MITSUBISHI PFA012D636D F Ceiling Suspended System

Specifications

- Model: PFA012D636D F

- Type: Ceiling suspended

Product Information:

The indoor unit manual is for the installation of a ceiling-suspended type indoor unit. It provides detailed instructions for electrical wiring, remote control installation, wireless kit installation, earth wiring precautions, safety precautions, correct circuit breaker usage, and installation location considerations.

Product Usage Instructions

Electrical Wiring Work:

Refer to page 67 of the manual for detailed instructions on electrical wiring work for the indoor unit.

Remote Control Installation:

For remote control installation, refer to page 71 of the manual.

Wireless Kit Installation:

Refer to page 116 of the manual for instructions on wireless kit installation.

Safety Precautions:

- Ensure proper earth wiring to prevent unit failure, electric shock, and fire.

- Install an earth leakage breaker to prevent fire and electric shocks.

- Use a circuit breaker of correct capacity to avoid system failure and fire.

- Avoid using incorrect materials for fuses as it could lead to unit failure and fire.

- Do not install the indoor unit near flammable gas leakages to prevent fire hazards.

Commissioning and Maintenance:

After installation, conduct commissioning to check for abnormalities. Explain safety precautions, correct operation methods, and maintenance procedures to customers. Secure adequate space for inspection and maintenance as specified in the manual.

Indoor Unit Usage:

Avoid using the indoor unit in places where water splashes occur as it is not waterproof and could lead to electric shock and fire hazards.

Ceiling suspended type (FDE)

- This manual is for the installation of an indoor unit.

- For electrical wiring work (Indoor), refer to page 67. For remote control installation, refer to page 71. For wireless kit installation, refer to page 116. For electrical wiring work (Outdoor) and refrigerant pipe work installation for outdoor unit, refer to page 84.

SAFETY PRECAUTIONS

- Read the “SAFETY PRECAUTIONS” carefully first of all and then strictly follow it during the installation work in order to protect yourself.

- The precautionary items mentioned below are distinguished into two levels, and CAUTION

- WARNING: Wrong installation would cause serious consequences such as injuries or death.

- CAUTION: Wrong installation might cause serious consequences depending on circumstances.

- Both mentions the important items to protect your health and safety so strictly follow them by any means.

- The meanings of “Marks” used here are as shown as follows:

Never do it under any circumstances.

Never do it under any circumstances.

Always do it according to the instruction.

Always do it according to the instruction.

- After completing the installation, do commissioning to confirm there are no abnormalities, and explain to the customers about “SAFETY PRECAUTIONS”, correct operation method and maintenance method (air filter cleaning, operation method and temperature setting method) with user’s manual of this unit.

- Ask your customers to keep this installation manual together with the user’s manual. Also, ask them to hand over the user’s manual to the new user when the owner is changed.

WARNING

- Installation should be performed by the specialist.

If you install the unit by yourself, it may lead to serious trouble such as water leakage, electric shock, fire, and injury due to overturn of the unit. - Install the system correctly according to these installation manuals. Improper installation may cause explosion, injury, water leakage, electric shock, and fire.

- When installing in small rooms, take prevention measures not to exceed the density limit of refrigerant in the event of leakage, referred by the formula (accordance with ISO5149).

- If the density of refrigerant exceeds the limit, please consult the dealer and install the ventilation system, otherwise lack of oxygen can occur, which can cause serious accidents.

- Use the genuine accessories and the specified parts for installation.

- If parts unspecified by our company are used it could cause water leakage, electric shock, fire, and injury due to overturn of the unit.

- Ventilate the working area well in case the refrigerant leaks during installation. If the refrigerant contacts the fire, toxic gas is produced.

- In case of R32, the refrigerant could be ignited because of its flammability.

- Install the unit in a location that can hold heavy weight.

- Improper installation may cause the unit to fall leading to accidents.

- Install the unit properly in order to be able to withstand strong winds such as typhoons, and earthquakes.

- Improper installation may cause the unit to fall leading to accidents.

- Do not mix air in to the cooling cycle on installation or removal of the air-conditioner.

- If air is mixed in, the pressure in the cooling cycle will rise abnormally and may cause explosion and injuries.

- Be sure to have the electrical wiring work done by qualified electrical installer, and use exclusive circuit.

- Power source with insufficient capacity and improper work can cause electric shock and fire.

- Use specified wire for electrical wiring, fasten the wiring to the terminal securely, and hold the cable securely in order not to apply unexpected stress on the terminal.

- Loose connections or hold could result in abnormal heat generation or fire.

- Arrange the electrical wires in the control box properly to prevent them from rising. Fit the lid of the services panel property.

- Improper fitting may cause abnormal heat and fire.

- Check for refrigerant gas leakage after installation is completed.

- If the refrigerant gas leaks into the house and comes in contact with a fan heater, a stove, or an oven, toxic gas is produced.

- Use the specified pipe, flare nut, and tools for R32 or R410A.

- Using existing parts (R22) could cause the unit failure and serious accident due to explosion of the cooling cycle.

- Tighten the flare nut according to the specified method by with torque wrench.

- If the flare nut were tightened with excess torque, it could cause burst and refrigerant leakage after a long period.

- Do not put the drainage pipe directly into drainage channels where poisonous gases such as sulfide gas can occur.

- Poisonous gases will flow into the room through drainage pipe and seriously affect the user’s health and safety. This can also cause the corrosion of the indoor unit and a resultant unit failure or refrigerant leak.

- Connect the pipes for refrigeration circuit securely in installation work before compressor is operated.

- If the compressor is operated when the service valve is open without connecting the pipe, it could cause explosion and injuries due to abnormal high pressure in the system.

- Stop the compressor before removing the pipe after shutting the service valve on pump down work.

- If the pipe is removed when the compressor is in operation with the service valve open, air would be mixed in the refrigeration circuit and it could cause explosion and injuries due to abnormal high pressure in the cooling cycle.

- Only use prescribed option parts. The installation must be carried out by the qualified installer.

- If you install the system by yourself, it can cause serious trouble such as water leaks, electric shocks, fire.

- Do not repair by yourself. And consult with the dealer about repair.

- Improper repair may cause water leakage, electric shock or fire.

- Consult the dealer or a specialist about removal of the air-conditioner.

- Improper installation may cause water leakage, electric shock or fire.

- Turn off the power source during servicing or inspection work.

- If the power is supplied during servicing or inspection work, it could cause electric shock and injury by the operating fan.

- Do not run the unit when the panel or protection guard are taken off.

- Touching the rotating equipment, hot surface, or high voltage section could cause an injury to be caught in the machine, to get burned, or electric shock.

- Shut off the power before electrical wiring work.

- It could cause electric shock, unit failure and improper running.

CAUTION

- Perform earth wiring surely.

- Do not connect the earth wiring to the gas pipe, water pipe, lightning rod and telephone earth wiring. Improper earth could cause unit failure, electric shock and fire due to a short-circuit.

- Earth leakage breaker must be installed.

- If the earth leakage breaker is not installed, it can cause fire and electric shocks.

- Use the circuit breaker of correct capacity. Circuit breaker should be the one that disconnect all poles under over current.

- Using the incorrect one could cause the system failure and fire.

- Do not use any materials other than a fuse of correct capacity where a fuse should be used.

- Connecting the circuit by wire or copper wire could cause unit failure and fire.

- Do not install the indoor unit near the location where there is possibility of flammable gas leakages.

- If the gas leaks and gathers around the unit, it could cause fire.

- Do not install and use the unit where corrosive gas (such as sulfurous acid gas etc.) or flammable gas (such as thinner, petroleum etc.) may be generated or accumulated, or volatile flammable substances are handled.

- It could cause the corrosion of heat exchanger, breakage of plastic parts etc. And inflammable gas could cause fire.

- Secure a space for installation, inspection and maintenance specified in the manual.

- Insufficient space can result in accident such as personal injury due to falling from the installation place.

- Do not use the indoor unit at the place where water splashes such as laundry.

- Indoor unit is not waterproof. It could cause electric shock and fire.

- Do not use the indoor unit for a special purpose such as food storage, cooling for precision instrument, preservation of animals, plants, and a work of art.

- It could cause the damage of the items.

- Do not install nor use the system near equipments which generate electromagnetic wave or high harmonics.

- Equipments like inverter equipment, private power generator, high-frequency medical equipment, or telecommunication equipment might influence the air-conditioner and cause a malfunction and breakdown. Or the air-conditioner might influence medical equipments or telecommunication equipments, and obstruct their medical activity or cause jamming.

- Do not install the remote control at the direct sunlight.

- It could cause breakdown or deformation of the remote control.

- Do not install the indoor unit at the place listed below.

- Places where flammable gas could leak.

- Places where carbon fiber, metal powder or any powder is floated.

- Place where the substances which affect the air-conditioner are generated such as sulfide gas, chloride gas, acid, alkali or ammonic atmospheres.

- Places exposed to oil mist or steam directly.

- On vehicles and ships

- Places where machinery which generates high harmonics is used.

- Places where cosmetics or special sprays are frequently used.

- Highly salted area such as beach.

- Heavy snow area

- Places where the system is affected by smoke from a chimney.

- Altitude over 1000m

- Do not install the indoor unit in the locations listed below (Be sure to install the indoor unit according to the installation manual for each model because each indoor unit has each limitation)

- Locations with any obstacles which can prevent inlet and outlet air of the unit

- Locations where vibration can be amplified due to insufficient strength of structure.

- Locations where the infrared receiver is exposed to the direct sunlight or the strong light beam. (in case of the infrared specification unit)

- Locations where an equipment affected by high harmonics is placed. (TV set or radio receiver is placed within 5m)

- Locations where drainage cannot run off safely.

- It can affect performance or function and etc..

- Do not install the motion sensor at following places. It could cause detection error, incapacity of detection, or characteristic degradation.

- Place where vibration is applied to it for a long period of time.

- Place where static electricity or electromagnetic wave generates.

- Place where it is exposed to high temperature or humidity for a long period of time.

- Dusty place or where the lens face could be fouled or damaged.

- Do not put any valuables which will break down by getting wet under the air-conditioner.

- Condensation could drop when the relative humidity is higher than 80% or drain pipe is clogged, and it damages user’s belongings.

- Do not use the base frame for the outdoor unit which is corroded or damaged after a long period of use.

- It could cause the unit falling down and injury.

- Pay attention not to damage the drain pan by weld sputter when brazing work is done near the unit.

- If sputter entered into the unit during brazing work, it could cause damage (pinhole) of drain pan and leakage of water.

- To avoid damaging, keep the indoor unit packed or cover the indoor unit.

- Install the drain pipe to drain the water surely according to the installation manual.

- Improper connection of the drain pipe may cause dropping water into room and damaging user’s belongings.

- Do not share the drain pipe for indoor unit and GHP (Gas Heat Pump system) outdoor unit.

- Toxic exhaust gas would flow into room and it might cause serious damage (some poisoning or deficiency of oxygen) to user’s health and safety.

- Be sure to perform air tightness test by pressurizing with nitrogen gas after completed refrigerant piping work.

- If the density of refrigerant exceeds the limit in the event of refrigerant leakage in a small room, lack of oxygen can occur, which can cause serious accidents.

- For drain pipe installation, be sure to make descending slope of greater than 1/100, not to make traps, and not to make air-bleeding.

- Check if the drainage is correctly done during commissioning and ensure the space for inspection and maintenance.

- Ensure the insulation on the pipes for refrigeration circuit so as not to condense water.

- Incomplete insulation could cause condensation and it would wet ceiling, floor, and any other valuables.

- Do not install the outdoor unit where is likely to be a nest for insects and small animals.

- Insects and small animals could come into the electronic components and cause breakdown and fire. Instruct the user to keep the surroundings clean.

- Pay extra attention, carrying the unit by hand.

- Carry the unit with 2 people if it is heavier than 20kg. Do not use the plastic straps but the grabbing place, moving the unit by hand. Use protective gloves in order to avoid injury by the aluminum fin.

- Make sure to dispose of the packaging material.

- Leaving the materials may cause injury as metals like nail and woods are used in the package.

- Do not operate the system without the air filter.

- It may cause the breakdown of the system due to clogging of the heat exchanger.

- Do not touch any button with wet hands.

- It could cause electric shock.

- Do not touch the refrigerant piping with bare hands when in operation.

- The pipe during operation would become very hot or cold according to the operating condition, and it could cause a burn or frostbite.

- Do not clean up the air-conditioner with water.

- It could cause electric shock.

- Do not turn off the power source immediately after stopping the operation.

- Be sure to wait for more than 5 minutes. Otherwise it could cause water leakage or breakdown.

- Do not control the operation with the circuit breaker.

- It could cause fire or water leakage. In addition, the fan may start operation unexpectedly and it may cause injury.

Before installation

- Install correctly according to the installation manual

- Confirm the following points:

- Unit type/Power source specification

- Pipes/Wires/Small parts OAccessory items

Accessory item

Selection of installation location for the indoor unit

- Select the suitable areas to install the unit under approval of the user. Areas where the indoor unit can deliver hot and cold wind sufficiently. Suggest to the user to use a circulator if the ceiling height is over 3m to avoid warm air being accumulated on the ceiling.

- In case of having the motion sensor, the installation height must be no higher than 4m. It could reduce the sensitivity of motion sensor, disabling the detection.

- Areas where there is enough space to install and service.

- Areas where it can be drained properly. Areas where drain pipe descending slope can be taken.

- Areas where there is no obstruction of air flow on both air return grille and air supply port.

- Areas where fire alarm will not be accidentally activated by the air-conditioner.

- Areas where the supply air does not short-circuit.

- Areas where it is not influenced by draft air.

- Areas not exposed to direct sunlight.

- Areas where dew point is lower than around 280C and relative humidity is lower than 80%.

- This indoor unit is tested under the condition of JIS (Japan Industrial Standard) high humidity condition and confirmed there is no problem. However, there is some risk of condensation drop if the air-conditioner is operated under the severer condition than mentioned above.

- If there is a possibility to use it under such a condition, attach additional insulation of 10 to 20mm thick for entire surface of indoor unit, refrigeration pipe and drain pipe.

- Areas where TV and radio stays away more than 1m. (It could cause jamming and noise.)

- Areas where any items which will be damaged by getting wet are not placed such as food, table wares, server, or medical equipment under the unit.

- Areas where there is no influence by the heat which cookware generates.

- Areas where not exposed to oil mist, powder and/or steam directly such as above fryer.

- Areas where lighting device such as fluorescent light or incandescent light doesn’t affect the operation. (A beam from lighting device sometimes affects the infrared receiver for the wireless remote control and the air-conditioner might not work properly.)

- Check if the place where the air-conditioner is installed can hold the weight of the unit. If it is not able to hold, reinforce the structure with boards and beams strong enough to hold it. If the strength is not enough, it could cause injury due to unit falling.

- If there are 2 units of wireless type, keep them away for more than 6m to avoid malfunction due to cross communication.

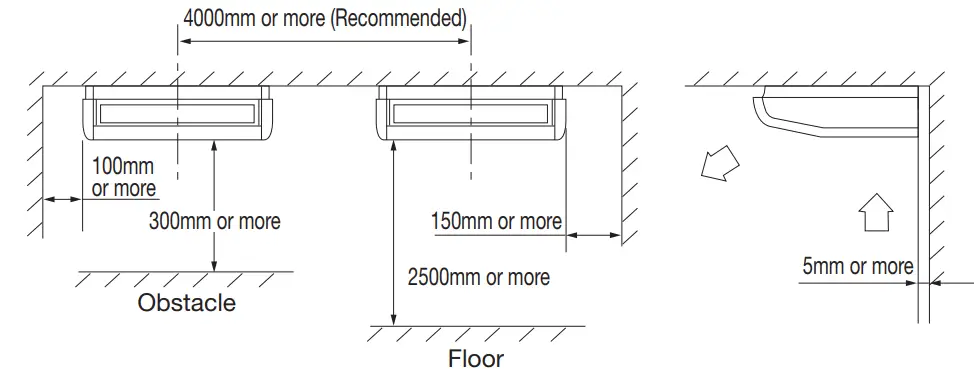

- When plural indoor units are installed nearby, it is recommended to separate each other more than 4m.

Space for installation and service

- In case of not installing in the above installation inhalation of the blow out wind, it could reduce the capability or cause the thermostat OFF.

- Install the indoor unit at a height of more than

Preparation before installation

- lf suspension bolt becomes longer, do reinforcement of earthquake resistant.

- For grid ceiling

- When suspension bolt length is over 500mm, or the gap between the ceiling and roof is over 700mm, apply earthquake resistant brace to the bolt.

- In case the unit is hanged directly from the slab and is installed on the ceiling plane which has enough strength.

- When suspension bolt length is over 1000mm, apply the earthquake resistant brace to the bolt.

- Prepare four (4) sets of suspension bolt, nut and spring washer (MI 0) on site.

Pitch of suspension bolts and pipe position

Pitch of suspension bolts

Location of pipe outlets

| Series / Type | A | B |

|---|---|---|

| Single Split (PAC) series | ||

| 40 to 50 type | 1070 | 1022 |

| 60 to 71 type | 1320 | 1272 |

| 100 to 140 type | 1620 | 1572 |

| VRF (KX) series | ||

| 36 to 56 type | 1070 | 1022 |

| 71 type | 1320 | 1272 |

| 112 to 140 type | 1620 | 1572 |

Pipe position

- Pipes can be taken out in 3 directions (rear, right or top).

- Cut out holes using nippers, etc.

- Cut out holes to take out pipes along the cutoff line on the rear cover.

- Cut out the top face cover aligning to the piping position.

- When taking pipe out to right-hand side, cut out a hole along the groove at the inside of side panel.

- After installing pipes and wires, seal clearances around pipes and wires with putty, etc to shut off dust.

- Make sure to install the covers at rear and top in order to protect the inside of unit from the intrusion of dust or protect wires from damages by sharp edges. When taking them out to the right-hand side, remove burrs or sharp edges from the cutout.

Haulage

- Move the box as close to the installation area as possible packed.

- If it must be unpacked, wrap the unit with a nylon sling, and be careful not to damage the unit.

- Do not hold fragile plastic parts, such as the side panel, blow louver, etc.

- If you need to lay the unit on a floor after unpacking, always put it with the intake grille facing upward.

Preparation before installation

- Remove the air return grille. Slide stoppers (4 places) of the catches, then pull out the pins ( 4 or 6 places).

- Remove the side panel. Remove the screw and detach the side panel by sliding it toward the direction indicated by the arrow mark.

- Remove the hanging plate. Remove the screw, and then loosen the fixing bolts.

Installation of indoor unit

WARNING

Completely seal the hole in the wall with putty. If not sealed properly, dust, insects, small animals, and highly humid air may enter the room from outside, which could result in fire or other hazards.

CAUTION

Completely seal the hole in the wall with putty. If not sealed properly, furniture and other fixtures may be damaged by water leakage or condensation.

Work procedure

- Select the suspension bolt locations and the pipe hole location.

- Use the enclosed paper pattern as a reference, and drill the holes for the suspension bolts and pipe. Decide the locations based on direct measurements

- Once the locations are properly placed, the paper pattern can be removed.

- Install the suspension bolts in place.

- Fix with 4 suspension bolts.

- Check the measurements given at the right figure for the length of the suspension bolts.

- Fasten the hanging plate onto the suspension bolts.

- Install the unit to the hanging plate. (See the figure at right.)

- Slide the unit in from front side to get it hanged on the hanging plate with the bolts.

- Fasten the four fixing bolts (M8: 2 each on the left and right sides) firmly.

- Fasten the two screws (M4: 1 each on the left and right sides).

WARNING: Hang a side panel on from the panel side to the rear side and then fasten it securely onto the indoor unit with screws. - To ensure smooth drain flow, install the unit with a descending slope toward the drain outlet.

Refrigerant pipe

Caution

Be sure to use new pipes for the refrigerant pipes. Use the flare nut attached to the product. Regarding whether existing pipes can be reused or not, and the washing method, refer to the instruction manual of the outdoor unit, catalogue or technical data.

- In case of reuse: Do not use old flare nut, but use the one attached to the unit.

- In case of reuse: Flare the end of pipe replaced partially for R32 or R41 OA.

WARNING: When flared joints are reused indoors, the flare part shall be re-fabricated. (only for R32)

- Use phosphorus deoxidized copper alloy seamless pipe (Cl 220T) for refrigeration pipe installation.

- In addition, make sure there is no damage both inside and outside of the pipe, and no harmful substances such as sulfur, oxide, dust or a contaminant stuck on the pipes.

- Do not use any refrigerant other than R32 or R41 OA.

- Using other refrigerant except R32 or R41 OA (R22 etc.) may degrade inside refrigeration oil. And air getting into refrigeration circuit may cause over-pressure and resultant it may result in bursting, etc.

- Store the copper pipes indoors and seal the both end of them until they are brazed in order to avoid any dust, dirt or water getting into pipe. Otherwise it will cause degradation of refrigeration oil and compressor breakdown, etc.

- Use special tools for R32 or R41 OA refrigerant.

Work procedure

- Remove the flare nut and blind flanges on the pipe of the indoor unit.

- Make sure to loosen the flare nut with holding the nut on pipe side with a spanner and giving torque to the nut with another spanner in order to avoid unexpected stress to the copper pipe, and then remove them. (Gas may come out at this time, but it is not abnormal.)

- Pay attention whether the flare nut pops out. (as the indoor unit is sometimes pressured.)

- Make a flare on liquid pipe and gas pipe, and connect the refrigeration pipes on the indoor unit.

- When pulling out pipes backward or upward, install them passing through the attached cover together with the electrical cabling.

- Seal the gap with putty, or other, to protect from dust, etc.

- Bend radius of pipe must be 4D or larger. Once a pipe is bent, do not readjust the bending.

- Do not twist a pipe or collapse to 2/3D or smaller.

- Make sure to use flare nuts assembled on the unions.

- Usage of other flare nuts could cause refrigerant leakage.

- Do a flare connection as follows:

- Make sure to hold the nut on indoor unit pipe side using double spanner method as indicated when fastening/loosening flare nuts in order to prevent unintentional twisting of the copper pipe.

- When fastening the flare nut, align the refrigeration pipe with the center of flare nut, screw the nut for 3-4 times by hand and then tighten it by spanner with the specified torque mentioned in the table above.

- Cover the flare connection part of the indoor unit with attached insulation material after a gas leakage inspection, and tighten both ends with attached straps.

- Make sure to insulate both gas pipes and liquid pipes completely.

- Incomplete insulation may cause dew condensation or water dropping.

- Use heat-resistant (120 oc or more) insulations on the gas side pipes.

- In case of using at high humidity condition, reinforce insulation of refrigerant pipes.

- Surface of insulation may cause dew condition or water dropping, if insulations are not reinfoced.

- Refrigerant is charged in the outdoor unit. As for the additional refrigerant charge for the indoor unit and piping, refer to the installation manual attached to the outdoor unit.

Caution:

- Refrigerating machine oil should not be applied to the threads of union or external surface of flare. It is because, even if the same tightening torque is applied, the oil is likely to decrease the slide friction force on the threads and increase, in turn, the axial component force so that it could crack the flare by the stress corrosion.

- Refrigerating machine oil may be applied to the internal surface of flare only.

The pipe can be connected from three different directions. (back, reight, top)

- When the pipe is routed through the back.

- If the bracket is removed, piping work will become easy.

- After piping, reinstall the removed bracket.

- When the pipe is routed through the top.

- Cut the removed top cover, and install to the rear panel instead of rear cover.

Drain pipe

The drain pipes may pull out either from back, right or left side.

Caution

Install the drain pipe according to the installation manual in order to drain properly.

- Imperfection in draining may cause flood indoors and wetting the household goods, etc.

- Do not put the drain pipe directly into the ditch where toxic gas such as sulfur, the other harmful and inflammable gas is generated. Toxic gas would flow into the room and it would cause serious damage to user’s health and safety (some poisoning or deficiency of oxygen). In addition, it may cause corrosion of heat exchanger and bad smell.

- Connect the pipe securely to avoid water leakage from the joint.

- Insulate the pipe properly to avoid condensation drop.

- Check if the water can flow out properly from both the drain outlet on the indoor unit and the end of the drain pipe after installation.

- Make sure to make descending slope of greater than 1/100 and do not make up-down bend and/or trap in the midway. In addition, do not put air vent on the drain pipe. Check if water is drained out properly from the pipe during commissioning. Also, keep sufficient space for inspection and maintenance.

Work procedure

- Insert drain hose completely to the base, and tighten the drain hose clamp securely. ( adhesive must not be used.)

- When plumbing on the left side, move the rubber plug and the cylindrical insulating materials by the pipe connecting hole on the left side of the unit to the right side.

- Beware of a possible outflow of water that may occur upon removal of a drain plug.

- Fix the drain hose at the lowest point with a hose clamp supplied as an accessory.

- Give a drain hose a gradient of 1 Omm as illustrated in the right drawing by laying it without leaving a slack.

- Take head of electrical cables so that they may not run beneath the drain hose.

- A drain hose must be clamped down with a hose clamp.

- There is a possibility that drain water overflows.

- Connect VP20(prepare on site) to drain hose. (adhesive must not be used.)

- Use commercially available rigid PVC general pipe VP20 for drain pipe.

- Do not to make the up-down bending and trap in the mid-way while assuming that the drain pipes is downhill. (more than 1/100)

- Never set up air vent.

- Insulate the drain pipe.

Insulate the drain hose clamp with the heat insulation supplied as accessories. When the unit is installed in a humid place, consider precautions against dew condensation such as heat insulation for the drain pipe.

Drain test

- After installation of drain pipe, make sure that drain system work in good condition and no water leakage from joint and drain pan.

- Do drain test even if installation of heating season.

Wiring-out position and wiring connection

- Electrical installation work must be performed according to the installation manual by an electrical installation service provider qualified by a power provider of the country, and be executed according to the technical standards and other regulations applicable to electrical installation in the country.

- Be sure to use an exclusive circuit.

- Use specified cord, fasten the wiring to the terminal securely, and hold the cord securely in order not to apply unexpected stress on the terminal.

- Do not put both power source line and signal line on the same route. It may cause miscommunication and malfunction.

- Be sure to do D type earth work.

- For the details of electrical wiring work, see attached instruction manual for electrical wiring work.

- Remove wiring from clips.

- Remove the control box (Screw (1), 2pcs).

- Pull out the control box by sliding along the groove on the bracket (Direction A to B)

- Remove the lid of control box (Screw 2), 2pcs).

- Hold each wiring inside the unit and connect to the terminal block surely.

- Fix the wiring by clamp.

- Install the lid of control box (Screw (2), 2pcs).

- Return the control box to the original place by sliding along the groove on the bracket (Direction

- Install the removed parts at their original places.

- Wiring for the signal receiving section of wireless kit (Option) and motion sensor kit (Option) are connected at the time of shipping from the factory. It is not necessary to disconnect these wiring when wired remote control is connected. When the wired/wireless kits are used together, it becomes necessary to set the slaves and remote control. For the methods of installing the wireless kit and the motion sensor kit, refer to the attached installation

Wiring-out position and wiring connection (continued)

Wiring-out position and wiring connection (continued)

Control mode switching

- The control content of indoor units can be switched in following way. ( is the default setting)

- Switch No. Control Content

- ON

- Indoor unit silent mode

- OFF

- Normal operation

Attaching the air return grille

The air return grille must be attached when electrical cabling work is completed.

- Fix the chains tied to the air return grille onto the indoor unit with screws supplied as accessories (4 pieces).

- Close the air return grille. This completes the unit installtion work.

Check list after installation

- Check the following items after all installation work completed.

| Check Item | Expected Trouble if Not Correct |

|---|---|

| Indoor and outdoor units are fixed securely? | Falling, vibration, noise |

| Inspection for leakage is done? | Insufficient capacity |

| Insulation work is properly done? | Water leakage |

| Water is drained properly? | Water leakage |

| Power source voltage is same as mentioned on model name plate? | PCB burnt out, not working at all |

| Mis-wiring or mis-connection of piping? | PCB burnt out, not working at all |

| Earth wiring is connected properly? | Electric shock |

| Cable size complies with specified size? | PCB burnt out, not working at all |

| Any obstacle blocks air flow on air inlet and outlet? | Insufficient capacity |

FAQs

Q: Can the indoor unit be used for food storage?

A: The indoor unit should not be used for special purposes such as food storage or precision cooling.

Documents / Resources

|

MITSUBISHI PFA012D636D F Ceiling Suspended System [pdf] User Guide PFA012D636D F, PFA01PF2AD06123D66D36DFF, PFA012D636D F Ceiling Suspended System, PFA012D636D F, Ceiling Suspended System, Suspended System, System |