INSTRUCTION MANUAL

INSTRUCTION MANUAL

LX2 ModLINK™

MODBUS Communication Interface

RS-485 Buff ered Conversion Module

Specifications

| Input Power | 1A@12-24Vdc Class II / Limited Energy Power Supply |

| Max Device Current | 1A |

| Port 1 | RS-485, 2-Wire Screw Terminals |

| Port 2 | RS-422, RJ-45 (GrowNET™) |

| Data Indicator | Red LED |

| Enclosure Rating | TYPE 12 NEMA |

| Protocols Supported | MODBUS RTU |

![]() Electrical Process Control Equipment File No.: E516807

Electrical Process Control Equipment File No.: E516807

KEEP THESE INSTRUCTIONS

This product is intended for commercial use only.

Warnings & Notices

This is a precision electronic instrument which requires proper installation and care to maintain reliability.

![]() READ & UNDERSTAND ENTIRE MANUAL PRIOR TO INSTALLATION OR OPERATION.

READ & UNDERSTAND ENTIRE MANUAL PRIOR TO INSTALLATION OR OPERATION.

Failure to read, understand and comply with warnings and installation requirements may result in propertydamage, personal injury or death.

![]() WARNING

WARNING

Do not use a power supply other than the intended or included power supply. Do not exceed the maximum ratings on the product serial label or specifi cations listed in this manual. Any power supply with energy levels exceeding the specifications must be current

limited or fused to prevent overcurrent to the device.

![]() NOTICE

NOTICE

GrowNET™ ports use standard RJ-45 connections but are NOT compatible the Ethernet network equipment. Do not connect GrowNET™ ports to Ethernet ports or network switch gear.

![]() DIELECTRIC GREASE

DIELECTRIC GREASE

Dielectric grease is recommended on RJ-45 GrowNET™ connections when used in humid environments.

Place a small amount of grease onto the RJ-45 plug contacts before inserting into the GrowNET™ port.

Non-conductive grease is designed to prevent corrosion from moisture in electrical connectors.

- Loctite LB 8423

- Dupont Molykote 4/5

- CRC 05105 Di-Electric Grease

- Super Lube 91016 Silicone Dielectric Grease

- Other Silicone or Lithium based insulating grease

![]() INDOOR LOCATIONS ONLY

INDOOR LOCATIONS ONLY

This product is designed for indoor mounting only and must be protected from weather and direct sunlight.

![]() WARNING

WARNING

This product may contain chemicals known to the State of California to cause cancer and birth defects or other reproductive harm.

Specifications

Agrowtek’s intelligent sensors, relays and peristaltic pumps are designed to communicate via the standard industrial MODBUS RTU protocol for PLC and OEM control applications.

Each device may be assigned an address of 1-247. Address 254 is a universal broadcast address. Addresses may be sent to the address register by MODBUS command, or confi gured using the LX1 USB link with PC software.

Supported Commands

- 0x01 Read Coils

- 0x03 Read Multiple Registers

- 0x05 Write Single Coil

- 0x06 Write Single Register

| Sensors | Relays | Pumps |

| Read 16bit Signed | Read Coil Status | Read Pump Speed |

| Read 32bit Float | Write Coil Status | Write Pump Speed |

| Write Calibration | Read Close Count | Read Pump Hours |

| Read Manufacturing Info | ||

Refer to individual product manuals for specifi c register maps and descriptions.

Register Types

Data registers are 16 bits wide with addresses using the standard MODICON protocol.

Floating point values use the standard IEEE 32-bit format occupying two contiguous 16 bit registers.

ASCII values are stored with two characters (bytes) per register in hexadecimal format.

Coil registers are single bit values which control and indicate the status of a relay; 1 = on, 0 = off .

Connections

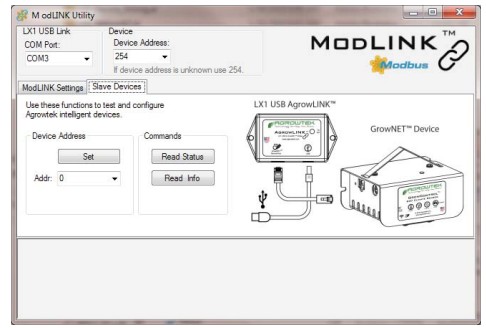

LX1 USB AgrowLINK

Agrowtek’s intelligent devices may be connected to the LX1 USB AgrowLINK for fi rmware updates, calibration, addressing and testing/manual operation.

Standard drivers automatically install in Windows for the LX1 USB AgrowLINK. MODBUS commands may be sent over USB from a terminal or software application. More advanced GrowNET™ commands are also available over the LX1 USB conection.

USB Connection Requirements:

115,200 baud, 8-N-1

LX2 ModLINK™

LX2 ModLINK™ connects Agrowtek’s intelligent sensors, peristaltic dosing pumps, and control relays equipped with a GrowNET™ RJ45 port to a standard RS-485 serial bus for use with the MODBUS RTU protocol. ModLINK is an MCU-buff ered bridge between Agrowtek’s high-speed, full duplex GrowNET™ devices connected with RJ45 cables, to a terminal block for integration with PLC systems. 15kV ESD rated RS485 terminals with 70V fault protection to protect against wiring errors and short circuits. LX2 may be confi gured for 19,200 -115,200 baud rates and any serial data format usung the LX1 USB Link and free PC application.

GrowNET™ Network with HX8 Hubs

GrowNET™ Network with HX8 Hubs

HX8 GrowNET hubs connect multiple devices to a MODBUS network using only one LX2 ModLINK.

HX8 hubs supply power to all 8 ports from one power supply to operate sensors and relays from the GrowNET (Ethernet) cable connection for fast, easy installation (pumps require their own power supply.) X8 Hubs are fully buff ered for excellent signal performance in long distance and distributed applications.

Daisy chain hubs as needed for the number of ports required.

Uses standard RJ45 Ethernet cable for all connections.

Data Format & Speed

The default serial data format for the LX2 ModLINK interface is: 19,200 baud, 8-N-1.

Alternate speeds and formats may be confi gured with the LX1 USB AgrowLINK and the cross-over adapter supplied with the LX2 ModLINK. If the cross-over adapter is not available, a cross-over cable can be fabricated according to the following diagram:

If the cross-over adapter is not available, a cross-over cable can be fabricated according to the following diagram: Open the ModLINK utility and set:

Open the ModLINK utility and set:

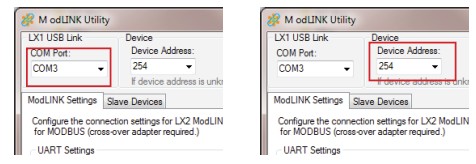

Device Address = 254 (address must be set to 254 to confi gure the LX2.) Download ModLINK Utility

Download ModLINK Utility

Confi gure the serial settings according to your master control device, then press the “Set” button.

“OK” reply confi rms the settings have been successfully confi gured on the LX2.

Setting Device (Slave) Address

The slave ID is stored in each device at address register 1 (40001) and can be modifi ed in several ways.

- Send a modbus command using the broadcast address (254) to modify the value in register 1.

- Use the LX1 USB link connected to a device with the AgrowLINK software utility to set the address.

Set Address via Modbus

Device address 254 is a universal broadcast address which can be used to set an address on a device which has an unknown address or has a 0 address. The device to be confi gured must be the only device on the bus when using the broadcast address or confl icts may occur.

To set a device address of “5”, send the value “5” to register# 1 (40001) using address 254.

Set Address via LX1 USB Link

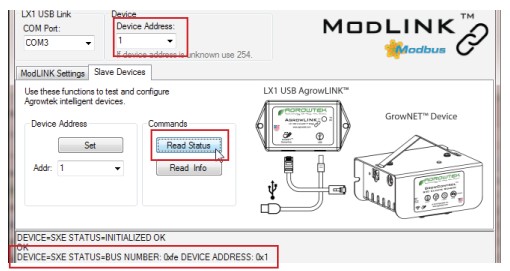

The LX1 USB AgrowLINK may be used to confi gure the LX2 ModLINK and set device (slave) addresss of devices.

The LX1 USB AgrowLINK may be used to confi gure the LX2 ModLINK and set device (slave) addresss of devices.

Download ModLINK Utility

- Connect the GrowNET™ device to the USB AgrowLINK with a standard Ethernet cable.

- Connect the USB AgrowLINK to the PC and allow the drivers to install automatically.

If the drivers do not install automatically download and install them Download Driver.

- The COM port should be automatically selected when the program is opened if the drivers are installed.

Select the COM Port drop-down to refresh and scan for a USB AgrowLINK. - Ensure device address “254” (universal broadcast address) is selected in the Connection box.

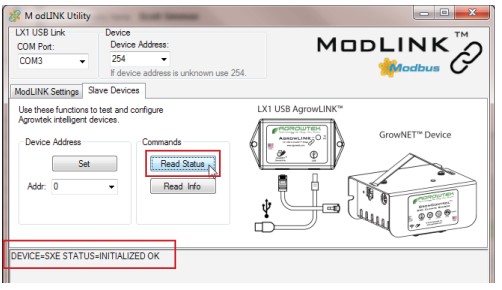

- Check the device connection by clicking the “Read Status” button; you should get a reply with last internal status update from the device.

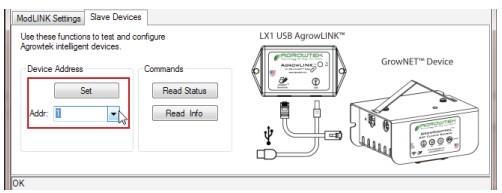

- Set the device address to the desired value by selecting the “Addr.” drop down then press “Set.”

- Verify the new address by selecting the new address in the Connection box then press “Read Status.”

- The device is ready to be deployed on a MODBUS network. Set the Device Address in the Connection box back to “254” to connect to the next device.

Technical Information

Troublshooting

Outputs are not activating, LED does not flash

The status LED will fl ash three times on power-up and each time data is transmitted.

Ensure the input power has 24Vdc and are correctly wired for polarity.

Maintenance & Service

Exterior Cleaning

Exterior may be wiped with a damp cloth wish mild dish detergent, then wiped dry. Disconnect power before cleaning the enclosure to prevent electrical shock.

Storage and Disposal

Storage

Store equipment in a clean, dry environment with ambient temperature between10-50°C.

Disposal

This indsutrial control equipment may contain traces of lead or other metals and environmental contaminants and must not be discarded as unsorted municipal waste, but must be collected separately for the purpose of treatment, recovery and environmentally sound disposal.

Wash hands after handling internal components or PCB’s.

Warranty

Agrowtek Inc. warrants that all manufactured products are, to the best of its knowledge, free of defective material and workmanship and warrants this product for one (1) year from the date of purchase. This warranty is extended to the original purchaser from the date of receipt. This warranty does not cover damages from abuse, accidental breakage, or units that have been modifi ed, altered, or installed in a manner other than that which is specifi ed in the installation instructions. This warranty is applicable only to products that have been properly stored, installed, and maintained per the installation and operation manual and used for their intended purpose. This limited warranty does not cover products installed in or operated under unusual conditions or environments including, but not limited to, excessive humidity or extreme temperature conditions outside of the specifi ed limits. Agrowtek Inc. must be contacted prior to return shipment for a return authorization. No returns will be accepted without a return authorization. Returns not purchased directly from Agrowtek Inc. must include proof of purchase date otherwise purchase date is considered date of manufacture. The products which have been claimed and comply with the aforementioned restrictions shall be replaced or repaired at the sole discretion of the Agrowtek Inc. at no charge. This warranty is provided in lieu of all other warranty provisions, express or implied. It is including but not limited to any implied warranty of fi tness or merchantability for a particular purpose and is limited to the Warranty Period. In no event or circumstance shall Agrowtek Inc. be liable to any third party or the claimant for damages in excess of the price paid for the product, or for any loss of use, inconvenience, commercial loss, loss of time, lost profi ts or savings or any other incidental, consequential or special damages arising out of the use of, or inability to use, the product. This disclaimer is made to the fullest extent allowed by law or regulation and is specifi cally made to specify that the liability of Agrowtek Inc. under this limited warranty, or any claimed extension thereof, shall be to replace or repair the Product or refund the price paid for the Product.

© Agrowtek Inc.

www.agrowtek.com

Technology to Help You Grow™

Documents / Resources

|

AGROWTEK LX2 ModLINK RS-485 Buffered Conversion Module [pdf] Instruction Manual LX2, LX2 ModLINK RS-485 Buffered Conversion Module, LX2 ModLINK, RS-485 Buffered Conversion Module, Buffered Conversion Module, Conversion Module, Module |