1. Introduction and Overview

The DAB Evosta 2 is an electronic, low-energy consumption circulator pump designed for water circulation in various domestic heating and air conditioning systems. This manual provides essential information for the safe and efficient installation, operation, and maintenance of your Evosta 2 pump.

The Evosta 2 series combines the robustness of mechanical circulators with the advantages of electronic control. It features a synchronous permanent magnet motor, a frequency converter, and an efficiency index (EEI) of ≤ 0.18, ensuring high efficiency and reliability. Its compact design and comprehensive performance make it suitable for replacing older three-speed circulators.

2. Safety Information

Important: Read all safety instructions before installation or operation. Failure to follow these instructions may result in electric shock, fire, or serious injury.

- Installation and maintenance must be performed by qualified personnel only.

- Ensure the power supply is disconnected before performing any work on the pump.

- The pump operates with hot liquids; allow it to cool before handling to prevent burns.

- Protect the pump from moisture and direct water spray.

- Do not operate the pump if it is damaged or if the electrical cable is frayed.

- The pump is designed for clean, non-viscous, chemically neutral liquids. Do not use with flammable or corrosive liquids.

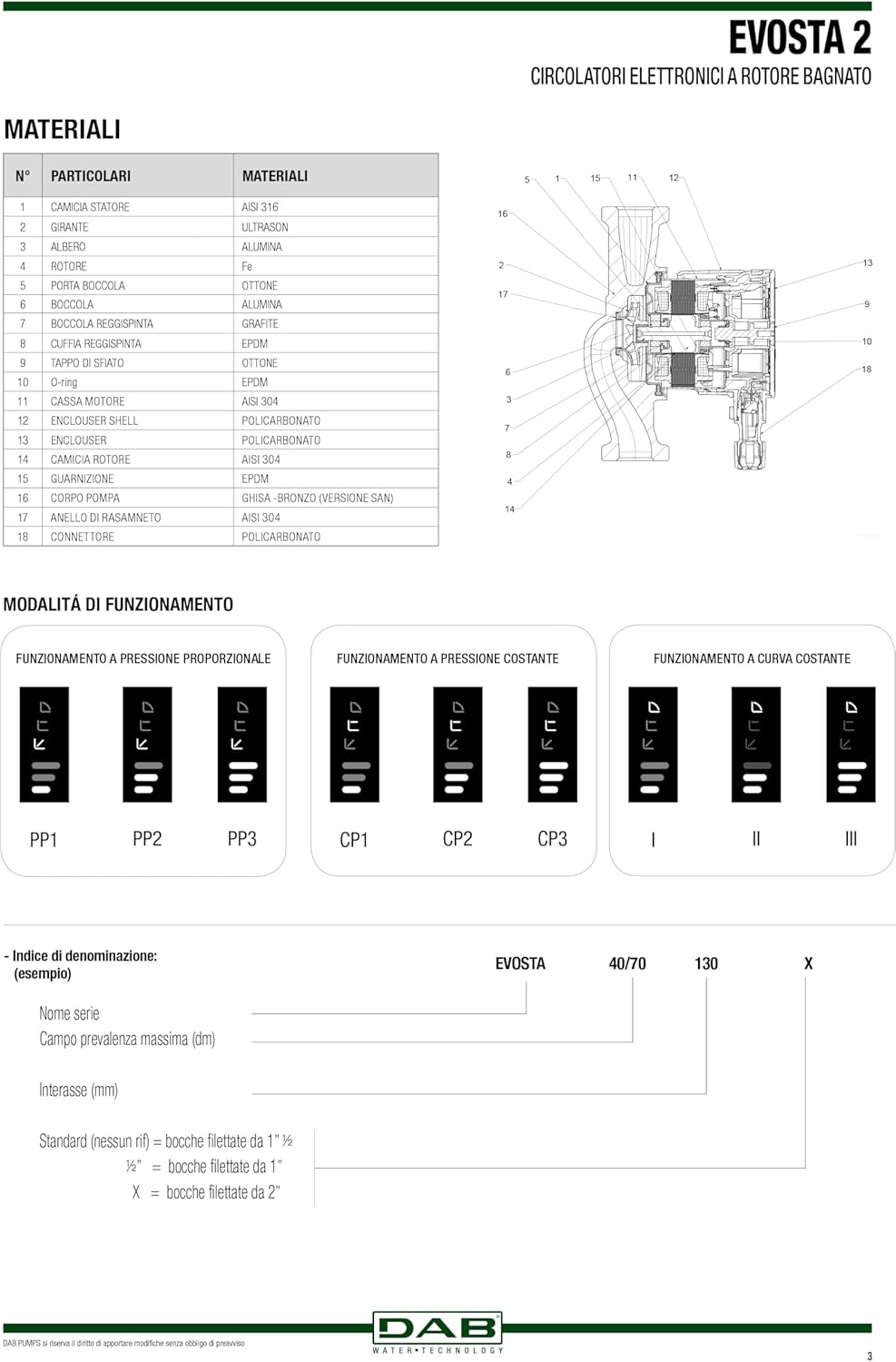

3. Product Description and Features

The Evosta 2 circulator pump is engineered for optimal performance and durability. Key features include:

- Energy Efficiency: Equipped with a synchronous permanent magnet motor and frequency converter, achieving an EEI ≤ 0.18.

- Robust Construction: Cast iron pump body with cataphoresis treatment, wet rotor motor, and ceramic shaft mounted on ceramic bushings lubricated by the pumped liquid.

- Integrated Protection: Internal motor protection eliminates the need for external overload protection.

- User-Friendly Control: A single sequential adjustment button on the control panel simplifies settings.

- Maintenance Access: Direct access to the crankshaft for potential unlocking.

- High Protection Rating: IPX5 degree of protection.

The pump casing is made of steel, with a technopolymer impeller. The rotor sleeve, stator sleeve, and closing flange are stainless steel. The thrust ring is graphite, and the sealing rings are EPDM. An air bleed plug made of brass is integrated.

4. Installation

Proper installation is crucial for the pump's performance and longevity. Follow these guidelines:

- Mounting Position: Install the pump with the motor axis horizontal.

- Pipe Connections: The Evosta 2 40-70/130 is equipped with 1" (G 1") threaded connections. The 1/2" designation refers to the thread intended for connection to 1" to 1/2" reduced female fittings. Verify compatibility with your existing pipes or fittings.

- Power Supply: Connect the pump to a single-phase 1 x 230 V ~ 50/60 Hz power supply. Ensure the electrical installation complies with local regulations.

- System Flushing: Before starting the pump, ensure the system is thoroughly flushed to remove any debris that could damage the pump.

- Air Purging: The pump includes an integrated air bleed plug. After filling the system, open the plug to release any trapped air.

Refer to the dimensional drawings for precise measurements and connection details to ensure proper fitment within your system.

5. Operation

The Evosta 2 pump features a control panel on the electronic control device cover, allowing for easy adjustment of its functions. The pump offers nine setting options, selectable via the MODE button.

- Setting Selection: Press the MODE button to cycle through the available settings. The selected setting is indicated by six illuminated segments on the display.

- Operating Modes: The pump supports various operating modes, typically including proportional pressure, constant pressure, and constant curve modes, to adapt to different system requirements.

Consult the specific icons or indicators on your pump's control panel to identify the active operating mode and adjust as needed for your heating or cooling system.

6. Maintenance

Regular maintenance ensures the long-term reliability and efficiency of your Evosta 2 pump.

- Air Purging: Periodically check and, if necessary, open the integrated brass air bleed plug to release any air trapped in the pump. This prevents cavitation and ensures smooth operation.

- Crankshaft Unlocking: In case of a blockage, the pump provides direct access to the crankshaft for manual unlocking. Refer to the technical diagrams for the exact location.

- Cleaning: Keep the exterior of the pump clean and free from dust and debris. Do not use abrasive cleaners.

- System Fluid: Ensure the pumped liquid remains clean and free of solid substances and mineral oils. Glycol content should not exceed 30%.

- No Overload Protection Needed: Due to internal motor protection, no external overload protection is required.

7. Troubleshooting

If you encounter issues with your Evosta 2 pump, consider the following common problems and solutions:

- Pump Not Starting:

- Check the power supply and circuit breaker.

- Ensure the pump is properly connected to the electrical mains.

- Verify that the motor is not seized. Use the direct access to the crankshaft to attempt manual unlocking if necessary.

- No Flow or Reduced Flow:

- Check for air in the system. Bleed air using the integrated plug.

- Inspect for blockages in the pipes or pump impeller.

- Ensure valves in the system are open.

- Verify the selected operating mode and setting are appropriate for the system's requirements.

- Unusual Noise:

- Noise can indicate air in the system. Purge air.

- Check for foreign objects in the pump.

- Ensure the pump is securely mounted and not vibrating excessively.

If problems persist after attempting these solutions, contact qualified service personnel or DAB customer support.

8. Technical Specifications

| Parameter | Value |

|---|---|

| Model | Evosta 2 40-70/130 |

| Manufacturer Part Number | 60231855 |

| Operating Range | 0.4 – 3.6 m³/h with head up to 6.9 meters |

| Liquid Temperature Range | 0 °C to +110 °C |

| Operating Pressure | 10 bar (1000 kPa) |

| Protection Index | IPX5 |

| Insulation Class | F |

| Installation | Motor axis horizontal |

| Power Supply | 1 x 230 V ~ 50/60 Hz |

| Pumped Liquid | Clean, free of solids/mineral oils, non-viscous, chemically neutral, water-like (max 30% glycol) |

| Pump Body Material | Cast iron with cataphoresis treatment |

| Motor Casing Material | Steel |

| Impeller Material | Technopolymer |

| Shaft Material | Ceramic |

| Weight | 1.86 kg |

| Package Dimensions | 15 x 14 x 10 cm |

9. Warranty and Support

The DAB Evosta 2 circulator pump comes with a 5-year warranty, ensuring peace of mind regarding its quality and durability. This warranty covers manufacturing defects under normal use conditions.

For technical assistance, warranty claims, or spare parts inquiries, please contact your authorized DAB dealer or customer support. When contacting support, please have your model number (60231855) and purchase date available.

Information regarding the availability of spare parts is not provided in the product data. Please consult your dealer for specific spare part availability.