I-Danfoss EKC 202A Isilawuli soLawulo loBubushushu

Intshayelelo

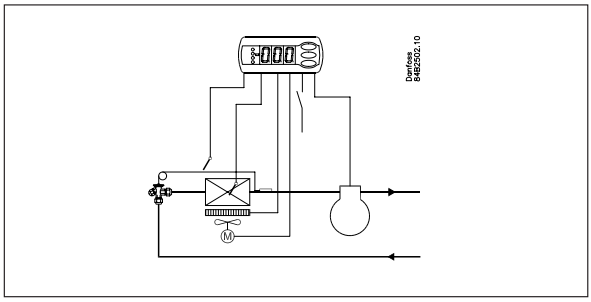

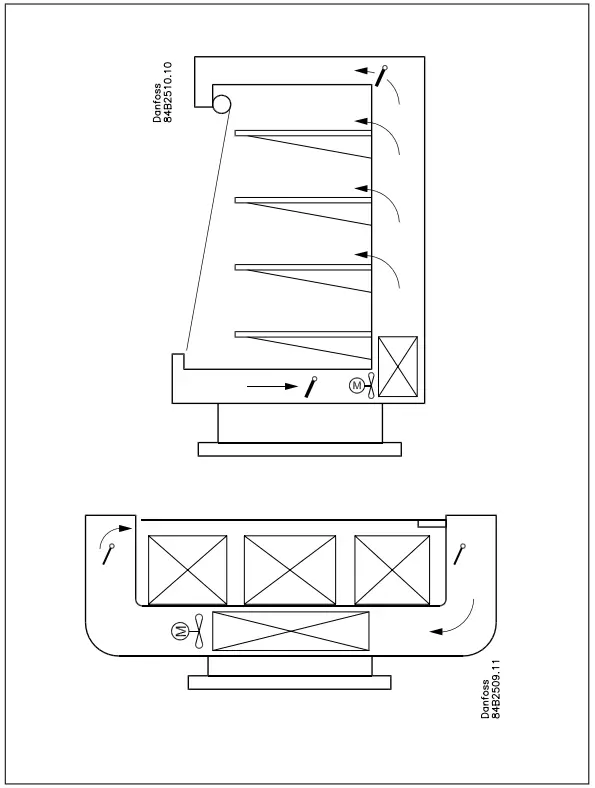

Isicelo

- Isilawuli sisetyenziselwa ukulawula ubushushu bezixhobo zefriji kunye namagumbi abandayo kwiivenkile ezinkulu

- Ukulawulwa kwe-defrost, abalandeli, i-alamu kunye nokukhanya

Umgaqo

Umlawuli uqulethe ulawulo lweqondo lokushisa apho umqondiso unokufunyanwa kwi-sensor enye yeqondo lokushisa. I-sensor ifakwe kwi-airflow ebandayo emva kwe-evaporator okanye kwi-air flow efudumele ngaphambi nje kwe-evaporator. Isilawuli silawula ukunyibilika kweqabaka nokuba yingqele yendalo okanye ukuthotywa kombane. Ukusika ngokutsha emva kokuchithwa kweqhwa kunokufezekiswa ngokusekelwe kwixesha okanye kwiqondo lobushushu. Umlinganiselo wokushisa kwe-defrost unokufumaneka ngokuthe ngqo ngokusetyenziswa kwenzwa ye-defrost. Iireyidi ezimbini ukuya kwezine ziya kusika imisebenzi efunekayo ngaphakathi nangaphandle - isicelo simisela ukuba yeyiphi:

- Ifriji (i-compressor okanye ivalve ye-solenoid)

- Ukhuselo

- Umlandeli

- Ialarm

- Ukukhanya

Usetyenziso olwahlukeneyo luchazwe kwiphepha elilandelayo.

Advantages

- Imisebenzi edibeneyo yefriji-yobugcisa

- Nciphisa ngokwemfuno kwiinkqubo ze-1:1

- Amaqhosha kunye nokutywinwa kufakwe ngaphambili

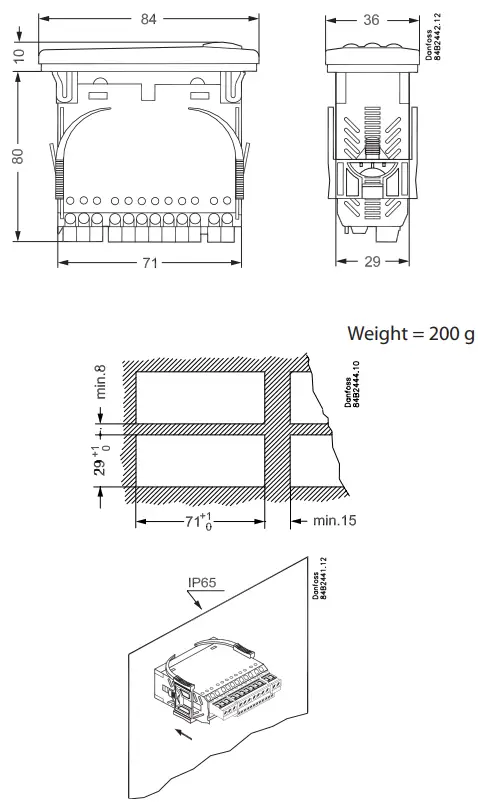

- IP65 ebiyelweyo kwindawo yolawulo

- Ungeniso lwedijithali nokuba:

- Umsebenzi woqhagamshelwano womnyango nge-alam

- Ukuqala kwe-Defrost

- Ukuqala/ukuyeka ummiselo

- Ukusebenza ebusuku

- Utshintsho phakathi kweembekiselo ezimbini zobushushu

- Umsebenzi wokucoca ityala

- Udweliso lwenkqubo olukhawulezileyo ngeqhosha lenkqubo

- I-HACCP Factory calibration eya kuqinisekisa ukuchaneka komlinganiselo ongcono kunoko kuchazwe kumgangatho we-EN ISO 23953-2 ngaphandle kolungelelwaniso olulandelayo (Pt 1000 ohm sensor)

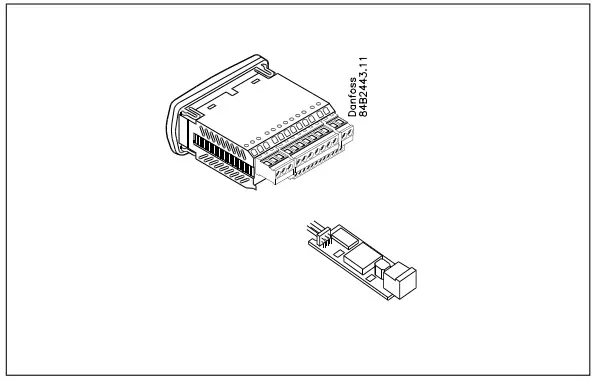

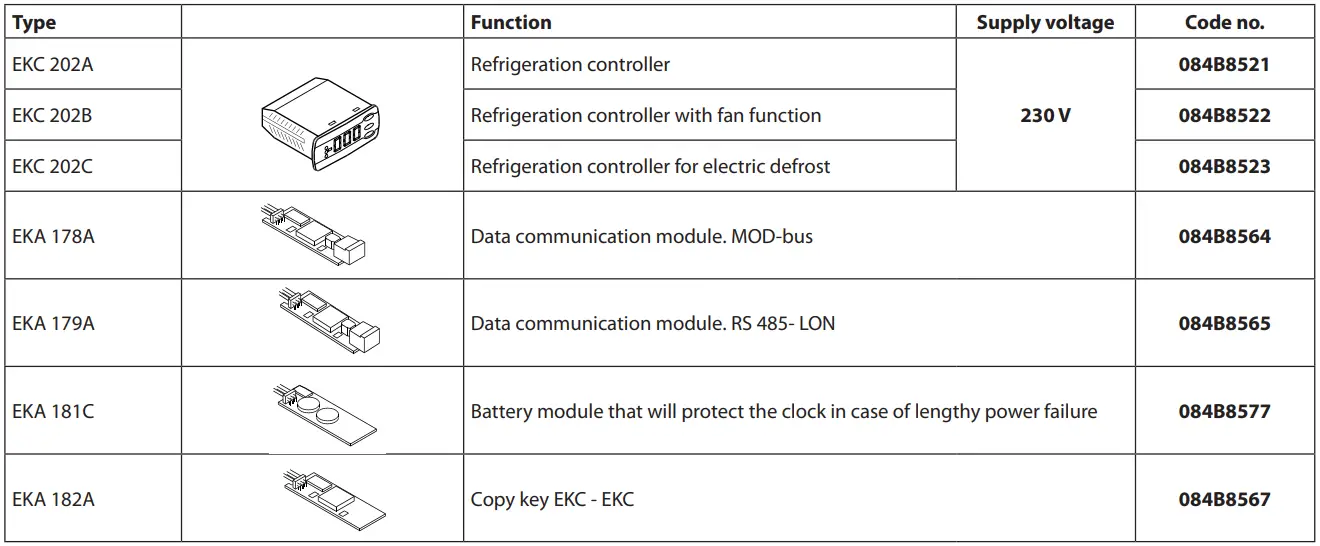

Imodyuli eyongezelelweyo

- Umlawuli emva koko angafakelwa imodyuli yofakelo ukuba isicelo siyayifuna. Umlawuli ulungiswe ngeplagi, ngoko ke imodyuli kufuneka ityhalelwe ngaphakathi.

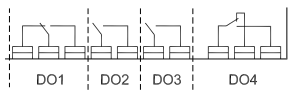

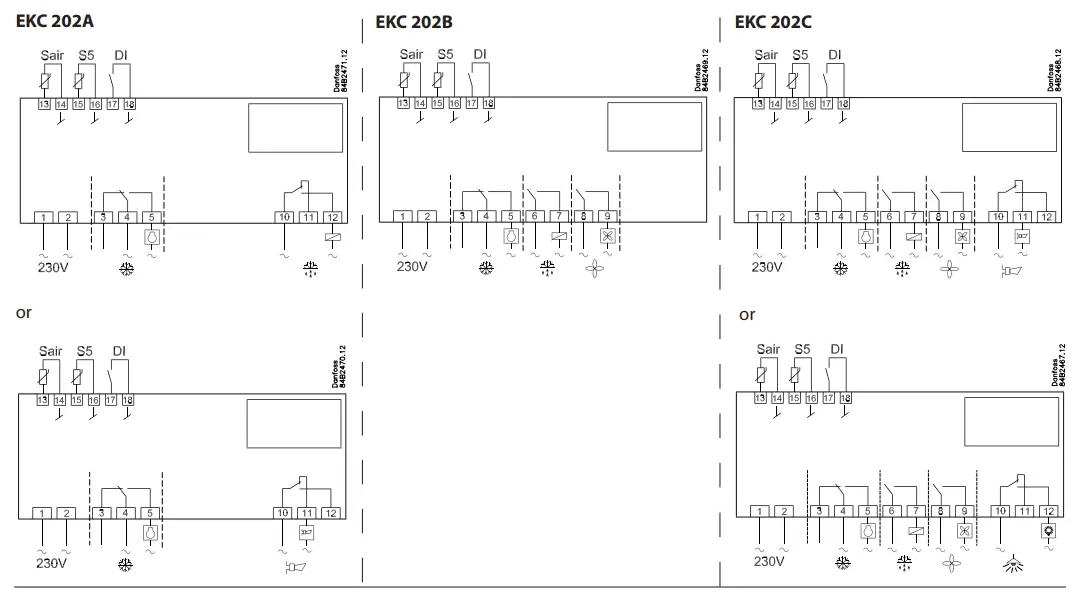

I-EKC 202A

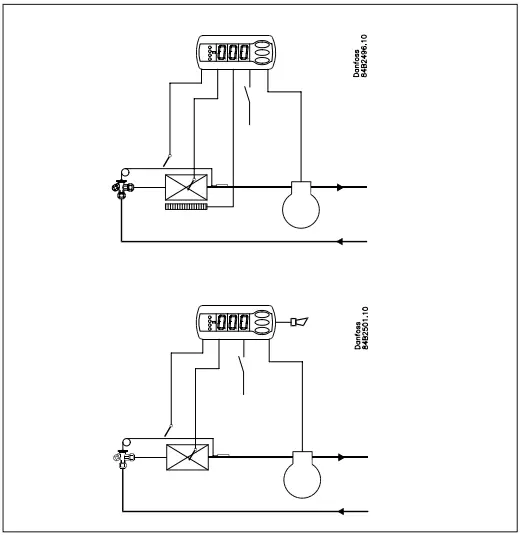

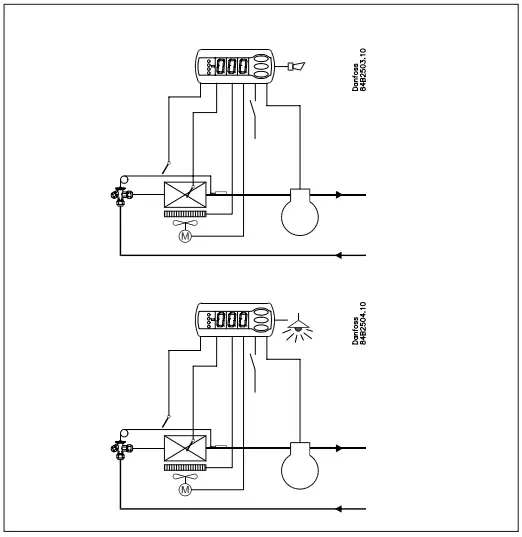

Isilawuli esineziphumo ezibini zokuhanjiswa, izinzwa zobushushu ezimbini, kunye negalelo ledijithali. Ukulawula ubushushu ekuqaleni / ukumisa kwe-compressor / i-valve ye-solenoid

Isivamvo sokunyibilikisa

Ukutshatyalaliswa kombane / ukunyibilika kwerhasi

Umsebenzi we-alam

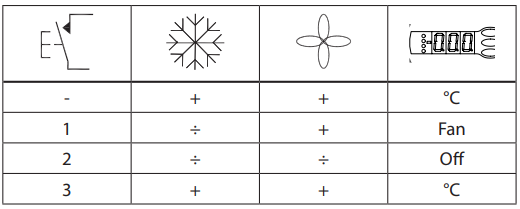

Ukuba i-alam iyafuneka, inombolo ye-relay yesibini inokusetyenziselwa yona. I-Defrost yenziwa apha ngokujikeleza komoya njengoko abalandeli besebenza ngokuqhubekayo.

I-EKC 202B

Isilawuli esineziphumo ezintathu zokulayishwa, izinzwa zobushushu ezimbini, kunye negalelo ledijithali. Ukulawula ubushushu ekuqaleni / ukumisa i-compressor / i-valve ye-solenoid, i-sensor ye-Defrost, i-Electrical defrost / i-gas defrost Imveliso ye-Relay 3 isetyenziselwa ukulawula i-fan.

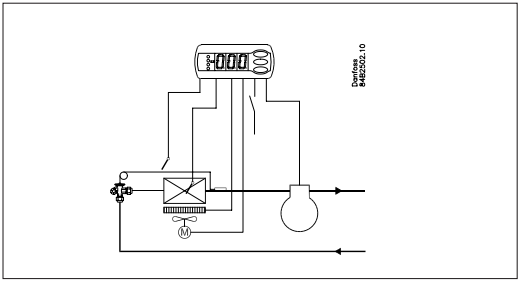

I-EKC 202C

Isilawuli esineziphumo ezine ezidluliswayo, izinzwa zobushushu ezimbini, kunye negalelo ledijithali. Ukulawula ubushushu ekuqaleni / ukumisa i-compressor / i-valve ye-solenoid, i-Defrost sens, okanye i-Defrost yoMbane / i-gas defrost. Ukulawulwa kwe-fan Relay output 4 ingasetyenziselwa umsebenzi we-alamu okanye umsebenzi wokukhanya.

Ukuqala kwe-defrost

I-defrost inokuqaliswa ngeendlela ezahlukeneyo

Ikhefu: I-Defrost iqalwa ngamaxesha amisiweyo, yithi rhoqo kwiiyure ezisibhozo

- Ixesha lokukhenkcisa: I-Defrost iqalwa ngamaxesha amiselweyo efriji. Ngamanye amazwi, imfuno ephantsi yesikhenkcezisi iya "kuhlehlisa" i-defrost ezayo

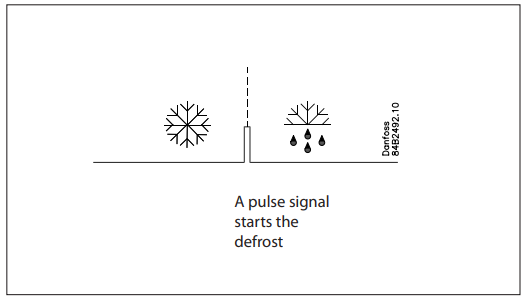

- Qhagamshelana I-Defrost iqalwa apha ngophawu lwepulse kwigalelo ledijithali.

- Incwadi yezandla: I-defrost eyongezelelweyo ingenziwa isebenze kwiqhosha elisezantsi lomlawuli

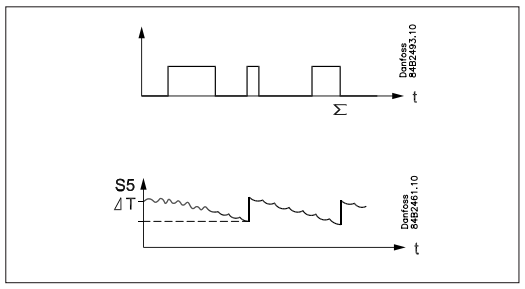

- Ubushushu be-S5. Kwiinkqubo ze-1: 1, ukusebenza kakuhle kwe-evaporator kunokulandelwa. Ukukhenkceza kuya kuqalisa ukunyibilikisa.

- Ishedyuli I-Defrost apha inokuqaliswa ngamaxesha amiselweyo emini nasebusuku. Kodwa max. ezintandathu defrosts

- Uthungelwano I-defrost ingaqalwa ngonxibelelwano lwedatha

Zonke iindlela ezikhankanyiweyo zingasetyenziswa ngokungaqhelekanga - ukuba enye yazo ivuliwe, i-defrost iya kuqaliswa. Xa i-defrost iqala, izibali-xesha ze-defrost zisetwa kwi-zero.

Ukuba ufuna i-coordinated defrost, oku kufuneka kwenziwe ngonxibelelwano lwedatha.

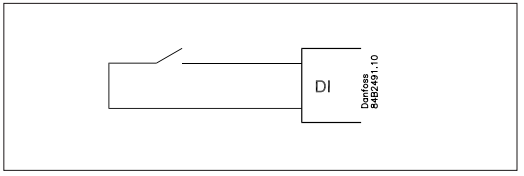

Igalelo ledijithali

Igalelo ledijithali lingasetyenziselwa le misebenzi ilandelayo:

- Umsebenzi wokuqhagamshelana nomnyango kunye ne-alarm ukuba umnyango uvulekele ixesha elide.

- Ukuqala kwe-Defrost

- Ukuqala/ukuyeka ummiselo

- Ukutshintshela ekusebenzeni ebusuku

- Ukucocwa kwetyala

- Tshintshela kwenye ireferensi yobushushu

- Tofa uvule/uvale

Umsebenzi wokucoca ityala

Lo msebenzi wenza kube lula ukulawula isixhobo sefriji kwisigaba sokucoca. Ngokutyhala kathathu kwiswitshi, utshintsha ukusuka kwesinye isigaba ukuya kwesinye. Utyhala lokuqala lumisa isikhenkcezisi – iifeni ziyaqhubeka nokusebenza.”Emva kwexesha”: Utyhala olulandelayo lumisa abalandeli.”Sekunjalo kamva,”: Utyhala olulandelayo luphinda luqalise isikhenkcezisi Iimeko ezahlukeneyo zinokulandelwa kumboniso. Akukho ukubeka iliso kwiqondo lokushisa ngexesha lokucoca kwimeko. Kwinethiwekhi, i-alamu yokucoca idluliselwa kwiyunithi yesistim. Le alarm inokuthi "ifakwe" ukuze kunikwe ubungqina bokulandelelana kweziganeko.

Defrost xa ufuna

- Ngokusekelwe kwixesha lefriji, xa ixesha elihlanganisiweyo lefriji lidlulile ixesha elimiselweyo, i-defrost iya kuqaliswa.

- Ngokusekelwe kwiqondo lokushisa, umlawuli uya kuhlala elandela iqondo lokushisa kwi-S5. Phakathi kwe-defrosts ezimbini, iqondo lobushushu le-S5 liya kuba lisezantsi ngakumbi i-evaporator ice phezulu (icompressor isebenza ixesha elide kwaye itsala iqondo lobushushu le-S5 ukuya ezantsi). Xa iqondo lobushushu lidlula iseti evumelekileyo ukuhluka, i-defrost iya kuqaliswa.

Lo msebenzi unokusetyenziswa kuphela kwiinkqubo ze-1:1

Ukusebenza

Bonisa

Amaxabiso aya kuboniswa enamanani amathathu, kwaye kunye nocwangciso unokugqiba ukuba ubushushu buboniswe kwi °C okanye kwi °F.

Iidiode ezikhupha ukukhanya (LED) kwiphaneli engaphambili

Kukho iiledi kwiphaneli yangaphambili eziya kuthi zikhanyise xa isilayidi esinayo sivuliwe.

Iidiode ezikhupha ukukhanya ziya kudanyaza xa kukho i-alam. Kule meko, unokukhuphela ikhowudi yempazamo kwisibonisi kwaye urhoxise / usayine i-alam ngokunika iqhosha eliphezulu utyhala olufutshane.

Ukhuselo

Ngexesha lokumisa iqhwa a–d- iboniswe kumboniso. Oku view iya kuqhubeka ukuya kwi-15 min. emva kokuba ukupholisa kuqale kwakhona. Nangona kunjalo, i view ye -d- iyakuyekwa ukuba:

- Ubushushu bufanelekile ngaphakathi kwemizuzu eyi-15

- Ummiselo umisiwe nge "Main switch"

- I-alam yobushushu obuphezulu ibonakala

Amaqhosha

Xa ufuna ukutshintsha isicwangciso, amaqhosha aphezulu nasezantsi aya kukunika ixabiso eliphezulu okanye elisezantsi, kuxhomekeke kwiqhosha olityhalayo. Kodwa ngaphambi kokuba utshintshe ixabiso, kufuneka ube nokufikelela kwimenyu. Ufumana oku ngokucofa iqhosha elingaphezulu imizuzwana embalwa - emva koko uya kufaka ikholamu kunye neekhowudi zeparameter. Fumana ikhowudi yeparameter ofuna ukuyitshintsha kwaye utyhale amaqhosha aphakathi de ixabiso le parameter libonisiwe. Xa utshintshile ixabiso, gcina ixabiso elitsha ngokucinezela kwakhona iqhosha eliphakathi.

ExampLes

Seta imenyu

- Cofa iqhosha eliphezulu de kuboniswe iparamitha r01

- Cofa iqhosha eliphezulu okanye elisezantsi kwaye ufumane iparameter ofuna ukuyitshintsha

- Cofa iqhosha eliphakathi de ixabiso leparameter libonisiwe

- Cofa iqhosha eliphezulu okanye elisezantsi kwaye ukhethe ixabiso elitsha

- Cofa iqhosha eliphakathi kwakhona ukufaka ixabiso. I-alam ye-Cutout, i-alam yokudlulisela / i-alam yerisithi/bona ikhowudi yesivusi

- Cofa ngokufutshane iqhosha eliphezulu

- Ukuba kukho iikhowudi ezininzi ze-alam, zifumaneka kwi-rolling stack. Cofa elona qhosha liphezulu okanye lisezantsi ukuskena istaki esiqengqelekayo.

Seta ubushushu

- Cofa iqhosha eliphakathi de ixabiso lobushushu libonisiwe

- Cofa iqhosha eliphezulu okanye elisezantsi kwaye ukhethe ixabiso elitsha

- Cofa iqhosha eliphakathi ukukhetha useto

UManuel uqala okanye ayeke ukunyibilikisa

- Cofa iqhosha elisezantsi imizuzwana emine. Jonga iqondo lobushushu kwinzwa ye-defrost

- Cofa ngokufutshane iqhosha elisezantsi. Ukuba akukho sixhobo soluvo sifakiweyo, u-"non" uya kuvela.

100% iqinile

Amaqhosha kunye netywina afakwe ngaphambili. Indlela ekhethekileyo yokubumba idibanisa iplastiki yangaphambili enzima, amaqhosha athambileyo kunye nesitywina, ukuze abe yinxalenye ebalulekileyo yepaneli yangaphambili. Akukho zivulekele ezinokufumana ukufuma okanye ukungcola.

| Iiparamitha | Umlawuli | Min.- ixabiso | Ubuninzi.- ixabiso | Umzi-mveliso ulungiselelo | Olona lungiselelo | |||

| Umsebenzi | Iikhowudi | I-EKC

202A |

I-EKC

202B |

I-EKC

202C |

||||

| Ukusebenza okuqhelekileyo | ||||||||

| Ubushushu (indawo yokumisela) | - | -50°C | 50°C | 2°C | ||||

| Thermostat | ||||||||

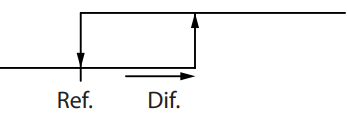

| Umahluko | R01 | 0,1 K | 20 K | 2 K | ||||

| Max. ukulinganiselwa kokusetwa kwendawo | R02 | -49°C | 50°C | 50°C | ||||

| Min. Ukusikelwa umda kokumiselwa kwendawo | R03 | -50°C | 49°C | -50°C | ||||

| Ukulungiswa kwesalathisi sobushushu | R04 | -20 K | 20 K | 0.0 K | ||||

| Iyunithi yobushushu (°C/°F) | R05 | °C | °F | °C | ||||

| Ukulungiswa komqondiso ovela eSair | R09 | -10 K | 10 K | 0 K | ||||

| Inkonzo yezandla (-1), ummiselo wokumisa(0), umgaqo wokuqalisa (1) | R12 | -1 | 1 | 1 | ||||

| Ukususwa kwereferensi ngexesha lokusebenza ebusuku | R13 | -10 K | 10 K | 0 K | ||||

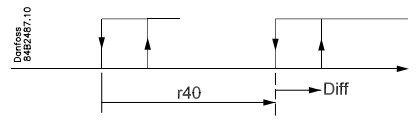

| Ukuqaliswa kokususwa kwereferensi R40 | R39 | CIMA | on | CIMA | ||||

| Ixabiso lokufuduswa kwereferensi (ukwenziwa kusebenze nge-r39 okanye i-DI) | R40 | -50 K | 50 K | 0 K | ||||

| Ialarm | ||||||||

| Ukulibaziseka kwe-alam yobushushu | A03 | 0 imiz | 240 imiz | 30 imiz | ||||

| Ukulibaziseka kwe-alam yomnyango | A04 | 0 imiz | 240 imiz | 60 imiz | ||||

| Ukulibaziseka kwe-alam yobushushu emva kokumiswa kweqhwa | A12 | 0 imiz | 240 imiz | 90 imiz | ||||

| Umda we-alam ophezulu | A13 | -50°C | 50°C | 8°C | ||||

| Umda we-alam ophantsi | A14 | -50°C | 50°C | -30°C | ||||

| Ukulibaziseka kwealam DI1 | A27 | 0 imiz | 240 imiz | 30 imiz | ||||

| Umda we-alam ephezulu yobushushu becondenser (o70) | A37 | 0°C | 99°C | 50°C | ||||

| Isicompressor | ||||||||

| Min. Ngexesha | c01 | 0 imiz | 30 imiz | 0 imiz | ||||

| Min. OFF-ixesha | c02 | 0 imiz | 30 imiz | 0 imiz | ||||

| I-Compressor relay kufuneka isike kwaye iphume ngokuphambeneyo (i-NC-function) | c30 | 0 / OFF | 1 / kwi | 0 / OFF | ||||

| Ukhuselo | ||||||||

| Indlela yokunyibilikisa (akukho/EL/gesi) | d01 | Hayi | igesi | EL | ||||

| Defrost stop iqondo lobushushu | d02 | 0°C | 25°C | 6°C | ||||

| Isithuba phakathi kokuqalisa kwe-defrost | d03 | iiyure ezi-0 | iiyure ezi-48 | iiyure ezi-8 | ||||

| Max. ubude beqhwa | d04 | 0 imiz | 180 imiz | 45 imiz | ||||

| Ukususwa kwexesha kwi-cutin ye-defrost ekuqaleni | d05 | 0 imiz | 240 imiz | 0 imiz | ||||

| Ukuchitha ixesha | d06 | 0 imiz | 60 imiz | 0 imiz | ||||

| Ukulibazisa ukuqala kwefeni emva kokumiswa kweqhwa | d07 | 0 imiz | 60 imiz | 0 imiz | ||||

| Ubushushu bokuqalisa kweFani | d08 | -15°C | 0°C | -5°C | ||||

| I-Fan cutin ngexesha lokuqhaqhazela

0:Yema 1: Ukubaleka ngexesha lonke isigaba 2: Ukubaleka ngexesha lesigaba sokufudumeza kuphela |

d09 | 0 | 2 | 1 | ||||

| Isivamvo sokunyibilikisa (0=ixesha, 1=S5, 2=Sair) | d10 | 0 | 2 | 0 | ||||

| Max. ixesha elidibeneyo lokukhenkceza phakathi kwe-defrosts ezimbini | d18 | iiyure ezi-0 | iiyure ezi-48 | iiyure ezi-0 | ||||

| Ukunyikiswa kweqabaka xa ifunwa – iqondo lobushushu le-S5 livumeleke ukuba litshintshe ngexesha lokwakhiwa kweqabaka. Vula

isityalo esiphakathi khetha 20 K (=cimile) |

d19 | 0 K | 20 K | 20 K | ||||

| Abalandeli | ||||||||

| Ukumisa ifeni kwi-cutout compressor | F01 | Hayi | Ewe | Hayi | ||||

| Ukulibaziseka kokumiswa kwefeni | F02 | 0 imiz | 30 imiz | 0 imiz | ||||

| Ubushushu bokumisa iFani (S5) | F04 | -50°C | 50°C | 50°C | ||||

| Ixesha lexesha elifanelekileyo | ||||||||

| Amaxesha amathandathu okuqalisa ukunyibilikisa. Ukusetwa kweeyure.

0 = Valiwe |

t01-t06 | iiyure ezi-0 | iiyure ezi-23 | iiyure ezi-0 | ||||

| Amaxesha amathandathu okuqalisa ukunyibilikisa. Ukusetwa kwemizuzu.

0 = Valiwe |

t11-t16 | 0 imiz | 59 imiz | 0 imiz | ||||

| Iwotshi – Ukusetwa kweeyure | t07 | iiyure ezi-0 | iiyure ezi-23 | iiyure ezi-0 | ||||

| Iwotshi – Ukusetwa komzuzu | t08 | 0 imiz | 59 imiz | 0 imiz | ||||

| Iwotshi – Ukusetwa komhla | t45 | 1 | 31 | 1 | ||||

| Ikloko – Ukusetwa kwenyanga | t46 | 1 | 12 | 1 | ||||

| Ikloko-Umiselo lonyaka | t47 | 0 | 99 | 0 | ||||

| Iintlobo ngeentlobo | ||||||||

| Ukulibaziseka kweempawu zemveliso emva kokusilela kwamandla | o01 | 0 s | 600 s | 5 s | ||||

| Isiginali yongeniso kwi-DI1. Umsebenzi:

0=ayisetyenziswanga. 1=isimo kwi-DI1. 2=umsebenzi wocango nge-alam xa uvuliwe. 3=i-alam yocango xa ivuliwe. 4=ukuqala kokuthomalalisa (i-pulse-signal). 5=ext.isitshixo esingundoqo. 6=umsebenzi wasebusuku 7=utshintsho lwereferensi (i-r40 iza kuvula) 8=i-alam xa ivaliwe. 9=umsebenzi we-alarm- xa ivuliwe. 10=ukucocwa kwetyala (uphawu lwepulse). 11=Tofa xa uvuliwe. |

o02 | 0 | 11 | 0 | ||||

| Idilesi yenethiwekhi | o03 | 0 | 240 | 0 | ||||

| Vula/Vala iswitsha (Umyalezo wePin yeNkonzo) | o04 | CIMA | ON | CIMA | ||||

| Ikhowudi yokufikelela 1 (zonke iisetingi) | o05 | 0 | 100 | 0 | ||||

| Uhlobo loluvo olusetyenzisiweyo (Pt /PTC/NTC) | o06 | Pt | ntc | Pt | ||||

| Bonisa inyathelo = 0.5 (i-0.1 eqhelekileyo kwi-Pt sensor) | o15 | Hayi | Ewe | Hayi | ||||

| Ubukhulu bexesha lokubamba emva kokumiswa kweqabaka | o16 | 0 imiz | 60 imiz | 20 | ||||

| Uqwalaselo lomsebenzi wokukhanya (i-relay 4)

1=KUVULIWE ngexesha lokusebenza kwemini. 2=VULA / VALIWE ngonxibelelwano lwedatha. 3=ON ulandela DI- umsebenzi, xa i-DI ikhethwe kumnyango womsebenzi okanye kwi-alam yomnyango |

o38 | 1 | 3 | 1 | ||||

| Ukuqaliswa kokunikezelwa kokukhanya (kuphela ukuba o38=2) | o39 | CIMA | ON | CIMA | ||||

| Ukucocwa kwetyala. 0=akukho tyala lokucocwa. 1=Abalandeli kuphela. 2=Zonke iziphumo zicinyiwe. | o46 | 0 | 2 | 0 | ||||

| Ikhowudi yokufikelela 2 (ufikelelo ngokuyinxenye) | o64 | 0 | 100 | 0 | ||||

| Gcina iisetingi ezikhoyo kwiqhosha lokucwangcisa. Khetha inombolo yakho. | o65 | 0 | 25 | 0 | ||||

| Layisha useto lwezicwangciso ukusuka kwiqhosha lokucwangcisa (ebeligcinwe ngaphambili nge-o65 umsebenzi) | o66 | 0 | 25 | 0 | ||||

| Buyisela useto lwefektri yesilawuli ngoseto lwangoku | o67 | CIMA | On | CIMA | ||||

| Isicelo esisesinye isicelo se-S5 sensor (gcina i-setting kwi-0 ukuba isetyenziswe njengenzwa ye-defrost, ngaphandle koko 1 = inzwa yemveliso kunye ne-2 = i-condenser sensor nge-alarm) | o70 | 0 | 2 | 0 | ||||

| Khetha usetyenziso lwe-relay 4: 1=defrost/light, 2= alarm | o72 | qhaqha iqhwa /

Ialarm |

Ukukhanya /

Ialarm |

1 | 2 | 2 | ||

| Inkonzo | ||||||||

| Ubushushu bulinganiswe nge-S5 sensor | u09 | |||||||

| Ubume kwigalelo le-DI1. kwi/1=ivaliwe | u10 | |||||||

| Imo yokusebenza ebusuku (ivuliwe okanye ivaliwe) 1=ivaliwe | u13 | |||||||

| Funda ireferensi yommiselo yangoku | u28 | |||||||

| Imo kwi-relay yokupholisa (Inokulawulwa ngesandla, kodwa kuphela xa r12=-1) | u58 | |||||||

| Imo kunikezelo lwabalandeli (Inokulawulwa ngesandla, kodwa kuphela xa r12=-1) | u59 | |||||||

| Ubume kwireyiti yokunyibilikiswa kweqhwa. (Inokulawulwa ngesandla, kodwa kuphela xa r12=-1) | u60 | |||||||

| Ubushushu bulinganiswe ngesivamvo seSair | u69 | |||||||

| Imo kwi-relay 4 (i-alamu, i-defrost, ukukhanya). (Inokulawulwa ngesandla, kodwa kuphela xa

R12=-1) |

u71 | |||||||

Ulungiselelo lwasefektri

Ukuba ufuna ukubuyela kumaxabiso aseti yefektri, inokwenziwa ngolu hlobo:

- Sika umthamo wonikezelotage kumlawuli

- Gcina amaqhosha aphezulu nasezantsi ecinezelekile ngaxeshanye njengoko uqhagamshela kwakhona umthamo wonikezelotage.

| Impazamo ikhowudi umboniso | Umboniso wekhowudi ye-alarm | Ubume ikhowudi umboniso | |||

| E1 | Impazamo kwisilawuli | A1 | I-alamu yobushushu obuphezulu | S0 | Ukulawula |

| E6 | Guqula ibhetri + khangela iwotshi | A2 | I-alamu yobushushu obuphantsi | S1 | Ilinde ukuphela kwe-defrost elungelelanisiweyo |

| E 27 | Impazamo yoluvo lwe-S5 | A4 | Isivusi socango | S2 | ON-ixesha Compressor |

| E 29 | Impazamo yesivamvo se-Sair | A5 | Max. Bamba ixesha | S3 | I-OFF-time Compressor |

| A15 | DI 1 alarm | S4 | Ixesha lokuphuma | ||

| A45 | Imo yokulinda | S10 | Isikhenkcezisi simiswe ngokutshintsha okungundoqo | ||

| A59 | Ukucocwa kwetyala | S11 | Isikhenkcisi simiswe yithermostat | ||

| A61 | Isivusisi sekhondensi | S14 | Defrost ulandelelwano. Ukuqhaqha | ||

| S15 | Defrost ulandelelwano. Ukulibaziseka kwabalandeli | ||||

| S16 | Ifriji iyekile ngenxa ye-DI evulekileyo

igalelo |

||||

| S17 | Ucango luvuliwe (vula igalelo likaDI) | ||||

| S20 | Ukupholisa okungxamisekileyo | ||||

| S25 | Ukulawulwa kweziphumo ngezandla | ||||

| S29 | Ukucocwa kwetyala | ||||

| S32 | Ukulibaziseka kwemveliso ekuqaleni | ||||

| hayi | Iqondo lobushushu le-defrost alinako ukuchithwa-

kudlaliwe. Kukho ukuma ngokusekelwe kwixesha |

||||

| -d- | Ukunyibilika kuyaqhubeka / Ukupholisa kokuqala emva

ongena |

||||

| PS | Igama lokugqithisa liyafuneka. Seta igama lokugqithisa | ||||

Ukuqala eqala:

Ummiselo uqala xa umqulutage ivuliwe.

- Yiya kwisaveyi yezicwangciso zasefektri. Yenza naluphi na utshintsho oluyimfuneko kwiiparamitha ezifanelekileyo.

- Yenethiwekhi. Seta idilesi ku-o03 kwaye emva koko uyigqithisele kwisango/iyunithi yesixokelelwano ngoseto o04.

Imisebenzi

Nantsi inkcazo yomsebenzi ngamnye. Umlawuli uqulethe kuphela le nxalenye yemisebenzi. Cf. uphando lwemenyu.

| Umsebenzi | Ipara-mitha | Ipharamitha ngokusebenza ngedatha com- ubugcisa |

| Okuqhelekileyo umboniso | ||

| Ngokuqhelekileyo ixabiso lobushushu elivela kwi-thermostat sensor Sair liyaboniswa. | Bonisa umoya (u69) | |

| Thermostat | Ulawulo lweThermostat | |

| Beka Indawo

Ummiselo usekelwe kwixabiso elimiselweyo kunye nokufuduswa, ukuba kufanelekile. Ixabiso licwangciswe ngokutyhala kwiqhosha eliphakathi. Ixabiso elimiselweyo lingatshixwa okanye lilinganiselwe kuluhlu kunye nezicwangciso kwi-r02 kunye ne-r03. Ireferensi nangaliphi na ixesha inokubonwa kwi-"u28 Temp. ref" |

Ukusika °C | |

| Umahluko

Xa iqondo lokushisa liphezulu kunereferensi + ukuhluka okusetiweyo, i-compressor relay iya kunqunyulwa kwakhona. |

R01 | Umahluko |

| Seta inqaku umda

Uluhlu lwesetingi somlawuli kwindawo emiselweyo lunokucuthwa, ukuze amaxabiso aphezulu kakhulu okanye aphantsi kakhulu angamiselwa ngengozi – ngomonakalo obangele. |

||

| Ukuphepha ukusetwa okuphezulu kakhulu kwendawo ebekiweyo, ubuninzi. ixabiso lereferensi elivumelekileyo kufuneka lithotywe. | R02 | Ubukhulu bokusika °C |

| Ukuze ugweme ukusetwa okuphantsi kakhulu kwendawo emiselweyo, i-min. ixabiso lereferensi elivumelekileyo malinyuswe. | R03 | Ukusika kancinci °C |

| Ukulungiswa kobushushu bomboniso oboniswayo

Ukuba iqondo lokushisa kwiimveliso kunye nobushushu obufunyenwe ngumlawuli alufani, ukulungiswa kwe-offset yeqondo lokushisa elibonisiweyo linokwenziwa. |

R04 | Disp. I-Adj. K |

| Iyunithi yobushushu

Seta apha ukuba isilawuli siza kubonisa amaxabiso obushushu ku °C okanye ku °F. |

R05 | Temp. iyunithi

°C=0. / °F=1 (Kuphela °C kwi-AKM, nokuba sithini na isicwangciso) |

| Ukulungiswa of uphawu ukusuka eSair

Imbuyekezo enokwenzeka ngentambo yoluvo olude |

R09 | Lungisa iSair |

| Ukuqala / ukumisa ifriji

Ngolu seto ifriji inokuqaliswa, iyeke okanye ugqithiso lwesandla lweziphumo lunokuvunyelwa. Ukuqala / ukumiswa kwefriji kunokufezekiswa kunye nomsebenzi wokutshintsha wangaphandle odityaniswe kwigalelo le-DI. Isikhenkcisi esimisiweyo siya kunika "i-alam yokulinda". |

R12 | Utshintsho oluphambili

1: Qala 0: Yeka -1: Ulawulo lwezandla lweziphumo ezivumelekileyo |

| Ixabiso lokubuyisela umva ebusuku

Isalathiso se-thermostat iya kuba yindawo yokumisela kunye neli xabiso xa umlawuli etshintsha ukuya ekusebenzeni ebusuku. (Khetha ixabiso elibi ukuba kukho uqokelelo olubandayo.) |

R13 | Ukunciphisa ebusuku |

| Ukuqaliswa kokususwa kwereferensi

Xa umsebenzi utshintshwa ube ON umahluko we-thermostat uya kwandiswa ngexabiso kwi-r40. Ukuqaliswa kunokuthi kwenzeke ngegalelo le-DI (elichazwe kwi-o02).

|

R39 | Th. i-offset |

| Ixabiso lokufuduswa kwereferensi

Ireferensi ye-thermostat kunye namaxabiso e-alamu atshintshelwe linani elilandelayo leedigri xa ukufuduswa kuvuliwe. Ukuqaliswa kunokwenziwa nge-r39 okanye ngegalelo le-DI |

R40 | Th. ukugqiba K |

| Ukubuyisela umva ebusuku

(ukuqala komqondiso wobusuku) |

| Ialarm | Useto lwe-alam | |

| Umlawuli unokunika i-alamu kwiimeko ezahlukeneyo. Xa kukho i-alam zonke ii-diode ezikhupha ukukhanya (i-LED) ziya kudanyaza kwiphaneli yangaphambili yesilawuli, kwaye i-alam yokudluliselwa iya kusikwa. | Ngonxibelelwano lwedatha, ukubaluleka kwee-alamu zomntu ngamnye kunokuchazwa. Ukuseta kuqhutywa kwimenyu ethi "Iindawo zeAlarm". | |

| Ukulibaziseka kwealam (ukulibaziseka kwe-alam emfutshane)

Ukuba elinye kumaxabiso amabini aqingqiweyo ligqithisiwe, umsebenzi wesibali-xesha uya kuqalisa. I-alam ayiyi sebenza kude kube ixesha elimisiweyo lidlule. Ukulibaziseka kwexesha kumiselwe kwimizuzu. |

A03 | Ukulibaziseka kwealam |

| Ukulibaziseka kwexesha le-alam yomnyango

Ukulibaziseka kwexesha kumiselwe kwimizuzu. Umsebenzi uchazwe kwi-o02. |

A04 | I-DoorOpen del |

| Ukulibaziseka kwexesha lokupholisa (ukulibaziseka kwexesha elide)

Eli xesha lokulibaziseka lisetyenziswe ngexesha lokuqalisa, ngexesha lokuqhaqha, kwaye ngokukhawuleza emva kokutshatyalaliswa. Kuya kubakho utshintsho-kwixesha eliqhelekileyo lokulibaziseka (A03) xa iqondo lobushushu liye lehla ngaphantsi komda we-alamu obekiweyo. Ukulibaziseka kwexesha kumiselwe kwimizuzu. |

A12 | Khupha phantsi del |

| Umda we-alam ophezulu

Apha useta xa i-alam yobushushu obuphezulu iqala. Ixabiso lomda limiselwe ku °C (ixabiso elipheleleyo). Ixabiso lomda liya kuphakanyiswa ngexesha lokusebenza ebusuku. Ixabiso liyafana neseti yokubuyisela umva ebusuku, kodwa lizakunyuswa kuphela ukuba ixabiso lilungile. Ixabiso lomda nalo liya kuphakanyiswa ngokunxulumene nereferensi yokufuduswa kwe-r39. |

A13 | Umoya weHighLim |

| Umda we-alam osezantsi

Apha useta xa i-alam yobushushu obuphantsi iza kuqala. Ixabiso lomda limiselwe ku °C (ixabiso elipheleleyo). Ixabiso lomda nalo liya kuphakanyiswa ngokunxulumene nereferensi yokufuduswa kwe-r39. |

A14 | Umoya ophantsi |

| Ukulibaziseka kwe-alam ka-DI

Igalelo lokusika/ukusika liya kubangela i-alam xa ukulibaziseka kwexesha kudlulile. Umsebenzi uchaziwe kwi o02. |

A27 | AI.Libazisa i-DI |

| Umda we-alarm ephezulu yobushushu becondenser

Ukuba i-sensor ye-S5 isetyenziselwa ukubeka esweni ubushushu be-condenser kufuneka ubeke ixabiso apho i-alam izakusebenza. Ixabiso limiselwe ku °C. Inkcazo ye-S5 njenge-condenser sensor ifezekisiwe kwi-o70. I-alam iphinda isetwe kwakhona ukuya ku-10 K ngaphantsi kobushushu obumiselweyo. |

A37 | Contemp Al. |

| Seta kwakhona ialam |

| Isicompressor | Ulawulo lweCompressor | |

| I-compressor relay isebenza ngokubambisana ne-thermostat. Xa i-thermostat ibiza ifriji iya kusebenza i-compressor relay. | ||

| Amaxesha okubaleka

Ukuthintela ukusebenza ngokungaqhelekanga, amaxabiso anokumiselwa ixesha lokuba icompressor isebenze xa sele iqalisiwe. Kwaye imele imiswe ixesha elingakanani? Amaxesha okubaleka awajongwa xa i-defrosts iqala. |

||

| Min. NGEXESHA (ngemizuzu) | c01 | Min. Ngexesha |

| Min. OFF-time (ngemizuzu) | c02 | Min. Ixesha lokuphumla |

| Umsebenzi wokubuyisela umva wecompressor relay

0: Umsebenzi oqhelekileyo apho i-relay inqumla xa ifriji ifunwa 1: Umsebenzi obuyiselwe umva apho ireyidi inqunyulwa xa ifunwa ifriji ikhupha isiphumo sokuba kuya kubakho ifriji ukuba unikezelo voltage kumlawuli akaphumeleli). |

c30 | Cmp relay NC |

| Ukhuselo | Ukulawula ukhenkce | |

| Umlawuli uqulethe umsebenzi wesibali-xesha esiseti zeroset emva kokuqala kwe-defrost nganye. Umsebenzi wesibali-xesha uyakuqala ukumisa ukuba/xa ixesha lekhefu ligqithisiwe.

Umsebenzi wesibali-xesha uqala xa umqulutagu-e uqhagamshelwe kumlawuli, kodwa uyasuswa okokuqala ngokusetwa kwi-d05. Ukuba kukho ukusilela kombane, ixabiso lesibali-xesha liyakugcinwa kwaye liqhubeke ukusuka apha xa amandla ebuya. Lo msebenzi wesibali-xesha ungasetyenziswa njengendlela elula yokuqalisa ukunyibilika kweqhwa, kodwa uya kuhlala usebenza njenge-defrost yokhuseleko ukuba enye ye-defrost elandelayo iqala ayifunyanwa. Umlawuli ukwanalo newotshi yexesha langempela. Ngokumiselwa kwale wotshi namaxesha ngamaxesha afunekayo okuphelisa iqabaka, ukunyibilikisa kweqabaka kunokuqaliswa ngamaxesha amiselweyo emini. Ukuba kukho umngcipheko wokungaphumeleli kwamandla kwixesha elide kuneeyure ezine, imodyuli yebhetri kufuneka ifakwe kumlawuli. Ukuqala kwe-Defrost kunokufezekiswa ngonxibelelwano lwedatha, ngemiqondiso yoqhagamshelwano okanye ngesandla ukuqala eqala. |

||

| Zonke iindlela zokuqalisa ziya kusebenza kumlawuli. Imisebenzi eyahlukeneyo kufuneka imiselwe, ukwenzela ukuba i-defrosts "ingezi ukudilika" enye emva kwenye.

I-Defrost inokufezekiswa ngombane, igesi eshushu okanye i-brine. I-defrost yangempela iya kumisa ngokusekelwe kwixesha okanye kwiqondo lokushisa kunye nomqondiso ovela kwinzwa yeqondo lokushisa. |

||

| Indlela yokuqhaqha

Apha ubeka ukuba i-defrost kufuneka iphunyezwe ngombane okanye "akukho". Ngexesha lokumisa i-defrost relay iya kusikwa. Xa i-gas defrosting i-compressor relay iya kunqunyulwa ngexesha lokutshatyalaliswa kweqhwa. |

d01 | Def. indlela |

| Defrost stop iqondo lobushushu

I-defrost imisiwe kwiqondo lokushisa elinikeziweyo elilinganiswa nenzwa (inzwa ichazwa kwi-d10). Ixabiso lobushushu libekiwe. |

d02 | Def. Misa iTemp |

| Isithuba phakathi kokuqalisa kwe-defrost

Umsebenzi ngu-zeroset kwaye uya kuqalisa umsebenzi wesibali-xesha ekuqaleni kwe-defrost nganye. Xa ixesha liphelile umsebenzi uya kuqalisa i-defrost. Umsebenzi usetyenziswa njengesiqalo esilula sokunyibilikisa, okanye unokusetyenziswa njengokhuselo ukuba isignali eqhelekileyo ayibonakali. Ukuba i-master/slave defrost ngaphandle komsebenzi wewotshi okanye ngaphandle konxibelelwano lwedatha isetyenzisiwe, ixesha lekhefu liya kusetyenziswa njengobuninzi. ixesha phakathi defrosts. Ukuba i-defrost iqala ngonxibelelwano lwedatha ayenzeki, ixesha lekhefu liya kusetyenziswa njengobuninzi. ixesha phakathi defrosts. Xa kukho i-defrost kunye nomsebenzi wewotshi okanye unxibelelwano lwedatha, ixesha lekhefu kufuneka limiselwe ixesha elithile elide kunelicwangcisiweyo, njengoko ixesha lekhefu liya kuqalisa ngenye indlela i-defrost eya kulandelwa emva kwexesha elicwangcisiweyo. Ngokunxulumene nokungaphumeleli kwamandla, ixesha lekhefu liya kugcinwa, kwaye xa amandla ebuyisela ixesha lekhefu liya kuqhubeka ukusuka kwixabiso eligciniweyo. Ixesha lekhefu alisebenzi xa limiselwe ku-0. |

d03 | Isithuba seDef (0=off) |

| Ubude bexesha lokumisa iqhwa

Olu seto lixesha lokhuseleko ukuze ukunyibilika kumiswe ukuba bekungekabikho kumiswa ngokusekwe kwiqondo lobushushu okanye ngendlela yokumisa iqhwa. (Useto iya kuba lixesha lokumisa ukuba i-d10 ikhethiwe ibe ngu-0) |

d04 | Ubukhulu becala ixesha |

| Ixesha stagi-gering ye-defrost cut-ins ngexesha lokuqalisa

Umsebenzi ufanelekile kuphela ukuba unezixhobo ezininzi zesikhenkcisi okanye amaqela apho ufuna i-defrost ibe s.tagzihambelana omnye komnye. Umsebenzi ubalulekile kuphela ukuba ukhethe ukunyibilikisa ngekhefu lokuqalisa (d03). Umsebenzi ulibazisa ixesha lekhefu d03 ngenani elibekiweyo lemizuzu, kodwa lenza kube kanye kuphela, kwaye oku kwidefrost yokuqala eyenzekayo xa vol.tagu-e uqhagamshelwe kumlawuli. Umsebenzi uya kusebenza emva kokusilela kombane ngakunye. |

d05 | Ixesha Stagg. |

| Ixesha lokuphuma

Apha ubeka ixesha eliza kudlula kwi-defrost kwaye de icompressor iqale kwakhona. (Ixesha apho amanzi ethontsiza kumphunga). |

d06 | Ixesha leDripOff |

| Ukulibaziseka kwefeni kuqala emva kokumiswa kweqhwa

Apha ubeka ixesha eliza kudlula ukusuka kwicompressor iqale emva kwe-defrost kwaye de ifeni ingaqala kwakhona. (Ixesha apho amanzi “ebotshelelwa” kwi-evaporator). |

d07 | FanStartDel |

| Ubushushu bokuqalisa kweFani

I-fan inokuthi iqalwe kwangaphambi kwexesha kunokuba kukhankanyiwe phantsi "Ukulibaziseka kwefeni emva kokutshatyalaliswa", ukuba i-sensor ye-defrost i-S5 ibhalisa ixabiso eliphantsi kunelo libekwe apha. |

d08 | FanStartTemp |

| Ifeni inqumle ngexesha lokuqhaqhazela

Apha unokuseta ukuba ngaba ifeni kufuneka isebenze ngexesha lokuqhaqhazela. 0: Imisiwe (Ibaleka ngexesha lokumpompa phantsi) 1: Ukubaleka ngexesha lonke isigaba 2: Ukubaleka ngexesha lesigaba sokufudumeza kuphela. Emva koko kuyeka |

d09 | FanDuringDef |

| Isivamvo sokunyibilikisa

Apha uchaza umenzi woluvo lwe-defrost. 0: Akukho, defrost isekelwe kwixesha 1: S5 2: Sahle |

d10 | I-DefStopSens. |

| I-Defrost xa ifunwa - ixesha elihlanganisiweyo lefriji

Beka apha lixesha lokukhenkceza elivumelekileyo ngaphandle kwe-defrosts. Ukuba ixesha lidlulile, i-defrost iya kuqaliswa. Ngokucwangcisa = 0 umsebenzi uyasikwa. |

d18 | MaxTherRunT |

| I-Defrost xa ifunwa - iqondo lobushushu le-S5

Umlawuli uya kulandela ukusebenza kwe-evaporator, kwaye ngokusebenzisa izibalo zangaphakathi kunye nemilinganiselo yobushushu be-S5 iya kukwazi ukuqalisa i-defrost xa ukuhluka kweqondo lokushisa kwe-S5 kuba kukhulu kunokuba kufunwa. Apha ubeka ukuba sikhulu kangakanani isilayidi sobushushu be-S5 sinokuvunyelwa. Xa ixabiso ligqithisiwe, i-defrost iya kuqala. Umsebenzi ungasetyenziswa kuphela kwiinkqubo ze-1: 1 xa iqondo lokushisa eliphumayo liya kuba liphantsi ukuqinisekisa ukuba ubushushu bomoya buya kugcinwa. Kwiinkqubo ezingundoqo umsebenzi kufuneka unqunyulwe. Ngokucwangcisa = 20 umsebenzi uyasikwa |

d19 | I-CucutS5Dif. |

| Ukuba unqwenela ukubona iqondo lobushushu kwi-S5 sensor, cofa iqhosha elisezantsi lomlawuli. | Iqondo lokushisa lokumisa. | |

| Ukuba unqwenela ukuqalisa i-defrost eyongezelelweyo, cofa iqhosha elisezantsi lomlawuli imizuzwana emine. Unako ukumisa i-defrost eqhubekayo ngendlela efanayo | Def Qala

Apha unokuqalisa ukunyibilikisa ngesandla. |

|

| Bamba emva kweDef

Ibonisa IVULIWE xa isilawuli sisebenza nge-coordinated defrost. |

||

| Defrost State State on defrost

1= pompoza phantsi / qhaqha iqhwa |

||

| Umlandeli | Ulawulo lwabalandeli | |

| Ifeni yema kwicompressor esikiweyo

Apha ungakhetha ukuba ifeni iza kuyekwa xa icompressor isikiwe |

F01 | Ukumisa abalandeli CO

(Ewe = Kumisiwe umlandeli) |

| Ukulibaziseka kokuyeka kwefeni xa icompressor isikiwe

Ukuba ukhethe ukumisa i-fan xa i-compressor inqanyuliwe, unokulibazisa ukuyeka i-fan xa i-compressor iyekile. Apha unokuseta ukulibaziseka kwexesha. |

F02 | Fan del. CO |

| Ubushushu bokumisa iFani

Umsebenzi umisa abalandeli kwimeko yempazamo, ukuze banganiki amandla kwisixhobo. Ukuba i-sensor ye-defrost ibhalisa ubushushu obuphezulu kunelo iseti apha, abalandeli baya kunqunyanyiswa. Kuyakubakho ukuphinda kuqalwe ngo 2 K ngaphantsi kwesicwangciso. Umsebenzi awusebenzi ngexesha lokutshitshiswa kweqhwa okanye ukuqalisa emva kokutshatyalaliswa kweqhwa. Ngokucwangcisa +50 °C umsebenzi uyaphazamiseka. |

F04 | IFanStopTemp |

| Ishedyuli yangaphakathi ye-defrosting / umsebenzi wewotshi | ||

| (Ayisetyenziswanga ukuba ishedyuli yangaphandle ye-defrosting isetyenziswa ngonxibelelwano lwedatha.) Ukuya kuthi ga kumaxesha amathandathu umntu ngamnye angamiselwa ukuqalisa kwe-defrost yonke imini. | ||

| Ukuqala kwe-Defrost, ukusetwa kweyure | t01-t06 | |

| Ukuqala kokunyibilikisa, ukusetwa kwemizuzu (u-1 kunye no-11 bekunye, njl. njl.) Xa zonke t01 ukuya ku-t16 zilingana no-0, iwotshi ayisayi kuqalisa ukunyibilika. | t11-t16 | |

| Iwotshi yexesha langempela

Ukuseta iwotshi kuyimfuneko kuphela xa kungekho nxibelelwano lwedatha. Kwimeko yokusilela kwamandla ngaphantsi kweeyure ezine, umsebenzi wewotshi uya kugcinwa. Xa ufaka imodyuli yebhetri umsebenzi wewotshi unokugcinwa ixesha elide. (EKC 202 kuphela) |

||

| Ikloko: Ukumiselwa kweyure | t07 | |

| Ikloko: Useto lomzuzu | t08 | |

| Ikloko: Ukumiselwa komhla | t45 | |

| Ikloko: Ukumiselwa kwenyanga | t46 | |

| Ikloko: Ukumiselwa konyaka | t47 |

| Iintlobo ngeentlobo | Iintlobo ngeentlobo | |

| Ukulibaziseka kophawu lwemveliso emva kokuqalisa

Emva kokuqalisa okanye ukungaphumeleli kombane, imisebenzi yomlawuli inokulibaziseka ukwenzela ukuba ukugqithiswa kwenethiwekhi yokubonelela ngombane kugwenywe. Apha unokuseta ukulibaziseka kwexesha. |

o01 | DelayOfOutp. |

| Isiginali yegalelo ledijithali – DI

Umlawuli unengeniso yedijithali enokusetyenziswa komnye wale misebenzi ilandelayo: Valiwe: Igalelo alisetyenziswa 1) Umboniso wesimo somsebenzi woqhagamshelwano 2) Umsebenzi womnyango. Xa igalelo livuliwe libonisa ukuba umnyango uvuliwe. Ifriji kunye nabalandeli bamisiwe. Xa ixesha lokuseta kwi-"A04" lidlulile, i-alamu iya kunikwa kwaye ifriji iya kuqaliswa kwakhona. 3) I-alamu yomnyango. Xa igalelo livuliwe libonisa ukuba umnyango uvuliwe. Xa ixesha lokumisa kwi-"A04" lidlulile, kuya kubakho i-alamu. 4) I-Defrost. Umsebenzi uqalwa ngophawu lwepulse. Umlawuli uya kubhalisa xa igalelo le-DI livuliwe. Umlawuli uya kuthi emva koko aqalise umjikelo we-defrost. Ukuba uphawu luza kufunyanwa ngabalawuli abaliqela kubalulekile ukuba LONKE uqhagamshelo lunyuswe ngendlela efanayo (DI ukuya ku-DI kunye ne-GND ukuya kwi-GND). 5) Ukutshintsha okuphambili. Ummiselo uqhutyelwa xa igalelo lifutshane-elijikelezayo, kwaye ummiselo umisiwe xa igalelo lifakwe. CIMA. 6) Ukusebenza ebusuku. Xa igalelo lifutshane, kuya kubakho umgaqo wokusebenza ebusuku. I-7) Ukufuduswa kwereferensi xa i-DI1 ifutshane-ijikelezwe. Ukufuduswa nge-“r40”. 8) Umsebenzi we-alarm eyahlukileyo. I-alamu iya kunikwa xa igalelo lifutshane. 9) Umsebenzi we-alarm eyahlukileyo. I-alam iya kunikwa xa igalelo livuliwe. (Kwi-8 kunye ne-9 ukulibaziseka kwexesha kusetelwe kwi-A27) 10) Ukucocwa kwetyala. Umsebenzi uqalwa ngophawu lwepulse. Cf. kwanengcaciso ekwiphepha lesi-4. 11) Tofa i/cima. Cima xa DI ivuliwe. |

o02 | DI 1 Config.

Inkcazo yenzeka ngexabiso lamanani eliboniswe ngasekhohlo. (0 = cima)

DI imo (Umlinganiselo) Ubume bangoku be-DI buboniswe apha. VULA okanye IVILE. |

| Idilesi

Ukuba umlawuli wakhiwe kwinethiwekhi ngonxibelelwano lwedatha, kufuneka abe nedilesi, kwaye isango eliphambili lonxibelelwano lwedatha kufuneka liyazi le dilesi. Ukufakwa kwentambo yonxibelelwano lwedatha kukhankanyiwe kuxwebhu olwahlukileyo, "RC8AC". Idilesi imiselwe phakathi kwe-1 kunye ne-240, isango limisiwe Idilesi ithunyelwa kumphathi wesixokelelwano xa imenyu o04 isetelwe ku-'ON', okanye xa umsebenzi wokuskena womphathi wesixokelelwano uvuliwe. (i-o04 iza kusetyenziswa kuphela ukuba unxibelelwano lwedatha lu-LON.) |

Emva kokufaka unxibelelwano lwedatha, umlawuli unokusebenza ngokulinganayo kunye nabanye abalawuli kwi-ADAP- KOOL® yokulawula ifriji. | |

| o03 | ||

| o04 | ||

| Ikhowudi yokufikelela 1 (Ufikelelo kuzo zonke iisetingi)

Ukuba useto kumlawuli kufuneka lukhuselwe ngekhowudi yofikelelo ungamisela ixabiso lamanani phakathi kwe-0 kunye ne-100. Ukuba akunjalo, ungawurhoxisa umsebenzi ngokucwangcisa u-0. (99 uya kusoloko enika). uyafikelela). |

o05 | - |

| Uhlobo lwenzwa

Ngokuqhelekileyo, i-sensor ye-Pt 1000 enokuchaneka okukhulu kwesignali isetyenziswa. Kodwa unokusebenzisa inzwa ngenye indlela yokuchaneka komqondiso. Oku kunokuba yi-PTC 1000 sensor okanye i-NTC sensor (5000 Ohm kwi-25 ° C). Zonke iisensi zoluvo ezinyusiweyo kufuneka zibe zodidi olufanayo. |

o06 | I-SensorConfig Pt = 0

PTC = 1 NTC = 2 |

| Bonisa inyathelo

Ewe: Inika amanyathelo ka-0.5 ° Hayi: Inika amanyathelo ka-0.1 ° |

o15 | Disp. Inyathelo = 0.5 |

| Max. ixesha lokulinda emva kolungelelwaniso lwe-defrost

Xa umlawuli egqibile ukucima, uya kulinda umqondiso oxelela ukuba ifriji ingaphinda iqalise. Ukuba lo mqondiso uyasilela ukuvela ngesizathu esinye okanye esinye, umlawuli uya kwenza ngokwayo iqala ifriji xa eli xesha lokulinda lidlulile. |

o16 | Max HoldTime |

| Ukucwangciswa komsebenzi wokukhanya

1) I-relay cuts ngexesha lokusebenza kwemini I-2) I-relay iya kulawulwa ngonxibelelwano lwedatha 3) I-relay iya kulawulwa sisitshi socango esichazwe nokuba ngu-o02 apho isethingi ikhethwe ukuya ku-2 okanye ku-3. Xa ucango luvulwa i-relay iya kusikwa. kwakhona kuya kubakho ukulibaziseka kwexesha lemizuzu emibini phambi kokuba isibane sicinywe. |

o38 | Uqwalaselo lokukhanya |

| Ukuqaliswa of isilayidi esikhanyayo

Isilayidi sokukhanya singenziwa apha (ukuba 038=2) |

o39 | Ukukhanya okukude |

| Ukucocwa kwetyala

Ubume bomsebenzi unokulandelwa apha okanye umsebenzi unokuqaliswa ngesandla. 0 = Ukusebenza okuqhelekileyo (akukho kucoca) 1 = Ukucoca ngeefeni ezisebenzayo. Zonke ezinye iziphumo ziValiwe. 2 = Ukucoca ngabalandeli abamisiweyo. Zonke iziphumo ziCinyiwe. Ukuba umsebenzi ulawulwa ngumqondiso kwigalelo DI, imeko efanelekileyo inokubonwa apha kwi imenyu. |

o46 | Ityala licocekile |

| Ikhowudi yokufikelela 2 (Ufikelelo kuhlengahlengiso)

Kukho ufikelelo kuhlengahlengiso lwamaxabiso, kodwa hayi kwisetingi zoqwalaselo. Ukuba izicwangciso kumlawuli ziza kukhuselwa ngekhowudi yokufikelela ungabeka ixabiso lamanani phakathi kwe-0 kunye 100. Ukuba akunjalo, ungarhoxisa umsebenzi ngoseto 0. Ukuba umsebenzi usetyenziswa, fikelela ikhowudi 1 (o05) kufuneka kwakhona zisetyenziswe. |

o64 | - |

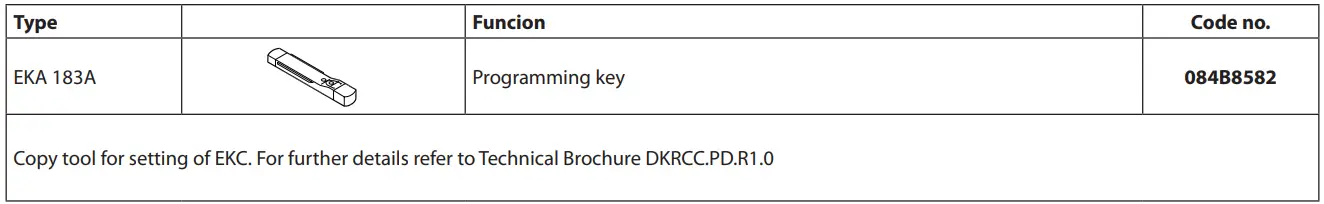

| Khuphela useto lwangoku lomlawuli

Ngalo msebenzi, izicwangciso zomlawuli zinokugqithiselwa kwiqhosha lokucwangcisa. Isitshixo sinokuqulatha ukuya kuthi ga kwiiseti ezingama-25 ezahlukeneyo. Khetha inombolo. Zonke iisetingi ngaphandle kwedilesi (o03) ziya kukotshwa. Xa ukukopa kuqalisiwe, isiboniso sibuyela ku-o65. Emva kwemizuzwana emibini, ungangena kwimenyu kwakhona kwaye ujonge ukuba ukukopa bekuyonelisa. Ukubonisa umzobo ongalunganga kuthetha iingxaki. Bona ukubaluleka kwicandelo lomyalezo ongalunganga. |

o65 | - |

| Khuphela kwiqhosha lokucwangcisa

Lo msebenzi ukhuphela isethi yesethingi ebigcinwe ngaphambili kwisilawuli. Khetha inombolo efanelekileyo. Zonke iisetingi ngaphandle kwedilesi (o03) ziya kukotshwa. Xa ukukopa kuqalisiwe isiboniso sibuyela ku-o66. Emva kwemizuzwana emibini, ungabuyela umva kwimenyu kwakhona kwaye ujonge ukuba ukukopa bekuyonelisa. Ukubonisa umzobo ongalunganga kuthetha iingxaki. Bona ukubaluleka kwi Fault Message icandelo. |

o66 | - |

| Gcina njengolungiselelo lwasefektri

Ngolu seto ugcina imimiselo eyiyo yomlawuli njengesicwangciso esitsha esisisiseko (ubuso bangaphambili- useto lwetory lubhalwe ngaphezulu). |

o67 | - |

| Esinye isicelo se-S5 sensor

Gcina isicwangciso kwi-0 ukuba inzwa ichazwe njengenzwa ye-defrost kwi-D10. Ukuba i-D10 ibekwe kwi-0 okanye i-2 igalelo le-S5 lingasetyenziswa njengenzwa yemveliso okanye i-condenser sensor. Apha uchaza ukuba yeyiphi: 0: Isivamvo sokunyibilikisa 1: Inzwa yemveliso 2: Inzwa yeCondenser ene-alarm |

o70 | Uqwalaselo lwe-S5 |

| Ukubuyisela 4

Apha uchaza isicelo se-relay 4: 1: Defrost (EKC 202A) okanye ukukhanya (EKC 202C) 2: I-Alarm |

o72 | DO4 Config |

| – – – Ukubuyisela umva ebusuku 0=Usuku

1=Ubusuku |

| Inkonzo | Inkonzo | |

| Ubushushu bulinganiswe nge-S5 sensor | u09 | Isantya seS5 |

| Ubume kwigalelo le-DI. kwi/1=ivaliwe | u10 | Ubume be-DI1 |

| Imo yokusebenza ebusuku (ivuliwe okanye icinyiwe) 1=umsebenzi wasebusuku | u13 | I-Night Cond. |

| Funda ireferensi yommiselo yangoku | u28 | Temp. Ref. |

| * Imo kwireyiti yokupholisa | u58 | Comp1/LLSV |

| * Ubume bokuhanjiswa kwefeni | u59 | Ugqithiso lwabalandeli |

| * Imo kwireyiti yokunyibilikiswa kweqhwa | u60 | Def. udluliselo |

| * Ubushushu bulinganiswe ngenzwa ye-Sair | u69 | Sair temp |

| * Imo kwi-relay 4 (i-alamu, i-defrost okanye umsebenzi okhanyayo) | u71 | DO4 ubume |

| *) Ayizizo zonke izinto eziya kuboniswa. Kuphela umsebenzi wesicelo esikhethiweyo unokubonwa. |

| Umyalezo onempazamo | Iialamu | |

| Kwimeko yempazamo ii-LED ezingaphambili ziya kudanya kwaye i-alarm relay iya kuvula. Ukuba ucofa iqhosha eliphezulu kule meko ungabona ingxelo ye-alamu kwisibonisi. Ukuba kukho ukutyhala ngakumbi kwakhona ukuze ubabone.

Kukho iindidi ezimbini zeengxelo zempazamo - inokuba yi-alam eyenzeka ngexesha lokusebenza kwemihla ngemihla, okanye kunokubakho isiphene kufakelo. Ii-alam aziyi kubonakala kude kuphele ukulibaziseka kwexesha elimiselweyo. Ii-alarm ze-E, kwelinye icala, ziya kubonakala xa kusenzeka impazamo. (I-alam ayizukubonakala okoko nje kukho i-alam ye-E esebenzayo). Nantsi imiyalezo enokuthi ivele: |

1 = i-alam |

|

| I-A1: I-alamu yokushisa okuphezulu | Phezulu t. ialam | |

| A2: I-alamu yobushushu obuphantsi | Ephantsi t. ialam | |

| A4: Isivusi socango | Umlo Alam | |

| A5: Ulwazi. Iparameter o16 iphelelwe lixesha | Max Bamba Ixesha | |

| A15: Ialam. Umqondiso ovela kwigalelo le-DI | DI1 ialam | |

| I-A45: Indawo yokulinda (iyeke ifriji nge-r12 okanye igalelo le-DI) | Imo yokulinda | |

| A59: Ukucocwa kwetyala. Umqondiso ovela kwigalelo le-DI | Ukucocwa kwetyala | |

| A61: I-alam yecondenser | Connd. ialam | |

| E1: Iimpazamo kumlawuli | Impazamo ye-EKC | |

| E6: Impazamo kwiwotshi yexesha lokwenyani. Jonga ibhetri / phinda usete iwotshi. | - | |

| E27: Impazamo yoluvo kwi-S5 | S5 impazamo | |

| E29: Impazamo yenzwa kwiSair | Sair impazamo | |

| Xa ukhuphela useto ukuya okanye ukusuka kwiqhosha lokukopa elinemisebenzi o65 okanye o66, olu lwazi lulandelayo lunokuvela:

0: Ukukopa kugqityiwe kwaye KULUNGILE 4: Iqhosha lokukopa alixhonywanga ngokuchanekileyo 5: Ukukhuphela akuchanekanga. Phinda ukhuphele i-6: Ukukhuphela kwi-EKC ayichanekanga. Phinda ukukopa 7: Ukukopa kwiqhosha lokukopa ayilunganga. Phinda ukukopa 8: Ukukopa akunakwenzeka. Inombolo ye-odolo okanye inguqulelo ye-SW ayihambelani ne-9: Impazamo yonxibelelwano kunye nexesha lokuvala 10: Ukukopa kusaqhubeka (Ulwazi lunokufumaneka ku-o65 okanye o66 kwimizuzwana embalwa emva kokuba kukhutshiwe waqala). |

||

| Iindawo zokuya kwi-alam | ||

| Ukubaluleka kwee-alam zomntu ngamnye kunokuchazwa ngokucwangcisa (0, 1, 2 okanye 3) |

Isilumkiso! Ukuqala ngokuthe ngqo kweecompressors

Ukuthintela i-compressor breakdown parameters i-c01 kunye ne-c02 kufuneka imiselwe ngokweemfuno zomthengisi o, r ngokubanzi, i-Hermetic Compressors c02 min. Imizuzu ye-5, i-Semihermetic Compressors c02 min. 8 imizuzu, kunye c01 min. Imizuzu emi-2 ukuya kwemi-5 ( Motor ukusuka kwi-5 ukuya kwi-15 KW ) * ). Ukusebenza ngokuthe ngqo kwee-valve ze-solenoid akufuni izicwangciso ezahlukeneyo kwi-factory (0).

Bhala ngaphezulu

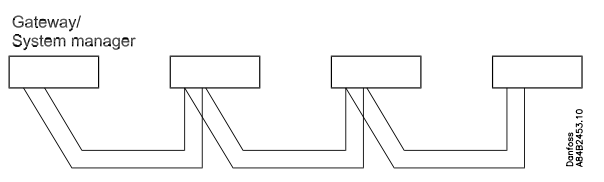

Umlawuli uqulethe inani lemisebenzi enokusetyenziswa kunye nomsebenzi ogqithisiweyo kwi-master gateway / uMphathi weNkqubo.

|

Umsebenzi ngonxibelelwano lwedatha |

Imisebenzi eza kusetyenziswa kwisango lesango umsebenzi ongaphezulu |

Iparameter esetyenzisiweyo kwi-EKC 202 |

| Ukuqala kokuqhaqha | Ulawulo lwe-Defrost Ishedyuli yexesha | – – – Def. qala |

| Ukunyibilikiswa kweqhwa | Ukulawula ukhenkce |

– – – HoldAfterDef u60 Def.relay |

| Ukubuyisela umva ebusuku |

Ulawulo lwemini/ubusuku Ishedyuli yexesha |

– – – Ukuseta ebusuku |

| Ukulawula ukukhanya | Ulawulo lwemini/ubusuku Ishedyuli yexesha | o39 Ukukhanya okukude |

Uqhagamshelwano

Ukunikezwa Amandla

- 230 V ac

Izivamvo

- I-Sair yinzwa ye-thermostat.

- I-S5 yinzwa yokuqhaqha kwaye isetyenziswa ukuba i-defrost kufuneka imiswe ngokusekelwe kwiqondo lokushisa. Nangona kunjalo, inokusetyenziswa njengenzwa yemveliso okanye i-condenser sensor.

Isiginali yeDijithali Vula/Cima

Igalelo lokusika lizakwenza umsebenzi usebenze. Imisebenzi enokwenzeka ichazwe kwimenyu o02.

IiRelay

Uqhagamshelo jikelele zezi: Isikhenkcisi. Umfowunelwa uya kunqunyulwa xa umlawuli efuna ifriji Defrost. Umlandeli.

- Ialarm. I-relay inqunywe ngexesha lokusebenza okuqhelekileyo kwaye iyancipha kwiimeko ze-alamu kwaye xa umlawuli efile (u-de-energized)

- Ukukhanya. Umfowunelwa uya kunqumla xa umlawuli efuna ukukhanya.

Ingxolo yombane

Iintambo zezivamvo, amagalelo e-DI, kunye nonxibelelwano lwedatha kufuneka zigcinwe zahlukile kwezinye iintambo zombane:

- Sebenzisa iitreyi zentambo ezahlukeneyo

- Gcina umgama phakathi kweentambo ubuncinci be-10 cm

- Iintambo ezinde kwigalelo le-DI kufuneka ziphetshwe

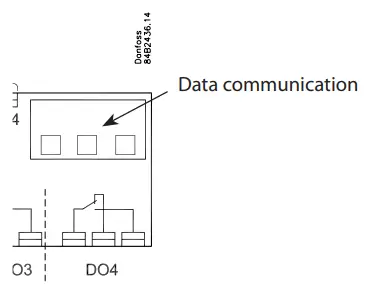

Unxibelelwano lwedatha

Ukuba unxibelelwano lwedatha lusetyenziswa, kubalulekile ukuba ukufakwa kwekhebula lonxibelelwano lwedatha lwenziwe ngokuchanekileyo. Jonga uncwadi olwahlukileyo Nomb. RC8AC.

- MODBUS okanye LON-RS485 ngokufaka amakhadi.

Ukuodola

- Izivamvo zobushushu: nceda ubhekisele kwi-lit. Hayi. I-RK0YG

Idatha yobugcisa

| Ukubonelela ngevoltage | 230 V ac +10/-15%. 2.5 VA, 50/60 Hz | ||

| Izinzwa 3 pcs off nokuba | Pt 1000 okanye

PTC 1000 okanye I-NTC-M2020 (5000 ohm / 25°C) |

||

|

Ukuchaneka |

Uluhlu lokulinganisa | -60 ukuya +99°C | |

|

Umlawuli |

±1 K ngaphantsi -35°C

±0.5 K phakathi -35 ukuya +25°C ±1 K ngaphezu +25°C |

||

| Pt 1000

isivamvo |

±0.3 K ku-0°C

±0.005 K ngebakala ngalinye |

||

| Bonisa | I-LED, i-3-digits | ||

|

Amagalelo edijithali |

Umqondiso ovela kwimisebenzi yoqhagamshelwano Iimfuno kubafowunelwa: Ukufakwa kwegolide, Ubude beCable kufuneka bube max. 15 m

Sebenzisa ii-relays ezincedisayo xa intambo inde |

||

| Intambo yoqhagamshelwano lombane | Ubuninzi.1,5 mm2 multi-core cable

Max. 1 mm2 kwizixhobo zoluvo kunye namagalelo e-DI |

||

|

iiRelay* |

IEC60730 | ||

| I-EKC 202

|

I-Do1 | 8 (6) A & (5 FLA, 30 LRA) | |

| I-Do2 | 8 (6) A & (5 FLA, 30 LRA) | ||

| I-Do3 | 6 (3) A & (3 FLA, 18 LRA) | ||

| DO4** | 4 (1) A, Min. 100 mA** | ||

| Unxibelelwano lwedatha | Ngekhadi lokufaka | ||

|

Ubume bendalo |

0 ukuya +55 ° C, Ngexesha lokusebenza

-40 ukuya +70 ° C, Ngexesha lokuthutha |

||

| 20 – 80% iRh, ayicondensed | |||

| Akukho mpembelelo yokothuka/ukungcangcazela | |||

| Indawo ebiyelweyo | IP 65 ukusuka ngaphambili.

Amaqhosha kunye nokupakisha kufakwe ngaphambili. |

||

| Indawo yokubalekela iwotshi |

iiyure ezi-4 |

||

|

Iimvume |

Umthamo ophantsi we-EUtage Umyalelo kunye ne-EMC ifuna ukuba ukumakishwa kwe-CE kuthotyelwe

I-EKC 202: Ukwamkelwa kwe-UL acc. UL 60730 I-LVD ivavanywe i-acc. I-EN 60730-1 kunye ne-EN 60730-2-9, A1, A2 I-EMC ivavanywe i-acc. I-EN 61000-6-3 kunye ne-EN 61000-6-2 |

||

- I-DO1 kunye ne-DO2 zine-16 A iilayidi. I-8 A ekhankanywe inokunyuswa ukuya kwi-10 A, xa ubushushu be-ambient bugcinwa bungaphantsi kwe-50 ° C. I-DO3 kunye ne-DO4 yi-8A yokuhanjiswa. Ngaphezulu kobuninzi. Umthwalo kufuneka ugcinwe.

- Ukufakwa kwegolide kuqinisekisa umsebenzi omhle kunye nemithwalo encinci yoqhagamshelwano

UDanfoss akanakwamkela uxanduva ngeempazamo ezinokwenzeka kwiikhathalogu, iincwadana, kunye nezinye izinto ezishicilelweyo. I-Danfoss inelungelo lokutshintsha iimveliso zayo ngaphandle kwesaziso. Oku kusebenza nakwiimveliso esele zenziwe ngokomyalelo ukuba olo tshintsho lunokwenziwa ngaphandle kokuba kubekho utshintsho olufunekayo kwiinkcukacha esele kuvunyelwene ngazo. Zonke iimpawu zokuthengisa kule mpahla ziyipropathi yeenkampani ezifanelekileyo. UDanfoss kunye noDanfoss logotype ziimpawu zorhwebo zikaDanfoss A/S. Onke Amalungelo Agciniwe.

Imibuzo ebuzwa qho

Ndiwuqala njani umjikelo wokunyibilikisa iqhwa?

Umjikelo we-defrost unokuqalwa ngeendlela ezahlukeneyo, kubandakanywa ikhefu, ixesha lokukhenkceza, uphawu loqhagamshelwano, ukusebenza ngesandla, ishedyuli, okanye unxibelelwano lwenethiwekhi.

Igalelo ledijithali lingasetyenziselwa ntoni?

Igalelo ledijithali lingasetyenziselwa imisebenzi efana noqhagamshelwano lomnyango kunye nesaziso se-alam ukuba ucango luhlala luvuliwe.

Amaxwebhu / Izibonelelo

|

I-Danfoss EKC 202A Isilawuli soLawulo loBubushushu [pdf] Isikhokelo somsebenzisi 202A, 202B, 202C, EKC 202A Controller For Temperature Control, EKC 202A, Controller For Temperature Control, For Control Control, Temperature Control |