1. Introduction

This manual provides essential information for the safe and effective installation, operation, and maintenance of the Yaskawa SERVOPACK model CACR-IR 151515FB. This device is a 3-axis servo drive designed for industrial applications requiring precise motor control. Please read this manual thoroughly before using the product to ensure correct handling and to prevent accidents.

2. Safety Information

Always observe the following safety precautions to prevent injury to personnel and damage to equipment.

- Electrical Hazard: Ensure all power is disconnected before performing any installation, wiring, or maintenance. High voltages are present within the SERVOPACK and can cause severe injury or death.

- Qualified Personnel: Installation, wiring, and maintenance should only be performed by qualified and trained personnel familiar with electrical equipment and safety standards.

- Grounding: Properly ground the SERVOPACK according to local and national electrical codes to prevent electric shock.

- Environmental Conditions: Do not expose the SERVOPACK to moisture, corrosive gases, flammable materials, or extreme temperatures outside its specified operating range.

- Secure Mounting: Mount the SERVOPACK securely in a stable location to prevent it from falling or vibrating excessively during operation.

3. Product Overview

The Yaskawa SERVOPACK CACR-IR 151515FB is a robust 3-axis servo drive designed for industrial automation systems. It provides precise control over servo motors, enabling accurate positioning and motion control in various machinery.

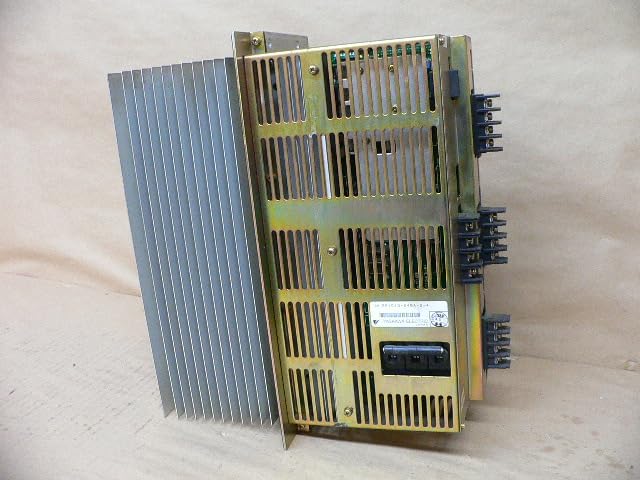

Figure 3.1: General view of the Yaskawa SERVOPACK CACR-IR 151515FB. This image displays the unit from an angled side, showing multiple connection terminals on the left side and ventilation grilles along the top and front surfaces, indicating its industrial design and cooling features.

Key features include its multi-axis capability, allowing for synchronized control of up to three servo motors, and its durable construction suitable for demanding industrial environments.

Figure 3.2: Side view of the Yaskawa SERVOPACK CACR-IR 151515FB. This perspective highlights a prominent heat sink on one side, essential for thermal management during operation, and additional connection points on the opposite side, emphasizing its robust cooling and connectivity.

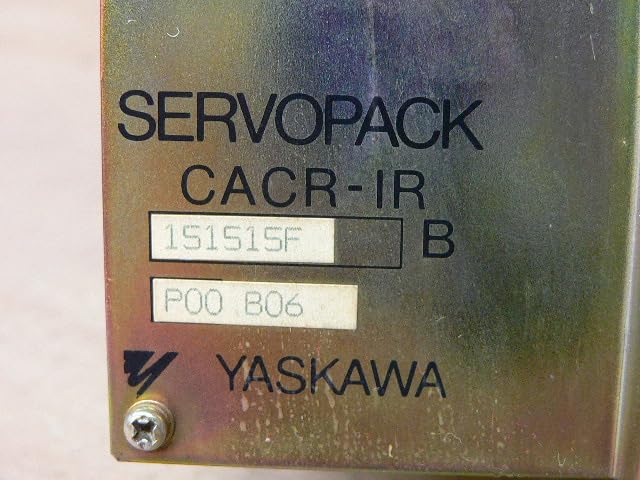

The model number and brand identification are clearly marked on the unit for easy reference.

Figure 3.3: Close-up of the product label on the Yaskawa SERVOPACK. The label clearly displays "SERVOPACK CACR-IR 151515FB" and the "YASKAWA" brand logo, confirming the model and manufacturer for identification and compliance purposes.

4. Setup

Proper setup is crucial for the reliable operation of the SERVOPACK. Follow these general guidelines:

- Mounting: Securely mount the SERVOPACK in a control cabinet or on a panel, ensuring adequate ventilation space around the unit, especially near the heat sink. Use appropriate fasteners for the unit's weight (approximately 22 pounds).

- Power Wiring: Connect the main power supply to the designated terminals. Ensure the voltage and current ratings match the SERVOPACK's specifications. Use appropriate wire gauges and circuit protection devices.

- Motor Wiring: Connect the servo motors to the corresponding motor output terminals. Pay close attention to phase sequence and ensure all connections are tight and secure.

- Feedback Wiring: Connect the motor encoder feedback cables to the SERVOPACK's feedback input terminals. Correct feedback connection is essential for precise control.

- Control Signal Wiring: Connect control signals (e.g., command signals, limit switches, emergency stop) from the host controller to the SERVOPACK's input/output terminals. Refer to the detailed wiring diagrams in the complete technical manual for specific pin assignments.

- Grounding: Establish a proper ground connection for the SERVOPACK chassis to the system's protective earth ground.

5. Operating Instructions

Once the SERVOPACK is correctly installed and wired, follow these steps for initial operation:

- Initial Power-Up: Apply power to the SERVOPACK. Observe the status indicators for any error codes or warnings.

- Parameter Settings: Configure the necessary operating parameters using the appropriate programming tool or interface. This includes motor parameters, control gains, and operational limits.

- Test Run: Perform a low-speed, no-load test run of the connected servo motors to verify correct rotation and response.

- Tuning: Adjust the servo gains to achieve optimal performance for your specific application. This may involve auto-tuning functions or manual adjustments.

- System Integration: Integrate the SERVOPACK with the overall control system, ensuring proper communication and command execution.

Always monitor the system during initial operation and make adjustments as needed to ensure stable and safe performance.

6. Maintenance

Regular maintenance helps ensure the longevity and reliable operation of your SERVOPACK.

- Inspection: Periodically inspect the SERVOPACK for signs of dust accumulation, loose connections, discolored components, or unusual odors.

- Cleaning: Keep the unit clean and free from dust and debris. Use compressed air to clear ventilation grilles, ensuring proper airflow for cooling. Ensure power is off before cleaning.

- Connection Checks: Verify that all electrical connections are tight and secure. Loose connections can lead to intermittent operation or overheating.

- Environmental Control: Maintain the operating environment within specified temperature and humidity ranges to prevent component degradation.

- Capacitor Life: Electrolytic capacitors have a finite lifespan. Consider periodic replacement based on operating hours and environmental conditions, as recommended by the manufacturer.

7. Troubleshooting

If the SERVOPACK exhibits abnormal behavior, consult the following general troubleshooting steps. For detailed error codes and specific solutions, refer to the comprehensive Yaskawa technical documentation.

- No Power: Check the main power supply, circuit breakers, and all power wiring connections.

- Motor Not Moving: Verify motor wiring, feedback connections, and control signal inputs. Check for emergency stop activation or limit switch engagement.

- Overcurrent/Overload: This may indicate a motor problem, incorrect parameter settings, or excessive load. Check motor current, load conditions, and SERVOPACK parameters.

- Overvoltage/Undervoltage: Check the input power supply voltage. Overvoltage can occur during deceleration if regeneration is not handled correctly.

- Encoder Error: Inspect encoder wiring for damage or loose connections. Verify encoder type and settings in the SERVOPACK parameters.

- Unstable Operation: This often points to incorrect servo gain tuning. Re-tune the system or adjust gain parameters.

If the issue persists after basic troubleshooting, contact Yaskawa technical support or a qualified service technician.

8. Specifications

| Specification | Value |

|---|---|

| Model Number | CACR-IR 151515FB |

| Manufacturer | Yaskawa |

| Product Dimensions | 7.09 x 6.3 x 8.27 inches |

| Weight | 22 Pounds |

| ASIN | B00OPH7WLE |

| Type | 3 Axis Servo Drive |

9. Warranty and Support

For specific warranty information regarding the Yaskawa SERVOPACK CACR-IR 151515FB, please refer to the original purchase documentation or contact your authorized Yaskawa distributor or reseller. Warranty terms typically cover manufacturing defects for a specified period from the date of purchase.

For technical support, service, or to obtain detailed wiring diagrams and advanced programming guides, please visit the official Yaskawa website or contact their customer service department. Ensure you have your product model number and serial number available when seeking support.