1. Introduction

This manual provides instructions for the proper installation, operation, and maintenance of the Zurn 34-850TXL Lead-Free FNPT Tapped Ball Valve. This valve is designed for residential, commercial, and industrial applications, suitable for throttling and balancing low-pressure steam, air, water, and non-corrosive gas or oil systems.

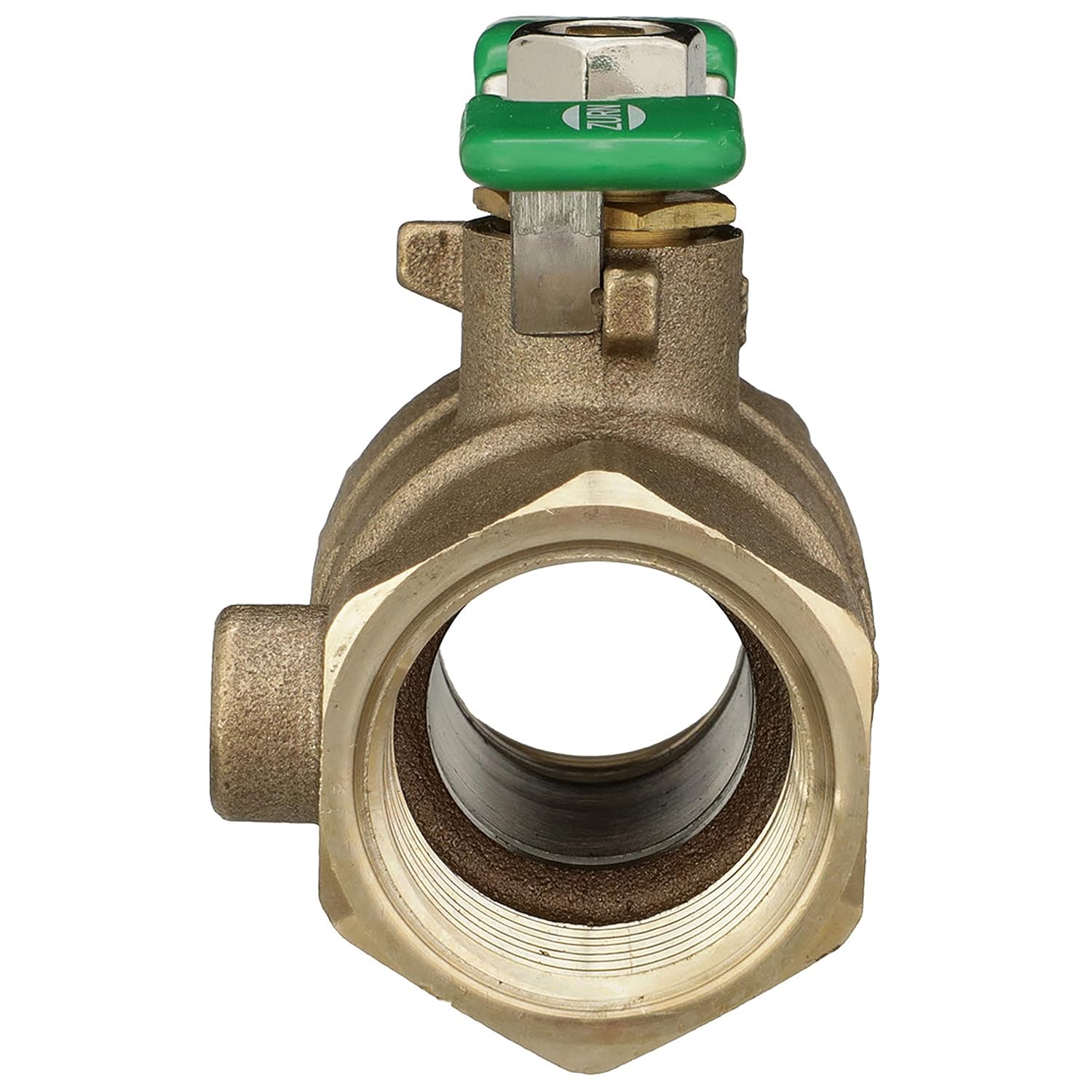

Figure 1: Front view of the Zurn 34-850TXL Lead-Free FNPT Tapped Ball Valve.

2. Safety Information

Read all instructions carefully before installation or operation. Failure to follow these instructions may result in property damage, personal injury, or death. Always wear appropriate personal protective equipment (PPE) during installation and maintenance.

- Ensure the system is depressurized and drained before installing or servicing the valve.

- Verify compatibility of the valve material with the fluid being handled.

- Do not exceed the maximum pressure rating of the valve.

- Installation should be performed by qualified personnel in accordance with local codes and regulations.

3. Package Contents

The package should contain the following item:

- One (1) Zurn 3/4" Tapped Ball Valve (Model 34-850TXL)

4. Product Specifications

| Feature | Detail |

|---|---|

| Model Number | 34-850TXL |

| Brand | Zurn |

| Material | Brass, Bronze |

| Exterior Finish | Bronze |

| Inlet Connection Size | 0.75 Inches |

| Inlet Connection Type | Full Port |

| Outlet Connection Size | 0.75 Inches |

| Outlet Connection Type | FNPT (Female National Pipe Taper) |

| Number of Ports | 2 |

| Product Dimensions (L x W x H) | 3 x 4 x 4 inches |

| Item Weight | 11.29 ounces |

| Compliance | Lead-Free Compliant, Specification Met: Steam |

Figure 2: Side view of the Zurn 34-850TXL valve, showing model markings.

5. Installation

Follow these steps for proper installation of the Zurn 34-850TXL ball valve:

- Preparation: Ensure the system is completely shut off, depressurized, and drained. Clean the pipe threads of any debris.

- Thread Sealant: Apply an appropriate thread sealant (e.g., PTFE tape or pipe dope) to the male pipe threads. Ensure the sealant is compatible with the system fluid and valve materials.

- Connection: Thread the valve onto the pipe. Use a wrench on the valve body flats to tighten. Do not overtighten, as this can damage the valve or pipe threads. Avoid applying torque to the valve handle.

- Orientation: The valve can be installed in any orientation. Ensure the handle has sufficient clearance for full quarter-turn operation.

- Tapped Port (if applicable): If utilizing the tapped port, ensure proper connection and sealing of any auxiliary devices (e.g., pressure gauges, drain valves).

- System Startup: Slowly repressurize the system and check for leaks at all connections.

Figure 3: View of the valve's FNPT inlet connection.

Figure 4: View of the valve's FNPT outlet connection.

6. Operation

The Zurn 34-850TXL is a quarter-turn ball valve, meaning it requires a 90-degree rotation of the handle to go from fully open to fully closed, or vice versa.

- To Open the Valve: Rotate the handle until it is parallel with the pipeline. This indicates a full port opening, allowing maximum flow.

- To Close the Valve: Rotate the handle until it is perpendicular to the pipeline. This indicates the valve is fully closed, stopping flow.

- Throttling/Balancing: The valve can be partially opened to regulate flow. For precise balancing, specialized balancing valves may be more suitable.

7. Maintenance

The Zurn 34-850TXL ball valve is designed for minimal maintenance. Regular inspection is recommended to ensure optimal performance.

- Inspection: Periodically check for any signs of leaks around the valve body or connections. Inspect the handle for damage or looseness.

- Cleaning: Keep the exterior of the valve clean. Avoid using harsh chemicals that could damage the bronze finish or internal components.

- Lubrication: The valve is designed with self-lubricating components and typically does not require external lubrication.

- Repair: In case of persistent leaks or operational issues, it is recommended to replace the valve. Attempting to repair internal components may void any warranty and could compromise the valve's integrity.

8. Troubleshooting

| Problem | Possible Cause | Solution |

|---|---|---|

| Leakage at pipe connections | Improper thread sealant, insufficient tightening, damaged threads. | Depressurize system, reapply thread sealant, retighten connections. If threads are damaged, replace the valve or pipe section. |

| Leakage from valve body/stem | Internal seal failure, manufacturing defect. | Replace the valve. |

| Valve difficult to turn | Debris inside valve, worn internal components, corrosion. | Attempt to cycle the valve several times. If resistance persists, replace the valve. |

| Incomplete shut-off | Debris preventing full closure, worn ball or seats. | Replace the valve. |

9. Warranty and Support

For specific warranty information and technical support regarding your Zurn 34-850TXL Lead-Free FNPT Tapped Ball Valve, please refer to the official Zurn website or contact Zurn customer service directly. Keep your purchase receipt for warranty claims.

Manufacturer: Zurn Industries

Website: www.zurn.com (Example link, actual link may vary)