1. Introduction

This manual provides comprehensive operating instructions for the Amada NC-9EXII Multiple Axis Gauging Machine. It covers essential information regarding control description, operation procedures, special accessories, electrical circuits, and technical specifications. Adherence to these instructions is crucial for safe and efficient operation of the machine.

This manual is intended for qualified personnel responsible for the setup, operation, and maintenance of the NC-9EXII machine.

Figure 1.1: Front cover of the Amada NC-9EXII Operating Instructions Manual. The cover displays the model name "NC-9EXII Multiple Axis Gauging" and "Operating Instructions" prominently, along with the Amada logo at the bottom.

2. Control Description

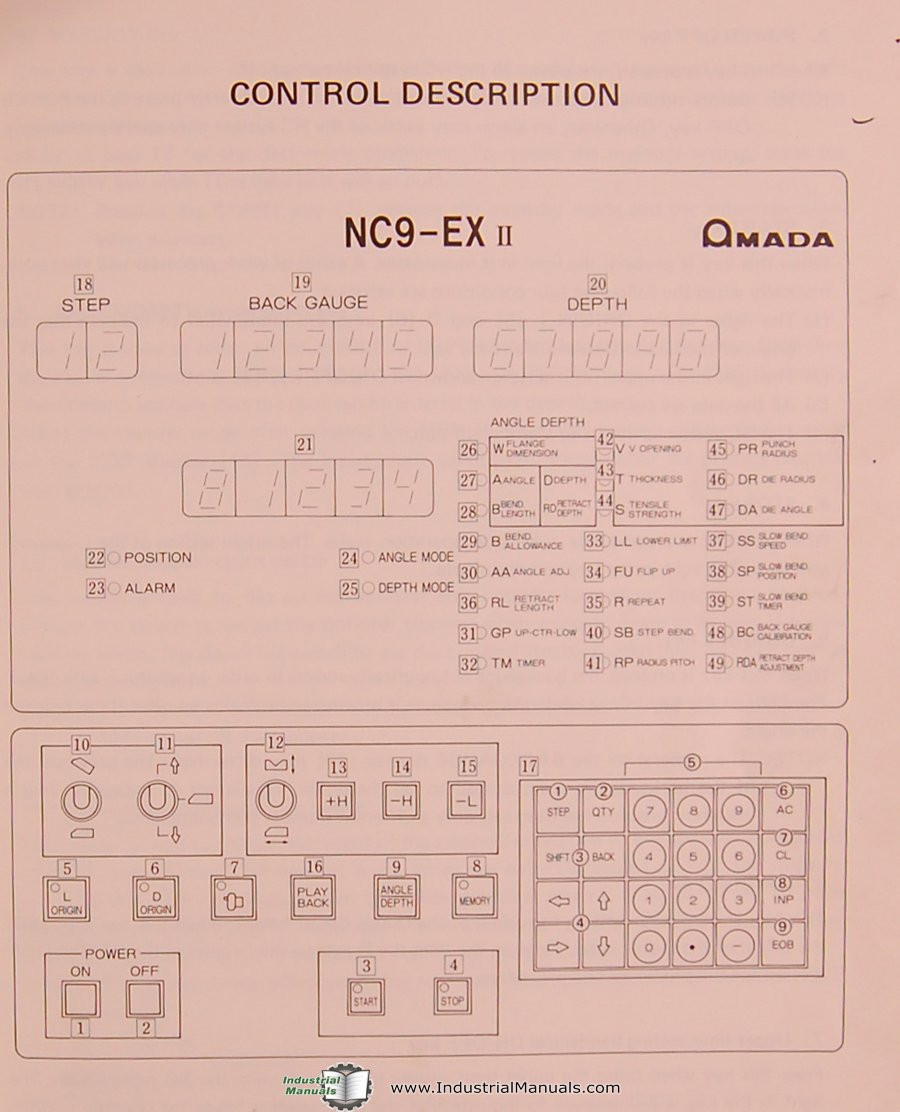

This section details the various controls and indicators on the Amada NC-9EXII machine, essential for understanding its functionality and operation.

Figure 2.1: Overview of the NC-9EXII control panel. This image illustrates the layout of the control panel, including numerical displays for STEP, BACK GAUGE, and DEPTH, along with various function buttons and indicators such as ANGLE DEPTH, BEND LENGTH, and ALARM. A keypad for input is also visible.

2.1. Main Control Elements

- STEP (18): Indicates the current program step.

- BACK GAUGE (19): Displays the back gauge position.

- DEPTH (20): Shows the bending depth.

- W.T. DIMENSION (21): Displays the workpiece thickness dimension.

- POSITION (22): Indicates the current machine position.

- ALARM (23): Illuminates when an error or fault occurs.

2.2. Function Keys and Indicators

- ANGLE DEPTH (26): For setting the desired bending angle depth.

- BEND LENGTH (28): Input for the required bend length.

- LL LOWER LIMIT (33): Sets the lower limit for operation.

- SP SLOW BEND (38): Activates slow bending mode.

- TM TIMER (32): Timer function.

- POWER ON/OFF: Main power control for the machine.

3. Operation

This section outlines the procedures for operating the Amada NC-9EXII, including preparations, automatic operation, and alarm handling.

3.1. Preparations for Operation

- Ensure the machine is connected to a stable power supply.

- Verify all safety guards are in place and functional.

- Check for any obstructions in the working area.

- Perform a visual inspection of the machine for any visible damage or loose components.

- Turn on the main power switch.

3.2. Automatic Operation

The NC-9EXII supports automatic operation for repetitive tasks. Follow these steps:

- Input the desired program parameters using the control panel.

- Select the "Automatic Operation" mode.

- Initiate the cycle by pressing the START button.

- Monitor the machine's progress and ensure proper material feeding.

3.3. Alarm Number Display

When an alarm occurs, the ALARM indicator will illuminate, and an alarm number will be displayed. Refer to the troubleshooting section for a list of alarm codes and their corresponding solutions.

4. Special Accessories

The Amada NC-9EXII can be enhanced with various special accessories to expand its capabilities and improve operational efficiency.

4.1. Cassette Tape Memory Device

This accessory allows for the storage and retrieval of machine programs and settings using cassette tapes. This is particularly useful for backing up critical operational data or transferring programs between machines.

- Function: Program storage and recall.

- Usage: Insert cassette, select save/load function from control panel.

4.2. Remote-Controlled Upper Limit Setting Unit

This unit provides remote adjustment of the upper limit for the gauging process, offering greater flexibility and precision during setup and operation.

- Function: Remote adjustment of upper limit.

- Benefits: Enhanced precision, reduced manual intervention.

4.3. Foot Switch

A foot switch can be integrated for hands-free operation of certain machine functions, improving operator convenience and safety.

- Function: Hands-free operation of selected functions.

- Benefits: Increased efficiency and safety.

5. Electrical Circuit with Diagrams

This section provides detailed information regarding the electrical circuitry of the Amada NC-9EXII machine, including diagrams. This information is critical for qualified technicians performing maintenance, troubleshooting, or repairs.

Warning: Only qualified and authorized personnel should attempt to work with the machine's electrical systems. Disconnect power before servicing.

The manual includes comprehensive electrical schematics covering:

- Power supply connections

- Control circuit diagrams

- Motor and actuator wiring

- Sensor and feedback loop diagrams

For specific diagrams and component identification, refer to pages 32 onwards in the physical manual.

6. Specifications

This section outlines the technical specifications of the Amada NC-9EXII Multiple Axis Gauging Machine.

| Feature | Detail |

|---|---|

| Model | NC-9EXII |

| Type | Multiple Axis Gauging Machine |

| Manual Pages | 45 Printed Pages |

| Included Sections | Control Description, Operation, Special Accessories, Electrical Circuit with Diagrams, Specifications |

| Inventory # | A-102SB |

For detailed dimensional, power, and performance specifications, refer to the dedicated specifications section within the manual, starting on page 45.

7. Maintenance and Troubleshooting

Regular maintenance is crucial for the longevity and optimal performance of the Amada NC-9EXII. This section provides general guidelines for maintenance and troubleshooting common issues.

7.1. Routine Maintenance

- Daily: Clean the machine exterior and work area. Check for any loose fasteners.

- Weekly: Inspect all cables and hoses for wear or damage. Lubricate moving parts as specified in the detailed maintenance schedule (refer to the full manual).

- Monthly: Check calibration of gauging systems. Verify emergency stop functionality.

7.2. Troubleshooting Common Issues

This table provides a basic guide for troubleshooting. For complex issues or alarm codes, consult the detailed troubleshooting section in the complete manual.

| Problem | Possible Cause | Solution |

|---|---|---|

| Machine not powering on | No power supply; Emergency stop engaged | Check power connection; Release emergency stop button |

| Inaccurate gauging | Calibration required; Sensor obstruction | Perform calibration procedure; Clean sensors |

| Alarm displayed | Specific error condition | Note alarm code and consult manual's alarm list for resolution |

8. Warranty and Support

This operating instructions manual itself does not contain specific warranty details for the Amada NC-9EXII machine. For information regarding product warranty, technical support, or service, please refer to the original purchase documentation or contact Amada directly.

Amada Customer Support:

- Visit the official Amada website for contact information and service centers.

- Refer to your sales invoice or warranty card for specific regional support details.