VEC100 Generic RTU Controller, Staged Heating

and Modulated Cooling Quick Start Guide

LIT-12013487

2021-07-14

About this guide

This quick start guide provides the basic information you need to configure and install the Verasys® Equipment Controller (VEC), LC-VEC100-0, using the Verasys generic

rooftop unit (RTU) staged heating and modulated cooling controller application. The application controls a third-party changeover bypass (COBP) system or a third-party variable air volume (VAV)unit.

For further information, refer to the Verasys Equipment Controller (VEC) Installation Guide (24-10143-1272) and theVEC100 GenericRTU Controller, StagedHeating and

Modulated Cooling Application Note (12013485).

Table 1: Application features

| Options available | Possible values |

| Number of Heating

Stages Installed |

0 to 2 |

| Cooling Valve | • State 0: not installed

•State 1: water coil |

| Economizer Installed | •State 0: the economizer is not available.

•State 1: the economizer is available. |

| Air Proving Switch Setup | •State 0: fan status device

•State 1: duct static pressure sensor •State 2: none |

| Rooftop Controller Type | •State 0: changeover bypass

• State 1: VAV |

| Cancel ASCD Timers | •State 0: false

•State 1: true |

| Demand Ventilation Feature | •State 0: demand ventilation is off.

•State 1: demand ventilation is on. |

Mounting the controller

To mount the controller, complete the following steps:

- Mount a 20 cm (8 in.) section of 35 mm (1.3 in.) DIN rail horizontally.

Note: Mount the controller in the horizontal position.

Note: Mount the controller in the horizontal position. - On the back of the controller, extend the two mounting clips.

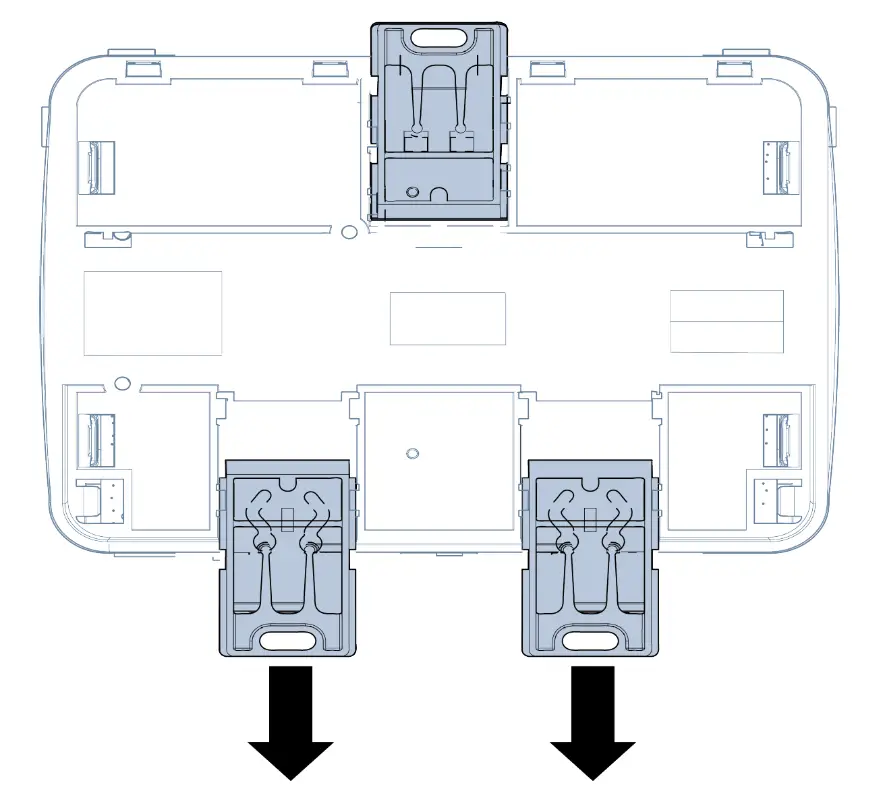

Figure 1: Pull down lower mounting clips

3. Place the controller on the DIN rail.

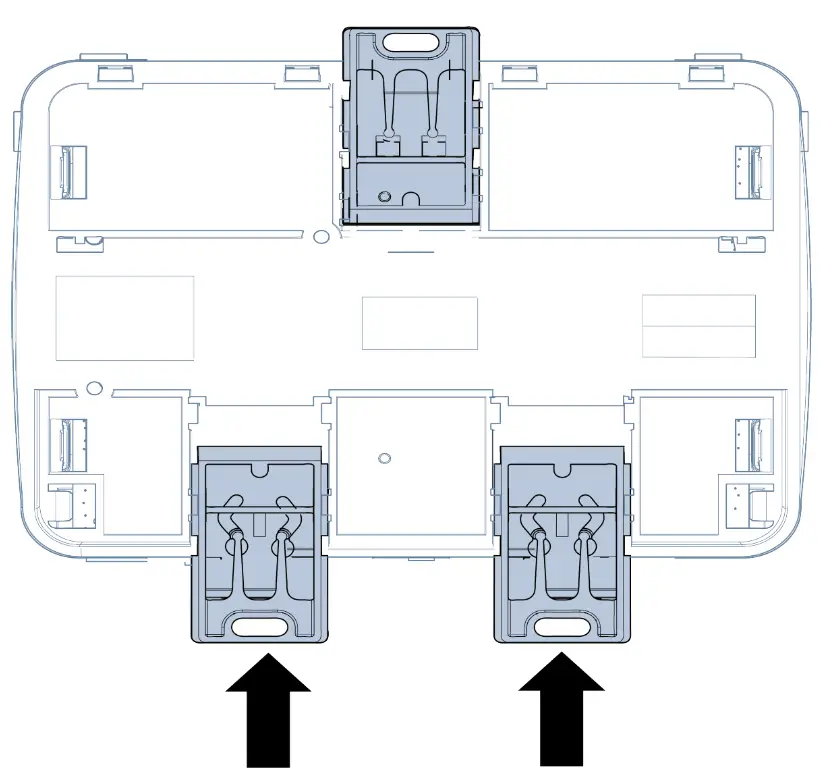

4. Push the bottom mounting clips inward (up) to secure the controller on the DIN rail.

Figure 2: Push up lower mounting clips

Wiring the controller

Zone bus terminal block

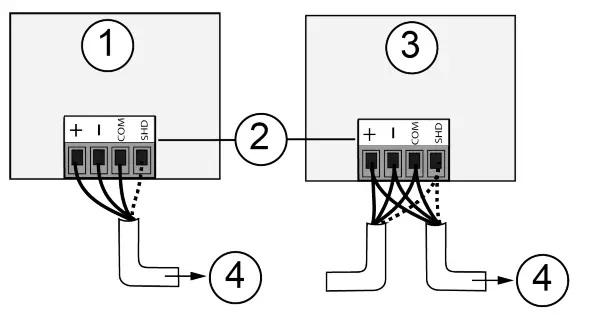

The zone bus terminal block is a grey, removable, 4terminal plug that fits into a board-mounted jack. Wire the removable zone bus terminal block plugs on the controller on the top row of the stacked connector, and other field controllers in a daisy-chain configuration using a 3-wire twisted, shielded cable as shown in the following figure.

Figure 3: Zone bus terminal block wiring

Table 2: Zone bus daisy-chaining configuration

| 1 | Terminating device on the sensor bus |

| 2 | Sensor bus terminal block plug on the terminating device |

| 3 | Daisy-chained devise on a sensor bus segment |

| 4 | Sensor bus terminal block plug on the daisy-chained device |

| 5 | Cable shield connection |

| 6 | Connects to the next device on the sensor bus. |

Note: The zone bus shield (SHD) terminal is isolated and can be used to connect (daisy chain) the shields for zone bus wiring.

Note: The zone bus shield (SHD) terminal is isolated and can be used to connect (daisy chain) the shields for zone bus wiring.

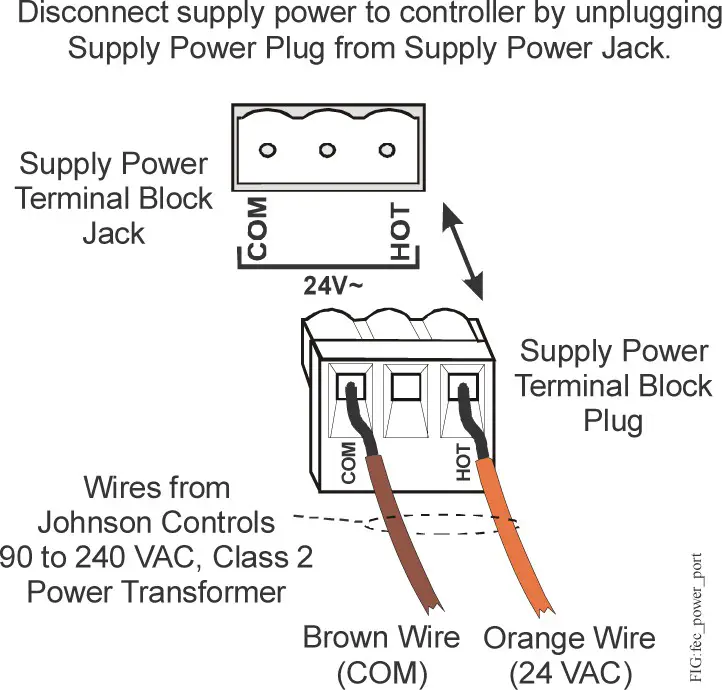

Supply power terminal block

The 24 VAC supply power terminal block is a gray, removable, 3-terminal plug that fits into a board-mounted jack on the top right of the controller. Wire the 24 VAC supply power wires from the transformer to the HOT and COM terminals on the terminal plug, as shown in the following figure. The middle terminal on the supply power terminal block is not used.

Figure 5: 24 VAC Supply Power Terminal Block

Note: The supply power wire colors may be different on transformers from other manufacturers. Refer to the transformer manufacturer’s instructions and the project installation drawings for wiring details.

Note: The supply power wire colors may be different on transformers from other manufacturers. Refer to the transformer manufacturer’s instructions and the project installation drawings for wiring details.

Setting the VEC address using the local display

To set the VEC address using the local display, complete the following steps:

- To access the menu, press the ENT (Enter) button.

- Navigate to the Controller menu with the up and down arrows, and press the ENT button.

- In the Controller menu, navigate to Network and press the ENT button.

- In the Network Parameters section, navigate to Address and press the ENT button. The display shows the default address value.

- Press the ENT button. The address blinks.

- Use the up or down arrow to increase or decrease the address to the value you want. Press the ENT button. The address stops blinking and the display shows the old address.

- Press either the up or down arrow. The screen refreshes to the new address.

- Press ESC (Escape) repeatedly, until you return to the main screen. Ensure that the main screen shows that the system is operational.

Configuring sensors

To configure the installed sensors, complete the following steps:

- Navigate to the Details menu.

- Navigate to the Service menu and select the Inputs section.

- Select the installed sensors using the drop-down menus for each parameter.

Updating the VEC

To update the VEC with the staged heating and modulated cooling application, complete the following steps:

- Go to verasyscontrols.com, and log in with your credentials.

- Navigate to Product Information & Support > Device Updates.

- Download the package file for the application to the root folder of a USB 2.0 drive. The package file name is the following: VEC100-StgHTGModCLG_xxxx.pkg

Note: Ensure that the USB drive is formatted exFAT or FAT32. - Insert the USB drive into the USB port on the VEC.

- If the download does not start immediately, then the controller’s local display, select the Update and Load Firmware option, then choose the package file on the USB drive, and press Enter.

- When the application update finishes, use the Verasys Smart Building Hub (SBH) or the local display to configure the controller.

COBP wiring diagram

Figure 6: Changeover bypass wiring diagram – VEC100

Figure 7: Changeover bypass wiring diagram – IOM3711

Table 4: Changeover bypass wiring diagram

| Number | Description | Object name (if

given) |

| 1 | Economizer Damper Output (optional) | MAD-O |

| 2 | Supply fan output (to fan VFD) | SF-O |

| 3 | Cooling valve output | CLG-O |

| 4 | Supply fan command (to fan VFD) | SF-C |

| 5 | Heating stage 1 command | HTG1-C |

| 6 | Heating stage 2 command | HTG2-C |

| 7 | 24 V HOT to damper motor | |

| 8 | 24 V COM to damper motor | n/a |

| 9 | 24 V COM | n/a |

| 10 | 24 V HOT | n/a |

| 11 | From last device | n/a |

| 12 | To next device | n/a |

| 13 | Zone humidity sensor – monitor only (optional) | ZN-H |

| 14 | Return air CO2

Range: 0 ppm to 2,000 ppm, 0 VDC to 10 VDC |

RA-CO2 |

| 15 | Return air temperature sensor | RA-T |

Table 4: Changeover bypass wiring diagram

| Number | Description | Object name (if

given) |

| 16 | Outside air temperature sensor

|

OA-T |

| 17 | Discharge air static pressure sensor

Range: 0 in. W.C. to 5 in. W.C., 0 VDC to 5 VDC |

DA-P |

| 18 | Discharge air temperature sensor | DA-T |

| 19 | Supply fan status (air proving switch, optional) | SF-S |

| 20 | Purge input (optional) | PURGE-S |

| 21 | Filter status (optional) | FILTER-S |

| 22 | From the last SA device | n/a |

| 23 | Mixed air temperature sensor

|

MA-T |

VAV wiring diagram

Figure 8: VAV wiring diagram – VEC100

Figure 9: VAV wiring diagram – IOM3711

Table 5: VAV wiring diagram

| Number | Description | Object name (if given) |

| 1 | Economizer Damper Output (optional) | MAD-O |

| 2 | Supply fan output (to fan VFD) | SF-O |

| 3 | Cooling valve output | CLG-O |

| 4 | Supply fan command (to fan VFD) | SF-C |

| 5 | Heating stage 1 command | HTG1-C |

| 6 | Heating stage 2 command | HTG2-C |

| 7 | 24 V HOT to damper motor | n/a |

| 8 | 24 V COM to damper motor | n/a |

| 9 | 24 V COM | n/a |

| 10 | 24 V HOT | n/a |

| 11 | From last device | n/a |

| 12 | To next device | n/a |

| 13 | Zone humidity sensor – monitor only (optional) | ZN-H |

| 14 | Return air CO2

Range: 0 ppm to 2,000 ppm, 0 VDC to 10 VDC |

RA-CO2 |

| 15 | Return air temperature sensor | RA-T |

Table 5: VAV wiring diagram

| Number | Description | Object name (if given) |

| 16 | Outside air temperature sensor

|

OA-T |

| 17 | Discharge air static pressure sensor

Range: 0 in. W.C. to 5 in. W.C., 0 VDC to 5 VDC |

DA-P |

| 18 | Discharge air temperature sensor | DA-T |

| 19 | Supply fan status (air proving switch, optional) | SF-S |

| 20 | Purge input (optional) | PURGE-S |

| 21 | Filter status (optional) | FILTER-S |

| 22 | From last SA device | n/a |

| 23 | Mixed air temperature sensor

|

MA-T |

Commissioning the system

To activate the outputs and verify system operation, navigate to the Commissioning menu, change Start Commissioning to Trigger, and adjust outputs individually. The following table describes the Details > Service > Factory menu options.

Table 6: Details : Service: Factory

| Object or parameter | Description | Adjustable | Defaults | Enum set or range |

| Cooling Valve | Sets the installation of the cooling valve. | Adjustable | Not Installed | 0 = Not Installed 1 = Water Coil |

| Number of Heating

Stages Installed |

Sets the number of heating stages installed. | Adjustable | 2 | 0 to 2 |

| Economizer Installed | Sets whether the economizer is installed. | Adjustable | No | 0 = No 1 = Yes |

| Air Proving Switch Setup | Selects the type of setup for airflow proof. | Adjustable | None | 0 = Fan Status Device 1 = Duct Static Pressure Sensor 2 = None |

| OAT Cooling Lockout

Temperature |

Sets the temperature at which outside cooling lockout occurs. | Adjustable | 50°F (10°C) | 0°F to 100°F (-18°C to 38°C) |

| Economizer Minimum

Position Setpoint |

Sets the minimum outside air damper position. | Adjustable | 20% | 0% to 100% |

| Rooftop Controller Type | Sets the controller type to changeover bypass or VAV. | Adjustable | Changeover Bypass | 0 = Changeover Bypass 1 = VAV |

| Variable Speed Drive | Sets whether the VEC100 controls a VFD fan instead of a bypass damper when the rooftop controller type is set to changeover

bypass. |

Adjustable | False | 0 = False 1 = True |

| Supply Air Temperature Alarm Offset | If SAT is not in this value range, the SAT alarm delay starts. Examples: If the supply air setpoint is 55°F and this is set to 5°F, then the supply air must be under 60°F, or the delay timer starts. If the supply air setpoint is 110°F and this is set to 5°F then the supply

air must be above 105°F, or the delay timer starts. |

Adjustable | 5 delta °F (2.78 delta °C) | 0 delta °F to 25 delta °F (0 delta °C to 14 delta °C) |

| Supply Air Temperature

Alarm Delay |

Sets the amount of time that must pass before the SAT alarm

occurs. |

Adjustable | 20 min | 0 min to 120 min |

| Cancel ASCD Timers | Resets the minimum on and off timers. | Adjustable | False | 0 = False 1 = True |

| Demand Ventilation Feature | Enables or disables the demand ventilation feature. | Adjustable | Off | 0 = Off 1 = On |

Product warranty

This product is covered by a limited warranty, details

of which can be found at www.johnsoncontrols.com/buildingswarranty.

Contact Johnson Controls: www.johnsoncontrols.com/contact-us

Software terms

Single point of contact

| APAC | Europe | NA/SA |

| JOHNSON CONTROLS C/O CONTROLS PRODUCT MANAGEMENT NO. 32 CHANGJIJANG RD NEW DISTRICT WUXI JIANGSU PROVINCE 214028 CHINA |

JOHNSON CONTROLWESTENDHOF 3 45143 ESSEN GERMANY |

JOHNSON CONTROLS 507 E MICHIGAN ST MILWAUKEE WI 53202 USA |

Contact information

www.johnsoncontrols.com/locations

All specifications and other information shown were current as of document revision and are subject to change without notice.

www.johnsoncontrols.com

Documents / Resources

|

VERASYS VEC100 Generic RTU Controller Staged Heating and Modulated Cooling [pdf] User Guide VEC100 Generic RTU Controller Staged Heating and Modulated Cooling, VEC100, Generic RTU Controller Staged Heating and Modulated Cooling |

|

VERASYS VEC100 Generic RTU Controller Staged Heating and Modulated Cooling [pdf] User Guide VEC100 Generic RTU Controller Staged Heating and Modulated Cooling, VEC100, Generic RTU Controller Staged Heating and Modulated Cooling |