8310-845

Programmable, 3-Relay, Advanced

Logic Module & Restroom Controller

(US version)

75.5954.03 ALLEGION 8310-845 20220727

75.5954.03 ALLEGION 8310-845 20220727

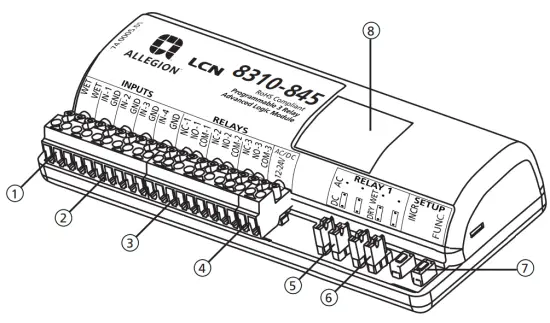

- WET input

- DRY inputs

- Relay outputs

- Power input

- AC/DC jumpers

- WET/DRY jumpers

- Programming buttons

- 7-segment display

PRECAUTIONS

![]() CAUTION

CAUTION

- Shut off all power going to header before attempting any wiring procedures.

- Maintain a clean & safe environment when working in public areas.

- Constantly be aware of pedestrian traffic around the door area.

- Always stop pedestrian traffic through the doorway when performing tests that may result in unexpected reactions by the door.

- ESD (electrostatic discharge): Circuit boards are vulnerable to damage by electrostatic discharge. Before handling any board ensure you dissipate your body’s ESD charge.

- Always check placement of all wiring before powering up to ensure that moving door parts will not catch any wires and cause damage to equipment.

- Ensure compliance with all applicable safety standards (i.e. ANSI A156.10) upon completion of installation.

- DO NOT attempt any internal repair of the components. All repairs and/or component replacements must be performed by Allegion, Inc. Unauthorized disassembly or repair:

1. May jeopardize personal safety and may expose one to the risk of electrical shock.

2. May adversely affect the safe and reliable performance of the product resulting in a voided warranty.

JUMPERS

PRECAUTIONS TO OBSERVE WHEN USING A ‘WET’ OUTPUT

Never change the jumper settings when the module has power connected to it or when a load is applied.

Never allow 2 different voltage sources to be connected to the load (electric strike for example) at the same time. This can result in serious damage to equipment.

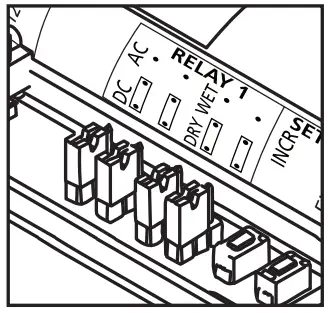

Always move both jumpers when changing a jumper set.

If an EL device is being powered by a separate power source, DO NOT select the ‘WET’ output option on the 8310-845. If ‘WET’ is selected, the next activation of the module will send a voltage to the load and if there is already a voltage being applied from another source, the 8310-845 and possibly the load will be permanently damaged.

When using the ‘WET’ output option on the 8310-845, set all desired switch positions (‘WET’ – ‘DRY’ and AC – DC) before the module is powered and before any loads are applied.

When DC ‘WET’ output is selected, COM terminal is positive (+) and the ground (-) is switched between NO and NC.

Ensure there is no other voltage connected to the load. Whatever the input voltage is at the 8310-845, the output will correspond. The following can also be observed:

1. If voltage input at the 8310-845 is AC, then output selection can be AC or DC.

2. If voltage input at the 8310-845 is DC, then output selection can only be DC.

3. The maximum load applied to Relay 1 should never exceed 1A. If more than one device is to be connected, add the consumption values together for a total value. If current is excessive, damage to equipment can result.

4. On the 8310-845, the ‘WET’ output is only available at Relay 1.

When supplying 8310-845 with AC input voltage and selecting Relay 1 output for ‘WET’ and DC OUTPUT VOLTAGE, note that the resulting DC output will be the rectified AC input voltage and therefore, about 40% higher than the AC input voltage (rms).

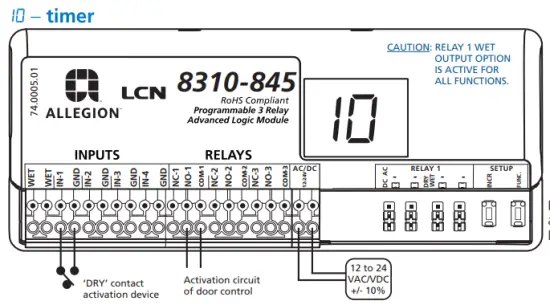

CAUTION: Relay 1 ‘WET’ OPTION IS ACTIVE FOR ALL FUNCTIONS!

| RELAY 1 OUTPUT | DRY/WET JUMPER2 | AC OUTPUT VOLTAGES | DC OUTPUT VOLTAGE) |

| DRY | both jumpers set to DRY | N/A | N/A |

| WET’ | both jumpers set to WET | both jumpers set to AC | both jumpers set to DC |

NOTES:

- “WET output” allows the 8310-845 to supply a voltage output of up to 1 A on relay 1 for powering Maglocks or Electric Strikes directly from the 8310-845.

Rating of power supply which powers the 8310-845 must be at least 1 A. - Default jumper settings make relay 1 DRY.

- AC voltage only available if 8310-845 is powered by AC voltage.

- DC voltage available if 8310-845 is powered by AC or DC voltage.

WIRING

Each 8310-845 function is wired differently. Please review and follow the appropriate wiring diagram shown for each function.

FUNCTIONS

| FUNCTION | DESCRIPTION | LOGIC |

| timer | • activation of relay 1 via trigger of input 1 • reverse logic available |

|

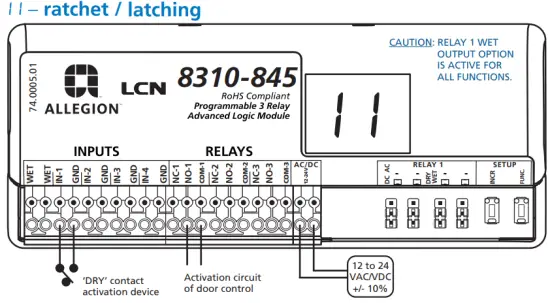

| ratchet / latching | • ratchet/latching of relay 1 via trigger of input 1 | |

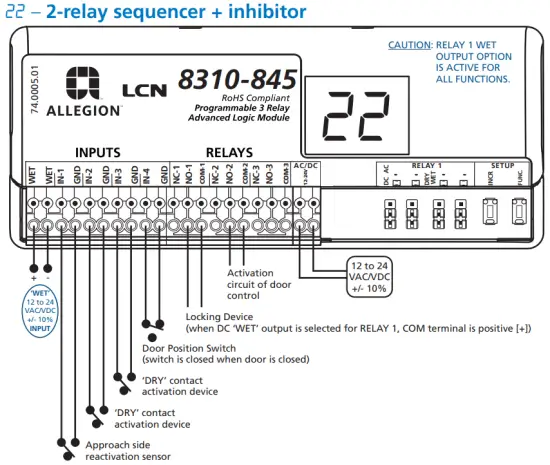

| 2-relay sequencer + inhibitor | • sequence of relay 1 and relay 2 with inhibiting of input 1 until input 2, input 3, or WET input is triggered • activation of input 4 reinhibits input 1 |

|

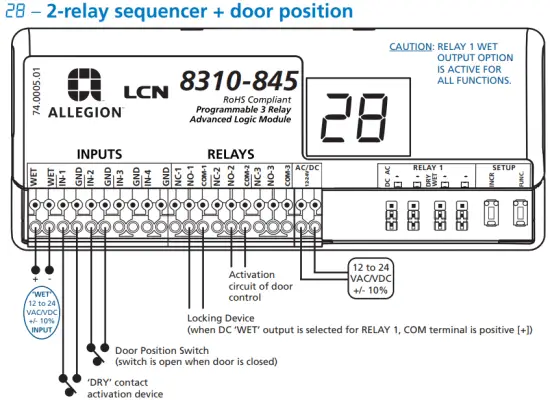

| 2-relay sequencer + door position | • sequence of relay 1 and relay 2 via trigger of input 1 or WET input • input 2 allows delay to run when open but not when closed |

|

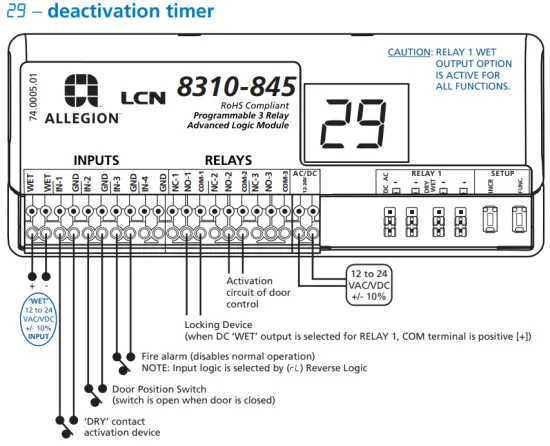

| deactivation timer | • sequence of relay 1 and relay 2 via trigger of input 1 or WET input • input 2, once opened after sequence, allows relay 1 to deactivate • input 2 allows delay to run when open but not when closed • input 3 disables sequence, reverse logic available |

|

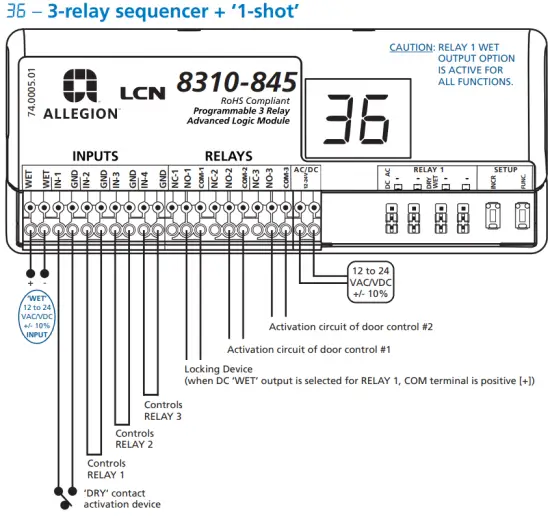

| 3-relay sequencer + ‘1-shot’ | • sequence of relay 1 and relay 2 and relay 3 via trigger of input 1 or WET input • relay 1, relay 2, and relay 3 can be maintained or ‘1-shot’ |

|

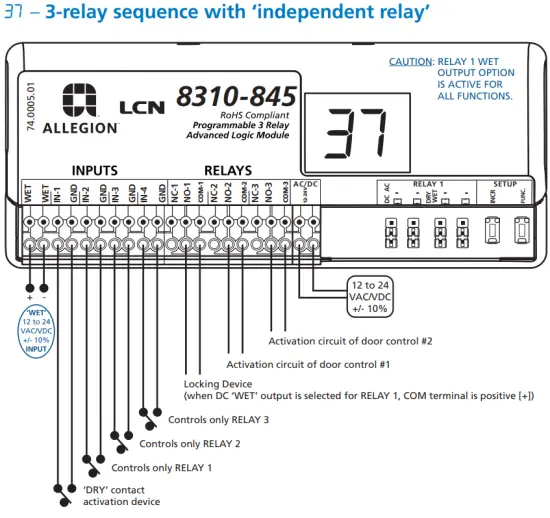

| 3-relay sequence with ‘independent relay’ | • sequence of relay 1 and relay 2 and relay 3 via trigger of input 1 or WET input • relay 1, relay 2, and relay 3 can be ‘independent or sequenced |

|

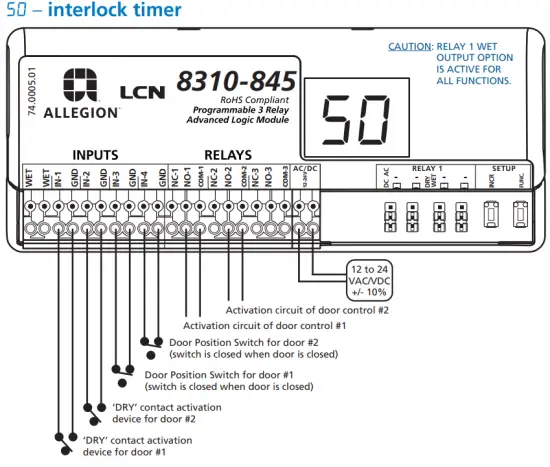

| interlock timer | • interlock of relay 1 and relay 2 via trigger of input 1 and input 2, respectively | |

| interlock ratchet /latching | • interlock ratchet of relay 1 and relay 2 via trigger of input 1 and input 2, respectively | |

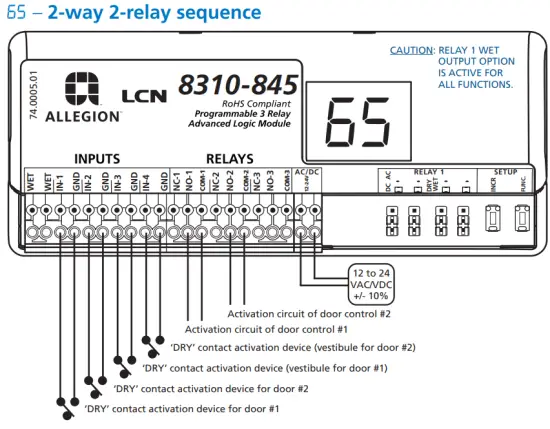

| 2-way 2-relay sequence | • sequence of relay 1 and relay 2 via trigger of input 1 • sequence of relay 2 and relay 1 via trigger of input 2 • input 3 triggers relay 1 individually, input 4 triggers relay 2 individually |

|

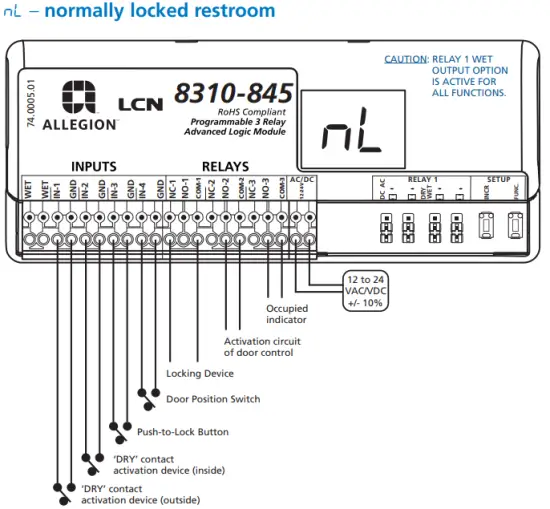

| normally locked restroom | • sequence of relay 1 (lock), relay 2 (door), and relay 3 (occupied indicators) for normally locked, single occupancy restrooms | |

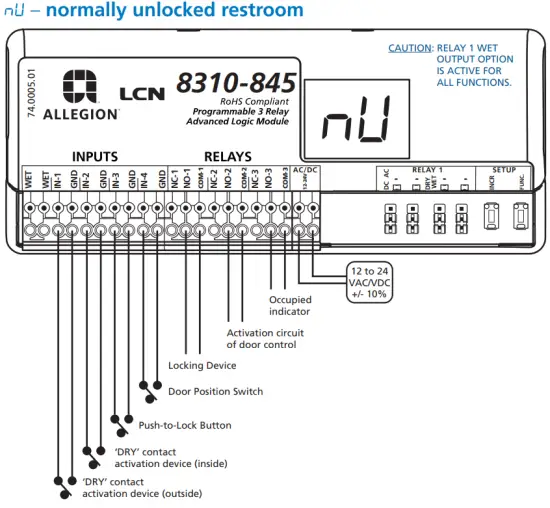

| normally unlocked restroom | • sequence of relay 1 (lock), relay 2 (door), and relay 3 (occupied indicators) for normally unlocked, single occupancy restrooms | |

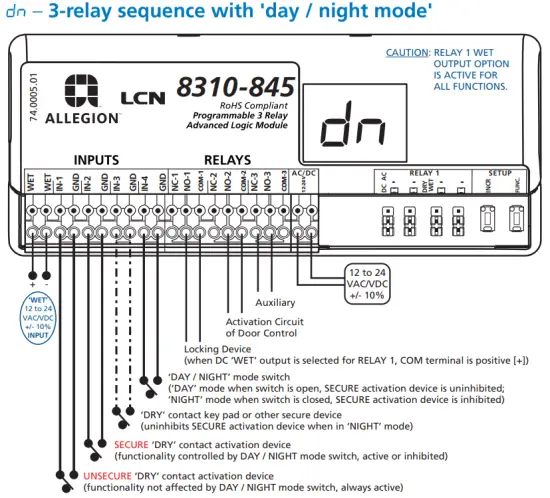

| 3-relay sequencer 4- ‘day / night mode’ | • sequence of relay 1 and relay 2 and relay 3 via trigger of input 1 or WET input • input 2 operation dependent upon input 4 (‘day / night mode’) |

|

| disable | • 8310-845 disabled • 00 is the default setting and has no assigned function |

PARAMETERS

| PARAMETER | DESCRIPTION | LOGIC |

| relay 1 hold time | 00 – 60 seconds countdown begins AFTER release of input 1 or WET input | |

| relay 2 hold time | 00 – 60 seconds countdown begins AFTER d1 (delay between relay 1 & relay 2) expires | |

| relay 3 hold time | 00 – 60 seconds countdown begins AFTER d2 (delay between relay 1 & relay 3) expires | |

| delay between relay 1 & relay 2 |

00 – 60, _1 (1/4), _2 (1/2), _3 (3/4) seconds delay begins AT activation of input 1 or WET input | |

| delay between relay 1 & relay 3 |

00 – 60, _1 (1/4), _2 (1/2), _3 (3/4) seconds delay begins AT activation of input 1 or WET input | |

| reverse logic | 00 = normal logic input 1 trigger must be NO and close its contact to trigger 01 = reverse logic input 1 trigger must be NC and open its contact to trigger |

|

| no parameters | no parameters available for selected function |

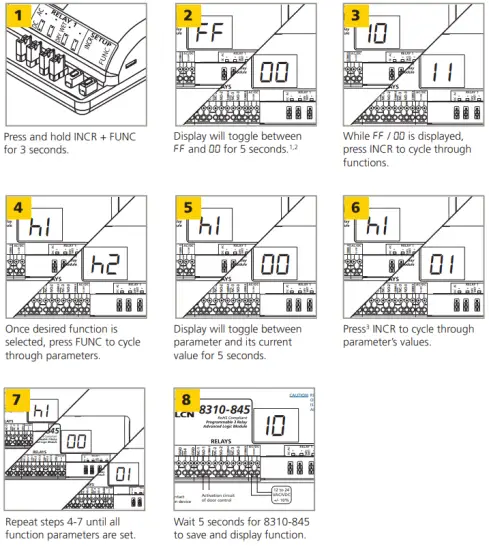

PROGRAMMING

![]() Relay hold time(s) and delay time(s) MUST be set for any relay that is to be utilized.

Relay hold time(s) and delay time(s) MUST be set for any relay that is to be utilized.

Ex: For function 36, if using only relay 1, h1 must be set…if using relay 1 and relay 2, h1, h2, and d1 must be set.

NOTES:

- Function 00 disables the 8310-845.

- “

” means no parameters are applicable for the selected function.

” means no parameters are applicable for the selected function. - Pressing and holding INCR will rapid cycle.

PROGRAMMING PARAMETERS

* see page 3 for specific parameter details *

AVAILABLE PARAMETERS:

![]() – relay 1 hold time

– relay 1 hold time

![]() – reverse logic

– reverse logic

1. Trigger INPUT 1.

• RELAY 1 will close and hold for time h1.

FUNCTION ![]() NOTE: Reverse logic allows for a Normally Closed (NC) INPUT 1.

NOTE: Reverse logic allows for a Normally Closed (NC) INPUT 1.

AVAILABLE PARAMETERS:

NONE

- Trigger INPUT 1.

• RELAY 1 will close and hold indefinitely. - Trigger INPUT 1.

• RELAY 1 will open.

AVAILABLE PARAMETERS:

![]() – relay 1 hold time

– relay 1 hold time

![]() – relay 2 hold time

– relay 2 hold time

![]() – delay between relays 1 & 2

– delay between relays 1 & 2

![]() must be greater than d1 when using an electric lock

must be greater than d1 when using an electric lock

- Trigger INPUT 2, 3, or ‘WET’.

• RELAY 1 will close and hold for time h1.

• RELAY 2 will close after time delay d1 and hold for time .

.

FUNCTION ![]() NOTE: Ensure INPUT 1 does not initiate the sequence and that INPUT 4 is closed when the door is closed.

NOTE: Ensure INPUT 1 does not initiate the sequence and that INPUT 4 is closed when the door is closed.

AVAILABLE PARAMETERS:

![]() – relay 1 hold time

– relay 1 hold time

![]() – relay 2 hold time

– relay 2 hold time

![]() – delay between relays 1 & 2

– delay between relays 1 & 2

![]() must be greater than

must be greater than ![]() when using an electric lock

when using an electric lock

1. Trigger INPUT 1 or ‘WET’.

• RELAY 1 will close and hold for time h1.

• RELAY 2 will close after time delay d1 and hold for time ![]() .

.

FUNCTION ![]() NOTE: INPUT 2 allows the delay to run when the contact is open but triggers RELAY 2 immediately when the contact is closed.

NOTE: INPUT 2 allows the delay to run when the contact is open but triggers RELAY 2 immediately when the contact is closed.

AVAILABLE PARAMETERS:

![]() – relay 1 hold time

– relay 1 hold time

![]() – relay 2 hold time

– relay 2 hold time

![]() – delay between relays 1 & 2

– delay between relays 1 & 2

![]() – reverse logic

– reverse logic

![]() must be greater than

must be greater than ![]() when using an electric lock

when using an electric lock

1. Trigger INPUT 1 or ‘WET’.

• RELAY 1 will close and hold for time ![]() .

.

• RELAY 2 will close after time delay d1 and hold for time h2.

FUNCTION ![]() NOTE: INPUT 2 deactivates RELAY 1 once INPUT 2 is opened (and after the sequence has run).

NOTE: INPUT 2 deactivates RELAY 1 once INPUT 2 is opened (and after the sequence has run).

INPUT 2 allows the delay to run when the contact is open, but triggers RELAY 2 immediately when the contact is closed. INPUT 3 disables the sequence.

AVAILABLE PARAMETERS:

![]() – relay 1 hold time

– relay 1 hold time

![]() – relay 2 hold time

– relay 2 hold time

![]() – relay 3 hold time

– relay 3 hold time

![]() – delay between relays 1 & 2

– delay between relays 1 & 2

![]() – delay between relays 1 & 3

– delay between relays 1 & 3

![]() must be greater than

must be greater than ![]() when using an electric lock

when using an electric lock

1. Trigger INPUT 1 or ‘WET’.

• RELAY 1 will close and hold for time ![]() .

.

• RELAY 2 will close after time delay d1 and hold for time ![]() .

.

• RELAY 3 will close after time delay d2 and hold for time ![]() .

.

FUNCTION ![]() NOTE: If INPUT 1 or ‘WET’ is maintained, jumping INPUT 2, 3, and/or 4 will allow RELAY 1, 2, and/or 3 (respectively) to close, run the hold time and then open. If no jumpers are set, RELAYS 1, 2, and/ or 3 will close, hold and not time out (open, i.e. 1-shot) until INPUT 1 or ‘WET’ is released.

NOTE: If INPUT 1 or ‘WET’ is maintained, jumping INPUT 2, 3, and/or 4 will allow RELAY 1, 2, and/or 3 (respectively) to close, run the hold time and then open. If no jumpers are set, RELAYS 1, 2, and/ or 3 will close, hold and not time out (open, i.e. 1-shot) until INPUT 1 or ‘WET’ is released.

AVAILABLE PARAMETERS:

![]() – relay 1 hold time

– relay 1 hold time

![]() – relay 2 hold time

– relay 2 hold time

![]() – relay 3 hold time

– relay 3 hold time

![]() – delay between relays 1 & 2

– delay between relays 1 & 2

![]() – delay between relays 1 & 3

– delay between relays 1 & 3

![]() must be greater than

must be greater than ![]() when using an electric lock

when using an electric lock

- Trigger INPUT 1 or ‘WET’.

• RELAY 1 will close and hold for time .

.

• RELAY 2 will close after time delay d1 and hold for time .

.

• RELAY 3 will close after time delay d2 and hold for time .

. - Trigger INPUT 2.

• RELAY 1 will close and hold for time .

. - Trigger INPUT 3.

• RELAY 2 will close and hold for time .

. - Trigger INPUT 4.

• RELAY 3 will close and hold for time .

.

AVAILABLE PARAMETERS:

![]() – relay 1 hold time

– relay 1 hold time

![]() – relay 2 hold time

– relay 2 hold time

- Trigger INPUT 1.

• RELAY 1 will close and hold for time .

. - Trigger INPUT 2.

• RELAY 2 will close and hold for time .

.

FUNCTION ![]() NOTE: If INPUT 1 is triggered, INPUT 2 and RELAY 2 will be inhibited until INPUT 3 (door position switch) is closed. Conversely, if INPUT 2 is triggered, INPUT 1 and RELAY 1 will be inhibited until INPUT 4 (door position switch) is closed.

NOTE: If INPUT 1 is triggered, INPUT 2 and RELAY 2 will be inhibited until INPUT 3 (door position switch) is closed. Conversely, if INPUT 2 is triggered, INPUT 1 and RELAY 1 will be inhibited until INPUT 4 (door position switch) is closed.

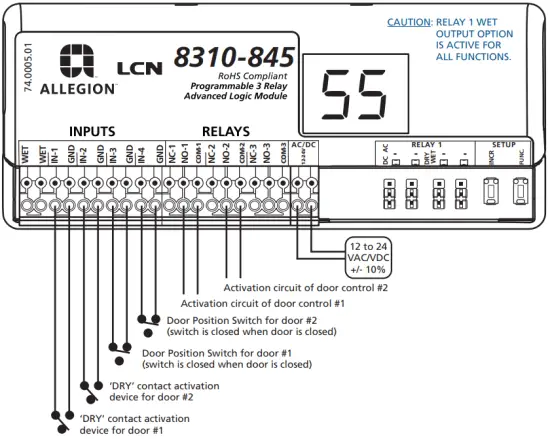

55 – interlock ratchet / latching

AVAILABLE PARAMETERS:

NONE

- Trigger INPUT 1.

• RELAY 1 will close and hold until indefinitely. - Trigger INPUT 1.

• RELAY 1 will open. - Trigger INPUT 2.

• RELAY 2 will close and hold indefinitely. - Trigger INPUT 2.

• RELAY 2 open.

FUNCTION ![]() NOTE: If INPUT 1 is triggered, INPUT 2 and RELAY 2 will be inhibited until INPUT 3 (door position switch) is closed. Conversely, if INPUT 2 is triggered, INPUT 1 and RELAY 1 will be inhibited until INPUT 4 (door position switch) is closed.

NOTE: If INPUT 1 is triggered, INPUT 2 and RELAY 2 will be inhibited until INPUT 3 (door position switch) is closed. Conversely, if INPUT 2 is triggered, INPUT 1 and RELAY 1 will be inhibited until INPUT 4 (door position switch) is closed.

AVAILABLE PARAMETERS:

![]() – relay 1 hold time

– relay 1 hold time

![]() – relay 2 hold time

– relay 2 hold time

![]() – delay between relays 1 & 2

– delay between relays 1 & 2

![]() – delay between relays 2 & 1

– delay between relays 2 & 1

- Trigger INPUT 1.

• RELAY 1 will close and hold for time .

.

• RELAY 2 will close after time delay and hold for time

and hold for time  .

. - Trigger INPUT 2.

• RELAY 2 will close and hold for time .

.

• RELAY 1 will close after time delay and hold for time

and hold for time  .

. - Trigger INPUT 3.

• RELAY 1 will close and hold for time .

. - Trigger INPUT 4.

• RELAY 2 will close and hold for time .

.

AVAILABLE PARAMETERS:

![]() – relay 1 hold time

– relay 1 hold time

![]() – relay 2 hold time

– relay 2 hold time

![]() – delay between relays 1 & 2

– delay between relays 1 & 2

![]() must be greater than

must be greater than ![]()

- Trigger INPUT 1.

• RELAY 1 will close and hold for time .

.

• RELAY 2 will close after time delay and hold for time

and hold for time  .

. - Trigger INPUT 3.

• RELAY 3 will close and INPUT 1 will be inhibited. - Trigger INPUT 2.

• RELAY 1 will close and hold for time .

.

• RELAY 2 will close after time delay and hold for time

and hold for time  .

.

• RELAY 3 will open.

FUNCTION ![]() NOTE: INPUT 3 will not function unless INPUT 4 is closed. INPUT 4 should be closed when door is closed.

NOTE: INPUT 3 will not function unless INPUT 4 is closed. INPUT 4 should be closed when door is closed.

AVAILABLE PARAMETERS:

![]() – relay 2 hold time

– relay 2 hold time

![]() – delay between relays 1 & 2

– delay between relays 1 & 2

- Trigger INPUT 1.

• RELAY 2 will close and hold for time .

. - Trigger INPUT 3.

• RELAY 1 and 3 will close and INPUT 1 will be inhibited. - Trigger INPUT 2.

• RELAY 1 will open.

• RELAY 2 will close after time delay and hold for time

and hold for time  .

.

• RELAY 3 will open.

FUNCTION ![]() NOTE: INPUT 3 will not function unless INPUT 4 is closed. INPUT 4 should be closed when door is closed.

NOTE: INPUT 3 will not function unless INPUT 4 is closed. INPUT 4 should be closed when door is closed.

AVAILABLE PARAMETERS:

![]() – relay 1 hold time

– relay 1 hold time

![]() – relay 2 hold time

– relay 2 hold time

![]() – relay 3 hold time

– relay 3 hold time

![]() – delay between relays 1 & 2

– delay between relays 1 & 2

![]() – delay between relays 1 & 3

– delay between relays 1 & 3

- Trigger INPUT 1, INPUT 2, or ‘WET’.

• RELAY 1 will close and hold for time .

.

• RELAY 2 will close after time delay and hold for time

and hold for time  .

.

• RELAY 3 will close after time delay and hold for time

and hold for time  .

. - Trigger INPUT 3.

• RELAY 1 will close and hold for time .

.

• INPUT 2 will be uninhibited for 5 seconds.

FUNCTION ![]() NOTE: INPUT 2 will only function if INPUT 4 is open.

NOTE: INPUT 2 will only function if INPUT 4 is open.

TEST

Upon completion of jumper settings, wiring, and programming, test the 8310-845 to ensure all function parameters are working correctly and as intended for the specific application.

RELAY STATUS

| STATUS | DESCRIPTION |

| relay 1 closed when wired NO or open when wired NC | |

| relay 2 closed when wired NO or open when wired NC | |

| relay 3 closed when wired NO or open when wired NC | |

| relay 1 and relay 2 closed when wired NO or open when wired NC | |

| relay 1 and relay 3 closed when wired NO or open when wired NC | |

| relay 1, relay 2, and relay 3 closed when wired NO or open when wired NC |

FUNCTION CROSS REFERENCE

| BR3 FUNCTION | BR3-X FUNCTION |

TROUBLESHOOTING

| 8310-845 will not react to any inputs |

Incorrect power | Verify power supply of 12 – 24 VAC/VDC ±10% is wired to correct terminals |

| Not programmed | Ensure a function is programmed, 8310-845 does not show 00, and all ‘h’ values are set to at least 01 | |

| Incorrect wiring | Verify wiring is applied exactly as described for specific function programmed | |

| Defective | Replace | |

| 8310-845 has no output |

Incorrect output devices | Ensure proper devices are connected to outputs for the specific function programmed |

| Not programmed | Ensure a function is programmed, 8310-845 does not show 00, and all ‘h’ values are set to at least 01 | |

| Incorrect wiring | Verify wiring is applied exactly as described for specific function programmed | |

| Incorrect jumper settings | Ensure all jumpers are configured correctly for specific application | |

| Defective | Replace | |

| Output is constant/ maintained |

One or more of IN-1 through IN-4 have shorted | Resolve respective short |

| EEPROM error | Reset and reprogram |

TECHNICAL SPECIFICATIONS

| Supply Voltage | 12 − 24 VAC/VDC ±10% |

| Current Consumption | 30 − 130 mA (DRY output) |

| Temperature Rating | -15 − 150 °F (-26 − 150 °C) If powered by AC voltage and using WET output to convert to DC voltage and current draw of device is greater than 0.9 A, the upper temperature range is 130 °F (54 °C) |

| Input Input 1, 2, 3, 4 WET input |

DRY contact 5 – 24 VAC/VDC ±10% |

| Contact Rating Relay 1 (DRY) Relay 1 (WET) Relay 2 Relay 3 |

3 A @ 24 VAC or 30 VDC 1 A 3 A @ 24 VAC or 30 VDC 1 A @ 24 VAC or 30 VDC |

| Dimensions | 5.2″ x 2.2″ x 1″ (133 mm x 55 mm x 25 mm) |

| Housing | ABS – white translucent |

Specifications are subject to change without prior notice.

All values measured in specific conditions.

INSTALLATION/SERVICE COMPLIANCE EXPECTATIONS

The sensor manufacturer cannot be held responsible for incorrect installations or incorrect adjustments of the sensor/device; therefore, the sensor manufacturer does not guarantee any use of the sensor/device outside of its intended purpose.

The sensor manufacturer strongly recommends that installation and service technicians be AAADM-certifi ed for pedestrian doors, IDAcertifi ed for doors/gates, and factory-trained for the type of door/gate system.

Installers and service personnel are responsible for executing a risk assessment following each installation/service performed, ensuring that the sensor/device system performance is compliant with local, national, and international regulations, codes, and standards.

Once installation or service work is complete, a safety inspection of the door/gate shall be performed per the door/gate manufacturer’s recommendations and/or per AAADM/ANSI/DASMA guidelines (where applicable) for best industry practices. Safety inspections must be performed during each service call – examples of these safety inspections can be found on an AAADM safety information label (e.g. ANSI/DASMA 102, ANSI/DASMA 107 , UL294, UL325, and International Building Code).

Verify that all appropriate industry signage, warning labels, and placards are in place.

![]()

Do not leave problems unresolved. If a satisfactory solution cannot be achieved after troubleshooting a problem, please contact Allegion at 1-877-671-7011. If you must wait for the following workday to call Allegion, leave the door inoperable until satisfactory repairs can be made. Never sacrifice the safe operation of the automatic door or gate for an incomplete solution.

Original Instructions | PLEASE KEEP FOR FURTHER USE – DESIGNED FOR COLOR PRINTING

For more information, visit www.allegion.com.

Documents / Resources

|

ALLEGION 8310-845 Programmable 3-Relay Advanced Logic Module and Restroom Controller [pdf] Instruction Manual 8310-845, 8310-845 Programmable 3-Relay Advanced Logic Module and Restroom Controller, Programmable 3-Relay Advanced Logic Module and Restroom Controller, 3-Relay Advanced Logic Module and Restroom Controller, Logic Module and Restroom Controller, Module and Restroom Controller, Restroom Controller |