Contents

hide

LS XBO-DA02A Programmable Logic Controller

Product Information

Specifications

- C/N: 10310001188

- Product: Programmable Logic Controller – XGB Analog

- Model: XBO-DA02A

Product Usage Instructions

Installation

- Ensure the PLC is powered off before installation.

- Connect the PLC according to the provided wiring diagram.

Programming

- Use the programming software provided to create your logic program.

- Upload the program to the PLC following the software instructions.

Operation

- Power on the PLC and monitor the status indicators for any errors.

- Test the inputs and outputs to ensure proper functionality.

INTRODUCTION

- This installation guide provides simple functional information on PLC control. Please read this data sheet and the manuals before using the products.

- Especially read the safety precautions and handle the products properly.

Safety Precautions

Meaning of warning and caution inscription

WARNING indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury

WARNING indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury CAUTION indicates a potentially hazardous situation that, if not avoided, may result in minor or moderate injury.

CAUTION indicates a potentially hazardous situation that, if not avoided, may result in minor or moderate injury.- It may also be used to alert against unsafe practices.

![]() WARNING

WARNING

- Do not contact the terminals while the power is applied.

- Protect the product from being contaminated by foreign metallic matter.

- Do not manipulate the battery(charge, disassemble, hit, short, soldering).

![]() CAUTION

CAUTION

- Be sure to check the rated voltage and terminal arrangement before wiring.

- When wiring, tighten the screw of terminal block with the specified torque range.

- Do not install flammable things in the surroundings.

- Do not use the PLC in an environment of direct vibration.

- Except for expert service staff, do not disassemble or fix, or modify the product.

- Use the PLC in an environment that meets the general specifications contained in this datasheet.

- Be sure that the external load does not exceed the rating of the output module.

- When disposing of the PLC and battery, treat them as industrial waste.

Operating Environment

To install, observe the following conditions:

| No | Item | Specification | Standard | |||

| 1 | Ambient temp. | 0 ~ 55℃ | – | |||

| 2 | Storage temp. | -25 ~ 70℃ | – | |||

| 3 | Ambient humidity | 5 ~ 95%RH, non-condensing | – | |||

| 4 | Storage humidity | 5 ~ 95%RH, non-condensing | – | |||

| 5 | Vibration Resistance | Occasional vibration | – | – | ||

| Frequency | Acceleration | Amplitude | Number | IEC 61131-2 | ||

| 5≤f<8.4㎐ | – | 3.5mm | 10 times in each direction for

X, Y, Z |

|||

| 8.4≤f≤150㎐ | 9.8㎨(1g) | – | ||||

| Continuous vibration | ||||||

| Frequency | Acceleration | Amplitude | ||||

| 5≤f<8.4㎐ | – | 1.75mm | ||||

| 8.4≤f≤150㎐ | 4.9㎨(0.5g) | – | ||||

Applicable Support Software

For system configuration, the following version is necessary.

- XBC Type: SU(V1.0 or above), E(V1.1 or above)

- XEC Type: SU(V1.0 or above), E(V1.1 or above)

- XG5000 Software: V4.0 or above

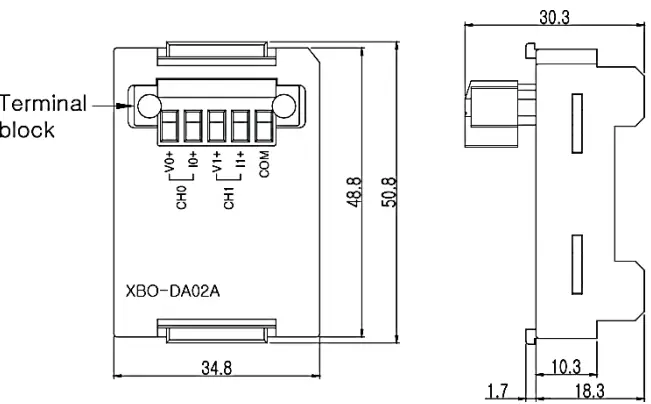

Parts Name and Dimension

Parts Name and Dimension (mm)

- This is the front part of the Module. Refer to each name when driving the system. For more information, refer to the user manual.

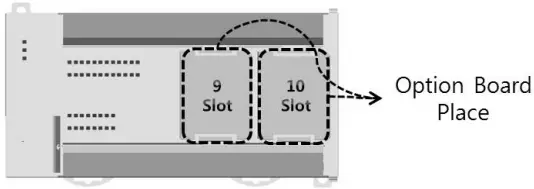

Installing/Removing Modules

- Option Board can be installed in 9 or 10 slot of the Main Unit(Standard/Economic Type) as shown below.

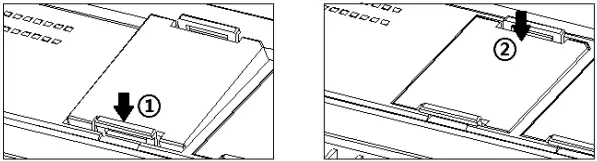

- When installing the Option Board, push the lower part(①) of the Option Board to contact with connector.

- After pushing the lower part(①) completely, push the upper(②) part of the Option Board entirely.

Performance Specifications

Performance specifications are as follows

| Item | XBO-DA02A | |||

| Analog input | Type | Voltage | Current | |

| Range | DC 0~10V | DC 4~20mA

DC 0~20mA |

||

| Digital output | Type | 12-bit binary data | ||

| Range | Unsigned value | 0~4,000 | ||

| Signed

value |

-2,000~2,000 | |||

| Precise value | 0~1,000 (DC 0 ~ 10V) | 400~2,000(DC 4~20mA)

0~2,000(DC 0~20mA) |

||

| Percentile value | 0~1,000 | |||

| Max. resolution | 1/4,000 | |||

| Accuracy | ±1.0% or less | |||

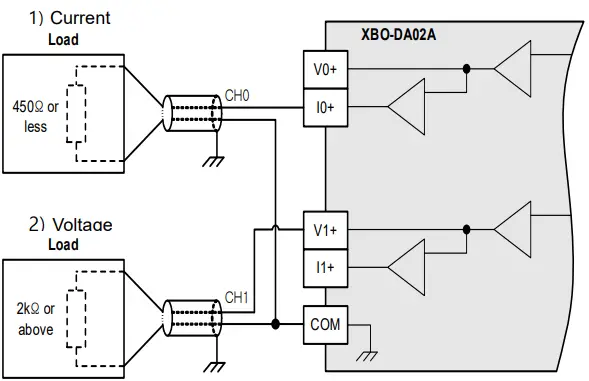

Wiring

Precautions for wiring

- Don’t let the AC power line near to analog option board’s external input signal line. With enough distance kept away between, it will be free from surge or inductive noise.

- Cable shall be selected in due consideration of ambient temperature and allowable current. More than AWG22 (0.3㎟) is recommended.

- Don’t let the cable come too close to hot device and material or in direct contact with oil for long, which will cause damage or abnormal operation due to short-circuit.

- Check the polarity when wiring the terminal.

- Wiring with a high-voltage line or power line may produce inductive hindrance, causing abnormal operation or defects.

- Enable the channel that you want to use.

Wiring examples

Warranty

- The warranty period is 36 months from the date of manufacture.

- The initial diagnosis of faults should be conducted by the user.

- However, upon request, LS ELECTRIC or its representative(s) can undertake this task for a fee.

- If the cause of the fault is found to be the responsibility of LS ELECTRIC, this service will be free of charge.

- Exclusions from warranty

- Replacement of consumable and life-limited parts (e.g., relays, fuses, capacitors, batteries, LCDs, etc.)

- Failures or damages caused by improper conditions or handling outside those specified in the user manual

- Failures caused by external factors unrelated to the product

- Failures caused by modifications without LS ELECTRIC’s consent

- Use of the product in unintended ways

- Failures that cannot be predicted/solved by current scientific technology at the time of manufacture

- Failures due to external factors such as fire, abnormal voltage, or natural disasters

- Other cases for which LS ELECTRIC is not responsible

- For detailed warranty information, please refer to the user’s manual.

- The content of the installation guide is subject to change without notice for product performance improvement.

- LS ELECTRIC Co., Ltd. www.ls-electric.com

- 10310001188 V4.5 (2024.6)

- E-mail: automation@ls-electric.com.

- Headquarters/Seoul Office Tel: 8222034403348884703

- LS ELECTRIC Shanghai Office (China) Tel: 862152379977

- LS ELECTRIC (Wuxi) Co., Ltd. (Wuxi, China) Tel: 8651068516666

- LS-ELECTRIC Vietnam Co., Ltd. (Hanoi, Vietnam) Tel: 84936314099

- LS ELECTRIC Middle East FZE (Dubai, U.A.E…) Tel: 97148865360

- LS ELECTRIC Europe B.V. (Hoofddorf, Netherlands) Tel: 31206541424

- LS ELECTRIC Japan Co., Ltd. (Tokyo, Japan) Tel: 81362688241

- LS ELECTRIC America Inc. (Chicago, USA) Tel: 18008912941

- Factory: 56, Samseong 4-gil, Mokcheon-eup, Dongnam-gu, Cheonan-si, Chungcheongnam-do, 31226, Korea

Frequently Asked Questions

- Q: What do the error codes signify?

- A: Error code 055 indicates a communication error. Refer to the manual for troubleshooting steps.

- Q: How do I calibrate the humidity sensor?

- A: For calibrating the humidity sensor, please refer to the specific calibration instructions provided with the device.

- Q: What does the ‘5f’ code represent?

- A: The ‘5f’ code could indicate a system fault. Please contact customer support for further assistance.

Documents / Resources

|

LS XBO-DA02A Programmable Logic Controller [pdf] Installation Guide XBO-DA02A, XBO-DA02A Programmable Logic Controller, Programmable Logic Controller, Logic Controller, Controller |