DOSATRON D14MZ2 Fail Safe Sanitizer System

Product Specifications

- Product Name: FAIL-SAFE SANITIZER SYSTEM

- Item Number: PS4G137-137-FAILSAFE

- Panel Size: 24 x 36 inches

- Concentration Range: 0.2% – 2%

- Manufacturer Website: www.dosatron.com

System Features:

- Turn-key system for blending PAA sanitizers with water

- Water-powered chemical metering pump with required accessories

- Simple to install and commission

- Concentration adjustments between 0.2% and 2%

- Conserves time and energy

- Minimizes employee exposure and spills

Product Usage Instructions

- Installation: Follow the provided installation manual to set up the system in the desired location.

- Commissioning: After installation, ensure all connections are secure before commissioning the system.

- Concentration Adjustment: Use the adjustment controls to set the desired sanitizer concentration between 0.2% and 2%.

- Operation: Turn on the system and monitor the blending process to ensure proper mixing of sanitizers with water.

- Maintenance: Regularly check for leaks, clean the system components, and replace any worn-out parts as needed.

Quick start-up

US

This document does not form a contractual engagement on the part of Dosatron International and is for information only. Dosatron International reserves the right to alter product specification or appearance without prior notice.

© DOSATRON INTERNATIONAL S.A.S. 2009

- You have just become the owner of one of the latest in the line of DOSATRON water-powered metering pumps and we congratulate you on your choice.

- The development of this model is the result of over 30 years of experience. Our engineers have placed the DOSATRON series at the forefront of technical development in the field of in the field of DOSATRON water-powered metering pumps.

- This DOSATRON will, as time goes by, prove itself to be a most faithful ally.

- A little care and attention, regularly spent, will guarantee you an operation in which the word breakdown has no place.

- THEREFORE, PLEASE, READ THIS MANUAL CAREFULLY BEFORE PUTTING THE DOSATRON INTO OPERATION.

Important!

The complete model reference and the serial number of your DOSATRON is stamped on the pump body. Please record this number in the space below and refer to it when you call your distributor for information, parts, and service.

- Ref. # ……………………………………………………………………..

- Serial # ………………………………………………………………….

- Purchase Date ……………………………………………………….

SPECIFICATIONS

| Specification | D14MZ3000 / D14T(1)MZ3000 | D14MZ2 / D14T(1)MZ2 | D14MZ5 / D14T(1)MZ5 | D14MZ10 | D14MZ520(2) |

|---|---|---|---|---|---|

| Practical Operating Flow Range | – | – | 1/3 US Pint/min – 14 US GPM | 0.4 US Pint/min – 14 US GPM | 1/3 US Pint/min – 9 US GPM |

| Maximum Operating Temperature | – | – | 104°F [40°C] | 140°F [60°C] | 104°F [40°C] |

| Operating Pressure (PSI/bar) | 4.3 – 85 / 0.30 – 6 | 4.3 – 85 / 0.30 – 6 | 4.3 – 85 / 0.30 – 6 | 7 – 85 / 0.50 – 6 | 7 – 57 / 0.50 – 4 |

| Injection Rate (Ratio / %) | 1:3000 – 1:333 / 0.03 – 0.3 | 1:500 – 1:50 / 0.2 – 2 | 1:200 – 1:2 / 0.5 – 5 | 1:100 – 1:10 / 1 – 10 | 1:20 – 1:4 / 5 – 25 |

| Concentrated Additive Injection (US GPM – MAXI) | 0.04 | 0.28 | 0.7 | 1.4 | 2.2 |

| Mini l/h – Maxi l/h | 0.0017 – 0.011 | 0.011 – 0.28 | 0.028 – 0.7 | 0.056 – 1.4 | 0.2818 – 2.2 |

| US Fl. oz/min – MINI | 0.003 – 9 | 0.02 – 60 | 0.05 – 150 | 0.05 – 150 | 0.05 – 500 |

| Connections (NPT/BSP male) | – | – | 3/4″ [Ø 20×27 mm] | – | – |

| Hydraulic Motor Capacity | – | – | About 0.14 US Gallons [0.53 l] | – | – |

Unit Size

| Dimension | D14MZ3000 / D14T(1)MZ3000 | D14MZ2 / D14T(1)MZ2 | D14MZ5 / D14T(1)MZ5 | D14MZ10 | D14MZ520(2) |

|---|---|---|---|---|---|

| Diameter | 4 7/16″ [11.2 cm] | 4 7/16″ [11.2 cm] | 4 7/16″ [11.2 cm] | 4 7/16″ [11.2 cm] | 4 7/16″ [11.2 cm] |

| Total Height | 21″ [53 cm] | 19 3/32″ [48.5 cm] | 21 3/16″ [53.8 cm] | 21 3/16″ [53.8 cm] | 26 1/8″ [66 cm] |

| Width | 6 5/16″ [16 cm] | 6 5/16″ [16 cm] | 6 5/16″ [16 cm] | 6 5/16″ [16 cm] | 6 5/16″ [16 cm] |

| Weight | 3.5 lbs [1.6 kg] | 3.7 lbs [1.7 kg] | 3.9 lbs [1.8 kg] | 4.4 lbs [2 kg] | 8.8 lbs [4 kg] |

SHIPPING CONTENTS: 1 DOSATRON / 1 mounting bracket for DOSATRON / 1 suction tube of concentrated additive / 1 strainer / 1 injection suction tube for “IE” model / 1 owner’s manual

- PACKAGE SIZE: 21 7/8″ x 6 5/8″ x 5 3/4″ [55.2 x 16.5 x 14.5 cm ]

- PACKAGE WEIGHT: ~ 4.4 – 8.8 US lbs [2 – 4 kg approx]

Precise, simple and reliable

A unique technology associating all dosing functions

Installed directly in the water supply line, the DOSATRON operates by using water pressure as the power source. The water activates the DOSATRON, which takes up the required percentage of concentrate. Inside the DOSATRON, the concentrate is mixed with the water. The water pressure forces the solution downstream. The dose of concentrate will be directly proportional to the volume of water entering the DOSATRON, regardless of variations in flow or pressure that may occur in the main line.

Installation

PRECAUTIONS

- GENERAL REMARKS

- When connecting a DOSATRON either to the public water supply or to its own water source, you must respect the regulations in force concerning the protection of the source i.e. backflow prevention, etc.

- When connecting the DOSATRON to the water supply, ensure that the water flows in the direction of the arrows on the unit.

- In a case where the water installation is higher than the DOSATRON itself, there is a possible risk of water and concentrate flowing back through the DOSATRON. In this case, installing a non-return valve downstream is recommended.

- It is recommended that you place an anti-siphon valve on the downstream side of the dosing pump in installations in which there is a risk of siphoning.

- Do not install the DOSATRON just above an acid container, (risk of acid fumes attacking the DOSATRON) and protect it from possible contact with corrosive products.

- Protect the DOSATRON from freezing temperatures by draining it and store it away from sources of excessive heat.

- Do not install the DOSATRON on the suction side of the supply pump (risk of siphoning).

- IMPORTANT! Use no tool or metallic utensils.

- During any intervention, the operator must stay in front of the DOSATRON and wear protective eyewear and gloves.

- It is the responsibility of the owner/operator to replace the injection seals annually to ensure precise injection.

- The setting of the Dosatron’s dosing rate is the sole responsibility of the user. The user has to respect the recommendations given by the manufacturer of the chemical product.

- AVERTISSEMENT

When installing, operating, and maintaining the DOSATRON water-powered metering pump, keep safety considerations foremost. Use proper tools, protective clothing, and eye protection when working on the equipment and install the equipment with a view toward ensuring safe operation. - Follow the instructions in this manual and take additional safety measures appropriate to the liquid being pumped and the temperature of the water that powers the DOSATRON.

Be extremely careful in the presence of hazardous substances (e.g. corrosives, toxins, solvents, acids, caustic, flammables, etc.). - Before applying any aggressive chemicals, please consult your distributor to confirm compatibility with the dosing pump.

When installing the DOSATRON on a hot water system (140°F/ 60°C max.), a dosing unit with a “T”-option is required. High temperature increases the risk and the dangerousness of the substances mentioned above. It is strongly recommended to identify and label the dosing unit and the complete hot water installation as such, and to respect the corresponding regulations in force.

IMPORTANT!

It is the responsibility of the owner/operator to check that the flow and pressure of the installation do not exceed the DOSATRON characteristics.

- Adjustments must be made when there is no pressure in the Dosatron.

- Turn off the water supply and allow the pressure to drop to zero.

- It is the responsibility of the owner/operator of the DOSATRON, to determine the correct amount of solution and injection ratio to obtain the desired result.

- An air inlet, an impurity or a chemical attack on seal can interrupt the dosing function. It is recommended to periodically check that the solution is being correctly drawn up into the DOSATRON.

- Change the suction tube as soon as it seems damaged by the chemical.

- Relieve the pressure after use (advised).

- Rinsing of the DOSATRON is required :

- when changing chemicals,

- before handling the DOSATRON, to avoid any contact with the chemical. – All assembly should be done without tools, hand tighten only.

WATER WITH HIGH PARTICLE CONTENT

A (ex.: 50 mesh – 300 microns depending on your water quality) water filter must be installed upstream from the DOSATRON (see accessories), if a filter is not installed abrasive substances will cause the DOSATRON to deteriorate prematurely.

WATER-HAMMER / EXCESSIVE FLOW

- For installations subject to water hammer a protection device such as a check valve or union ball check must be fitted (pressure/flow control system).

- For automatic installations, slow-opening and closing solenoid valves are preferable.

- In an installation where a DOSATRON serves several sectors, the closing of one sector and the opening of another sector must be done at the same time (simultaneous operation of the solenoid valves).

INSTALLATION LOCATION

- The location of the DOSATRON and concentrate container should be accessible, but should never present a risk of pollution or contamination.

- It is recommended to label all water lines with a warning about the injected solution i.e.

IMPORTANT! Not For Human Consumption.

MAINTENANCE

- Rinse the injection areas after using the DOSATRON. To do this, insert a suction tube into a container of clean water and inject about 1/4 liter [8 1/2 US Fl.oz].

- Routine maintenance once a year will add to the life of your DOSATRON. Replace the injection seals as well as the suction hose annually to ensure proper injection.

SERVICE

- This DOSATRON was tested prior to packaging.

- Complete maintenance and seal kits are available.

- Call your DOSATRON distributor for service or parts.

ASSEMBLING THE DOSATRON

ASSEMBLY SHOULD BE CARRIED OUT WITHOUT THE USE OF TOOLS

- The DOSATRON is delivered with :

- a mounting bracket,

- a suction tube with a strainer.

- The bracket enables the DOSATRON to be fixed to a wall.

- Snap the DOSATRON into the bracket by fitting the two lugs on one side of the body (Fig. 1-A) into the corresponding holes in the bracket (Fig. 1-B), and springing the bracket arms apart until the other 2 lugs click into place.

- Remove the plastic caps (Fig. 1-C) which block the inlet and outlet of your DOSATRON before connecting to the water supply.

RECOMMENDATIONS

- The DOSATRON can be connected to the water supply by means of Ø3/4” [20 x 27mm] bore flexible hose and hose tail fittings with hose clips. Make certain that the water flows in the direction of the arrows on the motor body.

- The DOSATRON is delivered with a suction tube (cut it to the needed length) enabling its use with a large capacity concentrate container.

- The tube must be fitted with its strainer and weights.

- The instructions for fitting the tube are to be found in the specific chapter.

- NOTE: The maximum suction height is 13 vertical feet (4 meters).

- Fit the tube, equipped with its strainer and its weight, and immerse it in the solution to be injected.

Model D14MZ520

CONNECTING THE EXTERNAL INJECTION (IE)

In order to use corrosive concentrates, the external injection model DOSATRON is also delivered with an external injection hose.

CAUTION screw in the components carefully!

IMPORTANT ! – Do not put the suction tube strainer on the bottom of the stock solution container. The strainer must be suspended at least 4”[10cm] above the bottom of the tank to avoid sucking up the insoluble particles that may damage the injection assembly (Fig.2).

Do not put the strainer on the ground.

Under no circumstance should the solution level be above the water inlet of the DOSATRON (to avoid siphoning situations) (Fig. 3).

INSTALLATION HINTS

- The DOSATRON can be connected to the main water line directly (Fig. 4) ; on a by-pass (Fig. 5), recommended. If your flow rate is above the operating limits of the DOSATRON, see EXCESSIVE FLOW.

- To prolong the working life of the DOSATRON it is advisable to install a filter (ex.: 300 mesh – 60 microns depending on your water quality) upstream.

- This is imperative if the water contains impurities or particles, especially if the water comes from a well.

- A filter is recommended and required for the warranty to be valid.

- Installing the DOSATRON on a bypass enables clean water to be supplied without operating the DOSATRON and the DOSATRON to be easily dismantled.

When connecting an installation to the public water supply, you must respect the rules and regulations in force in the country.

EXCESSIVE FLOW (as an indication)

If your DOSATRON clicks more than 46 times, that is 23 cycles in 15 seconds*, you are close to the superior flow limit. If you need more flow, you must install a DOSATRON with a superior capacity of flow.

D14MZ520 = 30 times, 15 cycles

Putting the DOSATRON into order

USING FOR THE FIRST TIME

- Partially open the water inlet valve.

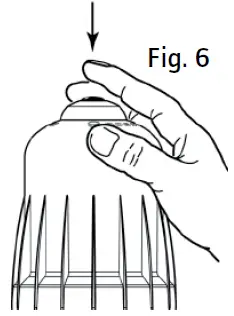

- Press the bleed button on the top of the DOSATRON (Fig. 6).

- When a constant flow of water is seen coming from around the bleed button (no more «spitting» of air), release the button.

- Open the water inlet valve slowly, the DOSATRON is self-priming.

- Operate the DOSATRON until the product to be injected is drawn up into the doser body (the product is visible through the plastic tube).

- The DOSATRON makes a characteristic “click-clack” noise when working.

NOTE: The time required to prime the suction tube depends on the water flow rate, the ratio setting and the length of the suction tube. To bleed the air from the suction tube and accelerate the priming, set the injection rate at maximum.

Once the DOSATRON is primed, adjust to the required inspection rate (see § ADJUSTING THE INJECTION RATE).

The DOSATRON may be fitted in its upper part with the function by-pass (optional equipment) :

- By-pass in ON, the DOSATRON works and the concentrate is drawn up.

- By-pass in OFF, the DOSATRON is stopped and does not draw up the product.

Maintenance

RECOMMENDATIONS

- When using soluble products to be made up into solutions, we recom-mend the periodic dismantling of the entire dosing part (see : § CLEANING AND REFITTING THE SUCTION VALVE, § CHANGING SEALS IN THE INJECTION ASSEMBLY). Thoroughly rinsing all the elements of the dosing part with water and re-assembling them after having previously lubricated the seal (Fig. 7) with a silicone lubricant, in the case of difficulty in re-fitting.

- Before putting the DOSATRON into operation after a non-use period, remove the motor piston and soak it into lukewarm water < 104° F [40° C] overnight. This helps to dissolve any deposits which may have dried onto the piston motor.

HOW TO DRAIN THE DOSATRON (in case of freezing temperature)

- Turn off the water supply and let the pressure drop to zero.

- Remove the injection assembly, see § CHANGING THE MOTOR PISTON.

- Remove the bell and the motor piston.

- Disconnect the water inlet and outlet fittings.

- Remove the lower pump body from the mounting bracket and empty any remaining water.

- The DOSATRON can now be reassembled, having first cleaned the seal.

INTERNATIONAL CONVERSIONS

- Principle: Setting at 1% ⇒ 1/100 = 1 part of concentrate for 100 parts of water.

- Ex. : Setting at 2% ⇒ 2/100 = 2 parts of concentrate for 100 parts of water.

- Ratio ⇒ 1/50.

FITTING THE SUCTION TUBE

If the DOSATRON has already been used, please imperatively refer to § PRECAUTIONS.

- Unscrew the nut (Fig. 11) at the bottom of the injection assembly and put it onto the tube.

- Push the tube onto the barbed fitting as far as it will go and screw up the nut by hand (Fig. 12).

ADJUSTING THE INJECTION RATE (with pressure off)

IMPORTANT! Use no tools.

Adjustments must be made when there is no pressure in the DOSATRON.

- Turn off the water supply and allow the pressure to drop to zero.

- Unscrew the blocking ring (Fig. 13).

- Screw or unscrew the adjusting nut in order to line up the 2 peaks of the eyelet with the desired ratio on the scale (Fig. 14).

- Tighten the blocking ring (Fig. 15).

CHANGING THE MOTOR PISTON (with pressure off)

- Turn off the water supply and allow the pressure to drop to zero.

- Unscrew and remove bell-housing by hand (Fig. 16).

- Remove the motor piston(Fig. 17) by pulling it up.

- The rod and plunger piston are fixed to the motor piston and taken out simultaneously.

- Change and reassemble in the reverse order to the above.

- Refit the bell housing (take care not to damage its seal) and tighten by hand.

CHANGING THE MOTOR PISTON D14MZ520 (with pressure off)

- Shut the water supply and let the pressure drop to zero.

- Unscrew the bell by hand (Fig. 18) and remove it.

- Unscrew the fixing nut of the dosing part (Fig. 19) and remove it.

- Retain the motor piston while turning the plunger piston ¼ turn (Fig. 20).

- Change parts and reassemble in the reverse order to the above.

- Refit the bell taking care not to damage its seal and screw by hand (Fig. 21).

- Refit the dosing part assembly.

CHANGING SEALS IN THE INJECTION ASSEMBLY (with pressure off)

- Frequency: Once per year.

- IMPORTANT! Use no tool or metallic utensils

- ADVICE: Before dismantling any part of the injection assembly it is advisable to operate the DOSATRON, injecting clean water so as to rinse through the injection system. In this way, risks of contact with concentrated solutions in the injection assembly are minimized.

- During any such intervention, wear protective eyewear and gloves !

METHOD OF REMOVING SEAL

- Fig. 22: Between finger and thumb, pinch the component and the seal ; push towards one side to deform the seal.

- Fig. 23: Increase the deformation to grip the part of the seal thus exposed and pull it out of its groove.

- Clean the seal seating without any tools.

- Refitting is done by hand.

- It is very important that the seal is not twisted once in place as this would impair its efficiency.

CHANGING THE DOSING SEALS

Please refer to the drawings of the different models at the end of this manual

- Change the seals once a year.

- Turn off the water supply and allow the pressure to drop to zero.

- Take off the suction tube of product (Fig. 24).

- Unscrew the retaining ring (Fig. 25).

- Pull downwards to remove the injection assembly (Fig. 26).

- Change the seals, the suction valve and the barbed fitting.

- Re-assemble in the reverse order to the above by hand.

CLEANING AND RE-ASSEMBLING THE SUCTION VALVE SEAL

- Turn off the water supply and allow the pressure to drop to zero.

- Unscrew the nut and pull downwards to remove the suction tube (Fig. 27).

- Unscrew and take off the suction valve retaining nut (Fig. 28), pull out the valve assembly, dismantle the valve and thoroughly rinse the separate components in clean water.

- Put the valve components in the order shown in the diagram (Fig. 29).

- Re-assemble the components in the reverse order to the dismantling process.

Reference Designation

Troubleshooting

| SYMPTOM | CAUSE | SOLUTION |

| Motor piston | ||

| DOSATRON does not start or stops | Piston stalled | Reset piston, by hand |

| Air has not been bled from unit | Bleed air from unit, by bleed button | |

| Maximum flow exceeded. | 1. Reduce flow, restart unit

2. Unscrew the bell. Take off the piston and check piston valves seals to ensure correct position |

|

| Motor piston is damaged | Return unit to your service center for repair | |

| Injection | ||

| Water flowing back into concentrate container | Contaminated, worn, or missing check valve parts | Clean or replace it |

| No suction of concentrate | The piston motor has stopped | See Motor piston section |

| Air leak (inlet) in the suction tube | Check the tightness bet- ween nut and suction hose | |

| Blocked suction tube or clogged strainer | Clean or replace it | |

| Missing or worn suction check valve seal | Clean or replace it | |

| Missing or worn plunger seal | Clean or replace it | |

| Worn injection stem | Replace it | |

| SYMPTOM | CAUSE | SOLUTION |

| Injection | ||

| Under injection | Suction of air | 1. Check the tightness of the nuts in the injection area

2. Check suction tube |

| Dirty or worn check valve seal. | Clean or replace it. | |

| Maximum flow exceeded (cavitation) | Reduce flow | |

| Worn plunger seal | Replace it | |

| Worn injection stem | Replace it | |

| Leaks | ||

| Leaks in the vicinity of the fixing ring under the body housing | Injector sleeve seal is damaged or

positioned incorrectly |

Replace it |

| Leaks between the setting sleeve and the blocking ring | Injector stem seal damaged,

positioned incorrectly or missing |

Replace it |

| Leaks between the body and bell | Pump body seal is damaged, positioned incorrectly or missing | Unscrew the bell, clean the seal seating,

replace or change the seal. Position correctly the bell. |

THE MANUFACTURER DECLINES ALL RESPONSIBILITY IF THE DOSATRON IS USED IN CONDITIONS THAT DO NOT CORRESPOND TO THE OPERATING INSTRUCTIONS AS INDICATED IN THIS MANUAL

Limited warranty

- DOSATRON INTERNATIONAL S.A.S. will provide for the replacement of all parts shown to be defective in material or workmanship during a period of twelve months from the date of purchase by the original purchaser. To obtain warranty replacement of a part, the DOSATRON must be returned with original proof of purchase receipt to the manufacturer or authorized distributor and thereafter recognized as defective after examination by the technical services of the manufacturer or distributor. The DOSATRON must be flushed of any chemical and sent to the manufacturer or distributor prepaid, but will be returned free of charge once repairs are made if found to be covered by the warranty.

- Any repairs made under warranty will not extend the initial warranty period. This warranty only covers circumstances where the part has failed due to defects caused by the manufacturing process. This warranty is invalid if the defects are found to be due to the product’s misuse, inappropriate use of tools, lack of maintenance or defective installation or environmental accidents or corrosion by foreign bodies and liquids found within or in proximity to the DOSATRON.

- Before using any aggressive chemicals, please consult your distributor to confirm compatibility with the dosing pump.

- The seals and “o-rings” are not covered under warranty, nor is damage to the DOSATRON caused by water impurities such as sand. A filter (ex.: 300 mesh – 60 microns depending on your water quality) must be used in front of the

- DOSATRON for the warranty to be valid. DOSATRON INTERNATIONAL S.A.S. declines any responsibility if the DOSATRON is not used in compliance with the operating instructions and tolerances as indicated in this owner’s manual.

- This warranty gives you specific legal rights and you may also have other rights which vary from state to state. But any implied warranty or merchantability or fitness for a particular purpose applicable to this product is limited in duration to the time period of this written warranty or any implied warranty.

- There is no warranty express or implied relating in any way to products used in conjunction with DOSATRON INTERNATIONAL S.A.S. products. The manufacturer or authorized distributor shall not be liable for incidental or consequential damage, such as any economic loss, resulting from a breach of this written warranty or any implied warranty.

- There are no warranties, express or implied, which extend beyond those described above.

Curves – Pressure loss

Parts diagram

NOTES

This document does not form a contractual engagement on the part of DOSATRON INTERNATIONAL and is for information only. The company DOSATRON INTERNATIONAL reserves the right to alter product specification or appearance without prior notice.

CE Conformity Statement: Document N° DOCE06050103

This Dosatron is in compliance with the European Directive 98/37/CEE. This declaration is only valid for countries of the European Community (CE).

MANUFACTURED BY DOSATRON INTERNATIONAL S.A.S.

- Rue Pascal – B.P. 6 – 33370 TRESSES (BORDEAUX) – FRANCE

- Tel. 33 (0)5 57 97 11 11

- Fax. 33 (0)5 57 97 11 29 / 33 (0)5 57 97 10 85

- e.mail :

NORTH & CENTRAL AMERICA :

- DOSATRON INTERNATIONAL INC. 2090 SUNNYDALE BLVD. CLEARWATER – FL 33765 – USA

- Tel. 1-727-443-5404 – Fax 1-727-447-0591

- Customer Service:

© DOSATRON INTERNATIONAL S.A.S 2009

FAQ

Q: How do I adjust the sanitizer concentration?

A: Use the concentration adjustment controls on the system to set the desired concentration level between 0.2% and 2%.

Q: Is the system difficult to install?

A: The system is designed to be simple to install with provided instructions. However, professional installation may be recommended for complex setups.

Q: How can I minimize employee exposure and spills?

A: By using this system, employee exposure and spills are minimized due to the controlled blending process and secure connections.

Documents / Resources

|

DOSATRON D14MZ2 Fail Safe Sanitizer System [pdf] Owner's Manual D14MZ2, PS4G137-137-FAILSAFE, D14MZ2 Fail Safe Sanitizer System, D14MZ2, Fail Safe Sanitizer System, Safe Sanitizer System, Sanitizer System |