1. Introduction

This manual provides essential instructions for the safe and efficient operation, setup, and maintenance of your KATOOL ME-T450 Tire Changer Machine and ME-B600 Wheel Balancer Combo. Please read this manual thoroughly before operating the equipment to ensure proper usage and to prevent injury or damage.

Figure 1: KATOOL ME-T450 Tire Changer Machine and ME-B600 Wheel Balancer Combo with included accessories.

2. Safety Information

Always prioritize safety when operating heavy machinery. Failure to follow safety guidelines can result in serious injury or equipment damage.

- Read and understand all instructions and warnings in this manual before use.

- Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and sturdy footwear.

- Ensure the machine is placed on a stable, level surface and properly secured before operation.

- Keep hands, feet, and loose clothing away from moving parts.

- Do not exceed the machine's specified capacities for rim size and tire width.

- Ensure proper air pressure supply and electrical connections are made according to specifications.

- Never attempt to service or repair the machine while it is powered on or under air pressure.

- Keep the work area clean and well-lit.

3. Product Overview

The KATOOL ME-T450/B600 combo provides a robust solution for tire changing and wheel balancing. The ME-T450 is a swing arm tire changer, and the ME-B600 is a wheel balancer designed for efficiency and durability.

3.1 ME-T450 Tire Changer Features

- Swing Arm Design: Facilitates easy positioning and operation.

- Clamping Range: External locking rim dimensions 12"-20", internal locking rim dimensions 22"-24".

- Mounting Head: Constructed from solution-treated, interface-polished stainless steel with a plastic cover to protect rims.

- Foot Pedals: Simple and intuitive controls for various operations.

3.2 ME-B600 Wheel Balancer Features

- Robust Construction: Body made of thick steel with solid welding for low vibration and high strength.

- High-Quality Motor: Features pure copper windings for fast heat dissipation, low defective rate, and long life.

4. Setup and Assembly

The ME-T450 and ME-B600 units require assembly before first use. Ensure all components are present and undamaged before proceeding.

4.1 Tire Changer (ME-T450) Assembly

- Securely attach the main column to the base unit using the provided bolts and washers.

- Install the swing arm assembly onto the main column, ensuring all pivot points are properly aligned and secured.

- Connect the pneumatic lines as indicated in the diagrams. Ensure all connections are tight to prevent air leaks.

- Attach the mounting head to the end of the swing arm.

- Connect the electrical power supply according to local regulations.

4.2 Wheel Balancer (ME-B600) Setup

- Place the balancer on a firm, level surface.

- Ensure the power supply is connected.

- Familiarize yourself with the control panel and display.

Video 1: SBM-988 Installation video. This video demonstrates the installation process for a similar tire changer model, providing a visual guide for assembly steps.

5. Operating Instructions

5.1 Tire Changer (ME-T450) Operation

- Lubricate Tire: Apply tire lubricant to the tire beads to facilitate easier mounting and demounting.

- Bead Breaking: Position the tire against the side-mounted bead breaker. Use the foot pedal to activate the bead breaker, ensuring the tire is flush against the machine to prevent movement. Avoid breaking the bead directly over the tire pressure sensor.

- Clamping the Wheel: Place the wheel on the turntable. Use the foot pedals to activate the clamping jaws, securing the wheel firmly. The machine supports both internal (22"-24") and external (12"-20") clamping.

- Mounting/Demounting Tire: Position the mounting head correctly. Use a tire lever to guide the tire bead over the mounting head. Activate the turntable rotation via the foot pedal to complete the mounting or demounting process. Ensure the mounting head does not scratch the rim by maintaining a slight gap.

- Inflation: Once the tire is mounted, inflate it to the recommended pressure. Do not inflate the tire while it is clamped on the machine.

Figure 2: Close-up of the side-mounted bead breaker and foot pedal for bead breaking.

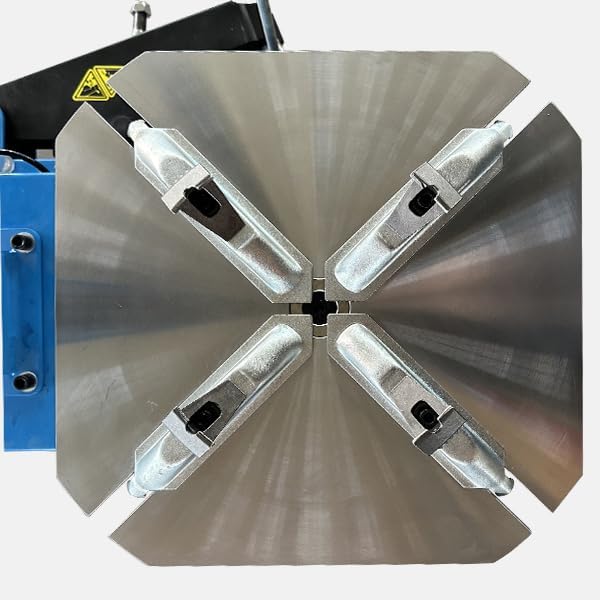

Figure 3: The four clamping jaws on the turntable, designed to securely hold the wheel.

Figure 4: The mounting head, crucial for lifting and lowering tire beads during changing.

Figure 5: The foot pedals control various functions of the tire changer, including clamping, bead breaking, and turntable rotation.

5.2 Wheel Balancer (ME-B600) Operation

- Mounting Wheel: Securely mount the wheel onto the balancer's shaft using the appropriate cones and quick-release nut.

- Input Data: Use the control panel to input the wheel's diameter, width, and offset.

- Start Balancing: Close the wheel guard (if applicable) and press the START button. The machine will spin the wheel and display the required weight and its placement location.

- Apply Weights: Attach the correct balance weights to the indicated positions on the rim.

- Re-spin: Spin the wheel again to verify balance. Repeat if necessary until the display shows zero imbalance.

Figure 6: The KATOOL ME-B600 Wheel Balancer, showing its control panel and various accessories for different wheel types.

Figure 7: Visual representation of common issues caused by unbalanced wheels, such as steering wheel shakes, vehicle resonance, tire wear, and shock absorber damage.

Video 2: ME-T450 details video. This video provides a detailed look at the features and operation of the ME-T450 tire changer.

6. Maintenance

Regular maintenance ensures the longevity and optimal performance of your KATOOL equipment.

- Lubrication: Regularly lubricate all moving parts, especially the swing arm pivot points and clamping mechanisms, to ensure smooth operation and prevent rust.

- Cleaning: Keep the machines clean from tire debris, dust, and lubricant residue. Wipe down surfaces after each use.

- Air Filter/Lubricator: Check and maintain the air filter/lubricator unit on the ME-T450. Drain water from the filter bowl and replenish oil in the lubricator as needed.

- Inspections: Periodically inspect all hoses, cables, and fasteners for wear, damage, or looseness. Tighten or replace as necessary.

7. Troubleshooting

This section addresses common issues you might encounter during operation.

7.1 Tire Changer (ME-T450)

- Machine Not Powering On: Check electrical connections and circuit breaker.

- Pneumatic Functions Not Working: Verify air supply pressure, check for kinks in air lines, and ensure the air filter/lubricator is functioning correctly.

- Difficulty with Bead Breaking: Ensure sufficient lubrication on tire beads. Check air pressure and proper positioning of the tire.

- Rim Damage During Operation: Ensure proper use of plastic protectors on the mounting head and clamping jaws. Maintain correct gap between mounting head and rim.

7.2 Wheel Balancer (ME-B600)

- Inaccurate Readings: Ensure the wheel is securely mounted and clean. Verify correct input of wheel data (diameter, width, offset).

- Machine Not Spinning: Check power connection and ensure the wheel guard is properly closed.

8. Specifications

8.1 ME-T450 Tire Changer

- External Locking Rim Dimensions: 12"-20"

- Internal Locking Rim Dimensions: 22"-24"

- Max. Tire Diameter: 960mm / 38"

- Max. Tire Width: 410mm / 17"

- Bead Breaker Force: 5500 LBS

- Working Pressure: 0.8MPA

- Motor Power: 0.75kW - 1.1KW

- Table Top Rotation Speed: 6/MIN

- Working Noise: <70DB

- Dimensions: 39"x33"x37"

- Shipping Weight: 510LBS / 230KG

- Gearbox Motor: 110V/220V/380V, 50/60HZ

8.2 ME-B600 Wheel Balancer

- Body Material: Thick steel with high strength and solid welding.

- Motor: Top of the line motor with pure copper windings.

9. Warranty and Support

For information regarding product warranty, technical support, or replacement parts, please contact KATOOL customer service or refer to the official product page. Extended protection plans (2-Year, 3-Year) may be available for purchase.