1. Kupu Whakataki

This manual provides essential instructions for the safe and efficient operation of your VEVOR 13.2 Gallon / 50 Liter Alcohol Still. Please read this manual thoroughly before assembly and use to ensure proper function and safety. This distillery kit is designed for various applications, including the distillation of water, essential oils, and alcoholic beverages where legally permitted.

Image 1.1: The VEVOR 13.2 Gallon / 50 Liter Alcohol Still, featuring the main boiler, thumper keg, and condenser unit.

2. Nga korero haumaru

WARNING: Distillation of alcohol may be illegal in your jurisdiction without proper licenses. Ensure compliance with all local, state, and federal laws before operating this equipment for alcohol production.

- Always operate the still in a well-ventilated area to prevent the buildup of flammable vapors.

- Ensure all connections are tight and leak-free before heating. Use Teflon tape on threaded connections as needed.

- Kaua rawa e waiho te mīhini me te kore e tirotirohia i te wā e whakamahia ana.

- Keep children and pets away from the operating still.

- Wear appropriate personal protective equipment, such as heat-resistant gloves, when handling hot components.

- Do not touch hot surfaces. The boiler and other components will become extremely hot during operation.

- Ensure the cooling system is functioning correctly throughout the distillation process to prevent pressure buildup.

- Always use food-grade materials for all components that come into contact with the product.

3. Nga Waahanga Nekeview

Your VEVOR Alcohol Still kit includes the following main components and accessories:

Image 3.1: Detailed diagram showing the numbered components of the VEVOR Alcohol Still.

- Pouaka Whakamutunga: Mo te releasing air during fermentation.

- Copper Coil (Condenser): Facilitates rapid cooling of vapor.

- Puta wai: For cooling water to exit the condenser.

- Whakauru Wai: For cooling water to enter the condenser.

- Liquid Outlet: Where the distilled product exits.

- Condenser Unit: Contains the copper coil for cooling.

- Kakau: For safe handling and transport of the main barrel.

- SS Connection Pipe: Stainless steel pipe connecting the thumper keg to the condenser.

- Thumper Keg: Used for secondary distillation and adding flavors.

- Copper Coil (Thumper): Internal coil within the thumper keg.

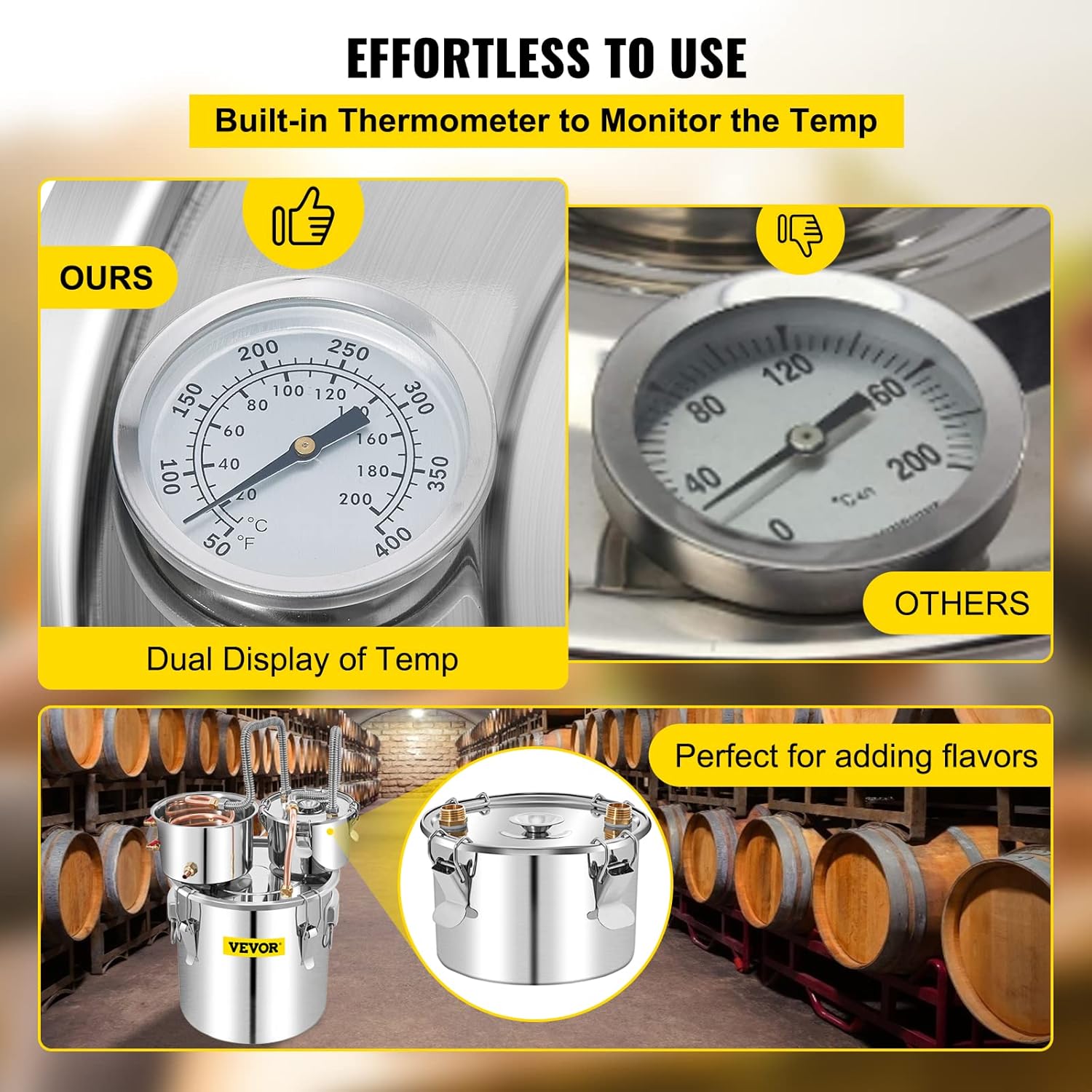

- Metal Thermometer: Built-in thermometer for real-time temperature monitoring.

- Porou: Secures the lid to the main barrel.

- Barrel (Boiler): The main fermentation and boiling vessel.

Additional accessories include food-grade silicone tubes, a circulating water pump, and silicone gaskets.

4. Tohutohu Tatūnga

Whāia ēnei mahi hei hanga i tō Pūwero Waipiro VEVOR:

- Wewete Waenga: Kia ata tangohia nga waahanga katoa mai i te kete. Tirotirohia mo te kino.

- Horoia ngā Wāhanga Katoa: Thoroughly wash all components that will come into contact with your product using warm water and mild soap. Rinse completely.

- Tāpirihia te Inemahana: Insert the metal thermometer into the designated port on the main lid. Ensure it is securely fastened.

- Install Silicone Gasket: Place the silicone cushion ring around the rim of the main boiler barrel and the lids of the thumper keg and condenser to ensure a tight seal.

- Assemble Thumper Keg and Condenser: Connect the thumper keg and condenser units to the main lid using the provided stainless steel connection pipes and fittings. Ensure all connections are tight.

- Connect Silicone Tubes: Attach the food-grade silicone tubes to the water inlet and outlet ports of the condenser. Connect the circulating water pump to the water inlet tube.

- Upi Haumaru: Place the assembled lid onto the main boiler barrel, ensuring the silicone gasket is properly seated. Secure the lid using the four buckles.

- Install One-Way Exhaust Valve: If fermenting, install the one-way exhaust valve into the designated port on the main lid. This allows gases to escape during fermentation without allowing air back in.

Ataata 4.1: He hua taipitopito mōview and setup guide for the VEVOR Alcohol Still. This video demonstrates the assembly process and key features of the distiller.

5. Nga Tohutohu Whakahaere

5.1 Preparing the Mash/Wash

Fill the main boiler barrel with your prepared mash or wash. Ensure it does not exceed 70-80% of the barrel's capacity to prevent boil-overs. For water distillation, fill with water.

5.2 Heating the Boiler

Place the boiler on a suitable heat source. The thickened bottom supports various heating methods, including gas stoves, firewood, electric ceramic heaters, and coal stoves.

Image 5.1: Illustration of compatible heating methods for the still, including gas stoves, firewood, and electric heaters.

5.3 Te Aroturuki i te Mahana

Use the built-in thermometer on the lid to monitor the temperature of the vapor inside the boiler. The thermometer provides a dual display of Celsius and Fahrenheit.

Image 5.2: The integrated thermometer on the still's lid, showing both Celsius and Fahrenheit scales for precise temperature control.

5.4 Cooling System Operation

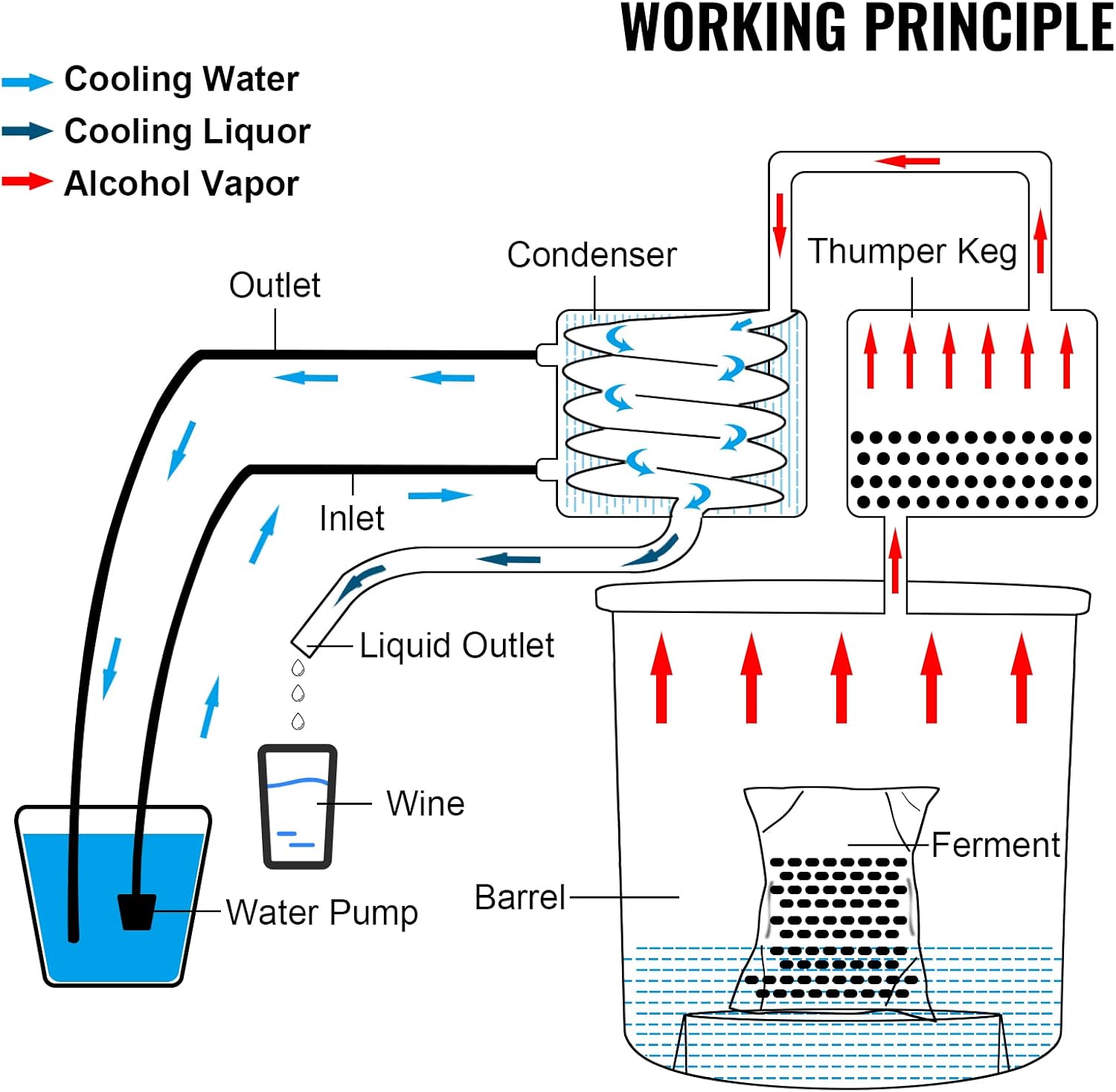

Once vapor begins to rise, activate the circulating water pump to supply cold water to the condenser. The copper coil within the condenser, combined with the open cooling method and rubber pad insulation, ensures rapid and efficient condensation of the vapor.

Image 5.3: A diagram explaining the flow of cooling water, cooling liquor, and alcohol vapor through the still's components.

5.5 Using the Thumper Keg (Optional)

The thumper keg can be used to add flavors to your distillate. Fill it with your desired spices, fruits, or other flavoring agents before starting the distillation process. The vapor will pass through the thumper keg, picking up flavors before entering the condenser.

5.6 Collecting Distillate

The condensed liquid will exit through the liquid outlet. Collect it in a suitable container. Monitor the flow rate and temperature throughout the process.

5.7 Nga tono maha

This still can be used to produce various products:

- Whiwhi

- Waina

- Parani

- Rum

- Tequila

- Vodka

- Wai Maama

- Ewaro

- Hinu Tino

Whakaahua 5.4: Examples of products that can be created using the VEVOR Alcohol Still, including various spirits and distilled water.

6. Tiaki

Regular cleaning and maintenance will prolong the life of your still and ensure optimal performance.

- Te horoi i muri i ia whakamahinga: After each distillation, allow the still to cool completely. Disassemble all components and wash them thoroughly with warm water and mild soap. Rinse all parts, especially the copper coils, to prevent residue buildup.

- whakamaroke: Ensure all components are completely dry before reassembly or storage to prevent corrosion.

- Tirohanga Gasket: Regularly inspect the silicone gaskets for any signs of wear, cracks, or damage. Replace them if necessary to maintain a tight seal.

- Tiaki Puma: Clean the circulating water pump regularly to prevent mineral buildup or blockages. Follow the pump manufacturer's instructions for specific maintenance.

- Rokiroki: Penapenahia te mea kakara ki te wāhi ma, maroke, kia matara atu i te rā tika me te pāmahana tino kino.

7. Te Raru

| Raruraru | Take pea | Rongoā |

|---|---|---|

| No distillate flow | Insufficient heat; cooling system not working; blockage in lines. | Increase heat; check water pump and cooling water supply; inspect tubes for blockages. |

| Nga hononga turuturu | Loose fittings; damaged gaskets; insufficient Teflon tape. | Tighten all fittings; replace damaged gaskets; apply more Teflon tape to threaded connections. |

| Low distillate purity | Too high heating temperature; improper cuts (for alcohol distillation). | Reduce heating temperature to maintain a steady, slow drip; research proper distillation cuts. |

| Overheating/Pressure buildup | Cooling system failure; blocked vapor path. | Immediately turn off heat; check cooling water flow; ensure all vapor paths are clear. |

8. Whakatakotoranga

Image 8.1: Visual representation of the still's capacity and key dimensions.

- Tauira Hua: 13.2 Gal / 50 L Alcohol Still

- Boiler Barrel Capacity: 13.2 Karani / 50 Ririta

- Boiler Barrel Dimensions: 15.7" x 15.7" (40 cm x 40 cm)

- Condenser Dimensions: 7.9" x 4.7" (20 cm x 12 cm)

- Thumper Keg Dimensions: 7" x 4" (18 cm x 10 cm)

- Rauemi: Food-grade Stainless Steel, Copper, Silicone

- Tikanga whakamatao: Open-type cooling with copper coil and circulating water pump

- Thermometer: Built-in, dual-display (Celsius & Fahrenheit)

- hiri: Four buckles and silicone gaskets for tight seal

- Heating Compatibility: Gas stoves, firewood, electric ceramic heaters, coal stoves

- Taumaha Tūemi: Tata ki te 15.3 pauna (6.92 kg)

- Rahi Hua: 15.7 x 0.03 x 15.7 inches (overall, approximate)

9. Raihana me te Tautoko

For warranty information, technical support, or to purchase replacement parts, please contact VEVOR customer service directly. Refer to the contact information provided with your product packaging or visit the official VEVOR webpae.

Kaihanga: VEVOR