Mini Modbus 1AI

Mini Modbus 1AI

Expansion Module – 1 analog input, 1 digital output

Version 1.5

User Manual

Mini Modbus 1AI Expansion Module

RS485 MODBUS Module 8AI

Thank you for choosing our product.

This manual will help you with proper support and proper operation of the device.

The information contained in this manual have been prepared with utmost care by our professionals and serve as a description of the product without incurring any liability for the purposes of commercial law.

This information does not release you from the obligation of own judgement and verification.

We reserve the right to change product specifications without notice.

Please read the instructions carefully and follow the recommendations contained therein.

![]() WARNING!

WARNING!

Failure to follow instructions can result in equipment damage or impede the use of the hardware or software.

Safety rules

- Before first use, refer to this manual

- Before first use, make sure that all cables are connected properly

- Please ensure proper working conditions, according to the device specifications (eg: supply voltage, temperature, maximum power consumption)

- Before making any modifications to wiring connections, turn off the power supply

Module Features

2.1. Purpose and description of the module

1AI module allows voltage or current measurement and has one digital put-put.

Values are read via RS485 (Modbus), so we can easily integrate the module with popular PLCs, HMI or PC equipped with the appropriate adapter.

The device has 1 input to voltage measurement and 1 input for current measurement (both inputs can be used in this same time). In addition, the module is equipped with 1 configurable digital output (PNP or NPN type).

This module is connected to the RS485 bus with twisted-pair wire.

Communication is via MODBUS RTU or MODBUS ASCII. The use of 32-bit ARM core processor provides fast processing and quick communication. The baud rate is configurable from 2400 to 115200.

The module is designed for mounting on a DIN rail in accordance with DIN EN 5002.

The module is equipped with a set of LEDs used to indicate the status of inputs and outputs useful for diagnostic purposes and helping to find errors.

Module configuration is done via USB by using a dedicated computer program.

You can also change the parameters using the MODBUS protocol.

2.2. Technical Specifications

| Power Supply | Voltage | 10-38VDC; 20-28VAC |

| Maximum Current | 70 mA @ 12V / 38 mA @ 24V | |

| Inputs | No of inputs | 2 |

| Voltage input | -10V to 10V | |

| Current input | -20mA to 20mA | |

| Measurement resolution | 16 bits | |

| ADC processing time | 70ms / channel | |

| Voltage measurement error | Max ±1.7% | |

| Current measurement error | Max ±0.1% | |

| Digital outputs | Maximum current and voltage | 250mA / 50V |

| Temperature | Work | -10 °C – +50°C |

| Storage | -40 °C – +85°C | |

| Connectors | Power Supply | 2 pin |

| Communication | 3 pin | |

| Inputs & Outputs | 2 x 3 pin | |

| Configuration | Mini USB | |

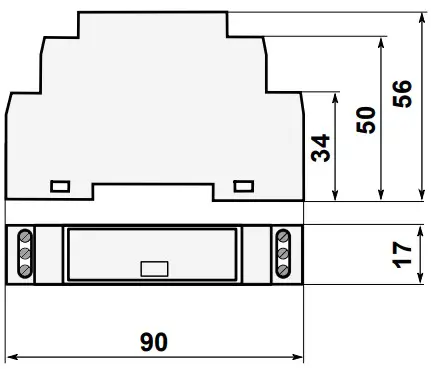

| Size | Height | 90 mm |

| Length | 56 mm | |

| Width | 17 mm | |

| Interface | RS485 | Up to 128 devices |

2.3. Dimensions of the product

Look and dimensions of the module are shown below. The module is mounted directly to the rail in the DIN industry standard.

Communication configuration

3.1. Grounding and shielding

In most cases, IO modules will be installed in an enclosure along with other devices which generate electromagnetic radiation. Examples of these devices are relays and contactors, transformers, motor controllers etc. This electromagnetic radiation can induce electrical noise into both power and signal lines, as well as direct radiation into the module causing negative effects on the system. Appropriate grounding, shielding and other protective steps should be taken at the installation stage to prevent these effects. These protective steps include control cabinet grounding, module grounding, cable shield grounding, protective elements for electromagnetic switching devices, correct wiring as well as consideration of cable types and their cross sections.

3.2. Network Termination

Transmission line effects often present a problem on data communication networks. These problems include reflections and signal attenuation.

To eliminate the presence of reflections from the end of the cable, the cable must be terminated at both ends with a resistor across the line equal to its characteristic impedance. Both ends must be terminated since the direction of propagation is bidirectional. In the case of an RS485 twisted pair cable this termination is typically 120 Ω.

3.3. Types of Modbus Registers

There are 4 types of variables available in the module

| Type | Beginning address | Variable | Access | Modbus Command |

| 1 | 00001 | Digital Outputs | Bit Read & Write | 1, 5, 15 |

| 2 | 10001 | Digital Inputs | Bit Read | 2 |

| 3 | 30001 | Input Registers | Registered Read | 3 |

| 4 | 40001 | Output Registers | Registered Read & Write | 4, 6, 16 |

3.4. Communication settings

The data stored in the modules memory are in 16-bit registers. Access to registers is via MODBUS RTU or MODBUS ASCII.

3.4.1. Default settings

| Parameter name | Value |

| Address | 1 |

| Baud rate | 19200 |

| Parity | No |

| Data bits | 8 |

| Stop bits | 1 |

| Reply Delay [ms] | 0 |

| Modbus Type | RTU |

3.4.2. Configuration registers

| Modbus | Dec | Hex | Name | Values |

| Address | ||||

| 40002 | 1 | 0x01 | Address | From 0 to 255 |

| 40003 | 2 | 0x02 | Baud rate | 0 – 2400 1 – 4800 2 – 9600 3 – 19200 4 – 38400 5 – 57600 6 – 115200 other – value * 10 |

| 40005 | 4 | 0x04 | Parity | 0 – none 1 – odd 2 – even 3 – always 1 4 – always 0 |

| 40004 | 3 | 0x03 | Stop Bits LSB | 1 – one stop bit 2 – two stop bits |

| 40004 | 3 | 0x03 | Data Bits MSB | 7 – 7 data bits 8 – 8 data bits |

| 40006 | 5 | 0x05 | Response delay | Time in ms |

| 40007 | 6 | 0x06 | Modbus Mode | 0 – RTU 1 – ASCII |

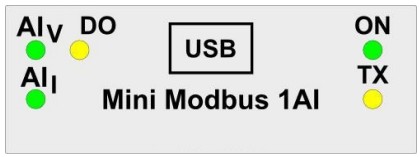

Indicators

| Indicator | Description |

| ON | LED indicates that the module is correctly powered. |

| TX | The LED lights up when the unit received the correct packet and sends the answer. |

| AIV, AII | LED indicates that the signal to input is connected and is different from 0 |

| DO | LED indicates that the output is on. |

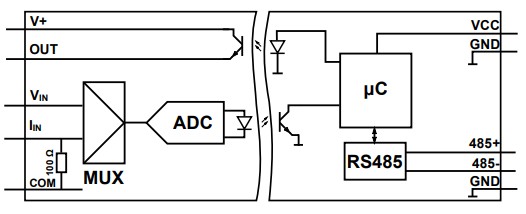

Block diagram

Module Connection

Modules Registers

7.1. Registered access

| Modbus | Dec | Hex | Register Name | Access | Description |

| 30001 | 0 | 0x00 | Version/Type | Read | Version and Type of the device |

| 30002 | 1 | 0x01 | Address | Read | Module Address |

| 40003 | 2 | 0x02 | Baud rate | Read & Write | RS485 baud rate |

| 40004 | 3 | 0x03 | Stop Bits & Data Bits | Read & Write | No of Stop bits & Data Bits (see 3.4.2) |

| 40005 | 4 | 0x04 | Parity | Read & Write | Parity bit |

| 40006 | 5 | 0x05 | Response Delay | Read & Write | Response delay in ms |

| 40007 | 6 | 0x06 | Modbus Mode | Read & Write | Modbus Mode (ASCII or RTU) |

| 40010 | 9 | 0x09 | Filter | Read & Write | Measurement filtering, value from 1 to 10 |

| 40033 | 32 | 0x20 | Received packets LSB | Read & Write | No of received packets |

| 40034 | 33 | 0x21 | Received packets MSB | Read & Write | |

| 40035 | 34 | 0x22 | Incorrect packets LSB | Read & Write | No of received packets with error |

| 40036 | 35 | 0x23 | Incorrect packets MSB | Read & Write | |

| 40037 | 36 | 0x24 | Sent packets LSB | Read & Write | No of sent packets |

| 40038 | 37 | 0x25 | Sent packets MSB | Read & Write | |

| 30051 | 50 | 0x32 | Inputs | Read | Connected inputs Bit in high state → signal is connected |

| 40052 | 51 | 0x33 | Outputs | Read & Write | Alarms state bit no. 3 digital output |

| 30053 | 52 | 0x34 | Voltage | Read | Voltage in μV |

| 30054 | 53 | 0x35 | Current | Read | Current in μA or ‰ |

| 30055 | 54 | 0x36 | Alarm – max voltage | Read & Write | Maximum value of voltage excess which causes set bit no 1 in the register 40052 |

| 30056 | 55 | 0x37 | Alarm – min voltage | Read & Write | Minimum value of voltage. If voltage drops below this voltage bit no 1 in the register 40052 is set. |

| 30057 | 56 | 0x38 | Alarm – max current | Read & Write | Maximum value of current excess which causes set bit no 1 in the register 40052 |

| 30058 | 57 | 0x39 | Alarm – min current | Read & Write | Minimum value of current. If current drops below this voltage bit no 1 in the register 40052 is set. |

| 30059 | 58 | 0x3A | Voltage alarm configuration | Read & Write | Alarms configuration

0 – alarms state depends on actual values 1 – alarms state need to clear by master |

| 30060 | 59 | 0x3B | Current alarm configuration | Read & Write | |

| 30061 | 60 | 0x3C | Voltage input configuration | Read & Write | 0 – OFF 1 – 0 .. 10V 2 – -10 .. 10V 3 – 0 .. 1V 4 – -1 .. 1V |

| 40062 | 61 | 0x3D | Current input configuration | Read & Write | 0 – OFF 1 – 0 .. 20mA (in μA) 2 – 4 .. 20mA (in ‰) 3 – -20mA .. 20mA (in μA) |

| 40063 | 62 | 0x3E | Digital output configuration | Read & Write | Digital output configuration 0 – output controlled by master 1 – output state depends voltage 2 – output state depends current +256 – output set if value is greater than alarm value (40065 register) („cooling”) +512 – output set if value is below than alarm value (40065 register) („warming”) |

| 40064 | 63 | 0x3F | Alarm value | Read & Write | Alarm value |

| 40065 | 64 | 0x40 | Alarm hysteresis | Read & Write | Hysteresis for alarm |

7.2. Bit access

| Modbus Address | Dec Address | Hex Address | Register name | Access | Description |

| 801 | 800 | 0x320 | Voltage input | Read | Voltage input state |

| 802 | 801 | 0x321 | Current input | Read | Current input state |

| 817 | 816 | 0x330 | Voltage alarm | Read & Write | Voltage alarm state |

| 818 | 817 | 0x331 | Current alarm | Read & Write | Current alarm state |

| 819 | 818 | 0x332 | Digital output | Read & Write | Digital output state |

Configuration software

Modbus Configurator is software that is designed to set the module registers responsible for communication over Modbus network as well as to read and write the current value of other registers of the module. This program can be a convenient way to test the system as well as to observe real-time changes in the registers.

Communication with the module is done via the USB cable. The module does not require any drivers.

Configurator is a universal program, whereby it is possible to configure all available modules.

Configurator is a universal program, whereby it is possible to configure all available modules.

Manufactured for: Aspar s.c.

Manufactured for: Aspar s.c.

ul. Oliwska 112

80-209 Chwaszczyno Poland

ampero@ampero.eu

www.ampero.eu

tel. +48 58 351 39 89; +48 58 732 71 73

Expansion Module – 1 analog input, 1 digital output

Documents / Resources

|

aspar Mini Modbus 1AI Expansion Module [pdf] User Manual Mini Modbus 1AI, Expansion Module, Mini Modbus 1AI Expansion Module, Module |