eyc-tech DPM05 Flow Computer

Specifications

- Product: eyc-tech DPM05 Flow Computer

- Function: Signal/Meter Flow Computer

- Features: Automatic calculation and cumulation of mass flow, standard volumetric flow, display of instantaneous flow and cumulative flow.

- Display: Digital display window with 5 digits

- Inputs: Flow, pressure compensation, temperature

- compensation

Function

The eyc-tech DPM05 Flow Computer is designed for automatic calculation and cumulation of mass flow and standard volumetric flow. It can simultaneously display measured values of instantaneous flow and cumulative flow. The unit of cumulative flow can be set without limitation. Users can switch between various display parameters such as instantaneous flow, time, current cumulative flow, total cumulative flow, input values for flow, pressure compensation, and temperature compensation.

Display Panel and Function Keys

The device features a digital display window with 5 digits forPV display. Function keys include OK key for confirmation, Page Down key for parameter settings, Setting exit key for return ng to the measurement screen, and keys for adjusting decimal point position.

Power-on Setting

Upon powering on, the flow computer enters self-test status andtransitions to working status upon completion. Users can navigate through various menus and settings using specific key combinat ions mentioned in the manual.

Parameters Setting

In the working status, users can access Level 1 parameters setting by following the instructions provided in the manual.

FAQs

Q: How do I reset the device to factory default settings?

A: If Loc = 577, in the Loc menu, press specific keys simultaneously to restore all parameters to factory default settings.

Q: How can I return to real-time measurement status fromparameter setting?

A: You can either manually press specific keys or wait for the device to automatically return to real-time measurement status after a certain period.

Flow computer

Flow computer Operation Instruction

I. Function Automatic calculation and cumulation of mass flow; Automatic calculation and cumulation of standard volumetric flow; Simultaneous display of measured values of instantaneous flow and cumulative flow (unit of

cumulative flow may be set without limitation); Switch between display of measured value of instantaneous flow, time, current cumulative flow,

total cumulative flow of 11-digit, flow (differential pressure, frequency) input, pressure compensation input value, temperature compensation input value;

Small signals cut-off function (display “0” when instantaneous flow is less than set value) available; Quantitative control of flow available; Automatic temperature and pressure compensation available; The following sensors may be chosen through programming: 1. P: differential pressure type flow sensor input; 2. P, T: differential pressure type flow sensor and temperature sensor input; 3. P, P, T: differential pressure type flow sensor, pressure sensor and temperature sensor input; 4. f: frequency type flow sensor input; 5. f, T: frequency type flow sensor and temperature sensor input; 6. f, P: frequency type flow sensor and temperature sensor input; 7. f, P, T: frequency type flow sensor, pressure sensor and temperature sensor input; 8. G: flow sensor (linear flow signals) input; 9. G, T: flow sensor and temperature sensor input; 10. G, P: flow sensor and pressure sensor input; 11. G, T, P: flow sensor, temperature sensor and pressure sensor input

Three kinds of compensation are available: Automatic temperature compensation; Automatic pressure compensation; Automatic temperature and pressure compensation Display function: Display of measured value of instantaneous flow, current cumulative flow, measured value of differential pressure, measured value of pressure compensation, measured value of temperature compensation and frequency etc of each channel; PV + SV display of cumulative flow: 11 digits (0 ~ 99999999.999) Display of current date and time Storage of total cumulative flow under power failure; automatic clear of total cumulative flow when it reaches full range (99999999.999); current cumulative flow will not be stored under power failure.

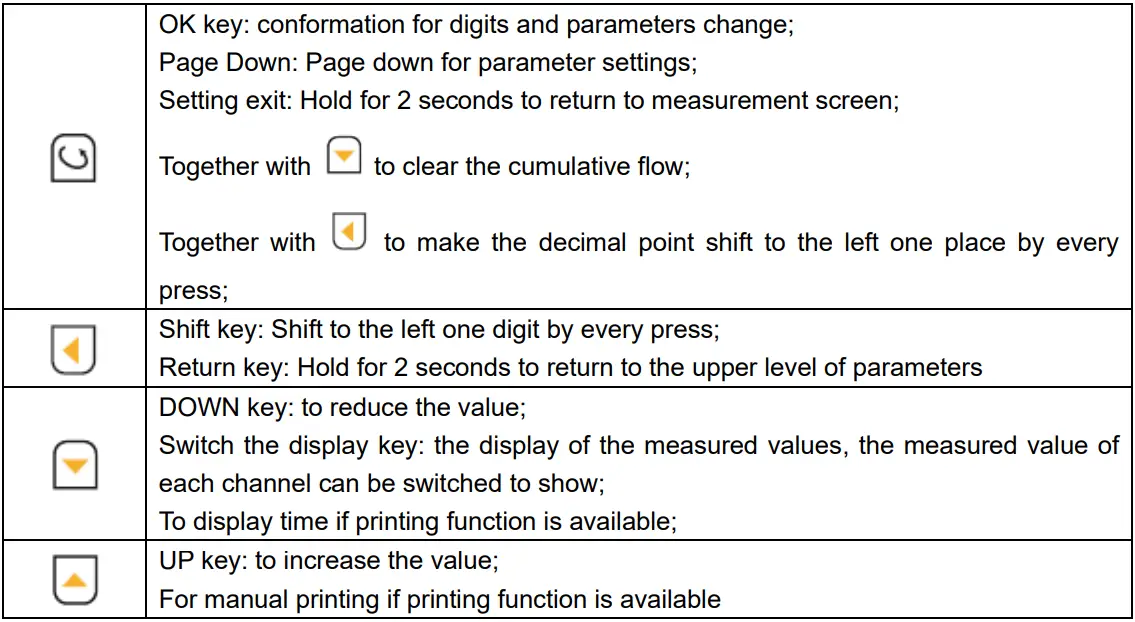

II. Display Panel and Function Keys

1

Signal / Meter

Flow computer

1) Digital display window: PV display window (5 digits): Display of instantaneous flow; in the parameters setting status, display of parameter symbols;

input of flow compensation, pressure compensation, and temperature compensation may also be displayed through proper setting;

SV display window (8 digits): Display of cumulative flow; in the parameters setting status, display of set value; PV + SV display window (totally 11 digits): internal parameters may be set to display total cumulative value of 11 digits (millions digit is the third digit on the right of number displayed on PV window). 2) Panel indicators AL1: Alarm 1 indicator AL2: Alarm 2 indicator t—-Time: Current time indicator q—-flow-rate: instantaneous flow indicator T—-Temperature: temperature compensation indicator P—-Pressure : pressure compensation indicator F—-Flow: differential pressure and flow indicator Sum: current cumulative value indicator 3) Operation button

OK key: conformation for digits and parameters change; Page Down: Page down for parameter settings; Setting exit: Hold for 2 seconds to return to measurement screen;

Together with to clear the cumulative flow;

Together with

to make the decimal point shift to the left one place by every

press; Shift key: Shift to the left one digit by every press; Return key: Hold for 2 seconds to return to the upper level of parameters DOWN key: to reduce the value; Switch the display key: the display of the measured values, the measured value of each channel can be switched to show; To display time if printing function is available; UP key: to increase the value; For manual printing if printing function is available 4) Instrument wiring Attention shall be paid to the following items during wiring: PV input (process input) 1. To reduce electrical interference, the low-voltage DC signal and sensor input wire should stay away from heavy-current electrical wire. Otherwise, shielded wire shall be used and grounding shall be made at the same point. 2. Any device between the sensor and terminal may affect the measurement accuracy due to resistance or leakage current. Thermocouple or pyrometer input Compensation wires corresponding to the thermocouple shall be used as extension wire, which

2

Signal / Meter

Flow computer

shall be shielded as far as possible. RTD (platinum resistance) input The resistance for 3 wires must be the same, which shall not exceed 15.

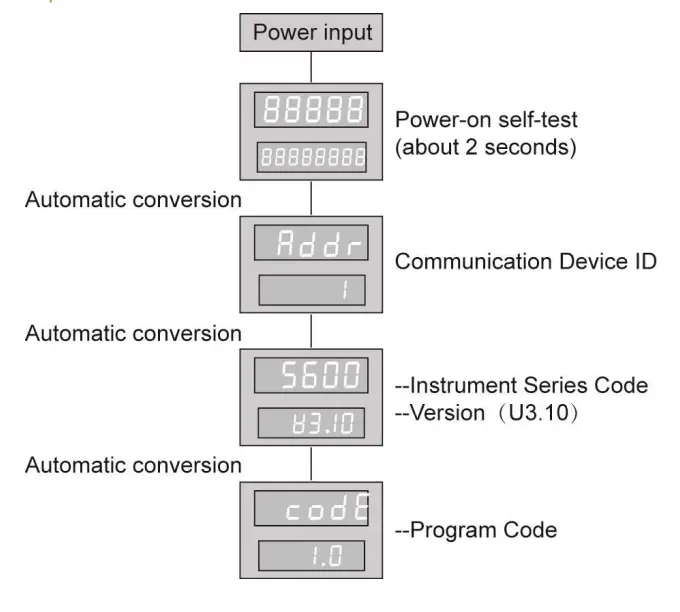

III. Power-on Setting As soon as the instrument is powered on, it enters into the self-test status (see figure in the right),

and when self-test is completed, it automatically enters into the working status. In the working status,

press

and it displays LOC. LOC parameters could be set as follows:

1.1) You can enter into Level 1 menu whatever the Loc is (no locking if LOC=00, 132);

2) When Loc = 132, press

for 4 seconds to enter into Level 2 menu;

3) When Loc = 128, press calculation of flow coefficient;

for 4 seconds to enter into Level 3 menu for automatic

4) When Loc = 130, press

for 4 seconds to enter into the time setting menu;

5) When Loc = 111, While pressing the key value manually cleared

and the key

to allow this accumulated flow

6) When Loc = 112, While pressing the key

and the key

the total accumulated flow values manually cleared;

to allow this accumulation and

7) When Loc = other values, pressure

for 4 seconds to return to the measuring screen.

2. If Loc = 577, in the Loc menu, press the parameters to factory default settings.

and for 4 seconds simultaneously to restore all

3. In any other menu, pressure Back to working status

for 4 seconds to return to the measuring screen.

1. Manual: In the status of parameters setting, press

for 4 seconds, the instrument will

automatically return to real-time measurement status. 2. Auto: In the status of parameters setting, do not press any key. After 30 seconds the instrument

will automatically return to real-time measurement status.

3

Signal / Meter Flow computer

4

IV. Parameters Setting 4.1 Level 1 parameters setting

In the working status, press

Signal / Meter Flow computer

and PV will display LOC and SV display the parameter values:

press or to set parameters. Press

for 2 seconds to return to upper level of parameters.

You can enter into Level 1 parameter setting by pressing

when Loc = any value.

Default setting

Parameters

Parameters locking

Alarm 1 set value Alarm 2 set value

Setting Range

0 ~ 999

-199999 ~ 999999

-199999 ~ 999999

Description LOC=00: No locking (Level 1 parameters can be modified) LOC00, 132: Locking (Level 1 parameters can not be modified) LOC=132: No locking (Level 1 and Level 2 parameters can be modified)

Set value of Alarm 1

Set value of Alarm 2

Alarm 1 return difference

0 ~ 999999 Return difference value of Alarm 1

Alarm 2 return difference

Flow coefficient 1 Flow coefficient 2 Flow coefficient 3 Flow coefficient 4

0 ~ 999999 Return difference value of Alarm 2

0 ~ 999999 0 ~ 999999 0 ~ 999999 0 ~ 999999

Display flow coefficient of differential pressure type flow sensor, frequency type flow sensor, and pressure sensor input See the figure of flow compensation coefficient Kx. Display flow coefficient of differential pressure type flow sensor, frequency type flow sensor, and pressure sensor input See the diagram of flow compensation coefficient Kx. Display flow coefficient of differential pressure type flow sensor, frequency type flow sensor, and pressure sensor input See the diagram of flow compensation coefficient Kx. Display flow coefficient of differential pressure type flow sensor, frequency type flow sensor, and pressure sensor input See the diagram of flow compensation coefficient Kx.

Density compensation

constant

0 ~ 999999

Display the density compensation constant of measured medium

Density compensation

coefficient

0 ~ 999999

Display the density compensation coefficient of measured medium

Density in operating condition

0 ~ 999999

Display the density of measured medium in operating condition (unit: Kg/m3)

Density in standard condition

0 ~ 999999

Display the density of measured medium in standard condition (1 bar, 20 ) ( unit: Kg/m3)

5

Signal / Meter Flow computer

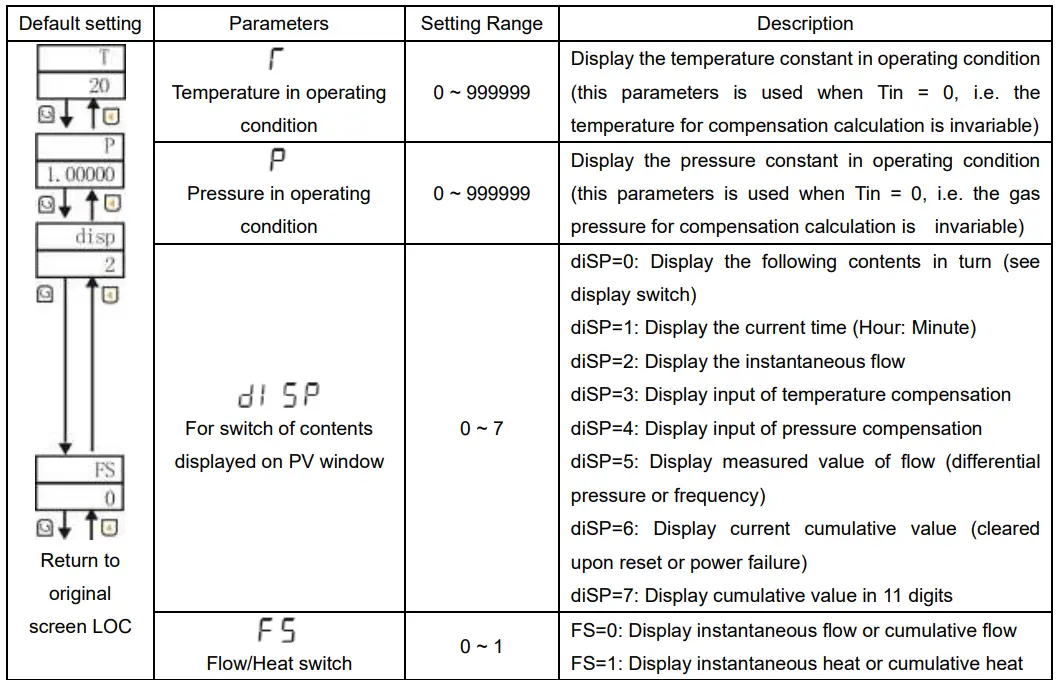

Default setting

Parameters

Setting Range

Description

Display the temperature constant in operating condition

Temperature in operating 0 ~ 999999 (this parameters is used when Tin = 0, i.e. the

condition

temperature for compensation calculation is invariable)

Display the pressure constant in operating condition

Pressure in operating

0 ~ 999999 (this parameters is used when Tin = 0, i.e. the gas

condition

pressure for compensation calculation is invariable)

diSP=0: Display the following contents in turn (see

display switch)

diSP=1: Display the current time (Hour: Minute)

diSP=2: Display the instantaneous flow

diSP=3: Display input of temperature compensation

For switch of contents

0 ~ 7

diSP=4: Display input of pressure compensation

displayed on PV window

diSP=5: Display measured value of flow (differential

pressure or frequency)

diSP=6: Display current cumulative value (cleared

Return to

upon reset or power failure)

original

diSP=7: Display cumulative value in 11 digits

screen LOC

Flow/Heat switch

0 ~ 1

FS=0: Display instantaneous flow or cumulative flow FS=1: Display instantaneous heat or cumulative heat

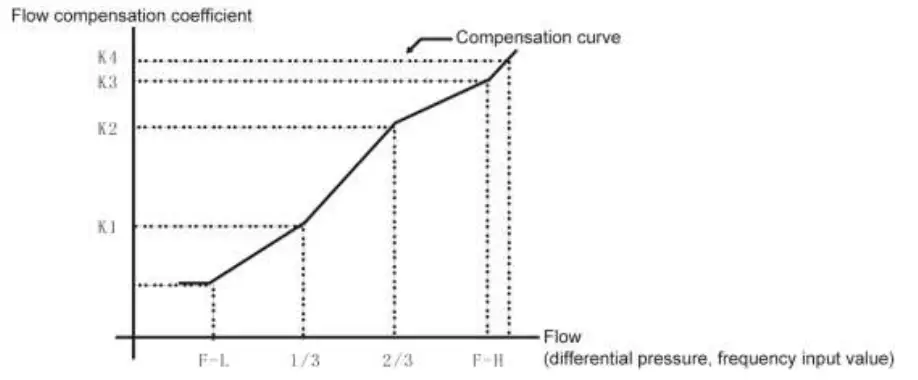

Notes on flow compensation coefficient Kx:

When Level 2 parameter KE = 1, nonlinear compensation of flow input can be achieved through

Level 1 parameter Kx. The figure of compensation coefficient K is as follows:

Nonlinear input signal of flow can be compensated through setting coefficient Kx; This function can be also used for small signal cut-off of frequency input; Flow rate (linear, differential or frequency) of the input value is less than 1/3, the coefficient K1 for compensation; flow rate (linear, differential or frequency) of the input value is greater than the FH by K4 as coefficient compensation. For linear compensation, Level 2 parameter KE will be generally set to be 0, so only parameter K1 will be served as compensation coefficient in Level 1 parameter setting, and K2, K3, K4 will not be displayed. Note: this function is invalid in the case of frequency input, in which case error will occur to the program if this parameter has been set. Control output type (AL1, AL2, AH1, AH2)

6

Signal / Meter

Flow computer

Control output type can be set by Level 2 parameter “ALM”; see details below.

Symbol Name Setting Range Function description

Output type

– No alarm;

– Upper limit alarm of instantaneous flow;

– Lower limit alarm of instantaneous flow;

ALM1 Alarm 1

Full range

– Quantitative process output of flow: auto start, output “1”,

– Quantitative result output of flow: auto start, output “0”,

– Quantitative result output of flow: auto start, auto clear, impulse See details

width output

below

– No alarm;

– Upper limit alarm of instantaneous flow;

ALM2 Alarm 2 Full range – Lower limit alarm of instantaneous flow;

– Quantitative process output of flow: auto start, output “1”;

– Quantitative result output of flow: auto start, output “0” ;

(1) This instrument will have a return difference for alarm/control output to prevent frequent action

during fluctuation of output relay at output critical point; it works as followed:

The measured value increases from a low value:

The measured value decreases from a high value: Upper limit alarm output: Lower limit alarm output:

7

Signal / Meter Flow computer (2) Quantitative control output of flow 1.Sequence diagram of AL1 quantitative control output: AL1 quantitative process control output: (auto start, output “1”)

AL1 quantitative result control output: (auto start, output “0”)

AL1 quantitative result control output: (auto clear, impulse width output)

2. AL2 quantitative control output timing diagram AL2 quantitative process control output: (manual start, and outputs “1”)

AL2 quantitative control output: (manually start the output of “0”)

AH2 means control output lead value. Upon control output of the instrument, if there’s still instantaneous flow input, it will continue to be accumulated. Upon the control output, current control is completed. Manual start is required for next control upon which control output will continue. Method of starting quantitative control of flow in AL2 (AL2: manual start of quantitative control) 1. Press the external switch of “Start”, and it starts quantitative control of flow; 2. Set Level 1 parameter LOC as 111, and in the status where PV window displays measured value,

8

Signal / Meter Flow computer

press

to start quantitative control of flow.

Method of stopping quantitative control of flow in AL2 (AL2: manual start of quantitative control): 1. Press the external switch of “Stop”, and it stops quantitative control output of flow; 2. Set Level 1 parameter LOC as 111, and in the status where PV window displays measured value,

press

and simultaneously to stop quantitative control output of flow.

When key “Stop” is pressed, control output will be stopped no matter whether there’s quantitative control output; if there’s still instantaneous flow input at this time, it will be accumulated. In order to initiate quantitative control output of cumulative flow, quantitative control output of flow must be “started” again.

Current cumulative value will be cleared in case of power failure or reset. Press

and

simultaneously for manual clear of value. In case of quantitative control with external switch, press external switch “Clear” for manual clear of value.

The total cumulative value will be cleared when it reaches full 11 digits. In case of need for clear before it reaches full 11 digits, set Level 1 parameter LOC as 111, and in the status where PV window

displays measured value, press

and

simultaneously for manual clear. In case of quantitative

control with external switch, press external switch “Clear” for manual clear of value. The maximum cumulative flow of the instrument is 99999999999, and Level 2 parameters can

be set to change display form within the range of 99999999.999 to 999999999.99. 4.2 Level 2 parameters setting

In the working status, press

and PV will display LOC and SV display parameter values; press

or

for setting. Press and hold the key

for 2 seconds to return back to the upper level

parameters; when Loc = 132, press

for 4 seconds to enter into Level 2 parameters setting.

9

Signal / Meter Flow computer

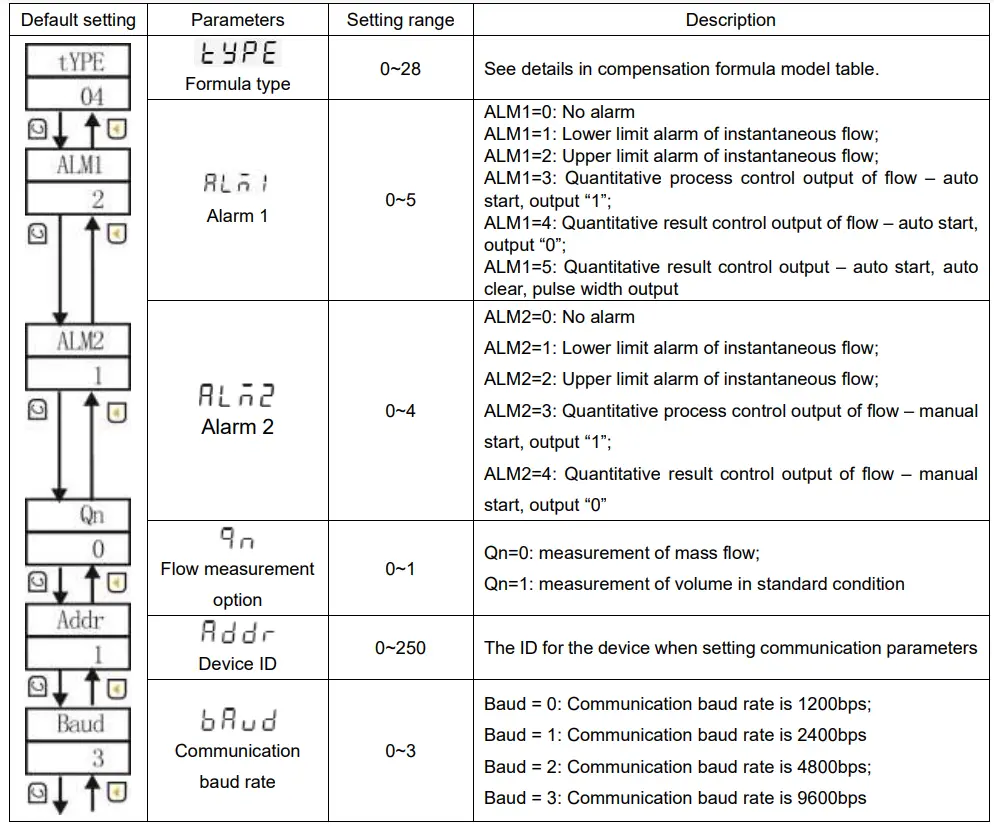

Default setting

Parameters

Setting range

Description

Formula type Alarm 1

Alarm 2

0~28 0~5

0~4

See details in compensation formula model table.

ALM1=0: No alarm ALM1=1: Lower limit alarm of instantaneous flow; ALM1=2: Upper limit alarm of instantaneous flow; ALM1=3: Quantitative process control output of flow auto start, output “1”; ALM1=4: Quantitative result control output of flow auto start, output “0”; ALM1=5: Quantitative result control output auto start, auto clear, pulse width output ALM2=0: No alarm

ALM2=1: Lower limit alarm of instantaneous flow;

ALM2=2: Upper limit alarm of instantaneous flow;

ALM2=3: Quantitative process control output of flow manual

start, output “1”;

ALM2=4: Quantitative result control output of flow manual

start, output “0”

Qn=0: measurement of mass flow;

Flow measurement

0~1

Qn=1: measurement of volume in standard condition

option

Device ID

Communication baud rate

0~250 0~3

The ID for the device when setting communication parameters

Baud = 0: Communication baud rate is 1200bps; Baud = 1: Communication baud rate is 2400bps Baud = 2: Communication baud rate is 4800bps; Baud = 3: Communication baud rate is 9600bps

10

Signal / Meter Flow computer

Default setting

Parameters

Setting range

Description

Time unit of instantaneous flow

display

Precision of cumulative flow

display

Decimal point of instantaneous flow

display

Time unit of instantaneous heat

display

Precision of cumulative heat

display

Decimal point of instantaneous heat

display

Q-Tn=0: second ;

Q-Tn=1: minute;

0~5

Q-Tn=2: hour;

Q-Tn=3: 1/10 hour;

Q-Tn=4: 1/100 hour;

Q-Tn=5: 1/1000 hour

M-dP=0: 1 (displayed as XXXXXX); M-dP=1: 0.1 (displayed as XXXXX.X); 0~3 M-dP=2: 0.01 (displayed as XXXX.XX); M-dP=3: 0.001 (displayed as XXX.XXX) Q-dP =0: no decimal point (displayed as XXXX); Q-dP =1: Ten decimal places (displayed as XXX.X) 0~3 Q-dP=2: One hundred decimal places (displayed as XX.XX) Q-dP=3: One thousand decimal places (displayed as X.XXX) H-Tn=0: second ; H-Tn=1: minute; H-Tn=2: hour; 0~5 H-Tn=3: 1/10 hour; H-Tn=4: 1/100 hour; H-Tn=5: 1/1 000 hour N-dP=0: 1 (displayed as XXXXXX); N-dP=1: 0.1 (displayed as XXXXX.X); 0~3 N-dP=2: 0.01 (displayed as XXXX.XX); N-dP=3: 0.001 (displayed as XXX.XXX) H-dP=0: no decimal point (displayed as XXXX); H-dP =1: Ten decimal places (displayed as XXX.X) 0~3 H-dP=2: One hundred decimal places (displayed as XX.XX) H-dP=3: One thousand decimal places (displayed as X.XXX)

Decimal point of temperature compensation display

T-dP=0: no decimal point (displayed as XXXX); T-dP =1: Ten decimal places (displayed as XXX.X) 0~3 T-dP =2: One hundred decimal places (displayed as XX.XX) T-dP=3: One thousand decimal places (displayed as X.XXX)

Decimal point of pressure

compensation display

P-dP=0: no decimal point (displayed as XXXX); P-dP =1: Ten decimal places (displayed as XXX.X) 0~3 P-dP=2: One hundred decimal places (displayed as XX.XX) P-dP=3: One thousand decimal places (displayed as X.XXX)

Decimal point of flow (linear differential

pressure) display

F-dP=0: no decimal point (displayed as XXXX); F-dP =1: Ten decimal places (displayed as XXX.X) 0~3 F-dP=2: One hundred decimal places (displayed as XX.XX) F-dP=3: One thousand decimal places (displayed as X.XXX)

Filter coefficient of instantaneous flow

0~19

Filter coefficient of instantaneous flow 11

Signal / Meter Flow computer

Default setting

Parameters

Setting range

Description

Type of temperature compensation input

0~35

See Graduation Table in Model Selection section.

Type of pressure compensation input

25~35

See Graduation Table in Model Selection section.

Type of flow input (linear, differential pressure type)

Zero shift of temperature compensation

25~36

See Graduation Table in Model Selection section.

Full range

Set the zero shift for display of measured value of temperature compensation (see Note 1)

Amplification scale of measuring range of temperature compensation

Zero shift of pressure compensation

0~1.999

Set the amplification scale of measuring range for display of temperature compensation (see Note 1)

Full range

Set the zero shift for display of measured value of pressure compensation (see Note 1)

Amplification scale of measuring range of pressure

compensation

Zero shift of flow input

0~1.999 Full range

Set the amplification scale of measuring range for display of pressure compensation (see Note 1)

Set the zero shift for display of measured value of flow input (see Note 1)

Amplification scale of measuring range of flow

input

Zero shift of transmission output 1

Amplification scale of transmission output 1

Zero shift of transmission output 2

Amplification scale of transmission output 2

Lower limit of measuring range of transmission output

0~1.999 0~1.200 0~1.900 0~1.200 0~1.900 0~999999

12

Set the amplification scale of measuring range for display of flow input (see Note 1)

Set the zero shift for display of transmission output 1 (see Note 2)

Set the amplification scale for display of transmission output 1 (see Note 2)

Set the zero shift for display of transmission output 2 (see Note 2)

Set the amplification scale for display of transmission output 2 (see Note 2) Set the lower limit of measuring range of transmission output, which shall be subject to the instantaneous flow.

Signal / Meter Flow computer

Default setting

Parameters

Upper limit of measuring range of transmission output

Atmospheric pressure in operating condition

Lower limit of measuring range of temperature compensation

Upper limit of measuring range of temperature compensation

Lower limit of measuring range of pressure compensation

Upper limit of measuring range of pressure compensation

Lower limit of measuring range of flow input

Upper limit of measuring range of flow input

Setting range 0~999999 Full range Full range Full range Full range

Full range Full range Full range

Description Set the lower limit of measuring range of transmission output, which shall be subject to the instantaneous flow. Set the atmospheric pressure at the site where the instrument operates. Unit: depending on set value of P-u; common units: MPa, KPa, Kgf/cm2, bar and etc. Standard unit: MPa Set the lower limit of measuring range of temperature compensation Unit: Set the upper limit of measuring range of temperature compensation Unit: Set the lower limit of measuring range of pressure compensation Unit: depending on set value of P-u; common units: MPa, KPa, Kgf/cm2, bar and etc. Standard unit: MPa Set the upper limit of measuring range of pressure compensation Unit: depending on set value of P-u; common units: MPa, KPa, Kgf/cm2, bar and etc. Standard unit: MPa Set the lower limit of measuring range of flow input Unit: same as output signal of flow meter; MPa in the case of differential pressure input Set the upper limit of measuring range of flow input Unit: same as output signal of flow meter; MPa in the case of differential pressure input

Small signal cutoff of flow input

Full range

Set small signal cutoff of flow input

Unit of temperature compensation

Unit of pressure compensation Unit of flow input

Unit of instantaneous flow Unit of instantaneous heat

0 ~ 45

0 ~ 45 0 ~ 45 0 ~ 45 0 ~ 45

13

See Unit Code Table See Unit Code Table See Unit Code Table See Unit Code Table See Unit Code Table

Signal / Meter Flow computer

Default setting

Return to original screen tyPE

Parameters Alarm printing Interval of printing

Mode of flow coefficient compensation

Temperature input Pressure input

Setting range 0 ~ 1

Description Pr-A = 0: no alarm printing function Pr-A = 1: alarm printing function available

1 ~ 2400 minutes Set the interval of timed printing

0 ~ 1

0 ~ 1 0 ~ 1

KE=0: flow coefficient K linear compensation (only Level 1 parameter K1 used for compensation ) KE=1: flow coefficient K nonlinear compensation (Level 1 parameters K1, K2, K3, K4 used for compensation) Tin=0: Temperature as a constant Tin=1: Temperature input from external sensor Tin=0: Pressure as a constant Tin=1: Pressure input from external sensor

Compensation formula model table:

Code

Compensation type

0

Internal reserved parameter

1

Superheated steam (temperature / pressure compensation)

2

Saturated steam (temperature compensation)

3

Saturated steam (pressure compensation)

4

General medium (temperature / pressure compensation)

5

General medium (temperature compensation)

6

General medium (pressure compensation)

7

General medium (no compensation)

8

Superheated steam (temperature / pressure compensation)

9

Saturated steam (temperature compensation)

10 Saturated steam (pressure compensation)

11 General medium (temperature / pressure compensation)

12 General medium (temperature compensation)

13 General medium (pressure compensation)

14 General medium (no compensation)

15 Superheated steam (temperature / pressure compensation)

16 Saturated steam (temperature compensation)

17 Saturated steam (pressure compensation)

18 General medium (temperature / pressure compensation)

19 General medium (temperature compensation)

20 General medium (pressure compensation)

21 General medium (no compensation)

22 Superheated steam (temperature / pressure compensation)

23 Saturated steam (temperature compensation)

14

Note Reserved parameter

Linear input Linear input Linear input Linear input Linear input Linear input Linear input Non-extracted signal Non-extracted signal Non-extracted signal Non-extracted signal Non-extracted signal Non-extracted signal Non-extracted signal Extracted signal Extracted signal Extracted signal Extracted signal Extracted signal Extracted signal Extracted signal Frequency input Frequency input

Signal / Meter

Flow computer

24 Saturated steam (pressure compensation)

Frequency input

25 General medium (temperature / pressure compensation)

Frequency input

26 General medium (temperature compensation)

Frequency input

27 General medium (pressure compensation)

Frequency input

28 General medium (no compensation)

Input signal types table:

Frequency input

Degree no .Pn

Signal types

measuring range Degree no Pn

Signal types

measuring range

0

Thermocouple B

4001800

18

Remote Resistance -19999999

0350

1

Thermocouple S

01600

2

Thermocouple K

01300

19

Remote Resistance -19999999

3 0350

20

020mV

-19999999

3

Thermocouple E

01000

21

040mV

-19999999

4

Thermocouple T

-200.0400.0

22

0100mV

-19999999

5

Thermocouple J

01200

23

-2020mV

-19999999

6

Thermocouple R

01600

24

-100100mV -19999999

7

Thermocouple N

01300

25

020mA

-19999999

8

F2

7002000

26

010mA

-19999999

9

Thermocouple Wre3-25

02300

27

420mA

-19999999

10

Thermocouple Wre5-26

02300

28

05V

-19999999

11

RTD Cu50

-50.0150.0

29

15V

-19999999

12

RTD Cu53

-50.0150.0

30

-55V

-19999999

13

RTD Cu100

-50.0150.0

31

010V

-19999999

14

RTD Pt100

-200.0650.0

32

010mA square -19999999

15

RTD BA1

-200.0600.0

33

420mA square -19999999

16

RTD BA2

-200.0600.0

34

05V square

-19999999

17

Linear resistance 0

-19999999

400

35

-19999999

15V square

Unit code table:

Code

0

Unit

kgf

1

2

3

4

5

6

Pa KPa MPa mmHg mmH2O

bar

7

8

9

10 11

%

Hz

m

t

Code

12

13

14

15

16

17

18

19

20

21

22

23

Unit

l

m3

kg

J

MJ

GJ

Nm3

m/h

t/h

l/h m3/h Kg/h

Code

24

25

26

27

28

29

30

31

32

33

34

35

Unit

J/h MJ/h GJ/h Nm3/h m/m

t/m

l/m

m3/m Kg/m J/m MJ/M GJ/m

Code

36

37

38

39

40

41

42

43

44

45

Unit Nm3/m m/s

t/s

l/s

m3/s

Kg/s

J/s

MJ/s GJ/s Nm3/s

Note1: T-b, T-k, P-b, P-k, F-b, F-k calculation formula:

X-k = set full range ÷ (original full range × original X-k)

X-b = lower limit of set measuring range {lower limit of original measuring range × (X-k) + original (X-b) }

Take one instrument with pressure compensation of 4~20mA and measuring range of 0~2MPa for

example. At the time of calibration, it’s found that in case of 4mA input, it will display -0.03 and in case of 20mA input, it will display 2.08. (Original P-k=1.000, original P-b=0)

15

Signal / Meter Flow computer Based on the formula: P-k = set full range ÷ (original full range × original P-k) = (2-0) ÷ (2.08 – (-0.03)) = 2 ÷ 2.11× 1.000 0.94787 P-b = lower limit of set measuring range (lower limit of original measuring range × P-k + original P-b} = 0 – (-0.03×0.94787) + 0 0.02836 So now It’s set that P-b = 0.02836, P-k = 0.94787 Note 2: the setting of output shift of O1-b, O1-K, O2-b, O2-K is as follows: Instrument transmission output will be collated at 0-20mA or 0-5V; change of output range or output error correction may be realized by the following formulas:

Where in case of current signal output, full range = 20; in case of voltage signal output, full range = 5. Example 1: transmission current output 0-20mA is now desired to be changed to 4-20mA output. In

case of zero input, the output is 0mA; in case of full range of input, the output is 20mA; current Oub=0, current OuK=1.

Therefore, if Oub is set to be 0.2 without change of OuK, the 0-20mA output will be changed to 4-20mA.

Small signal cutoff: when measured value of instantaneous flow is less than CAA, instantaneous flow will be displayed as zero, and the flow will not be accumulated.

In parameters setting, if required parameters are not available currently, the following parameters may be set first. After one cycle of setting, the require parameters may appear as they may be closed by the following parameters.

The unit in parameters setting must be the same as that for actual measurement. In the case of saturated steam measurement, either temperature compensation or pressure compensation may be selected. Print interval: Pr-T = 0 is not printed, the print format right:

4.3 Level 3 parameters setting (automatic calculation of flow coefficient K) In the working status, press and PV will display LOC and SV display parameter values; press

16

Signal / Meter

Flow computer or for setting. Press and hold the key for 2 seconds to return back to the upper level parameters; when Loc = 128, press for 4 seconds to enter into Level 3 parameters setting.

Default setting

Parameters Instantaneous flow

Operating flow Operating temperature

Operating pressure

Setting range 0~999999

Description Maximum Instantaneous flow value in the working status

0~999999 Maximum flow signal input in the working status

0~999999 0~999999

Temperature compensation input value in the working status

Pressure compensation input value in the working status

Return to original

Flow coefficient

0~999999

Display the calculation result and change Level 1 parameter K1

screen A-Q

Level 3 parameters are used for automatic calculation of flow coefficient K. It gives user great

convenience to set parameters and improve the instrument’s user-friendliness. Before setting of Level

3 parameters, Level 2 parameters setting shall be completed to determine instrument type, display

precision, input type, compensation range, measuring range and unit. And then we can enter into Level

3 parameters setting to set maximum instantaneous flow A-Q, operating flow A-F, operating

temperature A-T, and operating pressure A-P. The instrument will automatically calculate the flow

coefficient A-K based on Level 2 parameters and upper limit of measuring range (differential pressure)

and change the Level 1 parameter K1.

Note: in the case of flow input of pulse signal, the automatic calculation function is invalid.

4.4 Time setting

In the working status, press and PV will display LOC and SV display parameter values; press

or for setting. When Loc = 130, press for 4 seconds to enter into time setting.

Symbol Name Setting Range

Description

Default setting

dATE Date

Set the date format: for example, 080210 means 2008-02-10

TIME Time

Set the time format: for example, 150935 means 15:09:35

4.5 Voltage Range Regulation in Frequency Input

1): With open collector, the input end has a voltage of 10V; with open emitter, there’s no voltage;

Frequency input: OC

Frequency input: OE

JP2 status

Frequency voltage range can be regulated as follows: Voltage regulation: 1. Regulate upper limit of input voltage: regulate potentiometer W1 (clockwise rotation for decrease and counterclockwise rotation for increase) so that voltage at negative end of frequency input of pin pair 7 of LM339 is not more than upper limit of input voltage.

17

Signal / Meter

Flow computer

2. Regulate lower limit of input voltage: regulate potentiometer W2 (clockwise rotation for decrease and counterclockwise rotation for increase) so that voltage at negative end of frequency input of pin pair 8 of LM339 is not less than lower limit of input voltage.

Regulate W1 and W2 to keep the amplitude of upper limit / lower limit of voltage is within the range of wave shape. The voltage is preset as about 2.5V and 4.5V for lower limit and upper limit amplitude.

2) Switch between voltage and current pulse input:

Current pulse input

Voltage pulse input

JP1 status

Remarks: the internal shunt resistor 1K resistor, if the amplitude of the signal is high JP1 inserted in the position of the input of the voltage pulse, and to achieve the signal input through the external resistor, which prevents the amplitude is too high damage to the internal device. V. Mathematical Models (1) Mass flow (M) calculation formula:

1. Input signal of differential pressure (P, non-extracted) Level 2 parameters setting: tYPE=14, Qn=0, F-n=27 Level 1 parameters setting: K,

2. Input signal of differential pressure (P, non-extracted), temperature compensation (T) Level 2 parameters setting: tYPE=12, Qn=0, T-n=14, F-n=27 Level 1 parameters setting: K, A1, A2

3. Input signal of differential pressure (P, non-extracted), pressure compensation (P) Level 2 parameters setting: tYPE=13, Qn=0, P-n=27, F-n=27 Level 1 parameters setting: K, A1, A2

4. Input signal of differential pressure (P, non-extracted), pressure compensation (P), temperature compensation (T)

Level 2 parameters setting: tYPE=11, Qn=0, T-n=14, P-n=27, F-n=27 Level 1 parameters setting: K, 20

5. Input signal of differential pressure (P, extracted) Level 2 parameters setting: tYPE=21, Qn=0, F-n=27 Level 1 parameters setting: K,

18

Signal / Meter Flow computer

6. Input signal of differential pressure (P, extracted), temperature compensation (T) Level 2 parameters setting: tYPE=19, Qn=0, T-n=14, F-n=27 Level 1 parameters setting: K, A1, A2

7. Input signal of differential pressure (P, extracted), pressure compensation (P) Level 2 parameters setting: tYPE=20, Qn=0, P-n=27, F-n=27 Level 1 parameters setting: K, A1, A2

8. Input signal of differential pressure (P, extracted), pressure compensation (P), temperature compensation (T)

Level 2 parameters setting: tYPE=18, Qn=0, T-n=14, P-n=27, F-n=27 Level 1 parameters setting: K, 20

9. Input signal of flow (G) Level 2 parameters setting: tYPE=7, Qn=0, F-n=27 Level 1 parameters setting: K,

10. Input signal of flow (G), temperature compensation (T) Level 2 parameters setting: tYPE=5, Qn=0, T-n=14, F-n=27 Level 1 parameters setting: K, A1, A2

11. Input signal of flow (G), pressure compensation (P) Level 2 parameters setting: tYPE=6, Qn=0, P-n=27, F-n=27 Level 1 parameters setting: K, A1, A2

12. Input signal of flow (G), pressure compensation (P), temperature compensation (T) Level 2 parameters setting: tYPE=4, Qn=0, T-n=14, P-n=27, F-n=27 Level 1 parameters setting: K, 20

13. Input signal of frequency (f) Level 2 parameters setting: tYPE=28, Qn=0, F-n=36 Level 1 parameters setting: K,

19

14. Input signal of frequency (f), temperature compensation (T) Level 2 parameters setting: tYPE=26, Qn=0, T-n=14, F-n=36 Level 1 parameters setting: K, A1, A2

Signal / Meter Flow computer

15. Input signal of frequency (f), pressure compensation (P) Level 2 parameters setting: tYPE=27, Qn=0, P-n=27, F-n=36 Level 1 parameters setting: K, A1, A2

16. Input signal of frequency (f), temperature compensation (T), pressure compensation (P) Level 2 parameters setting: tYPE=25, Qn=0, T-n=14, P-n=27, F-n=36 Level 1 parameters setting: K, 20

17. In superheated steam measurement, linear input signal (G), and input signal of temperature compensation (T), pressure compensation (P)

Level 2 parameters setting: tYPE=1, Qn=0, T-n=14, P-n=27, F-n=27 Level 1 parameters setting: K

18. In superheated steam measurement, input signal of differential pressure (P, non-extracted), temperature compensation (T), pressure compensation (P)

Level 2 parameters setting: tYPE=8, Qn=0, T-n=14, P-n=27, F-n=27 Level 1 parameters setting: K

19. In superheated steam measurement, input signal of differential pressure (P, extracted), temperature compensation (T), pressure compensation (P)

Level 2 parameters setting: tYPE=15, Qn=0, T-n=14, P-n=27, F-n=27 Level 1 parameters setting: K

20. In superheated steam measurement, input signal of frequency (f), temperature compensation (T), pressure compensation (P)

Level 2 parameters setting: tYPE=22, Qn=0, T-n=14, P-n=27, F-n=36 Level 1 parameters setting: K

21. In saturated steam measurement, linear input signal (G), and input signal of temperature compensation (T) or pressure compensation (P)

Level 2 parameters setting: tYPE=2, Qn=0, T-n=14, F-n=27 (temperature compensation) Or tYPE=3, Qn=0, P-n=27, F-n=27 (pressure compensation)

Level 1 parameters setting: K

22. In saturated steam measurement, input signal of differential pressure (P, non-extracted),

20

Signal / Meter

Flow computer temperature compensation (T) or pressure compensation (P)

Level 2 parameters setting: tYPE=9, Qn=0, T-n=14, F-n=27 (Temperature compensation) Or tYPE=10, Qn=0, P-n=27, F-n=27 (Pressure compensation)

Level 1 parameters setting: K

23. In saturated steam measurement, input signal of differential pressure (P, extracted), temperature compensation (T) or pressure compensation (P)

Level 2 parameters setting: tYPE=16, Qn=0, T-n=14, F-n=27 (temperature compensation) Or tYPE=17, Qn=0, P-n=27, F-n=27 (pressure compensation)

Level 1 parameters setting: K

24. In saturated steam measurement, input signal of frequency (f), temperature compensation (T) or pressure compensation (P)

Level 2 parameters setting: tYPE=23, Qn=0, T-n=14, F-n=36(temperature compensation) Or tYPE=24, Qn=0, P-n=27, F-n=36 (pressure compensation)

Level 1 parameters setting: K

(2) Standard volumetric flow (Qn) calculation formula: Level 2 parameters setting: Qn=1 Level 1 parameters setting: 20

(3) Density calculation formula (model) 1. Either pressure or temperature compensation Level 2 parameters setting: T-nX, P-n=X, F-nX (temperature compensation) Or T-n=X, P-nX, F-nX (pressure compensation) Level 1 parameters setting: A1, A2 =A1+A2×P or =A1+A2×T As pressure or temperature has a linear relation with density in a narrow range, so compensation

will be made based on linear relations, and A1 and A2 will be worked out at the time of use, which may be obtained simply by a system of linear equations of two unknowns with two groups of pressure or temperature value and corresponding density value. If relatively high compensation precision is required, density can be worked out by referring to the density table (measured medium or density table shall be specified in the order).

2. Both pressure and temperature compensation Level 2 parameters setting: T-nX, P-nX, F-nX Level 1 parameters setting: 20 PA

(4) Calculation of compensation coefficient K 1. Linear input signal a) Flow input unit: volume (e.g. m3/h): K=1 b) Flow input unit: mass (e.g. T/h): compensation coefficient K will be calculated based on relevant

21

Signal / Meter

Flow computer

mass flow calculation formula. 2. Input signal of frequency a) If coefficient of frequency type flow transducer is known, it may be set according to default set

value: K= flow coefficient of frequency type flow transducer (unit: /liter)

b) If the flow coefficient of transducer is unknown, it may be worked out based on relevant mass flow calculation formula.

3. Input signal of differential pressure a) Compensation coefficient K will be worked out based on relevant mass flow calculation formula. b) Based on standard formula:

K=3.995×××P-n —- M unit: Kg/h; DP unit: MPa K=0.1264×××P-n —- M unit: Kg/h; DP unit: MPa K=0.01251×××P-n —- M unit: Kg/h; DP unit: mmH20

Where: M measured value of mass flow; flow coefficient; expansion coefficient of flow; C outflow coefficient; diameter ratio; d diameter of open hole of throttling device or orifice plate in operating condition (mm) D inner diameter of upstream tube in operating condition (inner diameter of classic Venturi

tube) (5) Symbols introduction

M measured value of mass flow (unit: defined by user) P input signal of differential pressure of flow meter (unit: depending on Level 2 parameter DCA; usually MPa) PA atmospheric pressure at the site where the instrument operates (local atmospheric pressure; unit: same as unit of Level 2 parameter DP pressure compensation; usually MPa) 20 density of measured medium in industrial standard condition (0.10133 MPa, 20) T input signal of temperature compensation (unit: ) T0 -273.15 P0 0.10133 MPa density in operating condition (unit: Kg/m3) input signal of pressure compensation (unit: same as unit of Level 2 parameter DP pressure compensation; usually MPa) A1 compensation coefficient A2 compensation coefficient K flow coefficient G input signal of linear flow meter (unit: same as output of flow meter; e.g. m3/h)

22

Signal / Meter

Flow computer

Qn volumetric flow in standard condition

(6) Superheated steam totalizing:

For superheated steam measurement, the compensation table may be referred to. The instrument

will automatically check the superheated steam compensation table inside the instrument with actually

measured value of flow (differential pressure) input, pressure compensation, and temperature

compensation for high-precision compensation calculation.

(7) Saturated steam totalizing:

For saturated steam measurement, the temperature or pressure compensation table may be

referred to. The instrument will automatically check the saturated steam compensation table inside the

instrument with actually measured value of flow (differential pressure) input, temperature compensation

or pressure compensation (either temperature compensation or pressure compensation may be

selected in saturated steam measurement; if both of them are selected, the calculation will be made

based on pressure compensation) for high-precision compensation calculation.

Temperature (t)

0 Pressure

()

Density ()

1 Pressure

()

Density ()

2 Pressure

()

Density ()

100

0.1013

0.5977

0.1050

0.6180

0.1088

0.6388

110

0.1433

0.8265

0.1481

0.8528

0.1532

0.8798

120

0.1985

1.122

0.2049

1.155

0.2114

1.190

130

0.2701

1.497

0.2783

1.539

0.2867

1.583

140

0.3614

1.967

0.3718

2.019

0.3823

2.073

150

0.4760

2.548

0.4888

2.613

0.5021

2.679

160

0.6181

3.260

0.6339

3.339

0.6502

3.420

170

0.7920

4.123

0.8114

4.218

0.8310

4.316

180

1.0027

5.160

1.0259

5.274

1.0496

5.391

190

1.2551

6.397

1.2829

6.532

1.3111

6.671

200

1.5548

7.864

1.5876

8.025

1.6210

8.188

210

1.9077

9.593

1.9462

9.782

1.9852

9.974

220

2.3198

11.62

2.3645

11.84

2.4098

12.07

230

2.7975

14.00

2.8491

14.25

2.9010

14.52

240

3.3477

16.76

3.4070

17.06

3.4670

17.37

Temperature (t)

100 110 120 130 140 150 160 170 180 190

3 Pressure

() 0.1127 0.1583 0.2182 0.2953 0.3931 0.5155 0.6666 0.8511 1.0737 1.3397

Density ()

0.6601 0.9057 1.225 1.627 2.129 2.747 3.502 4.415 5.509 6.812

4 Pressure

() 0.1167 0.1636 0.2250 0.3041 0.4042 0.5292 0.6835 0.8716 1.0983 0.3690

Density ()

0.6952 0.9359 1.261 1.672 2.185 2.816 3.586 4.515 5.629 6.955

23

5 Pressure

() 0.1208 0.1691 0.2321 0.3130 0.4155 0.5433 0.7008 0.8924 1.1233 1.3987

Density ()

0.7105 0.9650 1.298 1.719 2.242 2.886 3.671 4.618 5.752 7.100

Signal / Meter

Flow computer

200

1.6548

8.354

1.6892

8.522

1.7242

8.649

210

2.0248

10.17

2.0650

10.37

2.1059

10.57

220

2.4559

12.30

2.5026

12.53

2.5500

12.76

230

2.9546

14.78

3.0085

15.05

3.0631

15.33

240

3.5279

17.68

3.5897

17.99

3.6522

18.31

Temperature (t)

100 110 120 130 140 150 160 170 180 190 200 210 220 230 240

6 Pressure Density

() () 0.1250 0.7277 0.1746 0.9948 0.2393 1.336 0.3222 1.766 0.4271 2.301 0.5577 2.958 0.7183 3.758 0.9137 4.723 1.1487 5.877 1.4289 7.248 1.7597 8.868 2.1474 10.77 2.5981 13.00 3.1185 15.61 3.7155 18.64

7 Pressure Density

() () 0.1294 0.7515 0.1804 1.025 0.2467 1.375 0.3317 1.815 0.4389 2.361 0.5723 3.032 0.7362 3.847 0.9353 4.829 1.1746 6.002 1.4596 7.398 1.7959 9.045 2.1896 10.98 1.6469 13.24 3.1746 15.89 3.7797 18.97

8 Pressure Density

() () 0.1339 0.7758 0.1863 1.057 0.2543 1.415 0.3414 1.864 0.4510 2.422 0.5872 3.106 0.7544 3.937 0.9573 4.937 1.2010 6.312 1.4909 7.551 1.8326 9.225 2.2323 11.19 2.6963 13.49 3.2316 16.18 3.8448 19.30

9 Pressure Density

() () 0.1385 0.8008 0.1923 1.089 0.2621 1.455 0.3513 1.915 0.4633 2.484 0.6025 3.182 0.7730 4.029 0.9797 5.048 1.2278 6.264 1.5225 7.706 1.8699 9.408 2.2757 11.41 2.7466 13.74 3.2892 16.47 3.9107 19.64

VI. Common Gas Density Table

Name

0 760mmHg 20 760mmHg

(Kg/m3)

(Kg/m3)

Dry air

1.2928

1.205

Nitrogen

1.2506

1.165

Hydrogen

0.08988

0.084

Oxygen

1.4289

1.331

Chlorine

3.214

3.00

Ammonia

0.771

0.719

CO

1.2504

1.165

CO2

1.977

1.842

Name

Acetylene Methane Ethane Propane Ethene Propylene natural gas Coal gas

0 760mmHg (Kg/m3) 1.1717 0.7167 1.3567 2.005 1.2604 1.914

Depending on components Depending on components

20 760mmHg (Kg/m3) 1.091 0.668 1.263 1.867 1.174 1.784

Depending on components Depending on components

VII. Saturated Steam Density Table (Unit: density = Kg/m3; pressure P = MPa; temperature t = )

In saturated steam measurement, either temperature or pressure compensation may be selected as compensation input.

Example of table checking: when temperature compensation is 218, the density is 11.19Kg/m3 When pressure compensation is +0.10133MPa = 2.2323MPa, the density is 11.19Kg/m3

Pressure in the table is absolute pressure. Absolute pressure = displayed pressure (compensated pressure) + atmospheric pressure.

24

Signal / Meter Flow computer

VIII. Superheated Steam Density Table (Unit: = Kg/m3)

t

MPa 150

170

190

210

230

0.10 0.5164 0.4925 0.4707 0.4507 0.4323

0.15 0.7781 0.7412 0.7079 0.6777 0.6500

0.20 1.0423 0.9918 0.9466 0.9056 0.8684

0.25 1.3089 1.2444 1.1869 1.1349 1.0849

0.30 1.5783 1.4990 1.4287 1.3653 1.3079

0.40 2.1237 2.0141 1.9166 1.8297 1.7513

0.50 2.6658 2.5380 2.4121 2.2997 2.1992

0.80 4.3966 4.1676 3.9372 3.7400 3.5655

1.10 6.1313 5.8332 5.5342 5.2356 4.7919

1.40 7.8785 7.5163 7.1540 6.7913 6.4288

1.70 9.8464 9.3688 9.2473 8.4130 7.9352

2.00 11.6295 11.0985 10.5676 10.0366 9.5054

2.50 15.1890 14.4516 13.7150 12.9776 12.2406

3.00 18.4168 17.5709 16.7243 15.8776 15.0367

3.50 22.7008 21.5713 20.4427 19.3131 18.2266

4.00 27.164 25.7470 24.3303 22.9129 21.4954

4.50 30.3852 28.9163 27.4475 25.9784 24.5096

5.00 35.4243 33.6293 31.8342 30.0384 28.2433

6.00 43.8954 41.7475 39.5988 37.4508 35.3020

7.00 56.7201 53.6991 50.6780 47.6561 44.6352

8.00 65.4713 62.1800 58.8883 55.5968 52.3061

9.00 84.5457 79.8261 75.1061 70.3863 65.6665

10.0 108.6250 102.0289 95.4346 88.8412 82.2486

12.5 158.3464 148.7516 139.1578 129.5629 119.9781

15.0 206.4175 194.4276 182.4477 170.4577 158.4766

17.5 250.3934 236.6910 222.8603 209.1592 195.4568

20.0 327.8165 309.9521 291.2953 273.4409 255.5786

21.5 384.6647 363.2975 341.9027 320.5455 299.1880

250 0.4156 0.6246 0.8342 1.0445 1.2540 1.6527 2.1081 3.4110 4.7459 6.1149 7.5219 8.9744 11.5036 14.1842 17.0530 20.0778 23.0407 26.4483 33.1541 41.6133 49.0145 60.9465 75.6543 110.3842 146.4967 181.6261 236.9217 277.7931

270 0.4001 0.6010 0.8027 1.0048 1.2077 1.6152 2.0255 3.2718 4.5445 5.8437 7.1713 8.5350 10.8794 13.3377 15.9243 18.6603 21.5717 24.6532 31.0062 38.5922 45.7231 56.220 65.7699 95.7769 127.6820 163.4280 219.0574 256.4260

290 0.3857 0.5795 0.7736 0.9682 1.1634 1.5554 1.9495 3.1453 4.3612 5.6006 6.8607 8.1447 10.3500 12.6359 15.0163 17.4997 20.1028 22.8580 28.8574 35.5704 42.4316 51.5077 62.4676 91.1964 122.5268 154.2312 201.2031 235.0688

MPa 0.10 0.15 0.20

310 0.3724 0.5594 0.7465

330 0.3600 0.5404 0.7214

350 0.3484 0.5230 0.6980

t

370

390

0.3375 0.3272

0.5066 0.4912

0.6759 0.6553

410 0.3176 0.4767 0.6360

430 0.3086 0.4631 0.6178

450 0.2998 0.4502 0.6005

MPa 0.10 0.15 0.20 0.25

470 0.2919 0.4381 0.5842 0.7316

490 0.2842 0.4270 0.5688 0.7113

510 0.2769 0.4156 0.5541 0.6925

t 530 0.2700 0.4052 0.5403 0.6757

25

550 0.2634 0.3953 0.5271 0.6591

570 0.2571 0.3858 0.5146 0.7558

590 0.2512 0.3768 0.5026 0.6284

Signal / Meter

Flow computer

0.30

0.8856

0.8540

0.8320

0.8108

0.7913

0.7724

0.7540

0.40

1.1708

1.1396

1.1102

1.0821

1.0556

1.0303

1.0062

0.50

1.4648

1.4258

1.3888

1.3537

1.3204

1.2887

1.2585

0.80

2.3500

2.2869

2.2274

2.1700

2.1164

2.0650

2.0168

1.10

3.2402

3.1529

3.0690

2.9902

2.9150

2.8449

2.7774

1.40

4.3496

4.2291

3.9157

3.8143

3.7183

3.6271

3.5401

1.70

5.0374

4.8972

4.7665

4.6408

4.5230

4.4116

4.3056

2.00

5.9419

5.7760

5.6204

5.4725

5.3322

5.1989

5.0745

2.50

7.4632

7.2511

7.0515

6.8637

6.6858

6.5177

6.3582

3.00

8.9991

8.738

8.4945

8.2657

8.0486

7.8437

7.6498

3.50 10.5512 10.2402

9.9499

9.6776

9.4197

9.1777

8.9480

4.00 12.1835 11.7548 11.4169 11.0994 10.8003 10.5191 10.2533

4.50 13.7009 13.2822 12.8950 12.5315 12.1894 11.8683 11.5650

5.00 15.3017 14.8249 14.3859 13.9749 13.5885 13.2267 12.8850

6.00 18.5495 17.9518 17.4029 16.8912 16.4119 15.9657 15.5440

7.00 21.8675 21.1373 20.4699 19.8506 19.2745 18.7350 18.2314

8.00 25.2640 24.3864 23.5905 22.8573 22.1742 21.5400 20.9500

9.00 28.4637 27.6971 26.7676 25.9068 25.1124 24.3771 23.6949

10.0 32.3002 31.0863 30.0116 29.0164 28.1000 27.2557 26.4738

12.5 41.5884 39.8569 38.3537 36.9936 35.7414 34.6072 33.5541

15.0 51.5265 49.1381 47.1249 45.3087 43.6680 42.1936 40.8349

17.5 62.1807 59.0050 56.3427 53.9875 51.8985 50.0237 48.3269

20.0 73.6858 69.5196 66.0602 63.0674 60.4493 58.1253 56.0402

21.5 81.0184 76.1621 72.1376 68.7108 65.7370 63.1132 60.7719

Note: The pressure in the table above is absolute pressure. The operating pressure in the formula

refers to displayed pressure. Absolute pressure = displayed pressure + atmospheric pressure.

IX. Enthalpy Table of Steam

1) Saturated steam pressure enthalpy table (ranked by pressure)

Pressure (MPa) Temperature () Enthalpy(KJ/Kg) Pressure (MPa) Temperature ()

0.0010

6.982

2513.8

1.00

179.88

0.0020

17.511

2533.2

1.10

0.0030

24.098

2545.2

1.20

0.0040

28.981

2554.1

1.30

0.0050

32.90

2561.2

1.40

184.06 187.96 191.60 195.04

0.0060

36.18

2567.1

1.50

198.26

0.0070 0.0080 0.0090 0.010

39.02 41.53 43.79 45.83

2572.2

1.60

2576.7

1.70

2580.8

1.80

2584.4

1.90

201.37 204.30 207.10 209.79

0.015 0.020 0.025 0.030

54.00 60.09 64.99 69.12

2598.9

2.00

2609.6

2.20

2618.1

2.40

2625.3

2.60

212.37 217.24 221.78 226.03

0.040

75.89

2636.8

2.80

230.04

26

Enthalpy(KJ/Kg) 2777.0 2780.4 2783.4 2786.0 2788.4 2790.4 2792.2 2793.8 2795.1 2796.4 2797.4 2799.1 2800.4 2801.2 2801.7

Signal / Meter

Flow computer

0.050

81.35

2645.0

3.00

233.84

0.060

85.95

2653.6

3.50

242.54

0.070

89.96

2660.2

4.00

250.33

0.080

93.51

2666.0

5.00

263.92

0.090

96.71

2671.1

6.00

275.56

0.10

99.63

2675.7

7.00

285.80

0.12

104.81

2683.8

8.00

294.98

0.14

109.32

2690.8

9.00

303.31

0.16

113.32

2696.8

10.0

310.96

0.18

116.93

2702.1

11.0

318.04

0.20

120.23

2706.9

12.0

324.64

0.25

127.43

2717.2

13.0

330.81

0.30

133.54

2725.5

14.0

336.63

0.35

138.88

2732.5

15.0

342.12

0.40

143.62

2738.5

16.0

347.32

0.45

147.92

2743.8

17.0

352.26

0.50

151.85

2748.5

18.0

356.96

0.60

158.84

2756.4

19.0

361.44

0.70

164.96

2762.9

20.0

365.71

0.80

170.42

2768.4

21.0

369.79

0.90

175.36

2773.0

22.0

373.68

2) Saturated steam temperature enthalpy table (ranked by temperature)

Temperature () Pressure (MPa) Enthalpy (KJ/Kg) Pressure (MPa) Temperature ()

0

0.0006108

2501.0

80

0.047359

0.01

0.0006112

2501.0

85

0.057803

1

0.0006566

2502.8

90

0.070108

2

0.0007054

2504.7

95

0.084525

3

0.0007575

2506.5

100

0.0101325

4

0.0008129

2508.3

110

0.14326

5

0.0008718

2510.2

120

0.19854

6

0.0009346

2512.0

130

0.27012

7

0.0010012

2513.9

140

0.36136

8

0.0010012

2515.7

150

0.47597

9

0.0011473

2517.5

160

0.61804

10

0.0012271

2519.4

170

0.79202

11

0.0013118

2521.2

180

1.0027

12

0.0014015

2523.0

190

1.2552

13

0.0014967

2524.9

200

1.5551

14

0.0015974

2526.7

210

1.9079

15

0.0017041

2528.6

220

2.3201

16

0.0018170

2530.4

230

2.7979

17

0.0019364

2532.2

240

3.3480

18

0.0020626

2534.0

250

3.9776

19

0.0021960

2535.9

260

4.6940

20

0.0023368

2537.7

270

5.5051

27

2801.9 2801.3 2799.4 2792.8 2783.3 2771.4 2757.5 2741.8 2724.4 2705.4 2684.8 2662.4 2638.3 2611.6 2582.7 2550.8 2514.4 2470.1 2413.8 2340.2 2192.5

Enthalpy (KJ/Kg) 2643.8 2652.1 2660.3 2668.4 2676.3 2691.8 2706.6 2720.7 2734.0 2746.3 2757.7 2768.0 2777.1 2784.9 2791.4 2796.4 2799.9 2801.7 2801.6 2799.5 2795.2 2788.3

Signal / Meter

Flow computer

22

0.0026424

2541.4

280

6.4191

2778.6

24

0.0029824

2545.0

290

7.4448

2765.4

26

0.0033600

2543.6

300

8.5917

2748.4

28

0.0037785

2552.3

310

9.8697

2726.8

30

0.0042417

2555.9

320

11.290

2699.6

35

0.0056217

2565.0

330

12.865

2665.5

40

0.0073749

2574.0

340

14.608

2622.3

45

0.00958172

2582.9

350

16.537

2566.1

50

0.012335

2591.8

360

18.674

2485.7

55

0.015740

2600.7

370

21.053

2335.7

60

0.019919

2609.5

371

21.306

2310.7

65

0.025008

2618.2

372

1.562

2280.1

70

0.031161

2626.8

373

21.821

2238.3

75

0.038548

2635.3

374

22.084

2150.7

3) Superheated steam temperature and pressure enthalpy table

T ()

MPa

0.001

0.005

0.010

0.1

0.5

1.0

3.0

5.0

0

0.0

0.0

0.0

0.1

0.5

1.0

3.0

5.0

10

2519.5

42.0

42.0

42.1

42.5

43.0

44.9

46.9

20

2538.1

83.9

83.9

84.0

84.3

84.8

86.7

88.6

40

2575.5 2574.6 167.4

167.5

167.9

168.3

170.1

171.9

60

2613.0 2612.3 2611.3 251.2

251.2

251.9

253.6

255.3

80

2650.6 2650.0 2649.3 335.0

335.3

335.7

337.3

338.8

100 2688.3 2687.9 2687.3 2676.5 419.4

419.7

421.2

422.7

120 2726.2 2725.9 2725.4 2716.8 503.9

504.3

505.7

507.1

140 2764.3 2764.0 2763.6 2756.6 589.2

589.5

590.8

592.1

160 2802.6 2802.3 2802.0 2796.2 2767.3 675.7

676.9

678.0

180 2841.0 2840.8 2840.6 2835.7 2812.1 2777.3 764.1

765.2

200 2879.7 2879.5 2879.3 2875.2 2855.5 2827.5 853.0

853.8

220 2918.6 2918.5 2918.3 2914.7 2898.0 2874.9 943.9

944.4

240 2957.7 2957.6 2957.4 2954.3 2939.9 2920.5 2823.0 1037.8

260 2997.1 2997.0 2996.8 2994.1 2981.5 2964.8 2885.5 1135.0

280 3036.7 3036.6 3036.5 3034.0 3022.9 3008.3 2941.8 2857.0

300 3076.5 3076.4 3076.3 3074.1 3064.2 3051.3 2994.2 2925.4

350 3177.2 3177.1 3177.0 3175.3 3167.6 3157.7 3115.7 3069.2

400 3279.5 3279.4 3279.40 3278.00 3217.80 3264.00 3231.60 3196.90

420 3321.06 3320.96 3320.96 3319.68 3313.80 3306.60 3276.90 3245.40

440 3362.62 3362.52 3362.52 3361.36 3355.90 3349.30 3321.90 3293.20

450 3383.40 3383.30 3383.30 3382.20 3377.10 3370.70 3344.40 3316.80

460 3404.52 3404.44 3404.42 3403.34 3398.30 3392.10 3366.80 3340.40

480 3446.76 3446.72 3446.66 3445.62 3440.90 3435.10 3411.60 3387.20

500 3489.00 3489.00 3488.90 3487.90 3483.70 3478.70 3456.40 3433.80

520 3531.92 3531.88 3531.82 3530.90 3526.90 3521.86 3501.28 3480.12

540 3574.84 3574.76 3574.74 3573.90 3570.10 3565.42 3546.16 3526.44

550 3596.30 3596.20 3596.20 3595.40 3591.70 3587.20 3568.60 3549.60

28

Signal / Meter

Flow computer 560 3618.10 3618.02 3618.00 3617.22 3613.64 3609.24 3591.18 3572.76 580 3661.70 3661.66 3661.60 3660.86 3657.52 3653.32 3636.34 3619.08 600 3705.30 3705.30 3705.20 3704.50 3701.40 3697.40 3681.50 3665.40

T () 7.0

MPa

10.0

14.0

20.0

25.0

30.0

0

7.1

10.1

14.1

0.1

25.1

30.0

10

48.8

51.7

55.6

61.3

66.1

70.8

20

90.4

93.2

97.0

102.5

107.1

111.7

40

173.6

176.3

179.8

185.1

189.4

193.8

60

256.9

259.4

262.8

267.8

272.0

276.1

80

340.4

342.8

346.0

350.8

354.8

358.7

100

424.2

426.5

429.5

434.0

437.8

441.6

120

508.5

510.6

513.5

517.7

521.3

524.9

140

593.4

595.4

598.0

602.0

605.4

603.1

160

679.2

681.0

683.4

687.1

690.2

693.3

180

766.2

767.8

769.9

773.1

775.9

778.7

200

854.6

855.9

857.7

860.4

862.8

856.2

220

945.0

946.0

947.2

949.3

951.2

953.1

240

1038.0

1038.4

1039.1

1040.3

1041.5

1024.8

260

1134.7

1134.3

1134.1

1134.1

1134.3

1134.8

280

1236.7

1235.2

1233.5

1231.6

1230.5

1229.9

300

2839.2

1343.7

1339.5

1334.6

1331.5

1329.0

350

3017.0

2924.2

2753.5

1648.4

1626.4

1611.3

400

3159.70

3098.50

3004.00

2820.10

2583.20

2159.10

420

3211.02

3155.98

3072.72

2917.02

2730.76

2424.70

440

3262.34

3213.46

3141.44

3013.94

2878.32

2690.30

450

3288.00

3242.20

3175.80

3062.40

3952.10

2823.10

460

3312.44

3268.58

3205.24

3097.96

2994.68

2875.26

480

3361.32

3321.34

3264.12

3169.08

3079.84

2979.58

500

3410.20

3374.10

3323.00

3240.20

3165.00

3083.90

520

3458.60

3425.10

3378.40

3303.70

3237.00

3166.10

540

3506.40

3475.40

3432.50

3364.60

3304.70

3241.70

550

3530.20

3500.40

3459.20

3394.30

3337.30

3277.70

560

3554.10

3525.40

3485.80

3423.60

3369.20

3312.60

580

3610.60

3574.90

3538.20

3480.90

3431.20

3379.80

600

3649.00

3624.00

3589.80

3536.90

3491.20

3444.20

X. Programming Examples

Some gas is measured with orifice plate with input of differential pressure as well as pressure and

temperature compensation without output; it’s required that no cumulation will be made when the

differential pressure is less than 10KPa. Relevant parameters are as follows:

Differential pressure transducer: 4~20mA; measuring range: 0~80KPa

Pressure transducer: 1~5V; measuring range: 0~3KPa Temperature transducer: 4~20mA; measuring range: 0~300

Atmospheric pressure at the site where the instrument operates (PA): 0.08 MPa

29

Signal / Meter

Flow computer

Density in standard condition: 20 = 2Kg/m3 When operating pressure (compensated pressure) P = 3MPa and operating temperature T =300, the maximum flow M = 100T/h. Instrument model selection: NHR-5600A-27/29/27-X/2/X/X-A Based on the formula:

The parameters are set as follows:

1. Level 2 parameters setting:

Parameter

Name

tYPE Flow model

ALM1 Alarm 1

ALM2 Alarm 2

Qn

Flow measurement option

Addr Device ID

Baud Communication baud rate

Q-Tn Time unit of instantaneous flow display

M-dp Precision of cumulative flow display

Q-dp Decimal point of instantaneous flow display

H-Tn Time unit of instantaneous heat display

N-dp Precision of cumulative heat display

H-dp Decimal point of instantaneous heat display

Y-dp

Decimal point of temperature compensation display

P-dp Decimal point of pressure compensation display

F-dp Decimal point of flow input

FK

Filter coefficient

T-n

Type of temperature compensation input

P-n

Type of pressure compensation input

F-n

Type of flow signal input

T-b

Zero shift of temperature compensation

T-k

Amplification scale of measuring range of temperature compensation

30

Set value 11 0 0 0 1 3 2 3 1 2 3 2 1 3 1 0 27 29 27 0

1.000

Signal / Meter

Flow computer

P-b

Zero shift of pressure compensation

0

P-k

Amplification scale of measuring range of pressure compensation

1.000

F-b

Zero shift of flow input

0

F-k

Amplification scale of measuring range of flow input

1.000

O1-b Zero shift of transmission output 1

0

O1-k Amplification scale of transmission output 1

1.000

OUL Lower limit of measuring range of transmission output

0

OUH Upper limit of measuring range of transmission output

1000

PA

Atmospheric pressure in operating condition

0.10133

T-L

Lower limit of measuring range of temperature compensation

0

T-H

Upper limit of measuring range of temperature compensation

300

P-L

Lower limit of measuring range of pressure compensation

0

P-H

Upper limit of measuring range of pressure compensation

3

F-L

Lower limit of measuring range of flow input

0

F-H

Upper limit of measuring range of flow input

80

Cut

Small signal cutoff of flow input

10

T-u

Unit of temperature compensation

3

P-u

Unit of pressure input

2

F-u

Unit of flow input

2

Q-u

Unit of instantaneous flow

20

H-u

Unit of instantaneous heat

26

Pr-A

Alarm printing

0

Pr-T

Interval of printing

0

KE

Mode of flow coefficient compensation

0

Tin

Temperature input

0

Pin

Pressure input

0

2. Exit Level 2 parameter setting screen and return back to Level 1 parameter setting screen:

Symbol

Name

Set value Symbol

Name

Set value

LOC Parameter locking

0

20

Density in standard condition

2

K1

Flow coefficient 1 2.00504

DIP

PV display content

2

3. Instrument collation instantaneous flow checking:

Measured value of flow input (KPa)

20.0

40.0

60.0

80.0

Pressure compensation input (MPa) Temperature compensation input ()

0.750 300

1.500 300

2.250 300

3.000 300

Instantaneous value (T/h)

25.9

50.6

75.3

100.0

31

eyc-tech Measuring Specialist

enhance your capability with sensor technology

Air flow | Humidity | Dew point | Differential pressure | Liquid flow Temp. | Pressure | Level | Air quality | Signal meter

Tel.886-2-8221-2958 Webwww.eyc-tech.com e-mailinfo@eyc-tech.com

Documents / Resources

|

eyc-tech DPM05 Flow Computer [pdf] Instruction Manual DPM05 Flow Computer, DPM05, Flow Computer, Computer |