heating), WG2AH (Forced air/heating/cooling with hydronic water heating)

- Compliance: UL 60335-2-40/CSA C22.2 No. 60335-2-40

Product Usage Instructions

Installation:

Ensure compliance with national, state, and local codes during installation. Follow the guidelines provided in the manual for proper installation.

Poe Oil Precaution:

- Vacuum pumps do not remove moisture from POE oil.

- Do not open the system to the atmosphere while under a vacuum.

- Wrap filter driers and service valves with a wet cloth when brazing.

Equipment Nomenclature

- Compressor Unit

- Air Handler Unit

Installation Guidelines:

- Insulate refrigerant and water lines with at least 1/2 wall thickness of Armaflex or equivalent insulation.

- Factor in all line set fittings when calculating equivalent length.

- Use the provided chart to determine fitting’s equivalent length.

Compressor Unit Placement:

- Compressor units can be located inside or outside. If outside, use a standard HVAC outdoor unit pad. If inside, place on a level, hard surface.

- Avoid placing near sound-sensitive areas of the residence.

M SERIES (Multi-Function Machines)

R-454B

WG2AD (Forced air/heating/cooling with domestic water heating) WG2AH (Forced air/heating/cooling with hydronic water heating)

Disclaimer

- Proper installation and servicing of the Total Green Mfg. Heat Pump is essential to its reliable performance. All Total Green Mfg. Systems must be installed and serviced by a qualified HVAC contractor. Equipment sizing, selection and installation are the sole responsibility of the installing contractor.

- Installation of equipment on an existing copper earth loop design that does not match a current Total Green Mfg. Earth loop design is not permitted, will void all warranties on the equipment, and is the sole responsibility of the installing contractor. Installation must be made in accordance with the instructions set forth in this manual. Failure to provide installation by a qualified HVAC contractor in a manner consistent with this manual will void and nullify the limited warranty coverage for the system.

- Total Green Mfg. shall not be liable for any defect, unsatisfactory performance, damage or loss, whether direct or consequential, relative to the design, manufacture, construction, application or installation of any field specified components.

- All commissioning and registration paper work must be filled out at start up and returned to Total Green Mfg. for full warranty coverage.

Please Note: Electrical data given in this manual is subject to change without notice. Please refer to the equipment data label for the most up to date specifications.

- This appliance is not intended for use by persons (including children) with reduced physical, sensory or mental capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction concerning use of the appliance by a person responsible for their safety.

- Children should be supervised to ensure that they do not play with the appliance.

WARNING REGARDING UNITS EQUIPPED WITH DESUPERHEATERS

A unit equipped with an optional Desuperheater can generate water temperatures up to 150° Fahrenheit. Water at this temperature can cause immediate and severe scalding. We recommend that when installing a unit with an optional Desuperheater, that an Anti-Scald Mixing valve be installed per the local plumbing code at the water heater. This should be set so that the water sent from the water heater is tempered down to 120° Fahrenheit.

WARNING

LIVE ELECTRICAL COMPONENTS!

Failure to follow this Warning could result in property damage, severe personal injury, or death. Follow all electrical safety precautions when exposed to live electrical components. It may be necessary to work with live electrical components during installation, testing, servicing, and troubleshooting of this product.

- The high voltage power supply must agree with the equipment nameplate.

- Check that cabling will not be subject to wear, corrosion, excessive pressure, vibration, sharp edges, or any Other adverse environmental effects.

- Power wiring must comply with national, state, and local codes.

- Follow instructions on unit wiring diagram located on the bottom side of the unit lid.

This equipment is designed for use with R-454B refrigerant that has an A2L classification. Only personnel trained in the proper handling of A2L refrigerants using compatible A2L service and installation tools should carry out services and installation of this equipment. This equipment ships without refrigerant with a dry nitrogen holding charge. Installing and service personnel are solely responsible for the proper servicing and charging of this equipment as set forth in this, and all Total Green Mfg. service and installation manuals.

This equipment is designed for use with R-454B refrigerant that has an A2L classification. Only personnel trained in the proper handling of A2L refrigerants using compatible A2L service and installation tools should carry out services and installation of this equipment. This equipment ships without refrigerant with a dry nitrogen holding charge. Installing and service personnel are solely responsible for the proper servicing and charging of this equipment as set forth in this, and all Total Green Mfg. service and installation manuals.

WARNING

RISK OF FIRE.

- FLAMMABLE REFRIGERANT USED.

- TO BE REPAIRED ONLY BY TRAINED SERVICE PERSONNEL.

- DO NOT PUNCTURE REFRIGERANT TUBING.

NOTICE

- LEAK DETECTION SYSTEM INSTALLED.

- UNIT MUST BE POWERED EXCEPT FOR SERVICE.

ALL phases of this installation must comply with NATIONAL, STATE, AND LOCAL CODES.

IMPORTANT: This document is customer property and is to remain with this unit. Please return to service information packet upon completion of work.

Please note that illustrations in these manuals are for reference only and may not show all detail. Also, specifications are subject to change without notice. It is imperative that only the manuals shipped with the equipment be used for each installation.

![]() This equipment is classified as a partial system and must be paired only with other equipment approved by Total Green Mfg. that is UL 60335-2-40/CSA C22.2 No. 60335-2-40 compliant.

This equipment is classified as a partial system and must be paired only with other equipment approved by Total Green Mfg. that is UL 60335-2-40/CSA C22.2 No. 60335-2-40 compliant.

POE OIL PRECAUTION

- The compressor oil used in a Waterless® Geothermal system is Copeland

- Ultra 32-3 MAF. Using any other brand or type will void the manufacturer’s equipment warranty.

- POE oils absorb moisture rapidly. Do not expose oil to the atmosphere. Always flow dry nitrogen anytime a system is open to prevent the atmosphere from entering any part of the system, as it will make its way to the compressor oil. This includes line sets, earth loops, earth loop manifolds, air handlers, cased coils and any other piece of equipment that is to be connected to the refrigerant circuit. All components must be swept of atmosphere with dry nitrogen to keep the system dry when installing or servicing. Flowing dry nitrogen is not just for brazing.

- Vacuum pumps will not remove moisture from POE oil.

- Never open a system to the atmosphere while it is under a vacuum.

- A liquid line filter drier is required and installed in every compressor unit from the factory.

- Wrap all filter driers and service valves with a wet cloth when brazing.

- When the system must be open for service, break vacuum after refrigerant recovery with dry nitrogen and always replace the filter drier.

EQUIPMENT NOMENCLATURE

COMPRESSOR UNIT

Air Handler Unit

Installation Guide Lines

- All refrigerant and water lines between these above-ground components must be insulated with at least 1/2” wall thickness Armaflex, Insul-Tube or equivalent insulation.

- All line set fittings must be factored in when calculating equivalent length.

- Please use the following chart to figure the fittings equivalent length.

Pipe Fitting Equivalent Lengths

- Long Radius 90 = 3 ft.

- Coupling = 1 ft.

- Swaged Connection = 1ft.

- 45 Degree Elbow = 1.5 ft.

Important Note: Short Radius 90° elbows are NOT permitted to be used in any piping.

LEGEND

LEGEND

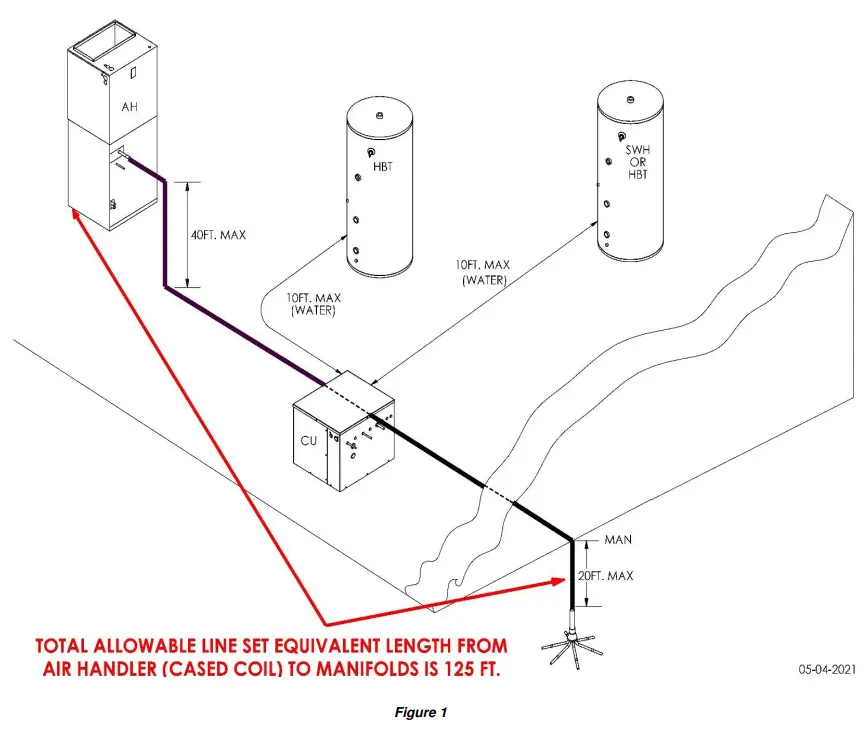

- CU – COMPRESSOR UNIT

- AH – AIR HANDLER ( OR CASED COIL)

- SWH – STORAGE WATER HEATER (OR TANK)

- HYDRONIC TANK

- MAN – MANIFOLDS FOR EARTH LOOPS

Compressor Unit Placement

- Total Green Mfg. Compressor units may be located inside or outside. If outside, place the compressor unit on a standard HVAC outdoor unit pad. If inside, place it on a level, hard surface. If the compressor unit is to be fastened down, see Figure 2 for bracket installation.

- Avoid placing the compressor unit in or near sound-sensitive areas of the residence.

- Clearance around the unit for service is illustrated in Figure 3. However, local codes and applicable regulations take precedence.

Placement instructions for other pieces of equipment that make up the Total Green Mfg. System are included with those pieces of equipment and, are included in the unit service information package.

Placement instructions for other pieces of equipment that make up the Total Green Mfg. System are included with those pieces of equipment and, are included in the unit service information package.

Refrigeration Piping

- After the Total Green Mfg. compressor unit and other system components are placed, the refrigeration system tubing is run from the compressor unit to the other components, as appropriate. Figure 4 illustrates the refrigeration and electrical connection points for the compressor unit. All pipe connections are measured in O.D.

| PORT | FUNCTION | CONNECTION | |

| A | ELECTRICAL | 7/8” HOLE | |

| B | ELECTRICAL | 1-1/4” HOLE | |

| 3 TON | 3.5 THRU | ||

| UNIT | 5 TON | ||

| ONLY | UINTS | ||

| ONLY | |||

| 1 | AH/CC LIQIUD SERVICE VALVE | 3/8” | ½” |

| 2 | EARTH LOOP LIQUID SERVICE VALVE | 3/8” | ½” |

| 3 | EARTH LOOP VAPOR SERVICE VALVE | 3/4” | 7/8” |

| 4 | AH/CC VAPOR SERVICE VALVE | 3/4” | 7/8” |

| 5 | N/A | PLUGGED | |

| 6 | N/A | PLUGGED | |

| 7 | HX OUT | 1 1/8” | |

| 8 | HX IN | 1 1/8” | |

| 9, 10 | (OPT.) VENTS | See Leak Mitigation | |

| and | Manual for Details on | ||

| 11 | Venting | ||

Figure 4. Connections

Compressor units are shipped from the factory with a dry nitrogen holding charge and Isolation Valves on all unit refrigerant line connections. DO NOT open these service valves until all brazing is complete and all connected components have been swept with dry nitrogen. Please refer back to Section 1, page 5, POE OIL PRECAUTIONS.

REQUIREMENT

REFRIGERANT PIPING CONNECTIONS

- Refrigerant joints must be brazed with 15% silver content brazing alloy, utilizing the DRY NITROGEN BRAZING PROCESS.

CAUTION!

NITROGEN BRAZING PROCESS

- PURPOSE: Utilize the DRY NITROGEN BRAZING PROCESS on all brazed refrigerant piping connections. This process eliminates oxidation products from inside joint surfaces.

- TECHNIQUE: “Trickle” dry nitrogen gas at 1-2 psi pressure through the joint area being brazed, to displace the oxygen. When oxygen has been displaced, turn off the dry nitrogen, and relieve the pressure at the joint to atmospheric prior to brazing.

- CONSEQUENCES: Failure to displace oxygen with dry nitrogen at the brazed joint will result in particulate matter being released into the system. The result is discoloration of refrigerant oil, contamination of the system and possible system failure.

!!!REQUIREMENT!!!

- Dry nitrogen should always be flowing through unit and any component and/or piping even when not brazing. This is to prevent an atmosphere that contains moisture from entering the system which will make its way to the compressor oil. This moisture cannot be vacuumed out of the oil once captured. Only the filter/drier removes this moisture.

- Please refer back to Section 1) page 5, POE OIL PRECAUTION

- For field-supplied line set sizes, refer to Figure 5. Line set sizes are for both field manifolds to the compressor unit and from the compressor unit to air handler or cased coil. The line set length is from field manifolds to air handler or cased coil with the compressor being anywhere in between. Line set length cannot exceed 125 ft. For maximum efficiency, line set lengths should not exceed 100 ft. Line set lengths as stated are equivalent lengths, not actual. Fittings must be accounted for. Example: a coupling is equal to 1 ft. of line set and a long radius elbow is equal to 3 ft. of line set. In addition, never use close radius elbows in the system piping.

Pipe Fitting Equivalent Lengths

- Long Radius 90 = 3 ft.

- Coupling = 1 ft.

- Swaged Connection = 1ft.

- 45 Degree Elbow = 1.5 ft.

Important Note: Short-radius 90° elbows are NOT permitted to be used in any piping.

LINE SET PIPING AND ADAPTERS REQUIRED ARE FIELD SUPPLIED. CHECK ALL APPROPRIATE COMPRESSOR UNIT STUB-OUT TUBING SIZES FOR REQUIRED FIELD SUPPLIED ADAPTERS!

| R-454B EARTHLOOP, AIR HANDLER, CASED COIL LINE SETS | ||

|

COMPRESSOR UNIT SIZE |

R-454B LINE SET O.D., INCHES |

|

|

LIQUID |

VAPOR |

|

|

3.0 Tons (-036) |

3/8 |

3/4 |

|

3.5 Tons (-042) |

1/2 |

7/8 |

|

4.0 Tons (-048) |

1/2 |

7/8 |

|

5.0 Tons (-060) |

1/2 |

7/8 |

Figure 5. Line set sizes for Units using R-454B

Service Valves

- All Total Green Mfg. compressor units’ ship with service valves for the field and air handler/cased coil connections installed and approximately 75 P.S.I.G. of dry nitrogen in the compressor unit. These valves are used to isolate the field and air handler/cased coil from the compressor unit. These valves are to remain closed until all components and piping is complete and has been swept with dry nitrogen.

- These valves MUST be wrapped with wet rags when brazing to protect them from heat damage.

Please refer to the applicable manual for installation of other Total Green Mfg. equipment:

- Air Handler

- Cased Coil

- Water Tanks

- Earth Loops

After installing, dry nitrogen brazing and, dry nitrogen sweeping the HVAC system components, turn the Service Valves to Full Open releasing the compressor unit’s dry nitrogen charge into the rest of the system. Add additional dry nitrogen as needed to pressurize the refrigeration system to 150 psig. Valve off the dry nitrogen tank from the HVAC system components and check for leaks. Please follow the seal test procedures later in this manual.

NOTE: Service valve ports are open to the earth loop and air handler/cased coil side of the system when service valves are closed. This provides a means to isolate the field and air handler/cased coil for dry nitrogen purging, pressure testing, etc. without exposing the compressor unit to atmosphere.

Storage Tanks and Water Piping

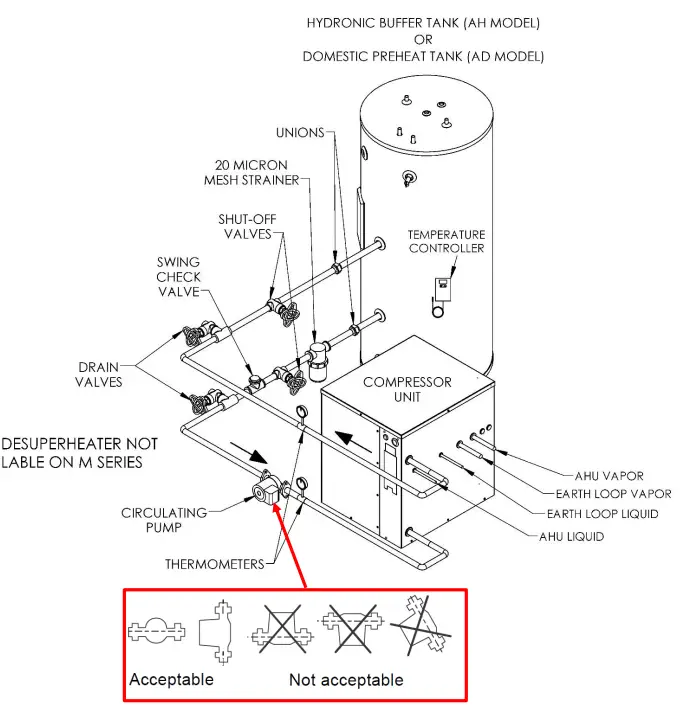

Figure 7 shows a typical water storage tank installation.

ADD MINIMUM COMPONENTS REQUIRED (AS LISTED PER DIAGRAM)

ON ALL INSTALLS:

- DRAIN VALVES

- ISOLATION VALVES

- CHECK VALVES

- THERMOMETERS

Important: The circulating pump must be installed with the motor shaft positioned horizontally. Under no circumstances should the pump be installed with the shaft vertical or where the shaft falls below the horizontal plane.

Figure 7. Typical WG2AD and WG2AH Primary Domestic/Hydronic Circuit Plumbing

The components are as follows:

- Circulating Pump: Circulating pumps, flange kits and mounting brackets are included and ship with the equipment. The design flow rate of the water circuit for the WG2AH and WG2AD should be 3 to 4 GPM per unit ton. This should be easily accomplished using the supplied circulator pump and following the piping instructions set forth in this manual. To verify the appropriate flow rate through the compressor unit heat exchanger, begin by fastening thermocouples securely on the water supply and water return copper stub outs of the compressor unit. Start the unit in heating mode. After the system has stabilized, determine the temperature differential between the supply temperature and the return temperature. The flow rate is correct if the temperature differential is 8 degrees or less. Ideally, no more than 7 degrees. If the temperature differential is higher than 8 degrees, corrections are to be made as needed to raise the flow rate.

- Important: The circulating pump must be installed with the motor shaft positioned horizontally. Under no circumstances should the pump be installed with the shaft vertical or where the shaft falls below the horizontal plane.

- Temperature Controllers: Digital thermostats can be provided by Total Green Mfg. These thermostats can be mounted remotely and come with a Sensor Wire 6.5 feet long.

- Tank: Tanks are available through Total Green Mfg. in 80 and 119/120 US Gallon capacities, and are designed for use with Waterless® geothermal systems. These tanks can be equipped with a 4.5 kW supplemental electric heating element.

- Other Plumbing Components and Parts: Fittings, isolation valves, drain valves, strainer, unions, copper pipe, pipe insulation, etc. meeting USA industry and local code standards are commercially available through plumbing supply outlets. All elbows should be long radius and all valves should be full port.

All plumbing installations are to be in accordance with the applicable local and national codes.

- Required minimum and recommended tank capacities, flow rates and piping sizes are shown in Figure 8 for the nominal tonnage of the compressor unit specified. All field supplied tanks and piping must match what is listed.

|

Compressor Unit Model/Capacity, BTUH |

Tank Size, US Gallons |

Minimum Nominal

Type L Hard Copper Pipe & Fittings, inches |

||

| 3, 3.5 Ton

(36 and 42) |

60, 80 | 1-1/4 I.D. | ||

| 4 and 5 Ton

(48 and 60) |

80, 119/120 | 1-1/2 I.D. | ||

| System Size | System Capacity | Water Heating Flow Rate in GPM | ||

| 3 Ton | 36,000 BTU | 9 to 12 gpm | ||

| 3½ Ton | 42,000 BTU | 10.5 to 14 gpm | ||

| 4 Ton | 48,000 BTU | 12 to 16 gpm | ||

| 5 Ton | 60,000 BTU | 15 to 20 gpm | ||

Figure 8. Storage Tank Capacity and Flow Rate per Unit Size

Note: All water piping to be insulated with ½ inch wall pipe insulation.

Hydronic Water Heating – AH Model

(NOT to be used for Domestic Water Heating)

Hydronic Water Heating Maximum Temperature is 110°F as Measured at the Heat Exchanger Outlet

The water tank thermostat should be adjusted, regardless of the temperature shown on its display, to satisfy the call when the above condition is met. It is also recommended, for maximum efficiency, that the water temperature as measured from the water outlet of the heat exchanger be kept at 100°F or less. Your hydronic heating distribution, such as a radiant floor system, should be designed to operate at 100°F or less. If a hydronic water temperature higher than 110°F is desired, that difference in temperature should be made up with a supplemental heat source.

Antifreeze Protection

- The water circulating system of a WG2AH unit must be protected from potential damage from corrosion, build-up and freeze-up by utilizing a 20% minimum of Propylene-glycol antifreeze with an Inhibitor to water solution. This antifreeze protection is provided by the installer prior to system start-up. Prior to adding glycol with an inhibitor, tank anode rods, if any, must be removed so as not to react with the glycol and inhibitor.

- Propylene glycol antifreeze solution with an inhibitor is the type of antifreeze solution required for Total Green Mfg. products utilized in radiant panel hydronic heating systems. These systems shall be freeze protected consistent with the application-specific minimum temperature as shown in the table below. Propylene-glycol antifreeze solutions should always be in the range of 20% to 50% by volume, as indicated in Figure 9.

| TEMPERATURE, °F | PROPYLENE GLYCOL, % |

| 18 | 20 |

| 8 | 30 |

| -7 | 40 |

| -29 | 50 |

Figure 9. Propylene Glycol Freeze Protection Table

ALWAYS REMOVE THE ANODE ROD(S) FROM THE STORAGE WATER TANK OR HEATER UTILIZED IN A RADIANT PANEL HYDRONIC HEATING IF THE ANODE ROD(S) ARE NOT REMOVED, THE PROPYLENE-GLYCOL SOLUTION WILL REACT WITH THE ANODE ROD(S) TO CREATE PARTICLES THAT BLOCK FLOW AND CAUSE SYSTEM FAILURE.

ALWAYS REMOVE THE ANODE ROD(S) FROM THE STORAGE WATER TANK OR HEATER UTILIZED IN A RADIANT PANEL HYDRONIC HEATING IF THE ANODE ROD(S) ARE NOT REMOVED, THE PROPYLENE-GLYCOL SOLUTION WILL REACT WITH THE ANODE ROD(S) TO CREATE PARTICLES THAT BLOCK FLOW AND CAUSE SYSTEM FAILURE.

Domestic Water Heating –AD Model

(NOT to be used for Hydronic Water Heating)

Domestic Water Heating Maximum Temperature 120°F

- Please note that the maximum water temperature for the WG2AD (domestic water heating) system is 120°F as measured at the water outlet of the unit heat exchanger. This temperature is enough to satisfy most domestic water heating needs. The water tank thermostat should be adjusted, regardless of the temperature shown on its display, to satisfy the call when the above condition is met. If a higher domestic water temperature is desired, that difference in temperature should be made up with a supplemental electric element. You also have the option of sending preheated water to the cold water inlet of a standard water heater.

Filtration and Water Quality

- The inclusion of a water filter in all applications for domestic water heating is necessary. A water filter reduces the potential for silt, dirt, rust and other particulate matter from entering the heated water system. This can be achieved using a whole-house water filtration system or, at the least, a water filter on the cold water line entering the water tank.

- When specifying a system for domestic water heating, it is important to ensure that the water is not hard, and to have the water analyzed and treated as appropriate for several factors that affect the quality of potable water.

- Please refer to the applicable manual for the installation of other Total Green Mfg. equipment:

- Air Handler

- Cased Coil

- Earth Loops

Electrical Data and Field Control Wiring

WARNING

LIVE ELECTRICAL COMPONENTS!

- Failure to follow this Warning could result in property damage, severe personal injury, or death. Follow all electrical safety precautions when exposed to live electrical components. It may be necessary to work with live electrical components during the installation, testing, servicing, and troubleshooting of this product.

- The high voltage power supply must agree with the equipment nameplate.

- Check that cabling will not be subject to wear, corrosion, excessive pressure, vibration, sharp edges, or any other adverse environmental effects.

- Power wiring must comply with national, state, and local codes.

- Follow instructions on the unit wiring diagram located on the bottom side of the unit lid.

Please Note: Electrical data is subject to change without notice. Please refer to the equipment data label for the most up to date specifications.

| WG-2-XXX-D-2-XX R-454B TWO STAGE SINGLE PHASE | |||||

| TON | SINGLE PHASE | LRA | RLA | MCA | MFS |

| 3 TON {036) | 230V – 60HZ | 106 | 18.2 | 22.8 | 35 |

| 3.5 TON {042) | 230V – 60HZ | 141 | 20.1 | 25.1 | 40 |

| 4 TON {048) | 230V – 60HZ | 149 | 22.3 | 27.9 | 40 |

| 5 TON {060) | 230V – 60HZ | 166 | 28 | 35 | 50 |

| MFS = Maximum Fuse or HACR Circuit Breaker Size MCA = Minimum Circuit Ampacity | |||||

| WG-2-XXX-D-2-XX R-454B TWO STAGE THREE PHASE | |||||

| TON | SINGLE PHASE | LRA | RLA | MCA | MFS |

| 3 TON {036) | 230V – 60HZ | 114 | 11.5 | 14.4 | 25 |

| 4 TON {048) | 230V – 60HZ | 150 | 14 | 17.5 | 25 |

| 5 TON {060) | 230V – 60HZ | 162.3 | 19.2 | 24 | 35 |

| MFS = Maximum Fuse or HACR Circuit Breaker Size MCA = Minimum Circuit Ampacity | |||||

Please reference your TGM air handler manual for your specific air handler field wiring requirements.

- Johnson Controls A419 thermostat shown as reference. Any brand of compatible thermostat may be used. Johnson Controls A421 thermostats are available for purchase from Total Green Mfg. Be sure to match wiring and terminals to the thermostat used.

Using the “X” and “LA” terminals

- Using the “X” terminal. For non-zoned single thermostat systems. Please note the “X” terminal circled in red on figure 10 on page 18. All Total Green Mfg. Waterless® Geothermal units utilize the “X” terminal along with an LED fault indicator light located above the “X” terminal on the field wiring terminal strip of the unit’s

electrical box. In the event of a system lock out, low pressure, high pressure, discharge temperature fault or,

a refrigerant leak having been detected, the “X” terminal energizes so that 24 volts can be read between ”X” and the common terminal “C”. The LED fault light will also light indicating a system lockout. The lockout circuit

is in place to protect the compressor unit from damage in the event the operating parameters of the system are out of range and, in the event of a refrigerant leak having been detected. Should a lockout occur, the system should be evaluated and, any corrections are to be made prior to placing the unit back into service. Please note that repeatedly resetting the lockout without any needed service can still result in compressor damage and may void the equipment warranty. - The “X” terminal can also be used to send a “service required” signal to a compatible thermostat. Thermostats with this feature will typically have an “L” or “L/A” terminal. Please review your thermostat manufacturer’s

installation manual for this function. Figure 11 below shows an example of a Honeywell thermostat service required indicator. - Please Note: If using a zone control system for air zoning requiring a separate control transformer, this feature will not function and should not be wired in.

Using the “LA” terminal

- Using the “LA” terminal. Please note the “LA” terminal circled in red on figure 10 on page 18. All Total Green Mfg. Waterless® Geothermal units utilize the “LA” terminal along with an LED fault indicator light located above the “LA” terminal on the field wiring terminal strip of the unit’s electrical box. “LA” is a refrigerant leak alert signal.

- Both the compressor unit and the air handler/cased coil are equipped with A2L refrigerant leak sensors.

- If either sensor detects a refrigerant leak, the unit will go into lockout mode, disabling the compressor and backup heat source. The blower on forced air units will be activated and, the “LA” (Leak Alert) light along with the “X” (Lock Out) will turn on along with the “LA” terminal being energized with 24 volts AC. This terminal can be used as a trigger, if required by your local building codes, to set off a remote alarm and/or trigger a mechanical room exhaust fan in the event of a refrigerant leak. Please refer to the “Leak Mitigation Manual” in the unit’s service information packet for more information about leak mitigation as it applies.

NOTICE

- LEAK DETECTION SYSTEM INSTALLED.

- UNIT MUST BE POWERED EXCEPT FOR SERVICE.

Leak Sensor Information: The leak sensors used in Total Green’s Waterless®

- Geothermal systems are designed for no less than a 15-year service life. Should a sensor failure occur during the life of the system, contact Total Green. Mfg. for replacement. No other sensor type or source should be considered. A sensor failure will result in the equipment staying in leak mitigation mode.

Dual Fuel Option and Thermostat Settings for the WG2Ax Units.

- WG2Ax units utilize a Smart Logic Control with built-in Dual Fuel system control. This dual fuel function must be utilized anytime the AUX/BACKUP heat source is applied prior to the indoor coil such as, a cased coil installed on the outlet of a furnace.

- When shipped, a WG2Ax unit will have a jumper wire installed across the “A” and “S” terminals as shown below.

- This jumper remains in place for a standard air handler with heat strips but, it must be removed in a dual fuel application as described above. A WG2A box is shown for reference.

- The unit will handle the dual fuel function. Please use the following settings in your thermostat when using the unit’s dual fuel function. A Honeywell thermostat is shown as reference.

Ducting, Air flow and Air Zoning

- Total Green Mfg. WG1A (single stage) refrigerant-to-air systems require 400 CFM of air flow per unit ton with no more than .5 inches of total static pressure. For WG2Ax (two-stage) refrigerant-to-air systems, the same specifications are required when in second-stage operation. When air zoning, it is recommended that a WG2Ax (two-stage) unit be used in conjunction with a fully variable air handler blower. When air zoning, it is recommended that the1st or largest zone be sized to 70% of the total air flow requirement and that the 2nd zone be sized for 60% of the total air flow requirement.

- This recommendation is due to a reliability feature called a “Maintenance Cycle” designed into the WG2Ax units. After four consecutive first-stage calls without reaching second stage prior to satisfying the zone call, the system will run in second stage for 5 minutes. This is to ensure proper oil return back to the compressor unit for a longer compressor life.

- In some instances, sizing zones as stated above may not be possible, leaving you with a small zone that may never call for second-stage or support the required air flow for the “Maintenance Cycle”. For this reason, a 24 volt signal, referred to as “Damper Override”, is provided by the “D” terminal on WG2Ax units. Terminal “D” is only energized while the unit is in the “Maintenance Cycle”. This 24-volt signal can be used to force open the largest zone of the duct system while the equipment is in the “Maintenance Cycle”. Utilizing this option requires the installation of a field-supplied SPDT relay with a 24-volt coil to isolate the zone board and air handler power supplies. The “D” terminal and relay provide a means of making the “R” and “Y” thermostat input of the zone board’s largest zone. When in the “Maintenance Cycle”, forcing that zone open relieves excessive static pressure at the air handler without the need of a bypass or dump zone. See Figure 12 for the Field Wiring Diagram for use with the damper override signal.

Seal Test

WARNING!

To avoid personal injury and equipment damage, follow all safety procedures set forth by OSHA in the handling of high-pressure gases. Always use a pressure regulator and hoses that are capable of withstanding the pressures prescribed herein. Do not subject system components OTHER than the earth loop/manifold/line set configuration to 400 PSIG dry nitrogen.

- After brazing in the earth loop system (includes manifolds, earth loops and earth loop line set, but NOT the compressor unit or any other HVAC refrigeration system component), the complete underground system is to be seal tested with at least 400 PSIG of dry nitrogen. After connecting a high-pressure hose from the regulator on the nitrogen tank to a Schrader port temporarily installed on the vapor line of the line set, slowly increase the dry nitrogen pressure to no less than 400 PSIG while checking for any obvious leaks audibly.

If no audible leaks are detected, check all joints to ensure they are sealed by one of the following methods:

- Ultrasonic Leak Detector or Bubble Solution Leak Detector

- Electronic Leak Detector (requires a trace amount of refrigerant in the system)

IMPORTANT – LOOP READINESS

Check for leaks by either of these methods or any other reliable method to ensure that there are no leaks and the earth loop system is sealed! It is absolutely necessary that the earth loop/manifold/line set assembly be completely sealed at no less than 400 psig of dry nitrogen. Recheck all leak detector readings. Local codes may require higher loop testing pressures. Always abide by your local codes.

- When the line set/manifolds/earth loops are deemed leak-free and sealed, valve off the nitrogen source and monitor the pressure on the underground system to ensure that at least 400 psig has been maintained for minimum of 8 hours.

- Monitor the pressure reading during the backfilling operation to ensure that the earth loop system remains sealed.

- Important: Final Whole System Seal Test.

- After having tested the field at no less than 400 P.S.I. as stated above, once the remaining equipment such as the compressor unit, air handler or cased coil, ETC, is installed, and the unit service valves have been open, the entire system should be pressurized to 150 P.S.I. and left to stand for a min. of 8 hours for a total system seal test.

- Please refer to your Vacuum and Charging procedures manual in your unit’s service packet for startup

- If you have any questions regarding these procedures, please contact Total Green

- Mfg. technical support at 419-678-2032.

IMPORTANT!

- If any specifications in this manual cannot be met, contact Total Green Mfg. for a possible solution and approval. Any approved solutions that differ from the specifications in this manual must be approved with a written variance from Total Green Mfg.

Unit Wiring Diagrams

WG2AD With Out Sure Start, Single phase, 230 Volts

WG2AD With Sure Start, single phase, 230 Volts

WG2AD three phase, 230 Volts

WG2AH Without Sure Start

WG2AH With Sure Start

WG2AH three-phase

- ELECTRICAL SCHEMATIC

- VG2ÅH-xxD2___

- 230V, THREE PHASE* 60HZ

- C11-19-e0242

Generic Distribution Piping, Tank and Design Examples, WG2AH only

Domestic Hot Water WG2AD units only.

CAUTION: IF BUILDING COLD WATER SUPPLY HAS A BACK-FLOW PREVENTER. CHECK VALVE OR WATER METER WRH CHECK VALVE. PROVISIONS FOR THERMAL EXPANSION OF WATER IN THE HOT WATER SYSTEM MUST BE PROVIDED.

Installer Function Options, Jumper Wires

- Shown on the top, the AD unit, forced air heating and cooling with 100% domestic hot water on demand, ships with a jumper wire across terminals “R” and “AW”. With this jumper installed, air heating and cooling take priority over water heating. Given the fast recovery time for water heating, we recommend removing this jumper to prioritize water heating for most installations. Please note the “N” on the input strip. This is the water tank thermostat call.

Shown below the AD unit, the AH unit, forced air heating and cooling with hydronic diverting circuit, has the following terminals and features:

- Please note the “N” on the input strip. This is the water tank thermostat call.

- Please Note the “SZ”, “R”, and “AW” . These are your function option terminals.

- Units are shipped with a jumper wire across terminals “R” and “AW”. This prioritizes the forced air call over the water heating call. Removing the jumper prioritizes the water heating call over the forced air call.

- Split Zoning: The “SZ” terminal (Split Zone) allows the unit to heat one zone or floor with hydronic heat and another zone or with forced air. “Split Zone” is active by removing the priority call jumper making hydronic water heating the priority over air, and jumping “R” to the Split Zone “SZ) terminals of the field wiring terminal block. In this mode, while the unit is heating water for the hydronic zone, any “Y” call for heating in the forced air zone is shifted to the Auxiliary heating “W” Terminal. After the call completes, the unit resumes normal operation.

Examples of when air heating should be a priority over hydronic water heating:

- When radiant floor heat is not the primary heat source, such as floor tempering, meaning just enough heat to not have cold floors, such as in a Master Bath or areas of the home with tile or hardwood floors.

- When the radiant floor system uses tubing spacing or lengths of tubing requiring water temperatures above 110°F to deliver adequate heat, to be the primary heat source. In this case, the radiant floor system is just tempering the floor.

- When heating set-backs are used and fast recovery times are required.

- When Split Zoning is not used.

If you have any questions regarding these procedures, please contact Total Green Mfg. technical support at 419-678-2032.

FAQs

Q: Can the compressor unit be placed indoors?

A: Yes, the compressor unit can be placed indoors on a level, hard surface.

Q: How should refrigerant and water lines be insulated?

A: Insulate all lines with at least 1/2 wall thickness of Armaflex or equivalent insulation.

Documents / Resources

|

WATERLEESS M Series Multi Function Machines [pdf] Installation Guide WG2AD, WG2AH, M Series Multi Function Machines, M Series, Multi Function Machines, Function Machines, Machines |