1. Introduction

This manual provides instructions for the proper use and maintenance of the Lang Tools Metric Thread Restorer Tap Set, model 2588. This set is designed to clean and restore damaged or corroded internal metric threads, ensuring proper fastener engagement and torque application. It is important to understand that these tools are for restoring existing threads and are not intended for cutting new threads or significantly re-tapping severely damaged threads.

2. Safety Information

- Always wear appropriate personal protective equipment, including safety glasses, when using hand tools.

- Ensure the workpiece is securely held to prevent movement during operation.

- Do not use excessive force. Forcing the thread restorer can damage the tool or the workpiece.

- Keep hands and fingers clear of moving parts and sharp edges.

- Use the correct size thread restorer for the thread being repaired. Using an incorrect size can cause further damage.

- These tools are not insulated. Avoid contact with live electrical circuits.

3. Package Contents

The Lang Tools Metric Thread Restorer Tap Set 2588 includes the following items:

- 6 x Metric Thread Restorers (various sizes)

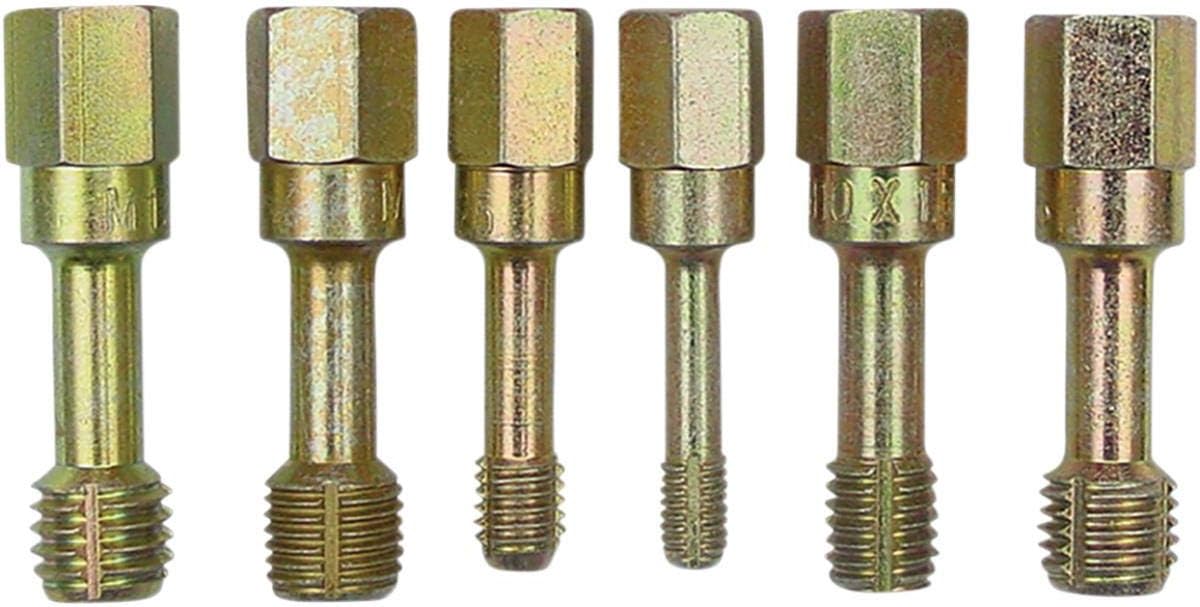

This image displays the complete Lang Tools Metric Thread Restorer Tap Set 2588. The set includes six distinct metric thread restorers, each featuring a hexagonal drive head and a fluted, threaded body designed for cleaning and repairing damaged internal threads. The tools are finished in a gold-colored coating, indicating a protective treatment.

4. Setup

- Identify Thread Size: Determine the correct metric thread size and pitch of the damaged thread. Select the corresponding thread restorer from the set.

- Clean Area: Remove any loose debris, dirt, or rust from the area around the damaged thread.

- Apply Lubricant: Apply a suitable cutting fluid or lubricant to the thread restorer and the damaged thread. This reduces friction, prevents galling, and aids in debris removal.

5. Operating Instructions

Follow these steps to effectively restore damaged metric threads:

- Insert Restorer: Carefully align the chosen thread restorer with the damaged thread. Ensure it is straight and not cross-threaded.

- Engage Thread: Gently turn the thread restorer clockwise (for right-hand threads) by hand or with a suitable wrench on its hexagonal head. Apply light, consistent pressure.

- Advance and Retract: Turn the restorer approximately one-half to one full turn clockwise, then back it out a quarter turn counter-clockwise. This action helps to clear debris from the flutes of the tool.

- Continue Process: Repeat the advance and retract motion, gradually working the thread restorer deeper into the damaged thread until it passes through the entire length of the thread.

- Remove Tool: Once the thread is restored, carefully turn the tool counter-clockwise to remove it from the workpiece.

- Clean Thread: Use compressed air or a brush to remove any remaining debris from the newly restored thread.

- Test: Test the restored thread with a bolt or fastener of the correct size to ensure smooth engagement.

Important Note: If the thread restorer binds or requires excessive force, stop immediately. The thread damage may be too severe for restoration, or the tool may be misaligned. Forcing the tool can cause breakage or further damage to the workpiece.

6. Maintenance

- Cleaning: After each use, clean the thread restorers thoroughly to remove any metal shavings, lubricant residue, or dirt. A wire brush can be used for stubborn debris.

- Lubrication: Apply a light coat of rust-preventative oil to the tools before storage, especially if they will not be used for an extended period.

- Storage: Store the thread restorers in their original case or a suitable tool organizer to protect them from damage and corrosion. Keep them in a dry environment.

- Inspection: Periodically inspect the tools for signs of wear, damage, or dullness. Damaged tools should be replaced to ensure effective and safe operation.

7. Troubleshooting

| Problem | Possible Cause | Solution |

|---|---|---|

| Thread restorer not engaging | Incorrect size selected; severe thread damage; misalignment. | Verify correct thread size; assess thread damage (may require re-tapping or insert); ensure proper alignment. |

| Difficulty turning the tool | Insufficient lubrication; excessive debris; cross-threading; thread damage too severe. | Apply more lubricant; retract and clear debris; ensure correct alignment; if damage is severe, consider alternative repair methods. |

| Tool breakage | Excessive force applied; severe thread damage; tool defect. | Avoid excessive force; replace broken tool; assess thread damage for alternative repair. |

8. Specifications

- Brand: Lang

- Model: 2588

- Product Type: Metric Thread Restorer Tap Set

- Number of Pieces: 6

- Product Dimensions: 4.6 x 4.5 x 0.7 inches

- Item Weight: 4.8 ounces

- Included Components: 6 Metric Thread Restorers

9. Warranty and Support

For information regarding warranty coverage, product support, or to inquire about replacement parts, please contact Lang Tools customer service directly. You can find more information by visiting the official Lang Store or their official website.