Non-Dispersive Infrared NDIR CO2 Sensors

Specifications

- Technology: Non-Dispersive Infrared (NDIR)

- Application: Indoor air quality monitoring, HVAC systems, environmental monitoring, industrial applications

- Advantages: Precision, long-term stability, operates in various environmental conditions

- Principle: Infrared light absorption by CO2 molecules

- Wavelength: Approximately 4.26 microns

Product Usage Instructions

Principle of Non-Dispersive Infrared:

The NDIR CO2 sensor measures CO2 concentration in the air using infrared light that is not dispersed, ensuring accurate readings.

How Does an NDIR CO2 Sensor Work?

- Infrared Light Source: Emitting infrared light for interaction with CO2 molecules.

- Gas Sample Chamber: Directing air sample into a chamber for efficient interaction with infrared light.

- Infrared Absorption by CO2: CO2 molecules absorb specific wavelength of light, reducing intensity reaching the detector.

- Optical Filter: Allowing only CO2-absorbed light to pass through for measurement.

- Infrared Detector: Measures the remaining light intensity for CO2 concentration determination.

Non-Dispersive Infrared (NDIR) CO2 Sensors, A Comprehensive Guide

Original link: https://sensor1stop.com/knowledge/ndir-co2-sensors/

- In the modern world, CO2 sensors play a crucial role in various industries, ranging from HVAC systems to agriculture and industrial safety. Among the different technologies for measuring carbon dioxide levels, the Non-Dispersive Infrared (NDIR) sensor is one of the most widely used for its accuracy and reliability. In this article, we will explore the principle of NDIR technology, its components, how it calculates CO2 levels, and its evolution from early sensors to the modern, miniaturized versions used today.

What is an NDIR CO2 Sensor?

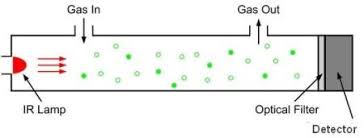

- An NDIR CO2 sensor is a type of gas sensor that measures the concentration of carbon dioxide in the air using infrared light. “Non-dispersive” means that the infrared light does not get scattered or dispersed during the process, providing a more accurate measurement of CO2 levels.

- NDIR sensors are widely used in indoor air quality monitoring, HVAC systems, environmental monitoring, and many industrial applications. Their key advantage is their precision, long-term stability, and ability to operate in various environmental conditions.

- What is the Principle of Non-Dispersive Infrared?

- The Non-Dispersive Infrared (NDIR) principle is based on the fact that gases, like CO2, absorb infrared (IR) light at specific wavelengths. The term “non-dispersive” refers to the fact that the IR light is not split into different wavelengths, unlike in dispersive methods like prisms. Instead, a single wavelength of light, specific to the gas being measured, is isolated using filters.

- In the case of CO2 detection, the key principle is that CO2 molecules absorb infrared light at awavelength of approximately 4.26 microns. This absorption reduces the amount of infrared light that reaches the detector, and the degree of this reduction corresponds to the concentration of CO2 in the air. By measuring the amount of absorbed light, the sensor can accurately determine the gas concentration

Key Concepts

- Infrared Absorption: CO2 absorbs specific wavelengths of infrared light.

- Non-Dispersive: Only the relevant IR light wavelength is measured.

- Proportional Absorption: More CO2 means more absorption, leading to lower IR light intensity at the detector

- How Does an NDIR CO2 Sensor Work?

- An NDIR CO2 sensor operates on the principle of infrared light absorption. Here’s a step-bystep breakdown of how the technology works:

- Infrared Light Source

- The sensor contains an infrared light source, typically a small lamp or LED, which emits infrared light. This light passes through the air sample that contains CO2.

- Gas Sample Chamber

- The air sample to be tested is directed into a gas sample chamber inside the sensor. This chamber is designed so that the infrared light passes through it efficiently, allowing the gas to interact with the light.

- Infrared Absorption by CO2

- As the infrared light passes through the gas sample, the CO2 molecules in the air absorb light at a specific wavelength (around 4.26 microns). This absorption reduces the intensity of the light reaching the detector. The amount of light absorbed is proportional to the concentration of CO2 in the air.

- Optical Filter

- An optical filter is placed between the light source and the detector. This filter allows only infrared light of a specific wavelength (the one absorbed by CO2) to pass through, ensuring that the sensor is only measuring CO2 levels and not other gases or substances in the air.

- Infrared Detector

- The remaining infrared light, which is not absorbed by the CO2, reaches the detector. Thedetector measures the intensity of this light. By comparing the original intensity of the light Non-Dispersive: Only the relevant IR light wavelength is measured. Proportional Absorption: More CO2 means more absorption, leading to lower IR lightintensity at the detector. (before it entered the chamber) with the detected light, the sensor calculates how much light was absorbed.

- Microprocessor and Signal Processing

- The sensor’s electronics analyze the amount of absorbed light and convert this information intoa CO2 concentration value. This value is typically expressed in parts per million (ppm), a standard unit of measurement for gas concentrations.

- Output and Display

- Finally, the CO2 concentration is outputted by the sensor and can be displayed on a screen, transmitted to a central system, or used to trigger an alarm if levels exceed a certain threshold.

Diagram: Working Process of an NDIR CO2 Sensor

| Step | Description |

| Infrared Light Source | Emits infrared light through the air sample. |

| Gas Sample Chamber | Holds the air sample for testing. |

| Infrared Absorption by CO2 | CO2 molecules absorb light at a specific wavelength. |

| Optical Filter | Filters light to only measure CO2 absorption. |

| Infrared Detector | Detects remaining light after CO2 absorption. |

| Signal Processing | Converts light absorption into CO2 concentration. |

| Output and Display | Shows CO2 levels on a screen or system. |

Why is NDIR Technology Used for CO2 Sensing?

- NDIR sensors are highly valued for CO2 sensing because of their accuracy, reliability, and long lifespan. Here are some reasons why NDIR technology is preferred:

- High Accuracy

- NDIR sensors provide precise and reliable measurements of CO2 levels. Because CO2 absorbs infrared light at a specific wavelength, NDIR technology can accurately measure concentrations without interference from other gases.

- Non-Consumptive

- Unlike chemical sensors, NDIR sensors do not consume the gas they measure. This means they have a longer operational life and require less frequent calibration.

- Low Maintenance

- NDIR sensors are low-maintenance compared to other types of CO2 sensors. They are robust, and their components, like the infrared light source, usually have a long lifespan.

- Stable Over Time

- NDIR sensors maintain their accuracy and stability over extended periods. This long-term stability makes them suitable for applications where consistent monitoring is required.

- Wide Range of Applications

- NDIR CO2 sensors can operate in a variety of environments, making them versatile for use in HVAC systems, greenhouses, industrial safety, and automotive industries.

Common Applications of NDIR CO2 Sensors

- Indoor Air Quality Monitoring

NDIR CO2 sensors are commonly used in smart homes, offices, schools, and public buildings

to monitor indoor air quality. High CO2 levels in confined spaces can lead to poor concentration, headaches, and discomfort, making these sensors crucial for ensuring healthy living environments.

Related Read: Understanding and Managing Typical CO2 Levels at Home: A Comprehensive Guide

Product Recommend: MH-Z19C NDIR CO2 Module - HVAC Systems

Heating, ventilation, and air conditioning (HVAC) systems use NDIR CO2 sensors to control airflow and ensure that CO2 levels remain within acceptable limits. This helps improve energy efficiency while maintaining good air quality.

Product Recommend: MH-Z1911A NDIR CO2 Module - Greenhouses and Agriculture

In greenhouses, CO2 levels are often artificially elevated to boost plant growth. NDIR CO2 sensors help monitor and control the CO2 levels, ensuring the environment is optimized for plant health.

Realted Read: The Benefits of CO2 for Plants: A Comprehensive Guide

Product Recommend: MH-Z16 Infrared CO2 Gas Module - Automotive and Transportation

NDIR sensors are used in automotive industries to monitor cabin air quality and ensure passengers are not exposed to high CO2 concentrations, especially in electric or autonomous vehicles where air recirculation is common.

Product Recommend: MH-V1512A NDIR CO2 Sensor - Industrial Safety

In industries like brewing, food processing, and fire suppression, monitoring CO2 levels is

essential for worker safety. NDIR sensors are used in gas detection systems to prevent dangerous CO2 buildup in enclosed spaces.

Product Recommend: MH-410D NDIR Infrared CO2 Sensor

Advantages and Disadvantages of NDIR CO2 Sensors

Advantages

- High Accuracy: Offers precise and reliable measurements.

- Long Lifespan: Minimal degradation over time.

- Low Maintenance: Requires less frequent calibration than other sensor types.

- Versatile Applications: Suitable for various environments and uses.

Disadvantages

- Cost: NDIR sensors tend to be more expensive than other CO2 sensor types.

- Size: The components required for NDIR technology can make these sensors bulkier compared to others.

- Environmental Sensitivity: Performance can be affected by extreme temperature and humidity.

Small NDIR CO2 Sensor Breakthrough

- One of the significant breakthroughs in CO2 sensing technology came with the miniaturization of NDIR CO2 sensors. Traditionally, NDIR sensors were large and used primarily in industrial applications. However, advances in semiconductor technology and optics have made it possible to shrink NDIR sensors to a size suitable for consumer electronics and small-scale applications like smart homes and portable air quality monitors.

Benefits of Small NDIR CO2 Sensors:

- Compact Size: Smaller sensors allow for integration into portable devices and residential air quality monitors.

- Low Power Consumption: These sensors consume less power, making them ideal for battery-operated devices.

- Cost-Effective: Advances in production techniques have also reduced the cost of manufacturing these sensors, making them more accessible to a broader market.

Modern NDIR CO2 Sensors

- Today’s NDIR CO2 sensors have become highly sophisticated, offering a range of features like:

- Automatic Calibration: Many sensors come with built-in calibration systems that adjust based on environmental changes, ensuring long-term accuracy.

- Temperature and Humidity Compensation: Modern sensors include compensation algorithms that adjust for fluctuations in temperature and humidity, further improving accuracy.

- Wireless Connectivity: Many NDIR CO2 sensors can now communicate with smart home systems or industrial monitoring platforms through Wi-Fi, Bluetooth, or other wireless protocols.

Popular Applications

- Smart Homes: These sensors monitor air quality in homes and adjust ventilation systems accordingly.

- HVAC Systems: NDIR sensors in HVAC systems optimize ventilation based on CO2 levels, enhancing energy efficiency.

- Greenhouses: In controlled agriculture, NDIR sensors regulate CO2 levels to promote plant growth.

Tips for Selecting the Right NDIR CO2 Sensor

- Consider Accuracy Requirements

Choose a sensor that meets your accuracy needs, especially for critical applications like environmental monitoring or industrial safety. - Check Calibration Features

Look for sensors with automatic calibration or easy manual calibration options to ensure long-term performance. - Evaluate Environmental Conditions

Consider factors like temperature, humidity, and pressure in the sensor’s operating environment. Select a sensor designed to handle these variables. - Review Maintenance Requirements

NDIR CO2 sensors are low maintenance, but some applications may require more frequent checks. Choose a sensor that fits your maintenance capacity. - Think About Integration

Make sure the sensor is compatible with your existing system, whether it’s an HVAC system, a greenhouse controller, or an industrial safety monitor.

CO2 Sensors in the Future

As environmental monitoring becomes increasingly important due to concerns about climate change and indoor air quality, the future of CO2 sensors looks promising. Some potential advancements include:

- Further Miniaturization

- As technology advances, sensors will become even smaller and more power-efficient, enabling their integration into more devices, such as smartphones and wearables.

- Improved Accuracy

- Ongoing research aims to improve the accuracy of NDIR sensors, especially under extreme environmental conditions like high humidity or temperature fluctuations.

- AI Integration

- The incorporation of artificial intelligence (AI) could allow CO2 sensors to predict air quality trends and automatically adjust ventilation or air purification systems.

- Environmental Impact Monitoring

- With growing concerns over greenhouse gases, advanced CO2 sensors will be essential in monitoring and reducing carbon footprints in various industries.

- New Sensor Materials

- Researchers are exploring new materials for infrared detectors and filters that could further enhance the sensitivity and reliability of NDIR sensors.

Key Components of an NDIR CO2 Sensor

- Infrared Light Source

- The light source is essential for emitting infrared radiation, which interacts with CO2 molecules in the air sample.

- Sample Chamber

- The sample chamber holds the air being analyzed. The design of this chamber is critical for ensuring accurate light transmission and absorption.

- Optical Filter

- This filter ensures that only the infrared light wavelength absorbed by CO2 is measured, preventing interference from other gases.

- Infrared Detector

- The detector measures the intensity of the remaining infrared light and is the key to calculating CO2 levels.

- Electronics and Signal Processing

- These components process the light absorption data and convert it into readable CO2 concentration values.

Conclusion

The NDIR CO2 sensor has revolutionized the way we monitor carbon dioxide levels, offering unparalleled accuracy, reliability, and longevity. From early chemical sensors to today’s advanced, miniaturized models, the technology has evolved dramatically, making it easier than ever to ensure good air quality in homes, workplaces, and industries. As we look to the future, advancements in sensor design and AI integration promise even greater possibilities for environmental monitoring and CO2 management.

FAQs

Q: Where are NDIR CO2 sensors commonly used?

A: NDIR CO2 sensors are widely used in indoor air quality monitoring, HVAC systems, environmental monitoring, and various industrial applications due to their precision and stability.

Q: How accurate are NDIR CO2 sensors?

A: NDIR sensors offer high precision in measuring CO2 levels due to the non-dispersive infrared principlec that ensures accurate readings

Q: How NDIR CO2 Sensors are Made

A: NDIR CO2 sensors are manufactured using a combination of optical, electronic, and mechanical components. The key steps in the manufacturing process include: Design and Prototyping: Sensor designs are developed and prototyped to ensure optimal performance. Component Assembly: Optical components like the light source and filter are carefully aligned with the detector to ensure accurate measurements. Calibration: Each sensor is calibrated using known CO2 concentrations to ensure accuracy. Testing: Sensors undergo rigorous testing under various environmental conditions, including temperature and humidity fluctuations. Modern manufacturing techniques have made it possible to produce high-quality NDIR sensors at a fraction of the cost of early models

Q: How Accurate are NDIR CO2 Sensors?

A :NDIR CO2 sensors are known for their high accuracy, typically offering measurement precision within ±(30 ppm + 3% of measured value). This level of accuracy is sufficient for most applications, including indoor air quality monitoring and greenhouse control. However, environmental factors such as temperature and humidity can affect sensor performance, so it's essential to consider these conditions when choosing an NDIR CO2 sensor.

Q: How to Calibrate an NDIR CO2 Sensor

A: Although NDIR CO2 sensors are generally stable over time, they still require periodic calibration to maintain accuracy. Calibration typically involves the following steps: Zero Calibration: Exposing the sensor to a gas with no CO2 (like nitrogen) to establish a baseline reading. Span Calibration: Using a reference gas with a known CO2 concentration to adjust the sensor’s reading. Some sensors come with automatic self-calibration features, but manual calibration is recommended in environments where CO2 levels fluctuate significantly

Q: How is the CO2 Level Calculated?

A: The CO2 concentration is calculated by measuring the amount of infrared light absorbed by the CO2 molecules in the gas sample. Here’s how the calculation process works: Emission of Infrared Light: The IR light source emits a beam through the sample chamber. Absorption by CO2: As the light passes through the chamber, CO2 molecules absorb the IR radiation at the 4.26-micron wavelength. Detection: The IR detector measures the intensity of the remaining light after some of it has been absorbed by the CO2. Comparison with Baseline: The sensor compares the detected light intensity with a reference measurement taken without CO2. Calculation of Concentration: Using a pre-determined relationship between the amount of absorbed light and CO2 concentration, the microprocessor calculates the CO2 level in parts per million (ppm). This process is known as Beer-Lambert Law, which relates the attenuation of light to the properties of the material through which the light is traveling

Q: Early Carbon Dioxide Sensor Technologies

A: Before the advent of NDIR sensors, early carbon dioxide measurement technologies included chemical methods like wet chemical analysis and electrochemical sensors. These methods often required frequent calibration, were less accurate, and had shorter lifespans. Key limitations of early technologies Frequent Calibration: The accuracy of chemical sensors degraded over time, requiring frequent recalibration. Limited Lifespan: Many early sensors had consumable components, leading to shorter operational life. Less Precision: Chemical-based sensors could be affected by other gases or environmental factors, resulting in less precise measurements.

Q: Alternatives to NDIR CO2 Sensors

A: While NDIR sensors are the most popular for CO2 measurement, other technologies are also used, including: Electrochemical Sensors: Often used in personal gas detectors, but their lifespan is shorter than NDIR sensors. Metal Oxide Semiconductor (MOS) Sensors: Used for low-cost applications, but less accurate compared to NDIR sensors.

Documents / Resources

|

Sensor Non-Dispersive Infrared NDIR CO2 Sensors [pdf] User Guide Non-Dispersive Infrared NDIR CO2 Sensors, Infrared NDIR CO2 Sensors, NDIR CO2 Sensors, CO2 Sensors |