General Service Bulletin

General Service Bulletin

IntelliPak™1 & IntelliPak™2 Condenser Fan Motor Failures

Product Code: 0383, 0504

IntelliPak 2 Condenser Fan Motor Failures

![]() SAFETY WARNING

SAFETY WARNING

Only qualified personnel should install and service the equipment. The installation, starting up, and servicing of heating, ventilating, and air-conditioning equipment can be hazardous and requires specific knowledge and training. Improperly installed, adjusted or altered equipment by an unqualified person could result in death or serious injury. When working on the equipment, observe all precautions in the literature and on the tags, stickers, and labels that are attached to the equipment.

Introduction

Read this manual thoroughly before operating or servicing this unit.

Warnings, Cautions, and Notices

Safety advisories appear throughout this manual as required.

Your personal safety and the proper operation of this machine depend upon the strict observance of these precautions.

The three types of advisories are defined as follows:

WARNING

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation which, if not avoided, could result in minor or moderate injury. It could also be used to alert against unsafe practices.

NOTICE

Indicates a situation that could result in equipment or property-damage only accidents.

Important Environmental Concerns

Scientific research has shown that certain man-made chemicals can affect the earth’s naturally occurring stratospheric ozone layer when released to the atmosphere. In particular, several of the identified chemicals that may affect the ozone layer are refrigerants that contain Chlorine, Fluorine and Carbon (CFCs) andthose containing Hydrogen, Chlorine, Fluorine and Carbon (HCFCs). Not all refrigerants containing these compounds have the same potential impact to the environment. Trane advocates the responsible handling of all refrigerants-including industry replacements for CFCs and HCFCs such as saturated or unsaturated HFCs and HCFCs.

Important Responsible Refrigerant Practices

Trane believes that responsible refrigerant practices are important to the environment, our customers, and the air conditioning industry. All technicians who handle refrigerants must be certified according to local rules. For the USA, the Federal Clean Air Act (Section 608) sets forth the requirements for handling, reclaiming, recovering and recycling of certain refrigerants and the equipment that is used in these service procedures. In addition, some states or municipalities may have additional requirements that must also be adhered to for responsible management of refrigerants. Know the applicable laws and follow them.

![]() WARNING

WARNING

Proper Field Wiring and Grounding Required!

Failure to follow code could result in death or serious injury. All field wiring MUST be performed by qualified personnel.

Improperly installed and grounded field wiring poses FIRE and ELECTROCUTION hazards. To avoid these hazards, you MUST follow requirements for field wiring installation and grounding as described in NEC and your local/state electrical codes.

![]() WARNING

WARNING

Personal Protective Equipment (PPE) Required!

Failure to wear proper PPE for the job being undertaken could result in death or serious injury. Technicians, in order to protect themselves from potential electrical, mechanical, and chemical hazards, MUST follow precautions in this manual and on the tags, stickers, and labels, as well as the instructions below:

- Before installing/servicing this unit, technicians MUST put on all PPE required for the work being undertaken (Examples; cut resistant gloves/sleeves, butyl gloves, safety glasses, hard hat/bump cap, fall protection, electrical PPE and arc flash clothing). ALWAYS refer to appropriate Safety Data Sheets (SDS) and OSHA guidelines for proper PPE.

- When working with or around hazardous chemicals, ALWAYS refer to the appropriate SDS and OSHA/GHS (Global Harmonized System of Classification and Labelling of Chemicals) guidelines for information on allowable personal exposure levels, proper respiratory protection and handling instructions.

- If there is a risk of energized electrical contact, arc, or flash, technicians MUST put on all PPE in accordance with OSHA, NFPA 70E, or other country-specific requirements for arc flash protection, PRIOR to servicing the unit. NEVER PERFORM ANY SWITCHING, DISCONNECTING, OR VOLTAGE TESTING WITHOUT PROPER ELECTRICAL PPE AND ARC FLASH CLOTHING. ENSURE ELECTRICAL METERS AND EQUIPMENT ARE PROPERLY RATED FOR INTENDED VOLTAGE.

![]()

Follow EHS Policies!

Failure to follow instructions below could result in death or serious injury.

- All Trane personnel must follow the company’s Environmental, Health and Safety (EHS) policies when performing work such as hot work, electrical, fall protection, lockout/tagout, refrigerant handling, etc.

Where local regulations are more stringent than these policies, those regulations supersede these policies. - Non-Trane personnel should always follow local regulations.

Copyright

This document and the information in it are the property of Trane and may not be used or reproduced in whole or in part without written permission. Trane reserves the right to revise this publication at any time, and to make changes to its content without obligation to notify any person of such revision or change.

Trademarks

All trademarks referenced in this document are the trademarks of their respective owners.

Revision History

A. Initial release

B. Corrective Actions updated to remove EC Control addressing and added TD7 Modbus Device Addressing. Removed converter from parts list.

Description

The purpose of this service bulletin is to advise the field of IPak™1 & 2 Condenser Fan Motor Failures.

The action described in this general service bulletin is NOT being taken to address a safety concern.

This is a MANDATORY retrofit.

Affected Units

IPak™1 & 2 model prefix SAHM*, SEHM*, SFHM*, SLHM*, SXHM*, SEHN*, SFHN*, SLHN*, SXHN* having High Efficiency, Low ambient, and/or eFlex™ Variable Speed compressor options with serial in range C22H06843 to C23K06625 shipped between April 2023 and April 2024. Only impacts units with EBM Condenser Fan motors which were manufactured with S/N 2406xxxxx (week 6 of 2024) or prior. DOES NOT IMPACT UNITS WITH REGAL MOTORS.

| Product | High Efficiency | Low Ambient | eFlex™ |

| IntelliPak™1 | Service model digit 26 = H | Service model digit 19 = 1 | Service model digit 26 = V |

| IntelliPak™2 | Not applicable | Service model digit 31 = 1 | Service model digit 28 = W or Z |

Only unit serials on the associated Affected unit List are Covered. Link to Affected Unit List: https://hub.tranetechnologies.com/docs/DOC220044

Discussion

Ipak1™ & Ipak2™ factory installed EBM condenser fan motors prematurely failing from motor stator winding and power electronic damage. Motor failure symptoms may occur including clicking, vibration, phantom running, no motor function, fan blade fatigue & cracking, and condenser Fan Motor Phase Loss (1A, 1B, 1C, 1D, 2A, 2B, 2C, or 2D) diagnosis will display on TD7 or TU.

Resolution will require proactively replacing the condenser fan motor. It may also require replacing additional components. See corrective action section for further details.

There are several pre-requisites needed prior to traveling to site, see corrective actions section for details.

Corrective Action – Process

The following actions should be taken only for unit serials identified in the affected unit list. It is recommended that you include your local parts team to plan a glide path for parts orders needed to ensure space to receive them in your local supply store.

Important before traveling to jobsite ensure you have the following items:

- If the unit has been installed and is running, you will need to order both replacement Condenser fan motors & fans. If unit has not been installed or has no run time, you will need to replace Condenser fan motors only. For quantities & part numbers (see parts section for more info – must use KIT# not MOT#). Save replacement part packaging to return removed motors to Trane Supply.

- Download latest Firmware version to your laptop and instructions: IntelliPak® with Symbio® 800 , Release: 6/19/2024 Version: 04.00.0003 (Figure 1). Link: Trane Controls Software & Firmware Downloads

Section 1: Replacing EBM Condenser Fan Motor & Fan Blades (Figure 2) to be done at site: Only impacts units with EBM Condenser Fan motors which were manufactured with S/N 2406xxxxx (week 6 of 2024) or prior. DOES NOT IMPACT UNITS WITH EGAL

MOTORS.

1.1. Update Firmware on Symbio 800 Controller: Updating-Firmware-on-a-Symbio-800-Controller.pdf (trane.com)

1.2. If the unit has been installed and is running, replace Condenser fan motors & fans. If unit has not been installed or has no run time, replace Condenser fan motors only. Save replacement part packaging to return removed motors to Trane Supply in it.

1.3. Power unit down

1.4. Remove condenser fan grill and set it to the side.

1.5. Loosen condenser fan set screw from motor’s shaft.

1.6. Remove condenser fan blade.

1.7. Disconnect Power and Modbus harnesses.

1.8. Remove 6 nuts that secure the motor and bracket and remove condenser fan motor assembly.

1.9. Install replacement condenser fan motor in its place and tightly secure all 6 nuts.

1.10. Reconnect Power and MODBUS wiring. IMPORTANT: If you are replacing multiple condenser fan motors, you can physically replace all motors at the same time but only reconnect Power and MODBUS cables of one of the new condenser motors initially.

Connecting multiple new motors at the same time will affect motor addressing (see steps below).

2. Section 2: Steps for Modbus device addressing after new motors/fans are installed.

IMPORTANT: each fan will need to be addressed separately. All the Modbus devices are on the same network, so each fan will need to be isolated before setting the address. For example, on a 4 fan / circuit unit, if all 4 fans are being replaced, unplug 3 of the 4 fans to isolate fan 1A, set address. Then, plug in 1B, set address, etc.

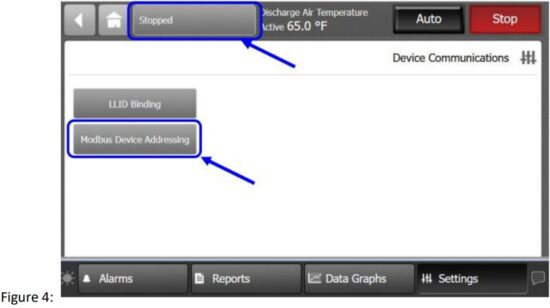

2.1. Open Trane Display TD7 and click on the ‘Device Communications’ button (figure 3).

2.2. Ensure Unit status is in ‘Stopped’ and then click ‘Modbus Device Addressing’ (figure 4).

2.3. You will receive warning for experienced service personnel, Click OK (figure 5).

2.4. See section 3 for Ipak 1 configurations (figure 9) and section 4 for Ipak 2 configurations (figure 10) for help to confirm Modbus Device name based on location of device in unit.

2.5. Select the Device Name and click the ‘Set/Clear Address’ button beside it (figure 6).

2.6. You will receive a Confirm message, click OK (figure 7).

2.7. If additional motors are to be programmed, power unit off and then connect Power and MODBUS connectors to the next motor to

be programmed and power back on. Repeat Steps above in section 2.

2.8. Confirm that any Condenser Fan Communication Loss diagnostics have been cleared (Figure 8).

3. Section 3: IntelliPak™ 1 Condenser Fan Configurations, Figure 9:

4. Section 4: IntelliPak™ 2 Condenser Fan Configurations, Figure 10:

Parts Ordering Information

Parts should be ordered through Trane Supply using the standard repair order process.

See affected unit list column-AT for Quantity, column-AU for Motor KIT number, & column AV for FAN part number for associated serial line (equal quantities of KITs & Fans are needed). We recommend placing orders for the needed parts quickly. For area offices with large quantities needed, please plan a glide path for bringing in parts which is appropriate for your local resources.

IMPORTANT NOTES:

• Removed Motors must be returned to Trane Supply for credit.

o Save replacement part packaging & reuse to return removed motors to Trane Supply in it.

o A picture of the defective motor nameplate is also required.

o Trane Supply must reach out to EBM, Tatianna Pollard – tatianna.pollard@us.ebmpapst.com / 860-507-8270) for Return Address & RMA. Trane Supply will need to provide the failed site location, picture of defective motor nameplates, and quantities to be returned.

▪ Re-use replacement part packaging to return removed/defective motors to EBM.

▪ If possible, a full pallet of 12 defective motors should be accumulated and then a single RMA can be requested from EBM for each group of motors on the full pallet.

▪ RMA should be attached to each individual package for defective motors as well as on the pallet.

▪ Shipments ≤ 70lbs use: FedEx Ground, Account number: 420450010

▪ Shipments ≥ 70lbs use: XPO Logistics Ground Collect, Account number: EBMIDXHR000.

• For XPO Logistics – US: 800-755-2728

• For XPO Logistics – Canada: 800-342-7618

▪ Clearly reference the RMA# as well as bulletin number RT-SVB194 on all boxes and shipping paperwork.

For bulletin you MUST use KIT# listed below for replacement motors. DO NOT use MOT#!

| Part Number | Description | Quantity |

| KIT20480 | MOTOR ASSEMBLY; FAN EC 1.5 HP; 200-240V 50/60HZ 3PH – X70378033001 (replaces MOT20716– do not use MOT part number to order) |

Purchase these through Trane Supply. See affected unit list for quantities needed by unit serial (columns AT thru AV) |

| KIT20481 | MOTOR ASSEMBLY; FAN EC 1.5 HP; 380-480V 50/60HZ 3PH – X70378033002 (replaces MOT20717– do not use MOT part number to order) |

|

| KIT20482 | MOTOR ASSEMBLY; FAN EC 1.5 HP; 575V 60HZ 3PH – X70378033003 (replaces MOT20718– do not use MOT part number to order) |

|

| KIT20483 | MOTOR ASSEMBLY; FAN EC 1.0 HP; 200-240V 50/60HZ 3PH – X70378034001 (replaces MOT20719– do not use MOT part number to order) |

|

| KIT20484 | MOTOR ASSEMBLY; FAN EC 1.0 HP; 380-480V 50/60HZ 3PH – X70378034002 (replaces MOT20720– do not use MOT part number to order) |

|

| KIT20485 | MOTOR ASSEMBLY; FAN EC 1.0 HP; 575V 60HZ 3PH – X70378034003 (replaces MOT20721– do not use MOT part number to order) |

|

| FAN01516 | FAN; 4 BLADE, STEEL, 26 DIA, 29 DEG, .62 BORE – X3801033501 | |

| FAN04077 | FAN; 3 BLADE, 19 DEGREE PITCH – X38010659010 – (FAN03865 supersedes to FAN04077) |

|

| FAN04078 | FAN; 3 BLADE, 23 DEGREE PITCH – X38011052010 |

Material Disposition

Dispose of all parts, including any unused parts and materials, in accordance with federal, state, and local laws and ordinances.

![]() Please recycle when possible.

Please recycle when possible.

Questions

Contact the Large Commercial: Ipak/Voy3/RAU(>25Tons) Technical Support team if you are a Trane Distributor or a Commercial Sales Office: https://support.trane.com/hc/en-us/requests/new. Otherwise, please contact the local Trane distributor or a Commercial Sales Office.

Trane – by Trane Technologies (NYSE: TT), a global climate innovator – creates comfortable, energy efficient indoor environments for commercial and residential applications. For more information, please visit trane.com or tranetechnologies.com.

Trane has a policy of continuous product and product data improvement and reserves the right to change design and specifications without notice. We are committed to using environmentally conscious print practices.

Confidential and proprietary Trane information

RT-SVB194B-EN 28-June-2024

(replaces RT-SVB194A-EN)

©2024 Trane

June 2024

RT-SVB194B-EN

Confidential and proprietary Trane information

Confidential and proprietary Trane information

Documents / Resources

|

TRANE IntelliPak 2 Condenser Fan Motor Failures [pdf] Instruction Manual IntelliPak 2 Condenser Fan Motor Failures, IntelliPak 2, Condenser Fan Motor Failures, Fan Motor Failures, Motor Failures |