Quatrosense B6 Dual Sensor Gas Transmitter

Specifications

- Product Name: B6 Dual-Sensor Gas Transmitter

- BACnet Protocol Implementation Conformance: PIC

- Communication Protocol: BACnet MS/TP

- Sensors: Dual sensors – electrochemical, catalytic, NDIR infrared

- Device Type: End device in terms of BACnet protocol

Product Description:

The B6 Gas Transmitter is equipped with dual sensors capable of detecting toxic gases, combustible gases, CO2, and CH4. It communicates via the BACnet protocol MS/TP and is designed to be an end device in the BACnet network.

Usage Instructions

Installation:

- Choose a suitable mounting location for the Gas Transmitter.

- Ensure proper power supply and connectivity according to the selected communication protocol.

- Mount the device securely following the provided installation guidelines.

Configuration:

- Access the configuration settings via the provided software interface or physical controls.

- Set up sensor calibration as per the user manual instructions for accurate detection.

- Configure network settings to ensure proper communication with other BACnet devices.

Operation

- Monitor gas levels and alarms using the display interface or connected BACnet workstation.

- Regularly check and maintain sensors for optimal performance.

- Respond promptly to any alerts or notifications from the Gas Transmitter.

INSTALLATION OPERATION AND MAINTENANCE MANUAL

AUTOMATION COMPONENTS, INC.

- 2305 PLEASANT VIEW ROAD | MIDDLETON, WI 53562

- PHONE: 888-967-5224 FAX: 608-831-7407

- Web: workaci.com

READ BEFORE OPERATING

- All individuals who have or will have the responsibility of using, maintaining, or servicing this product must carefully read this manual. The product will perform as designed only if it is used, maintained, and serviced in accordance with the manufacturer’s instructions.

- The B6 is a state-of-the-art dual-sensor gas transmitter that can operate as an independent, stand-alone system or as part of an integrated system. Setup procedures are simplified with user friendly push buttons and LCD menus.

The B6 is the Q6 gas transmitter with BACnet® MS/TP master protocol. B6 consists of B6M and Q6R. - BACnet MS/TP protocol is a peer-to-peer, multiple master protocol based on token passing. Only master nodes are allowed to send and receive tokens on the MSTP network. Passive slave nodes on the other hand may only transmit data frames on the network in response to a request from a master node. Passing the token represents overhead in the sense that the messages used for managing the token do not carry data that is useful to automation or monitoring.

- The B6 can be set to be a Master Node or a Slave Node in the field. Factory default is master node.

- B6M: B6 Main unit with smart sensor, relay, digital port, display and keypad

- Q6R: Q6 Remote unit with smart sensor only

Specifications

Electrical/Mechanical Specifications

| Input Power: | 24VDC nominal, range 18 to 30VDC, 0.3A DC Total Max. 24VAC nominal, range 18 to 24VAC, 0.3A AC Total Max. |

| Fuse: | F2 on Main Board: Polyswitch 750mA

Polyswitch device resets after the fault is cleared and power to the circuit is removed. |

| Sensor: | Combustible gases: Catalytic or NDIR Toxic gases and Oxygen: Electrochemical

Carbon Dioxide: Non-Dispersive Infra-Red (NDIR) |

|

Sampling: |

Diffusion or Pump-through |

| Panel Indicators: | 5 Status LED’s

· RS-485 TX Status (Green) · RS-485 RX Status (Green) · Relay1 Status (Red) · Relay2 Status (Red) · Relay2 Status (Red) |

| Display: | LCD graphic display c/w backlight |

| Keypad: | 3 capacitive touch sensing Keys: F1, F2, F3 |

| Relays: | 3 Relays SPDT, Dry contacts

· 1.0A maximum at 30 VDC (resistive load) · 0.3A maximum at 125VAC (resistive load) |

| Buzzer: | 55 dB at 10 feet, 2700 Hz

Buzzer 1, 2, 3: Programmable tone Tone: chirp once / chirp twice / 50% duty cycle / constant ON |

| Output Signal: | BACnet® MS/TP master /slave protocol |

| Enclosure Rating: | IP 66 & NEMA 4, 4X, 12 & 13 |

| Operating Temperature: | -40°C to 50°C, depends on sensor specification |

| Ambient Humidity: | 5% to 95% RH (non-condensing) |

| Storage Temperature: | 0°C to 25°C, depends on sensor specification |

| Size: | 150mm X 90mm X 65mm |

| Weight: | Less than 0.5lbs |

Sensor Specifications

| Code | Gas | Symbol | Gas Density | Span | Operating Temperature |

| 16 | Methane | CH4 | Lighter | 0 – 100%LEL | -10°C to +50°C |

| 17 | Propane | C3H8 | Heavier | 0 – 100%LEL | -10°C to +50°C |

| 18 | Hydrogen | H2 | Lighter | 0 – 100%LEL | -10°C to +50°C |

| *19 | Combustible | LEL | 0 – 100%LEL | -10°C to +50°C | |

| *20 | Ethylene | C2H4 | Slightly Lighter | 0 – 100%LEL | -10°C to +50°C |

| *21 | Iso-Butane | C4H10 | Heavier | 0 – 100%LEL | -10°C to +50°C |

| *22 | Iso-Pentane | C5H12 | Lighter | 0 – 100%LEL | -10°C to +50°C |

| *23 | Methanol | CH3OH | Lighter | 0 – 100%LEL | -10°C to +50°C |

| *24 | Benzene | C6H6 | Lighter | 0 – 100%LEL | -10°C to +50°C |

| *25 | Acetone | CH3CO | Lighter | 0 – 100%LEL | -10°C to +50°C |

| *26 | Butanol, n-Butane | BUTAN | Heavier | 0 – 100%LEL | -10°C to +50°C |

| Code | Gas | Symbol | Gas Density | Span | Operating Temperature |

| 0 | Oxygen | O2 | 0 – 25%VOL | -30°C to +55°C |

| Code | Gas | Symbol | Gas Density | Span | Operating Temperature |

| 1 | Carbon Monoxide | CO | Slightly Lighter | 0 – 250ppm | -20°C to +50°C |

| 1 | Carbon Monoxide | CO | Slightly Lighter | 0 – 1000ppm | -20°C to +50°C |

| 2 | Hydrogen Sulfide | H2S | Heavier | 0 – 25ppm | -20°C to +50°C |

| 2 | Hydrogen Sulfide | H2S | Heavier | 0 – 100ppm | -20°C to +50°C |

| 3 | Sulphur Dioxide | SO2 | Heavier | 0 – 6ppm | -20°C to +50°C |

| 5 | Nitrogen Dioxide | NO2 | Heavier | 0 – 10ppm | -20°C to +50°C |

| 6 | Hydrogen | H2 | Lighter | 0 – 1000ppm | -20°C to +50°C |

| 6 | Hydrogen | H2 | Lighter | 0 – 2000ppm | -20°C to +50°C |

| 7 | Hydrogen Cyanide | HCN | Lighter | 0 – 50ppm | -20°C to +50°C |

| 9 | Ammonia | NH3 | Lighter | 0 – 100ppm | -30°C to +50°C |

| 9 | Ammonia | NH3 | Lighter | 0 – 1000ppm | -30°C to +50°C |

| 11 | Ozone | O3 | Heavier | 0 – 1ppm | -20°C to +40°C |

| 13 | Chlorine | Cl2 | Heavier | 0 – 5ppm | -20°C to +50°C |

| 14 | Chlorine Dioxide | ClO2 | Heavier | 0 – 2ppm | -20°C to +40°C |

| 96 | Arsine | AsH3 | Heavier | 0 – 1ppm | -20°C to +40°C |

| 97 | Phosphine | PH3 | Heavier | 0 – 5ppm | -20°C to +40°C |

| 97 | Phosphine | PH3 | Heavier | 0 – 1ppm | -20°C to +40°C |

| 98 | Silane | SiH4 | Heavier | 0 – 50ppm | -20°C to +40°C |

| 99 | Germane | GeH4 | Heavier | 0 – 2ppm | -20°C to +40°C |

| 100 | Diborane | B2H6 | Slightly Lighter | 0 – 2ppm | -20°C to +40°C |

| 4 | Nitric Oxide | NO | Slighter Heavier | 0 –100ppm | -20°C to +50°C |

| 8 | Hydrogen Chloride | HCl | Heavier | 0 – 30ppm | -20°C to +40°C |

| 12 | Ethylene Oxide | ETO | Heavier | 0 – 20ppm | -20°C to +50°C |

| 101 | Hydrogen Bromide | HBr | Heavier | 0 – 30ppm | -20°C to +40°C |

| Code | Gas | Symbol | Gas Density | Span | Operating Temperature |

| 15 | Carbon Dioxide | IR-CO2 | Heavier | 0 – 5000ppm | -20°C to +50°C |

| 15 | Carbon Dioxide | IR-CO2 | Heavier | 0 – 5%VOL | -20°C to +50°C |

| 15 | Carbon Dioxide | IR-CO2 | Heavier | 0 – 20%VOL | -20°C to +50°C |

| 15 | Carbon Dioxide | IR-CO2 | Heavier | 0 – 100%VOL | -20°C to +50°C |

| 16 | Methane | IR-CH4 | Lighter | 0 – 100%LEL | -20°C to +50°C |

| 16 | Methane | IR-CH4 | Lighter | 0 – 100%VOL | -20°C to +50°C |

NOTE: Mounting Heights

- Low = 9-18 inches (0.25-0.5 meters) from floor

- Mid = 4-6 feet (1.25-1.75 meters) from floor

- High = 9-18 inches (0.25-0.5 meters) from ceiling

Installation

Enclosures Physical Dimensions

The enclosure is a NEMA 4 rated enclosure and can be wall mounted with 4 screws. To maintain the NEMA rating, it is important that the conduit opening is sealed upon installation.

The enclosure is a NEMA 4 rated enclosure and can be wall mounted with 4 screws. To maintain the NEMA rating, it is important that the conduit opening is sealed upon installation.

Location

- The transmitter should be mounted where the gas to be measured is most likely to be present. This location will be dependent on the source of the target gas and whether that gas is lighter or heavier than air. Air circulation and mixture should also be taken into account.

- CO gas is lighter than regular air, it can be mounted on the walls at least a couple of feet below the height of the ceiling. As the transmitter has a digital read-out, placing it at about eye level is strong recommended.

- The location should be accessible for the purposes of routine re-calibration and periodic sensor replacement. Sufficient room should be left to allow the enclosure cover to be removed and the connection of the calibration adapter to the sensor chamber. For sensor element replacement there will need to be enough room to remove enclosure cover and the sensor board assembly.

- NOTE: The transmitter can also be installed in limited outdoor environment – An ambient air environment that is not climate controlled and is not in direct contact with the elements of nature, such as wind, rain, sleet or snow. Examples of limited outdoor environments include parking garages, construction complexes, sports venues, boats and recreational vehicles.

- NOTE: Avoid mounting the transmitter near 600 VAC switchgear and other sources of radio frequency and/or electromagnetic interference. While RFI/EMI protection is built in to the transmitter, excessive levels of interference may cause instability in the output signal.

Terminals

Q6R Terminals

Q6R Terminals

Wire and Cable

- Terminal blocks TB1 to TB7 accept 12 AWG to 24 AWG wire. Use 16 AWG or 18 AWG wire for the power supply in long wiring runs, which can be up to 1km (1,000 meters) long.

- We recommend using BELDEN 9841 for communications. This wire has 120 ohm input impendence, which will eliminate RS-485 communication problems.

Power Requirements

- The B6M and Q6R power supply voltage requirements are nominally 24VAC or 24VDC.

- The B6M and Q6R both have full wave rectifier and half wave rectifier on board. You will damage devices if you mix half wave and full wave rectifiers on the same AC source. Use extreme caution when sharing a common AC source. Sharing a common DC source is less problematic.

RS-485 Terminator

The terminator on each end of the RS485 run is designed to match the electrical impedance characteristic of the twisted pair wire, and will prevent signal echoes from corrupting the data on the line. The terminator should be enabled on BOTH ends of the RS485 run. Short and medium length Modbus/485 runs can operate without the terminating resistor. Longer runs may require the terminating resistors. But adding terminator dramatically increases power consumption.

The factory default setting is disabled terminator.

The B6 supplies this resistor on the main board, and it is chosen using a jumper at J4.

- J4 1-2: Terminator Disabled / OFF (default)

- J4 2-3: Terminator Enabled / ON

RS-485 Driver Replacement

RS-485 lines in heavy industrial environments are sometimes subjected to magnetic disturbances causing sufficient inducted power surges to damage the driver integrated circuit (IC). This IC (U6) has a socket on the circuit card for ease of replacement in the field.

B6 Operation And Maintenance Manual

Relays Output

- The B6 has three onboard programmable Single-Pole Double-Throw (SPDT) relays. These relays can be used to control other equipment, such as fans, lights, horns, etc. eliminating the need for a separate controller.

- Three terminal blocks (TB1, TB2 and TB3) are located on the main board. Each relay can be programmed individually.

The switching capability of each relay is:

- 1.0 A maximum resistive load at 30 VDC

- 0.3A maximum resistive load at 125VAC

Note for B6:

- The B6 supports BACnet MS/TP protocol and can be networked to form a BACnet MS/TP network.

- The B6 default baud rate is 38400bps.

- Each B6 on the MS/TP network must have a unique BACnet MAC address and unique Device Instance Number (Object ID).

- B6 valid MAC addresses are 0-127 for master node, 0-254 for slave node.

- B6 default MAC address is 126.

- Default Device Instance Number (Object ID) is 4005.

- Avoid running communication wires or sensor input wires next to AC power wires or the relay output wires. These can be sources of noise that can affect signal quality.

- When the B6 input power is AC, make sure all devices on the network use same rectifier circuit. The B6M and Q6R both have full wave rectifier and half wave rectifier on board. You will damage devices if you mix half wave and full wave rectifiers on the same AC source.

Function and Configuration

Indicators

The indicators consist of five LED’s – two to indicate RS-485 digital communication, three to indicate the status of relays 1-3.

RS485-TX/RX:

When the B6 is connected to a controller system via RS-485, the traffic of the communication can be monitored visually through the two RS-485 indicators. One is RX LED, which indicates the data stream received in from the controller. The other is TX LED, which indicates the data stream out of the B6.

Note: If the TX LED or the RX LED is always ON, is indicative of a communication problem. See Troubleshooting for RS-485.

Relay 1-3 LED:

Indicate the status of each relay. When the relay is actuated/closed, the relay LED is ON. When the relay is de-actuated/open, the relay LED is OFF.

Note: If you set the relay to be Normally Energized (Fail Safe), the relay LED will turn ON at non-alarm state and turn OFF at alarm state, because the LED reflects the relay coil status.

Tool Function

Press key [F3] to enter tool functions that might be used frequently in the field.

Enter Main Menu

- Press key [F1] to browse previous item of the current menu.

- Press key [F2] to browse next item of the current menu.

- Press key [F3] to enter the main menu for more configuration and settings.

Hush Buzzer and Relay

Press key [F3] to silence the buzzer and buzzer-style relays.

Reset Latched/Hushed

To acknowledge a latched condition or a hushed condition, press key [F3] to reset latched relays and hushed buzzer for which the alarm condition has been removed. If the alarm condition (e.g. high gas concentration) is still present the relay(s) will not reset.

Reset MENU Password

If you forgot the main menu password, you can reset the menu password to default password “4321” by entering a correct active code. For the active code, contact ACI.

Exit Tool Mode

Press key [F3] to return to monitoring mode.

Main Menu Tree

The main menu is password protected. Once the password is accepted, you are allowed into the main menu tree.

Factory default password is 4321.

Note: While in the menu tree, all normal monitoring operations stop. The alarm status does not change.

Menu “1_SYSTEM SETUP”

The system setup subdivision contains general settings for monitor operations, communications and 4-20mA calibrations.

System Settings

|

Password: |

Default password is 4321. |

|

MAC Address: |

The B6 RS-485 address can be defined from 0 to 255. B6 default address is 126. |

|

Object ID: |

BACnet Device Instance Number. Default is 4005. |

|

Baud rate: |

Define baud rate for RS-485 communication with BACnet protocol. B6 default baud rate is 38400 bps. |

|

Scroll Rate: |

In normal operation, the sensor and relay status information scrolls automatically. Set the number of seconds for each item to be displayed. Default value is 3 seconds. |

|

Backlight: |

The LCD backlight can be set to Always Off, Always On and Auto Power Saving mode. In Auto Power Saving mode, the backlight will turn on for 10 seconds after any key has been pressed. Default setting is Auto. |

|

UTC Offset |

The B6 supports the execution of the TimeSynchronization service and UTCTimeSynchronization service. It indicates the number of minutes ( – 780 to +780) offset between local standard time and Universal Time Coordinated. Default is +300 (US & Canada Eastern Time). |

|

Daylight Saving |

It indicates whether daylight saving time is in effect (Enabled) or not (Disabled) at the B6 location in UTCTimeSynchronization service.

Default is Enabled. |

|

New Password: |

The new password can be any combination of up to four digits. Default password is 4321.

Warning: Be sure that you record the new password in a safe and secure location! |

|

Protocol: |

The B6 supports BACnet MS/TP master or slave protocol. Default is MS/TP master. |

|

Display Mode: |

· Display Instant: displays instantaneous gas concentration

· Display Average: o Displays STEL (15min average reading) o Displays TWA (8 hour average reading) o Displays daily peak · Display Alarm: displays alarm 1-8 status · Display Relay: displays relay 1-3 status · Display Buzzer: displays buzzer 1-3 status · Display A-Out mA: Not Available for B6 · Display A-Out VDC: Not Available for B6 · Display Clock: displays real time clock (Default is no clock display) If there is nothing to display, the unit will display “Running…” |

|

Auto Zero: |

Settings for both B6M sensor and Q6R sensor

When AutoZero is set to ON, the unit will gather the lowest reading in 7- day period and set the unit into Zeroing Calibration mode so that the lowest reading goes to zero. When AutoZero is set to OFF, the unit will not adjust its own zero and work off the last manual or factory calibration.

Default value is OFF. NOTE: AutoZero works best in situations where the building will purge at night (or over a weekend) to a zero concentration of target gas. |

|

Key Beeper: |

ON: Beeping when keypad is touched OFF: No beeping when keypad is touched |

|

Restore Default: |

Note: Don’t do this if you don’t have calibration gas and precision reference instrumentation to calibrate the unit. To load defaults to factory settings, to restore the unit to correct operation. The settings below will be restored to default values: -Password, -Baud rate, -Scroll rate, -Backlight, -Display mode, -Key beeper, -LCD contrast, -Gas type on the Sensor Board, –Alarm settings, – Relay/Buzzer settings. Zero and span calibrations are needed. |

|

ADJ Clock: |

Adjust real time clock. |

|

The B6 supports the execution of the TimeSynchronization service and UTCTimeSynchronization service. The clock can be adjusted remotely. |

|

|

ADJ Contrast: |

Adjust the LCD contrast. Valid values are between 10 (light) and 50 (dark). Default is 21. |

|

B6 Sensors: |

If the smart sensor in B6M unit is not installed, it can be disabled here, so the B6 will not detect the smart sensor board and will not report any fault on the sensor offline

If the smart sensor in Q6R is not installed, it can be disabled too.

Both default values are ON, that means both B6M and Q6R sensors are installed. |

|

Output Priority: |

Alarm output (BV) present_value and relay output (BO) present_value support command prioritization. The B6 has priority #12 as default.

The lower the priority umber the more critical the nature of the output. Priority #1 is considered the highest priority. Priority #16 is the lowest priority. |

Menu “2_ZERO CAL”

- First to select which sensor is going to be calibrated, B6M or Q6R? The subsequent zero calibration will be performed on that sensor.

- The calibration is using a two-point calibration process. First, use a “Zero Gas”, then use a “CAL Gas” containing a known concentration of a standard reference gas, to set the second point of reference.

Equipment Required

- A cylinder of Zero Gas, (clean air or nitrogen).

- A cylinder of Cal Gas

- Flow Limiting Regulator(s) 0.2 to 1.0 lpm

- Tubing

Zeroing Calibration Procedure

“2_ ZERO CAL:”

- Press key [F3] and the device will show the calibration notice and then ask if you want to continue. The middle line will display the current concentration.

- Apply the Zero Gas.

- Wait for about 3 minutes or until the reading is stable.

- Press key [F3] to confirm Zeroing Cal.

- When the device is in Zeroing CAL, it will take 3 seconds to 20 seconds to complete.

- When the zeroing CAL operation is over, the device will display “Accepted” and return to “2_ZERO CAL”.

- Make sure there is no Cal Error displayed. If Cal Error is reported, repeat the procedures above. If the Cal Error is still showed up, the sensor may be expired.

- Remove the gas.

- Exit the menu to Monitoring Mode.

Menu “3_SPAN CAL”

First to select which sensor is going to be calibrated, B6M or Q6R? The subsequent span calibration will be performed on that sensor.

“3_ SPAN CAL”

- Press key [F3] and the device will ask for the CAL GAS, input the concentration of the calibration gas.

- Press key [F3] and the device will show the calibration notice and then show the flow rate for the span calibration. Press any key to continue, and then the device will ask you if you want to continue. The middle line will display the current concentration.

- Apply the calibration gas.

- Wait for about 3 minutes or until the reading is stable.

- Press key [F3] to confirm SPAN CAL.

- When the device is in span cal, it will take 10 seconds to 1 minute to complete.

- When the span cal operation is over, the device will display “Accepted” and return to “3_SPAN CAL”.

- Make sure there is no Cal Error displayed. If Cal Error is reported, repeat the procedures above. If the Cal Error is still showed up, the sensor maybe expired.

- Remove the gas.

- Exit menu to Monitoring Mode.

Menu “4_OUT TEST”

- During system installation and testing, it may be necessary to force relays and buzzers on and off.

- The Relay Testing feature allows the user to force the actuation of each relay. This function forces an Actuate vs. De-actuate action, not an energized vs. non-energized action. Therefore the user must be aware of these relays, which have been defined as normally energized or not normally energized.

- According to UL2075 standard for safety, the Q6 Endurance Test will automatically perform 6000 cycles of Relay/Buzzer On and Off operation at a rate of not more than 15 cpm.

- Note: The 4mA and 20mA outputs are not available for Q6.

Menu “5_VIEW SETTING”

- This function is to verify the settings for the alarms, relays, buzzers and analog outputs.

- Note: The View of A-Out Setup is not available for B6.

Menu “6_ALARM SETUP”

- First to select which sensor’s alarm is going to be set, B6M or Q6R? The subsequent alarm settings will be performed on that sensor. The B6M supports alarm 1 to alarm 8 on its sensor. The Q6R supports alarm 1 to alarm 8 on its sensor too.

- Alarm is a programmable condition that can receive a selectable input and trigger relays and buzzers.

|

Disabled or Enabled: |

Each alarm may be individually set to be enabled or disabled. If the alarm is disabled, the alarm will not be used to calculate or trigger anything.

Default: Alarm 1 to Alarm 4 is enabled. Alarm 5 to Alarm 8 is disabled. |

|

Input: |

One of five inputs is selected to calculate the alarm condition status to trigger the selected outputs: · INSTANT: instantaneous gas reading. · 15 MIN AVG (STEL): Short Term Exposure Limit, average reading over 15 minutes. · 8 HOURS AVG (TWA): 8-hour Time Weighted Average, average reading over 8 hours. · DAILY PEAK: daily peak reading. · FAULT: If the unit reports any faults, no matter the gas concentration, it will trigger the selected outputs. |

|

Alarm On and Alarm Off Reading: |

If Alarm On is greater than or equal to Alarm Off:

Alarm On: Sets the concentration at or above which the relay will actuate.

Alarm Off: Sets the concentration at or below which the relay will de- actuate.

If Action On is less than Action Off: Action On: Sets the concentration below that the relay will actuate. Action Off: Sets the concentration above that the relay will de-actuate. |

|

Trigger: |

Trigger Outputs: Relay 1, Relay 2, Relay 3, Buzzer 1, Buzzer 2, Buzzer 3 |

Menu “7_RELAY STYLE”

|

Enabled: |

Each relay may be individually set to be enabled or disabled. If it’s disabled, the relay will always de-actuate no matter what the current gas concentration.

Default is Enabled. |

|

Normally

De- energized: |

Each relay may be individually set to be normally energized or normally de-energized.

Default is normally de-energized. |

|

Latching: |

Each relay may be set to latch in actuate status until acknowledged by a front-panel action.

Default is Non-Latching. |

|

ON Delay: |

“Delay on Actuation” or “Delay on Make”. For each relay a separate time delay may be set from 0 to 990 seconds before an alarm condition will cause the relay to actuate.

Default is 5 seconds. |

|

OFF Delay: |

“Delay on De-Actuation” or “Delay on Break”. For each relay a separate time delay may be set from 0 to 990 seconds before a return to a non- alarming signal condition will cause the relay to de-actuate.

Default is 5 seconds. |

|

Style: |

Normal Relay Style: Work as normal relay.

Buzzer Style Relay: When the relay is used to control a buzzer or horn. Working as a buzzer style will make the relay have the same function as the buzzer. It will be switched off when performing the Hush Buzzer/Relay function in the Tool Menu.

Default is OFF. |

Menu “8_BUZZER STYLE”

The buzzer style is almost identical to that of the relays, except the style that represents the buzzer tone options:

- Tone 1: Chirp once.

- Tone 2: Chirp twice.

- Tone 3: Intermittent 50% duty cycle.

- Tone 4: Continuous.

The menus are identical to those for the Relay Style.

Menu “A_ALL DISABLE”

This function is for calibration, system testing etc. When All Disable is ON, the status of the relay, buzzer and analog output, etc., will freeze in their current state.

Default is OFF.

Menu “B_SIMULATION”

- First to select B6M or Q6R to be set into simulation mode

- Simulation mode is used to assist in testing the installation before commissioning. When simulation is enabled, the unit will not detect gas concentrations; it will display the simulated value and use it to calculate the status of relays and buzzers. This feature is available for evaluating the user settings and testing the installation (e.g.: the activation of the valve, fan speed, relay set points, etc. can be verified.)

- Any concentration between 0ppm and 9999ppm can be simulated.

Menu “C_SITE SERVICE” and “D_FACTROY SET”

- Factory service staff access only. The customer has no need to operate it.

BACnet PIC Statement Supported By B6

- See document: 86650-103-000 (B6 PIC Statement).

Smart Sensor Assembly Replacement

Disassembling

Observe all safety and electrical codes and regulations before removing enclosure lid.

Important: Calibrate the transmitter whenever a component is replaced. But if you replace a smart sensor assembly with a sensor onboard from ACI, you don’t need to recalibrate the transmitter, as all the calibration information has been stored in the smart sensor board in the factory process.

Important: Calibrate the transmitter whenever a component is replaced. But if you replace a smart sensor assembly with a sensor onboard from ACI, you don’t need to recalibrate the transmitter, as all the calibration information has been stored in the smart sensor board in the factory process.

Replacement Procedure

To replace the entire smart sensor assembly, complete the following steps:

- Power down the transmitter.

- Remove the four screws securing the enclosure lid assembly to the base enclosure and remove the enclosure lid assembly.

- Remove the two screws securing the smart sensor board and remove the smart sensor board from the lid assembly

- Feed the O-ring over the sensor on the new smart sensor assembly

- Plug the new smart sensor assembly and secure with two screws. Ensure that the connectors are correctly matched. Incorrect installation may damage the sensor assembly and/or the display board.

Replacement Parts

| Code | Gas | Symbol | Span | Smart Sensor Assembly |

| 0 | Oxygen | O2 | 0 – 25%VOL | 85930-016-000 |

| Code | Gas | Symbol | Span | Smart Sensor Assembly |

| 16 | Methane | CH4 | 0 – 100%LEL | 85930-017-016 |

| 17 | Propane | C3H8 | 0 – 100%LEL | 85930-017-017 |

| 18 | Hydrogen | H2 | 0 – 100%LEL | 85930-017-018 |

| *19 | Combustible | LEL | 0 – 100%LEL | 85930-017-019 |

| *20 | Ethylene | C2H4 | 0 – 100%LEL | 85930-017-020 |

| *21 | Iso-Butane | C4H10 | 0 – 100%LEL | 85930-017-021 |

| *22 | Iso-Pentane | C5H12 | 0 – 100%LEL | 85930-017-022 |

| *23 | Methanol | CH3OH | 0 – 100%LEL | 85930-017-023 |

| *24 | Benzene | C6H6 | 0 – 100%LEL | 85930-017-024 |

| *25 | Acetone | CH3CO | 0 – 100%LEL | 85930-017-025 |

| *26 | Butanol, n-Butane | BUTAN | 0 – 100%LEL | 85930-017-026 |

|

Code |

Gas |

Symbol |

Span |

Smart Sensor Assembly |

| 1 | Carbon Monoxide | CO | 0 – 250ppm | 85930-018-001 |

| 1 | Carbon Monoxide | CO | 0 – 1000ppm | 85930-018-201 |

| 2 | Hydrogen Sulfide | H2S | 0 – 25ppm | 85930-018-002 |

| 2 | Hydrogen Sulfide | H2S | 0 – 100ppm | 85930-018-202 |

| 3 | Sulphur Dioxide | SO2 | 0 – 6ppm | 85930-018-003 |

| 5 | Nitrogen Dioxide | NO2 | 0 – 10ppm | 85930-018-005 |

| 6 | Hydrogen | H2 | 0 – 1000ppm | 85930-018-006 |

| 6 | Hydrogen | H2 | 0 – 2000ppm | 85930-018-206 |

| 7 | Hydrogen Cyanide | HCN | 0 – 50ppm | 85930-018-007 |

| 9 | Ammonia | NH3 | 0 – 100ppm | 85930-018-009 |

| 9 | Ammonia | NH3 | 0 – 1000ppm | 85930-018-209 |

| 11 | Ozone | O3 | 0 – 1ppm | 85930-018-011 |

| 13 | Chlorine | Cl2 | 0 – 5ppm | 85930-018-013 |

| 14 | Chlorine Dioxide | ClO2 | 0 – 2ppm | 85930-018-014 |

| 96 | Arsine | AsH3 | 0 – 1ppm | 85930-018-096 |

| 97 | Phosphine | PH3 | 0 – 5ppm | 85930-018-097 |

| 97 | Phosphine | PH3 | 0 – 1ppm | 85930-018-297 |

| 98 | Silane | SiH4 | 0 – 50ppm | 85930-018-098 |

| 99 | Germane | GeH4 | 0 – 2ppm | 85930-018-099 |

| 100 | Diborane | B2H6 | 0 – 2ppm | 85930-018-100 |

|

Code |

Gas |

Symbol |

Span |

Smart Sensor Assembly |

| 4 | Nitric Oxide | NO | 0 –100ppm | 85930-018-004 |

| 8 | Hydrogen Chloride | HCl | 0 – 30ppm | 85930-018-008 |

| 12 | Ethylene Oxide | ETO | 0 – 20ppm | 85930-018-012 |

| 101 | Hydrogen Bromide | HBr | 0 – 30ppm | 85930-018-101 |

|

Code |

Gas |

Symbol |

Span |

Smart Sensor Assembly |

| 15 | Carbon Dioxide | IR-CO2 | 0 –5000ppm | 85930-019-015 |

| 15 | Carbon Dioxide | IR-CO2 | 0 – 5%VOL | 85930-019-215 |

| 15 | Carbon Dioxide | IR-CO2 | 0 – 20%VOL | 85930-019-315 |

| 15 | Carbon Dioxide | IR-CO2 | 0 – 100%VOL | 85930-019-415 |

| 16 | Methane | IR-CH4 | 0 – 100%LEL | 85930-019-016 |

| 16 | Methane | IR-CH4 | 0 – 100%VOL | 85930-019-216 |

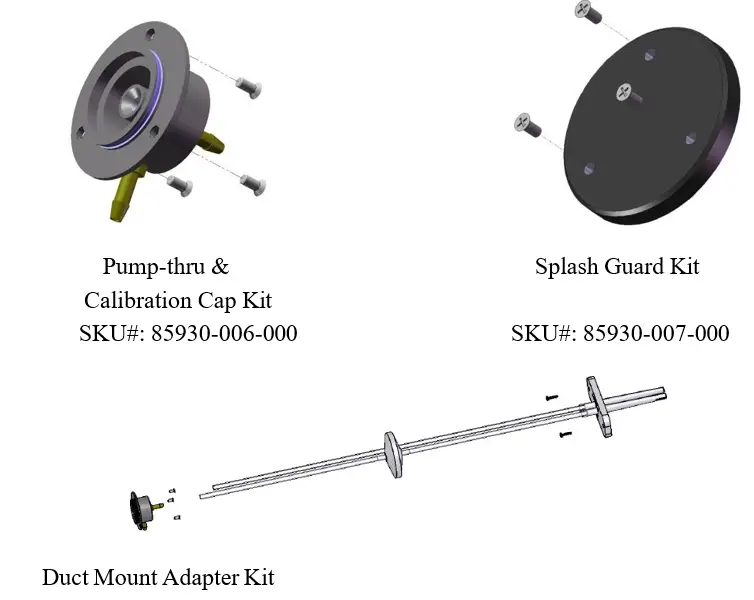

Accessories

SKU#: 85930-040-000

Note: For Duct Mount Installation, B6 needs both the Pump-thru Kit and Duct Mount Kit.

Troubleshooting

This troubleshooting guide is intended as an aid in identifying the cause of unexpected behavior and determining whether the behavior is due to normal operation or an internal or external problem.

| SYMPTOMS | PROBABLE CAUSE | SUGGESTED SOLUTION |

| RS-485 RX LED or

TX LED constantly ON |

· RS-485 bus connection has a problem

· RS-485 driver U6 is damaged · Controller side RS-485 driver has problem |

· Disconnect the cable to isolate the problem

· Replace U6 IC on main board · Replace the RS-485 driver on the controller |

| No response to gas | · Sensor screen is dirty

· Sensor has expired |

· Clean sensor opening

· Replace smart sensor assembly, see Replacement Parts |

| Apparent false alarm | · Puff of gas

· Not properly calibrated · Solvent fumes or interference from high levels of interfering gas · Radio frequency interference |

· Monitor is functioning

· Recalibrate · Remove source of interfering gas

· Check that grounding and shielding is correct |

WARRANTY STATEMENT

The information contained in this manual is based upon data considered accurate; however, no warranty is expressed or implied regarding the accuracy of this data. All ACI equipment is warranted against defects in material and workmanship for a period of two years from date of shipment with the following exceptions:

- Electrochemical Sensors (Toxic) Six Months

- Catalytic Sensors (Combustible) One Year

During the warranty period we will repair or replace, at our discretion, any components or complete units that prove, in our opinion, to be defective. We are not liable for consequential or incidental damage to auxiliary interfaced equipment.

- A returned material authorization number should be obtained from the factory prior to returning any goods. All return shipments must be shipped freight prepaid and a copy of the maintenance records should accompany the unit concerned.

- Warranty should be considered F.O.B. the factory. Labour and travel time are chargeable for any field site visits required for warranty work.

LIMITED LIABILITY

- All ACI systems shall be installed by a qualified technician/electrician and maintained in strict accordance with data provided for individual systems in the form of installation/maintenance manuals. ACI assumes no responsibility for improper installation, maintenance, etc., and stresses the importance of reading all manuals. ACI shall not be responsible for any liability arising from auxiliary interfaced equipment nor any damage resulting from the installation or operation of this equipment.

- ACI’s total liability is contained as above with no other liability expressed or implied, as the purchaser is entirely responsible for installation and maintenance of systems.

- This warranty is in lieu of all other warranties, expressed or implied, and no representative or person is authorized to represent or assume for ACI any liability in connection with the sales of our products other than that set forth herein.

NOTE: Due to on-going product development, ACI reserves the right to change specifications without notice and will assume no responsibility for any costs as a result of modifications.

For further information or assistance, contact:

- AUTOMATION COMPONENTS, INC. 2305 Pleasant View Road

- Middleton, Wisconsin

- Tel: 888-967-5224

- Fax: 608-831-7407

- Web: www.workaci.com

- 86650-101-000 RB

FAQs

Q: What are the supported BACnet Interoperability Building Blocks?

A: The B6 Gas Transmitter supports Data sharing-ReadProperty-B, Data sharing-ReadPropertyMultiple-B, Data sharing-WriteProperty-B, Device Management-Device Communication Control-B, Device Management-TimeSynchronization-B, and Device Management-UTCTimeSynchronization-B.

Q: Is static device binding supported for two-way communication?

A: Yes, static device binding is supported for two-way communication with MS/TP slaves and certain other devices.

Documents / Resources

|

Quatrosense B6 Dual Sensor Gas Transmitter [pdf] User Manual B6-MAC -xxx, B6-AMCU-1-08, B6-BMCU-1-04, B6 Dual Sensor Gas Transmitter, B6, Dual Sensor Gas Transmitter, Sensor Gas Transmitter, Gas Transmitter, Transmitter |