1. Product Overview

The Dosatron D14MZ2 is a water-powered proportional injector designed for precise and consistent dosing of various solutions into a water line. This device operates without electricity, utilizing water flow as its power source. Its volumetric proportioning technology ensures that the mixture remains consistent, even with variations in water pressure and flow rates. The internal piston technology accurately mixes the incoming water with the concentrated solution for a blended output.

Figure 1: The Dosatron D14MZ2 water-powered doser. This image displays the main unit, a blue cylindrical device with black components, designed for inline installation in a water system.

2. Key Features

- Water-Powered Operation: Requires no electricity, operating solely on water pressure.

- Adjustable Dosage Rate: Features an easy-to-use dial for setting the desired injection percentage.

- Volumetric Proportioning: Maintains a consistent solution mixture regardless of water flow or pressure fluctuations.

- Piston Technology: Ensures accurate and reliable mixing of concentrate with water.

- Wide Dilution Range: Capable of dilutions from 1:500 to 1:50 (0.2% to 2%).

- High Flow Capacity: Supports water flow rates from 0.05 to 14 GPM.

- Durable Construction: Designed for operating pressures from 4.3 to 85 PSI.

- Compact Design: Dimensions of approximately 19 1/8" x 6 5/16" with a 3/4" NPT connection size.

3. Setup and Installation

Proper installation is crucial for the optimal performance of your Dosatron D14MZ2. Ensure all connections are secure and leak-free.

3.1 Basic Installation

A basic installation typically involves connecting the doser inline with your water supply. It is recommended to include a filter, a pressure regulator, and a check valve for protection and optimal operation.

Figure 2: Basic installation diagram for the Dosatron D14MZ2. This diagram illustrates the doser connected to a water line, with a filter, pressure regulator, and check valve installed upstream for system protection and performance.

3.2 Recommended Industrial Plumbing Kit (IPK34)

For industrial applications, the IPK34 kit is recommended to ensure robust and reliable operation. This kit includes various components for a comprehensive setup.

Figure 3: Recommended IPK34 Industrial Plumbing Kit installation. This diagram shows a more complex setup with additional valves, filters, and fittings for industrial use, ensuring precise control and durability.

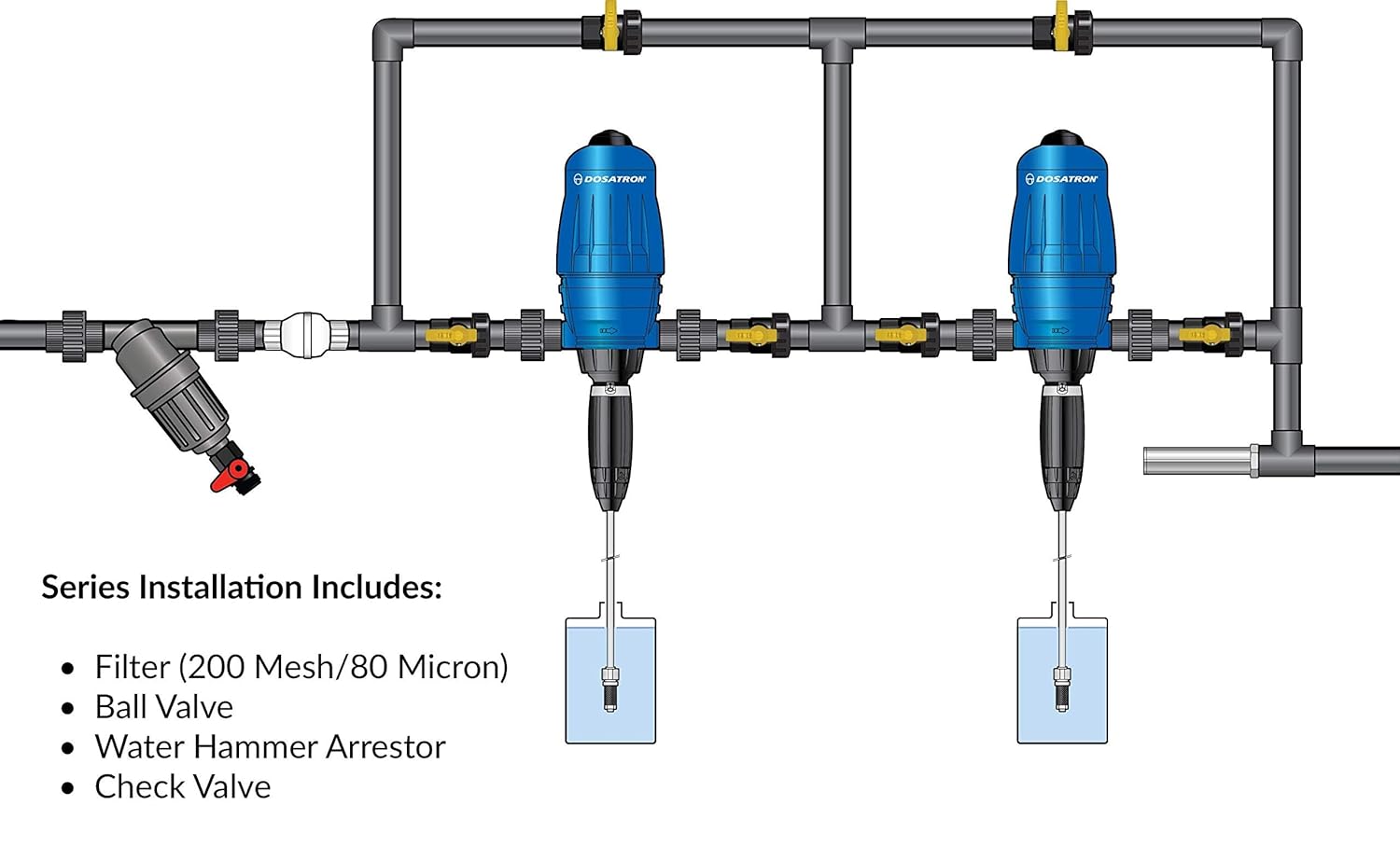

3.3 Series Installation

For certain applications, multiple Dosatron units can be installed in series. This setup typically includes a filter, ball valve, water hammer arrestor, and check valve for each unit.

Figure 4: Series installation of multiple Dosatron doser units. This diagram illustrates two dosers connected sequentially in a water line, each with its own protective components, suitable for multi-stage dosing.

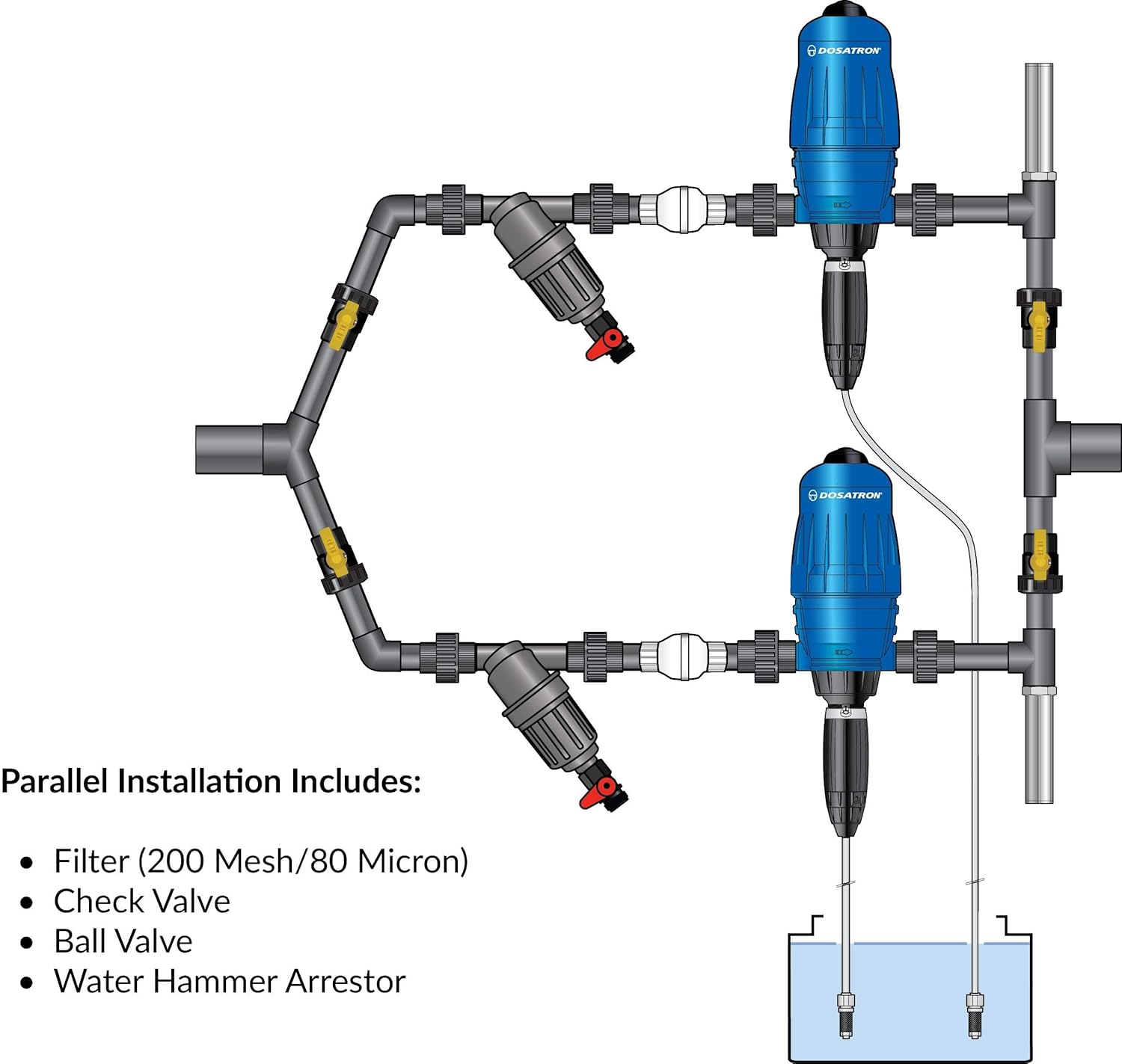

3.4 Parallel Installation

Parallel installation allows for increased flow capacity or redundant dosing. This configuration also requires appropriate filtration, check valves, and water hammer arrestors.

Figure 5: Parallel installation of multiple Dosatron doser units. This diagram shows two dosers connected in parallel, allowing for higher flow rates or the use of different concentrates simultaneously, each with necessary protective elements.

4. Operating Instructions

The Dosatron D14MZ2 is designed for straightforward operation. Once installed, ensure your concentrate solution is prepared and the suction hose is properly submerged.

4.1 Setting the Dosage Rate

The dosage rate is adjusted by turning the dial located on the lower part of the doser. Refer to the markings on the dial to select the desired percentage or dilution ratio. A chart is typically provided with the unit to guide you in setting the correct proportion for your application.

Figure 6: Close-up view of the Dosatron D14MZ2 dosage adjustment dial. This image highlights the mechanism used to set the desired injection percentage, showing clear markings for precise control.

4.2 Initiating Dosing

Once the dosage rate is set and the concentrate is ready, open the water supply valve. The water flow will activate the internal piston, drawing the concentrate through the suction hose and mixing it proportionally with the water. The mixed solution will then exit the doser.

5. Maintenance

Regular maintenance ensures the longevity and accurate performance of your Dosatron D14MZ2.

5.1 Filter Cleaning

The system includes a filter to prevent debris from entering the doser. Periodically inspect and clean this filter to maintain optimal water flow and prevent blockages. The filter is designed for easy access and cleaning.

5.2 Post-Use Flushing

After each use, especially when using corrosive or sticky concentrates, it is advisable to flush the doser with clean water. This helps prevent residue buildup and extends the life of internal components. To flush, remove the suction hose from the concentrate and place it into a bucket of clean water, allowing the doser to run until the system is clear.

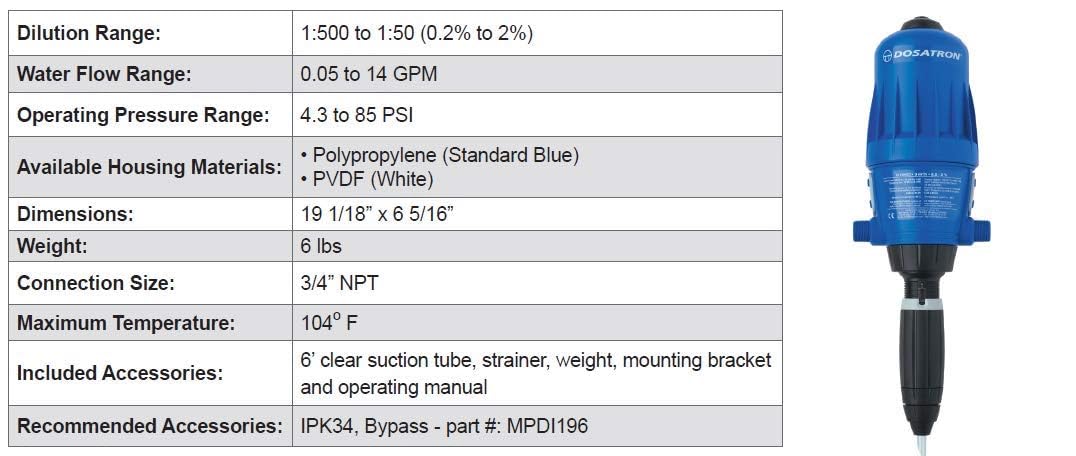

6. Specifications

The following table outlines the technical specifications for the Dosatron D14MZ2.

Figure 7: Technical specifications table for the Dosatron D14MZ2. This image provides a clear summary of the product's performance parameters and physical characteristics.

| Specification | Value |

|---|---|

| Model Number | D14MZ2 |

| Dilution Range | 1:500 to 1:50 (0.2% to 2%) |

| Water Flow Range | 0.05 to 14 GPM |

| Operating Pressure Range | 4.3 to 85 PSI |

| Dimensions (L x W x H) | 19 1/8" x 6 5/16" (Product), 22" x 6.75" x 5.75" (Shipping) |

| Connection Size | 3/4" NPT |

| Weight | 6 lbs (Product), 4.35 lbs (Item) |

| Maximum Temperature | 104° F |

| Power Source | Water Pressure |

| Material | Metal (internal components), Polypropylene/PVDF (housing) |

| Color | Black (main body), Blue (top housing) |

7. What's in the Box

The Dosatron D14MZ2 package includes the following components:

- Dosatron D14MZ2 Doser Unit

- 6' clear suction tube

- Strainer

- Weight

- Mounting bracket

- Operating manual