Product Overview

The Reboot RBM-2100D is a versatile 5-in-1 IGBT Inverter Multiprocess Welder designed for various welding applications, including MIG Gas, MIG Gasless, Stick, Lift TIG, and Spool Gun welding. It supports both 110V and 220V input voltages, offering flexibility for different power sources.

Key Features:

- Multi-Process Capability: MIG Gas, MIG Gasless, Stick (MMA), Lift TIG, and Spool Gun welding.

- Dual Voltage Input: Operates on 110V or 220V.

- High Output: Up to 210A (220V) and 150A (110V).

- IGBT Technology: Ensures stable performance and energy efficiency.

- Digital Control: Synthetic digital control for automatic voltage adjustment with current changes.

- Spool Gun Function: Facilitates easy aluminum welding.

- Portable Design: Lightweight and compact for easy transport.

Component Identification:

Setup

1. Power Connection

Ensure the welder is connected to an appropriate power supply (110V or 220V) as indicated on the machine's specifications. Use a dedicated circuit if possible to avoid overloading.

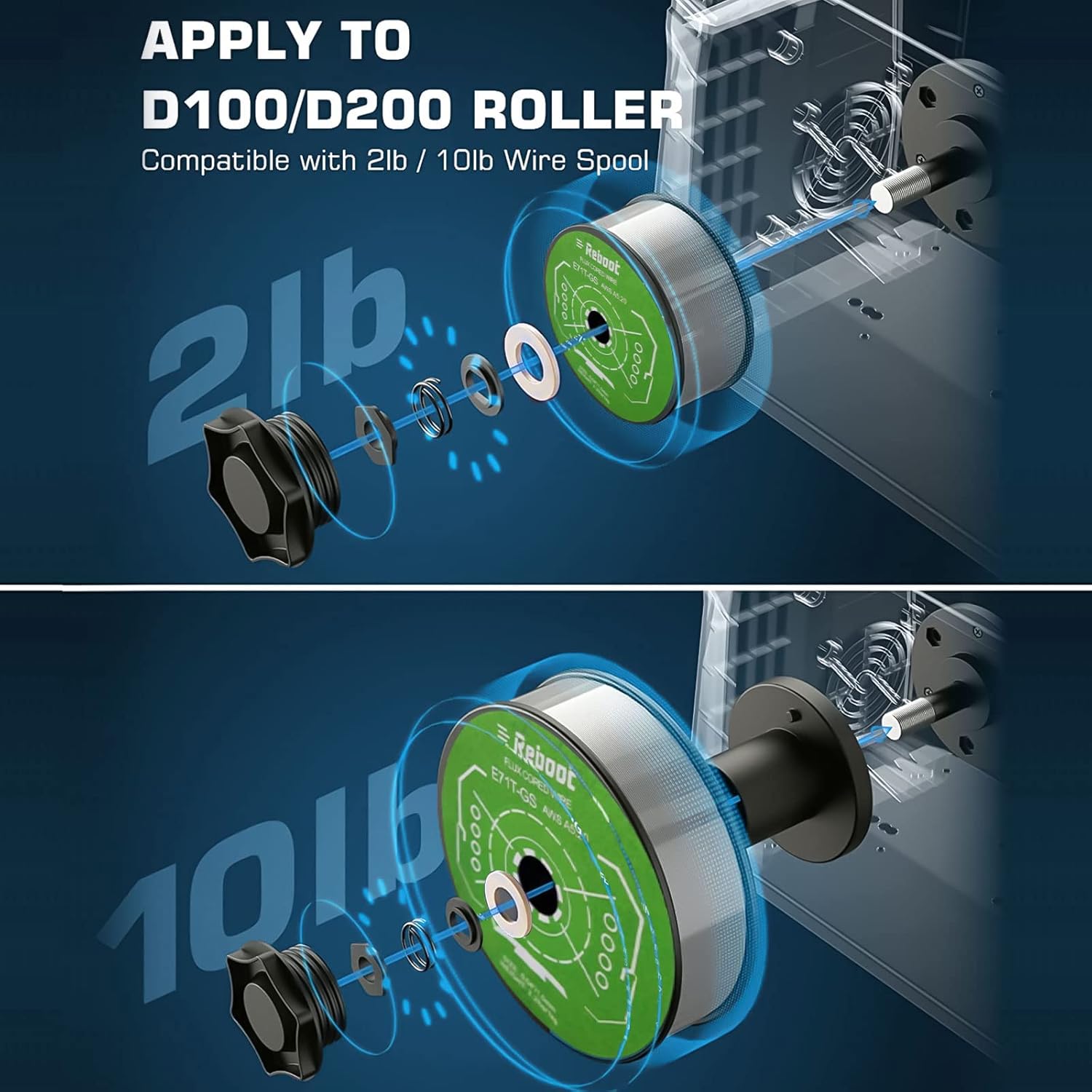

2. Wire Installation

The RBM-2100D supports 2LB and 10LB wire spools. Ensure the wire is correctly loaded onto the D100/D200 roller and fed through the torch liner.

3. Gas Connection (for MIG Gas and Spool Gun)

For MIG Gas welding, connect your shielding gas cylinder (e.g., CO2 for solid wire, Argon for aluminum with spool gun) to the gas input on the rear of the machine using appropriate hoses and regulators.

Operating Modes

The RBM-2100D offers multiple welding modes. Select the desired mode using the Welding Mode Selection knob on the front panel.

1. MIG Welding (Gas/Gasless)

MIG welding is suitable for various metals including mild steel, stainless steel, and aluminum. Use solid wire with shielding gas for MIG Gas, or flux-cored wire without gas for MIG Gasless.

Video 1: Reboot MIG Welder 210A 110/220V MIG Welding With Gas. This video demonstrates the process of MIG welding with gas, showing setup and actual welding operation.

Video 2: Reboot MIG Welder 210A 110/220V Flux Core Welding. This video illustrates the flux core welding process, which does not require external shielding gas.

2. Stick Welding (MMA)

The machine supports stick electrodes up to 3.2mm (1/8"). It performs well with 7018 1/8" electrodes, and also with 6013 and 7018 3/32".

3. Lift TIG Welding

For Lift TIG welding, connect a TIG torch (not included) to the machine. This mode provides precise control for thinner materials.

Video 3: Welds 3/50" sheet in Lift TIG mode. This video demonstrates the Lift TIG welding capability on thin metal sheets, showcasing the precision of this mode.

4. Spool Gun Welding

The additional spool gun function (spool gun not included) offers improved performance for aluminum welding, reducing the inconvenience of frequent wire changes.

Video 4: Reboot RBM2100 Spool Gun Welding Aluminum. This video demonstrates the use of a spool gun with the RBM2100D for welding aluminum, highlighting its effectiveness.

5. 2T/4T Operative Mode

The 2T/4T function allows for semi-automatic operation, reducing finger fatigue during extended welding sessions. In 2T mode, the trigger must be held down. In 4T mode, a single press starts the arc, and another press stops it.

Important Safety Information

Welding can be dangerous. Always ensure proper safety precautions are taken to prevent injury or damage. Read and understand all safety warnings and instructions before operating this equipment.

- Always wear appropriate personal protective equipment (PPE), including welding helmet, gloves, protective clothing, and safety shoes.

- Ensure adequate ventilation to avoid inhalation of welding fumes.

- Protect eyes and skin from arc rays.

- Do not operate in damp or wet conditions.

- Keep children and unauthorized personnel away from the welding area.

- Disconnect power before performing any maintenance or adjustments.

- Refer to local safety regulations and standards.

Maintenance

Regular maintenance ensures the longevity and optimal performance of your welder.

- Cleaning: Periodically clean the machine's exterior and ventilation openings to prevent dust and debris buildup. Use compressed air to clear internal components if necessary, ensuring power is disconnected.

- Cable Inspection: Inspect all cables, including welding cables, power cord, and torch leads, for any signs of damage, cuts, or fraying. Replace damaged cables immediately.

- Consumables: Regularly check and replace worn-out consumables such as contact tips, nozzles, and diffusers on the MIG torch, and tungsten electrodes for TIG welding.

- Wire Feeder: Keep the wire feeder mechanism clean and free of debris. Ensure the drive rollers are appropriate for the wire size and are properly tensioned.

Troubleshooting

| Problem | Possible Cause | Solution |

|---|---|---|

| No output power | Power switch off; circuit breaker tripped; loose connections. | Turn on switch; reset breaker; check all connections. |

| Wire not feeding | Wire tangled; drive roller tension incorrect; wrong drive roller size; clogged liner. | Untangle wire; adjust tension; install correct roller; clean/replace liner. |

| Poor weld quality | Incorrect settings (voltage/current); improper gas flow; contaminated material; worn consumables. | Adjust settings; check gas supply/flow; clean workpiece; replace contact tip/nozzle. |

| Overheat indicator on | Exceeded duty cycle; poor ventilation. | Allow machine to cool down; ensure proper airflow around the unit. |

Specifications

| Feature | Detail |

|---|---|

| Model Number | RBM-2100D |

| Input Voltage | 110V/220V |

| Output Current (220V) | 210A (60% duty cycle at 200A, 100% at 150A) |

| Output Current (110V) | 150A (60% duty cycle at 150A, 100% at 116A) |

| Welding Modes | MIG Gas, MIG Gasless, Stick, Lift TIG, Spool Gun |

| Supported Wire Sizes | 0.8mm / 1.0mm (1kg/5kg spools) |

| Supported Electrode Sizes (Stick) | Max 3.2mm (1/8") |

| Technology | IGBT Inverter |

| Dimensions | 16.14 x 7.09 x 12.2 inches |

| Weight | 30.6 pounds |

Warranty and Customer Service

Your Reboot RBM-2100D welder comes with a 1-year limited warranty from the date of purchase. This warranty covers defects in materials and workmanship under normal use.

For technical support, troubleshooting assistance, or warranty claims, please contact our customer service team. Our team is available 24 hours a day to help you with any issues you may encounter.

Please have your model number (RBM-2100D) and purchase information ready when contacting support.

For more information, visit the official Reboot Store on Amazon.