Condensing unit OPTYMATM

Lighter and more compact,

fast installation and simple maintenance

R22/R402B/R134a/R404A/R507/R448A/R449A/R452A/R513A

![]()

An optimal solution for refrigeration

![]() Reduction in the coolant charge

Reduction in the coolant charge

Condenser units with microchannel heat exchangers use up to 30% less coolant charge compared to units with a tube-fin condenser, resulting in significant savings for the installer.

![]() Faster installation

Faster installation

Reduction in the coolant charge time since the equipment uses less coolant;

Reduction in the vacuum time as the volume inside the microchannel condenser is suficiently reduced compared to an equivalent tube-fin condenser.

Quicker installation improves the productivity of the installer (they can do more installations per day).

The fact that it is lighter than conventional units further reduces the installation time.

![]() Lighter condenser unit

Lighter condenser unit

When compared with conventional units, the new condenser units with a microchannel condenser are up to 15 kg lighter.

The reduction in the weight of the unit makes it easier to handle.

![]() Simpler maintenance

Simpler maintenance

The units have service valves in the suction and discharge connections, making maintenance easier and faster;

Cleaning of the microchannel heat exchangers is simpler and faster than those in the tube-fin condensers;

The two factors above mean preventative maintenance of these units is up to 50% faster than that of traditional units.

Product range & Features

| Crankcase resistance | Microchannel condenser | Rotolok valves |

|

|

|

| • The crankcase resistance reduces the risk of the compressor breaking as a result of flooding by up to 23.5% and as a result prolongs the operating life of the condenser unit. | • The microchannel condenser has a lower internal volume and therefore uses less coolant charge and is more eficient, reducing the charge time and the vacuum time. Cleaning and maintenance are also simpler and faster. | • The presence of Rotolok valves in the suction and discharge lines of the condenser unit makes replacing the compressor faster and reduces the vacuum time, streamlining maintenance. |

Nominal capacity ranges (Kcal/h)

Condensing unit limits

Ambient temp [°C] Up to 43°C

| T Evaporation [°C] | Min | Max |

| MBP R22 | -10 | 10 |

| MBP R402B | -20 | 10 |

| MBP R404A/R507 | -20 | 10 |

| MBP R134a | -10 | 10 |

| MBP R448A/R449A | -15 | 10 |

| MBP R452A | -15 | 10 |

| MBP 513A | -10 | 10 |

| LBP R404A/R507 | -35 | -10 |

Limits depends on the selected unit

![]() For more information, please refer to Coolselector® at coolselector.danfoss.com or contact Danfoss

For more information, please refer to Coolselector® at coolselector.danfoss.com or contact Danfoss

Application envelope

LBP

Nomenclature

Model designation

| 1 | Application: H = MBP L = LBP |

5 | Platform: D = Microchannel technology |

| 2 | Design: J = condenser unit with a fan and a hermetic compressor G = condenser unit with two fans and a hermetic compressor |

6 | Equipment level: 20 / 39 / 49 = See table below |

| 3 | Refrigerant/Lubricant: M = R22/R402B – Mineral oil Z = R134a/R404A/R507 – POE |

7 | Voltage code: N = Compressor 230V / 1F / 60Hz, Fan 230V/ 1F / 60 Hz Q = Compressor 230V / 3F / 60Hz, Fan 230V/ 1F / 60 Hz V = Compressor 380V / 3F / 60Hz, Fan 230V/ 1F / 60 Hz |

| 4 | Compressor model: MT and MTZ family for MBP NTZ family for LBP |

Note

The unit may only be used with the coolants listed in the capacity tables.

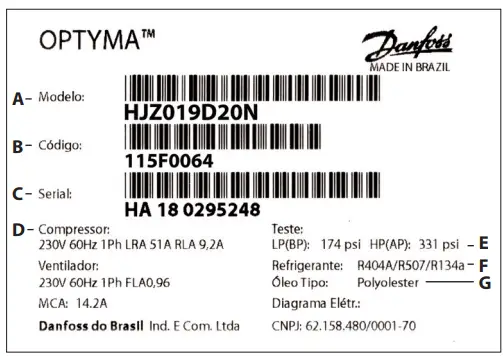

Label – Designation

A: Model

B: Code number

C: Serial number and bar code

D: Supply voltage, Locked Rotor Ampere

E: Housing service pressure

F: Refrigerant gas

G: Oil type

Version – Equipment level

| D20 | D39 | D49 | |

| Receiver | X | X | X |

| Danfoss Filter drier | X | X | X |

| Danfoss Sight glass | X | X | X |

| Low pressure switch – KP1 Danfoss | X | X | X |

| High pressure switch – Danfoss cartridge design | X | X | X |

| Oil separator | X | ||

| Suction accumulator | X | ||

| Crankcase heater | X | X | X |

| Rotolok suction and discharge valves | X | X | X |

| Electric terminals and connectors | X | ||

| Electric box with a circuit breaker, meter and sequence phase relay | X | X |

General data – MBP

| Model | Condenser | Fan motor Ø [mm] | Receiver

[l] |

Connection | Weight [kg] |

||||

| Type | Air ow [m3/h] |

Internal volume [l] |

Suction line | Liquid line | Gross | Net | |||

| OP-HJM(Z)19 | D8 | 2400 | 0,4 | 1×350 | 4 | 1/2” | 3/8” | D20 = 62 | D20 = 53 |

| D39 = 64 | D39 = 55 | ||||||||

| D49 = 69 | D49 = 60 | ||||||||

| OP-HJM(Z)22 | D8 | 2400 | 0,4 | 1×350 | 4 | 1/2” 5/8” (N) | 3/8” | D20 = 62 | D20 = 53 |

| D39 = 64 | D39 = 55 | ||||||||

| D49 = 69 | D49 = 60 | ||||||||

| OP-HJM(Z)28 | G8 | 4800 | 0,5 | 1×450 | 6 | 1/2” 5/8” (N) | 1/2” | D20 = 83 | D20 = 71 |

| D39 = 85 | D39 = 73 | ||||||||

| D49 = 90 | D49 = 78 | ||||||||

| OP-HJM(Z)32 | G8 | 4800 | 0,5 | 1×450 | 8 | 5/8” | 1/2” | D20 = 85 | D20 = 73 |

| D39 = 87 | D39 = 75 | ||||||||

| D49 = 93 | D49 = 81 | ||||||||

| OP-HJM(Z)36 | G8 | 4800 | 0,5 | 1×450 | 8 | 5/8” | 1/2” | D20 = 85 | D20 = 73 |

| D39 = 87 | D39 = 75 | ||||||||

| D49 = 93 | D49 = 81 | ||||||||

| OP-HJM(Z)40 | J8 | 6300 | 1,3 | 1×450 | 8 | 5/8” | 1/2” | D20 = 93 | D20 = 80 |

| D39 = 95 | D39 = 82 | ||||||||

| D49 = 101 | D49 = 88 | ||||||||

| OP-HJM(Z)44 | J8 | 6300 | 1,3 | 1×450 | 8 | 7/8” | 1/2” | D20 = 104 | D20 = 91 |

| D39 = 107 | D39 = 94 | ||||||||

| D49 = 115 | D49 = 102 | ||||||||

| OP-HJM(Z)50 | J8 | 6300 | 1,3 | 1×450 | 8 | 7/8” | 1/2” | D20 = 104 | D20 = 91 |

| D39 = 107 | D39 = 94 | ||||||||

| D49 = 115 | D49 = 102 | ||||||||

| OP-HJM(Z)56 | J8 | 6300 | 1,3 | 1×450 | 8 | 7/8” | 1/2” | D20 = 104 | D20 = 91 |

| D39 = 107 | D39 = 94 | ||||||||

| D49 = 115 | D49 = 102 | ||||||||

| OP-HJM(Z)64 | J8 | 6300 | 1,3 | 1×450 | 8 | 7/8” | 1/2” | D20 = 104 | D20 = 91 |

| D39 = 107 | D39 = 94 | ||||||||

| D49 = 115 | D49 = 102 | ||||||||

| OP-HGM(Z)072 | N8 | 8800 | 1,6 | 2×450 | 14 | 1 1/8” | 5/8” | D20 = 140 | D20 = 125 |

| D39 = 143 | D39 = 128 | ||||||||

| D49 = 152 | D49 =137 | ||||||||

| OP-HGM(Z)080 | N8 | 8800 | 1,6 | 2×450 | 14 | 1 1/8” | 5/8” | D20 = 143 | D20 = 128 |

| D39 = 146 | D39 = 131 | ||||||||

| D49 = 155 | D49 = 140 | ||||||||

| OP-HGM(Z)100 | N8 | 8800 | 1,6 | 2×450 | 14 | 1 1/8” | 5/8” | D20 = 159 | D20 = 154 |

| D39 = 162 | D39 = 147 | ||||||||

| D49 = 171 | D49 = 156 | ||||||||

| OP-HGM(Z)125 | Q8 | 13980 | 2,5 | 2×600 | 18 | 1 1/8” | 5/8” | D20 = 243 | D20 = 225 |

| D39 = 247 | D39 = 229 | ||||||||

| D40 = 287 | D40 = 269 | ||||||||

| D49 = 257 | D49 = 239 | ||||||||

| OP-HGM(Z)144 | Q8 | 13980 | 2,5 | 2×600 | 18 | 1 1/8” | 5/8” | D20 = 248 | D20 = 230 |

| D39 = 252 | D39 = 234 | ||||||||

| D49 = 262 | D49 = 244 | ||||||||

| OP-HGM(Z)160 | Q8 | 13980 | 2,5 | 2×600 | 18 | 1 1/8” | 5/8” | D20 = 248 | D20 = 230 |

| D39 = 252 | D39 = 234 | ||||||||

| D49 = 262 | D49 = 244 | ||||||||

General data – LBP

| Model | Condenser | Fan motor Ø [mm] | Receiver [l] |

Connection | Weight [kg] | ||||

| Type | Air ow [m3/h] |

Internal volume [l] |

Suction line |

Liquid line |

Gross |

Net |

|||

| OP-LJZ048D | D8 | 2400 | 0,4 | 1×350 | 4 | D20 5/8″ | 3/8″ | D20 = 62 | D20 = 53 |

| D49 1/2” | D49 = 69 | D49 = 60 | |||||||

| OP-LJZ068D | D8 | 2400 | 0,4 | 1×350 | 4 | D20 5/8” | 3/8″ | D20 = 62 | D20 = 53 |

| D49 1/2” | D49 = 69 | D49 = 60 | |||||||

| OP-LJZ096D | G8 | 4800 | 0,5 | 1×450 | 8 | 7/8″ | 1/2″ | D20 = 96 | D20 = 86 D49 = 81 |

| D49 = 93 | |||||||||

| OP-LJZ108D | J8 | 6300 | 1,3 | 1×450 | 8 | 7/8″ | 1/2″ | D20 = 104 | D20 = 91 D49 = 102 |

| D49 = 115 | |||||||||

| OP-LJZ136D | J8 | 6300 | 1,3 | 1×450 | 8 | 7/8″ | 1/2″ | D20 = 104 | D20 = 91 D49 = 102 |

| D49 = 115 | |||||||||

| OP-LGZ215D | N8 | 8800 | 1,6 | 2×450 | 14 | 1 1/8″ | 5/8″ | D20 = 159 | D20 = 154 D49 = 156 |

| D49 = 171 | |||||||||

| OP-LGZ271D | N8 | 8800 | 1,6 | 2×450 | 14 | 1 1/8″ | 5/8″ | D20 = 159 | D20 = 154 D49 = 156 |

| D49 = 171 | |||||||||

Condensing unit R22 (MBP)

Condensing unit R402B (MBP)

Condensing unit R134a (MBP)

Condensing unit R404A/R507 (MBP)

Condensing unit R448A/R449A (MBP)

Condensing unit R452A (MBP)

Condensing unit R513A (MBP)

Condensing unit R404A/R507 (LBP)

Spare parts and optional items

All of the units are equipped with:

– Crankcase resistance PTC 35 W (code 120Z0459);

– High pressure switch model ACB 2UB – 215 W – 26.5/18.0 bar (code 061F6050);

– Low pressure switch model KP1 (code 060-110191).

Lubricating oil:

– For units OP-HJM/OP-HGM: code 7754001 (2-liter pack);

– For units OP-HJZ/OP-HGZ: code 120Z0638 (1-liter pack);

– For units OP-LJZ/OP-LGZ: code 120Z0638 (1-liter pack);

Notes:

(*) The housing is an optional item

(**) The fan kit consists of a motor, grill, propeller and capacitor.

(***) The condenser kit consists of a microchannel, hood and seal.

(****) Both valve codes have the same interface and functionality.

Compressor

| Application | Model | Compressor | |||||

| 220V 1F 60Hz (N) | 220V 3F 60Hz (Q) | 380V 3F 60Hz (V) | |||||

| Code | Model | Code | Model | Code | Model | ||

| MBP | OP-HJM019D | MT19-1VI | MT19-1VI | MT19-3VI | MT19-3VI | MT19-4VI | MT19-4VI |

| OP-HJZ019D | MTZ19-1VI | MTZ19-1VI | MTZ19-3VI | MTZ19-3VI | MTZ19-4VI | MTZ19-4VI | |

| OP-HJM022D | MT22-1VI | MT22-1VI | MT22-3VI | MT22-3VI | MT22-9VI | MT22-9VI | |

| OP-HJMZ022D | MTZ22-1VI | MTZ22-1VI | MTZ22-3VI | MTZ22-3VI | MTZ22-9VI | MTZ22-9VI | |

| OP-HJM028D | MT28-1VI | MT28-1VI | MT28-3VI | MT28-3VI | MT28-9VI | MT28-9VI | |

| OP-HJZ028D | MTZ28-1VI | MTZ28-1VI | MTZ28-3VI | MTZ28-3VI | MTZ28-9VI | MTZ28-9VI | |

| OP-HJM032D | MT32-1VI | MT32-1VI | MT32-3VI | MT32-3VI | MT32-9VI | MT32-9VI | |

| OP-HJZ032D | MTZ32-1VI | MTZ32-1VI | MTZ32-3VI | MTZ32-3VI | MTZ32-9VI | MTZ32-9VI | |

| OP-HJM036D | MT36-1VI | MT36-1VI | MT36-3VI | MT36-3VI | MT36-9VI | MT36-9VI | |

| OP-HJZ036D | MTZ36-1VI | MTZ36-1VI | MTZ36-3VI | MTZ36-3VI | MTZ36-9VI | MTZ36-9VI | |

| OP-HJM040D | MT40-1VI | MT40-1VI | MT40-3VI | MT40-3VI | MT40-4VI | MT40-4VI | |

| OP-HJMZ040D | MTZ40-1VI | MTZ40-1VI | MTZ40-3VI | MTZ40-3VI | MTZ40-4VI | MTZ40-4VI | |

| OP-HJM044D | MT44-1VI | MT44-1VI | MT44-3VI | MT44-3VI | MT44-9VI | MT44-9VI | |

| OP-HJZ044D | MTZ44-1VI | MTZ44-1VI | MTZ44-3VI | MTZ44-3VI | MTZ44-9VI | MTZ44-9VI | |

| OP-HJM050D | MT50-1VI | MT50-1VI | MT50-3VI | MT50-3VI | MT50-9VI | MT50-9VI | |

| OP-HJZ050D | MTZ50-1VI | MTZ50-1VI | MTZ50-3VI | MTZ50-3VI | MTZ50-9VI | MTZ50-9VI | |

| LBP | OP-HJM056D | MT56-1VI | MT56-1VI | MT56-3VI | MT56-3VI | MT56-9VI | MT56-9VI |

| OP-HJZ056D | MTZ56-1VI | MTZ56-1VI | MTZ56-3VI | MTZ56-3VI | MTZ56-9VI | MTZ56-9VI | |

| OP-HJM064D | MT64-1VI | MT64-1VI | MT64-3VI | MT64-3VI | MT64-9VI | MT64-9VI | |

| OP-HJZ064D | MTZ64-1VI | MTZ64-1VI | MTZ64-3VI | MTZ64-3VI | MTZ64-9VI | MTZ64-9VI | |

| OP-HGM072D | — | — | MT72-3VI | MT72-3VI | MT72-9VI | MT72-9VI | |

| OP-HGZ072D | — | — | MTZ72-3VI | MTZ72-3VI | MTZ72-9VI | MTZ72-9VI | |

| OP-HGM080D | — | — | MT80-3VI | MT80-3VI | MT80-9VI | MT80-9VI | |

| OP-HGZ080D | — | — | MTZ80-3VI | MTZ80-3VI | MTZ80-9VI | MTZ80-9VI | |

| OP-HGM100D | — | — | MT100-3VI | MT100-3VI | MT100-9VI | MT100-9VI | |

| OP-HGZ100D | — | — | MTZ100-3VI | MTZ100-3VI | MTZ100-9VI | MTZ100-9VI | |

| OP-HGM125D | — | — | MT125-3VI | MT125-3VI | MT125-9VI | MT125-9VI | |

| OP-HGZ125D | — | — | MTZ125-3VI | MTZ125-3VI | MTZ125-9VI | MTZ125-9VI | |

| OP-HGM144D | — | — | MT144-3VI | MT144-3VI | MT144-9VI | MT144-9VI | |

| OP-HGZ144D | — | — | MTZ144-3VI | MTZ144-3VI | MTZ144-9VI | MTZ144-9VI | |

| OP-HGM160D | — | — | MT160-3VI | MT160-3VI | MT160-9VI | MT160-9VI | |

| OP-HGZ160D | — | — | MTZ160-3VI | MTZ160-3VI | MTZ160-9VI | MTZ160-9VI | |

| OP-LJZ048D | 120F0293 | NTZ048-1 | 120F0279 | NTZ048-3 | 120F0302 | NTZ048-9 | |

| OP-LJZ068D | 120F0294 | NTZ068-1 | 120F0280 | NTZ068-3 | 120F0303 | NTZ068-9 | |

| OP-LJZ096D | 120F0295 | NTZ096-1 | 120F0281 | NTZ096-3 | — | — | |

| OP-LJZ108D | 120F0296 | NTZ108-1 | 120F0282 | NTZ108-3 | 120F0304 | NTZ108-9 | |

| OP-LJZ136D | 120F0297 | NTZ136-1 | 120F0283 | NTZ136-3 | 120F0305 | NTZ136-9 | |

| OP-LGZ215D | — | — | 120F0284 | NTZ215-3 | 120F0306 | NTZ215-9 | |

| OP-LGZ271D | — | — | 120F0285 | NTZ271-3 | 120F0307 | NTZ271-9 | |

Dimensions

Version D20 e D39 (1 Fan)

Version D49 (1 Fan)

Version D20 e D39 (2 Fans)

Version 49 (2 Fans)

Electrical wiring diagrams

| Legenda | |

| CH | Switch on/o |

| CP | Compressor |

| CR | Capacitor run |

| CS | Capacitor start |

| CV | Capacitor fan |

| DJ* | Circuit breaker |

| K* | Contactor |

| PH | High pressure switch |

| PL | Low pressure switch |

| RC | Crankcase heater |

| RL | Relay |

| V | Fan |

* Items not available for version D20.

| Application | Model | Condensing unit | Compressor 230V / 1F |

Fan 230V / 1F |

||

| MCA [A] | LRA [A] | MCA [A] | FLA [A] | Potência [W] | ||

| MBP | OP-HJM(Z)019 | 14.40 | 53.0 | 13.0 | 1.00 | 240 |

| OP-HJM(Z)022 | 18.40 | 53.0 | 17.0 | 1.00 | 240 | |

| OP-HJM(Z)028 | 27.76 | 81.0 | 25.0 | 1.97 | 450 | |

| OP-HJM(Z)032 | 29.26 | 84.0 | 26.5 | 1.97 | 450 | |

| OP-HJM(Z)036 | 32.76 | 84.0 | 30.0 | 1.97 | 450 | |

| OP-HJM(Z)040 | 336.76 | 99.0 | 334.0 | 1.97 | 450 | |

| OP-HJM(Z)044 | 33.76 | 97.0 | 31.0 | 1.97 | 450 | |

| OP-HJM(Z)050 | 38.76 | 114.0 | 36.0 | 1.97 | 450 | |

| OP-HJM(Z)056 | 45.26 | 136.0 | 42.5 | 1.97 | 450 | |

| OP-HJM(Z)064 | 48.76 | 143.0 | 46.0 | 1.97 | 450 | |

| LBP | OP-LJZ048 | 14.60 | 52.0 | 13.2 | 1.00 | 240 |

| OP-LJZ068 | 22.40 | 76.0 | 21.0 | 1.00 | 240 | |

| OP-LJZ096 | 33.76 | 112.0 | 31.0 | 1.97 | 450 | |

| OP-LJZ108 | 35.76 | 97.0 | 33.0 | 1.97 | 450 | |

| OP-LJZ136 | 43.76 | 140.0 | 41.0 | 1.97 | 450 | |

MCA: Minimum Circuit Amps

LRA: Locked Rotor Amperage

MCC: Maximum Continuous Current

FLA: Full Load Amperage

Electrical code Q – 230V / 3F / 60Hz

| Legenda | |

| CH | Switch on/o |

| CP | Compressor |

| CV | Capacitor fan |

| DJ* | Circuit breaker |

| K* | Contactor |

| PH | High pressure switch |

| PL | Low pressure switch |

| RC | Crankcase heater |

| SFF* | Sequence phase relay |

| V1-V2 | Fan |

* Items not available for version D20.

| Application | Model | Condensing unit | Compressor 230V / 1F |

Fan 230V / 1F |

||

| MCA [A] | LRA [A] | MCA [A] | FLA [A] | Potência [W] | ||

| MBP | OP-HJM(Z)019 | 10.40 | 38.0 | 9.0 | 1.00 | 240 |

| OP-HJM(Z)022 | 12.40 | 38.0 | 11.0 | 1.00 | 240 | |

| OP-HJM(Z)028 | 18.76 | 57.0 | 16.0 | 1.97 | 450 | |

| OP-HJM(Z)032 | 20.76 | 60.0 | 18.0 | 1.97 | 450 | |

| OP-HJM(Z)036 | 19.76 | 74.0 | 17.0 | 1.97 | 450 | |

| OP-HJM(Z)040 | 24.76 | 98.0 | 22.0 | 1.97 | 450 | |

| OP-HJM(Z)044 | 19.76 | 115.0 | 17.0 | 1.97 | 450 | |

| OP-HJM(Z)050 | 24.76 | 120.0 | 22.0 | 1.97 | 450 | |

| OP-HJM(Z)056 | 26.76 | 130.0 | 24.0 | 1.97 | 450 | |

| OP-HJM(Z)064 | 30.76 | 135.0 | 28.0 | 1.97 | 450 | |

| OP-HGM(Z)072 | 37.52 | 155.0 | 32.0 | 3.94 | 450 (x2) | |

| OP-HGM(Z)080 | 41.52 | 140.0 | 36.0 | 3.94 | 450 (x2) | |

| OP-HGM(Z)100 | 48.52 | 157.0 | 43.0 | 3.94 | 450 (x2) | |

| OP-HGM(Z)125 | 61.84 | 210.0 | 54.0 | 5.60 | 600 (x2) | |

| OP-HGM(Z)144 | 71.84 | 259.0 | 64.0 | 5.60 | 600 (x2) | |

| OP-HGM(Z)160 | 77.84 | 259.0 | 70.0 | 5.60 | 600 (x2) | |

| LBP | OP-LJZ048 | 11.50 | 32.0 | 10.1 | 1.00 | 240 |

| OP-LJZ068 | 16.20 | 48.5 | 14.8 | 1.00 | 240 | |

| OP-LJZ096 | 23.16 | 72.0 | 20.4 | 1.97 | 450 | |

| OP-LJZ108 | 24.16 | 72.0 | 21.4 | 1.97 | 450 | |

| OP-LJZ136 | 31.76 | 97.2 | 29.0 | 1.97 | 450 | |

| OP-LGZ215 | 47.82 | 147.7 | 42.3 | 3.94 | 450 (x2) | |

| OP-LGZ271 | 62.02 | 198.0 | 56.5 | 3.94 | 450 (x2) | |

MCA: Minimum Circuit Amps

LRA: Locked Rotor Amperage

MCC: Maximum Continuous Current

FLA: Full Load Amperage

Electrical code V – 380V / 3F / 60Hz

| Legenda | |

| CH | Switch on/o |

| CP | Compressor |

| CV | Capacitor fan |

| DJ* | Circuit breaker |

| K* | Contactor |

| PH | High pressure switch |

| PL | Low pressure switch |

| RC | Crankcase heater |

| SFF* | Sequence phase relay |

| V1-V2 | Fan |

* Items not available for version D20.

| Application | Model | Condensing unit | Compressor 230V / 1F |

Fan 230V / 1F |

||

| MCA [A] | LRA [A] | MCA [A] | FLA [A] | Potência [W] | ||

| MBP | OP-HJM(Z)019 | 6.40 | 23.0 | 5.0 | 1.00 | 240 |

| OP-HJM(Z)022 | 7.40 | 22.5 | 6.0 | 1.00 | 240 | |

| OP-HJM(Z)028 | 11.26 | 32.0 | 8.5 | 1.97 | 450 | |

| OP-HJM(Z)032 | 11.76 | 35.0 | 9.0 | 1.97 | 450 | |

| OP-HJM(Z)036 | 12.26 | 35.0 | 9.5 | 1.97 | 450 | |

| OP-HJM(Z)040 | 12.76 | 38.0 | 10.0 | 1.97 | 450 | |

| OP-HJM(Z)044 | 15.76 | 78.0 | 13.0 | 1.97 | 450 | |

| OP-HJM(Z)050 | 16.26 | 78.0 | 13.5 | 1.97 | 450 | |

| OP-HJM(Z)056 | 17.76 | 72.0 | 15.0 | 1.97 | 450 | |

| OP-HJM(Z)064 | 20.26 | 72.0 | 17.5 | 1.97 | 450 | |

| OP-HGM(Z)072 | 24.02 | 100.0 | 18.5 | 3.94 | 450 (x2) | |

| OP-HGM(Z)080 | 28.02 | 102.0 | 22.5 | 3.94 | 450 (x2) | |

| OP-HGM(Z)100 | 31.52 | 110.0 | 26.0 | 3.94 | 450 (x2) | |

| OP-HGM(Z)125 | 37.84 | 150.0 | 30.0 | 5.60 | 600 (x2) | |

| OP-HGM(Z)144 | 47.84 | 165.0 | 40.0 | 5.60 | 600 (x2) | |

| OP-HGM(Z)160 | 53.84 | 165.0 | 46.0 | 5.60 | 600 (x2) | |

| LBP | OP-LJZ048 | 6.40 | 22.0 | 5.0 | 1.00 | 240 |

| OP-LJZ068 | 9.90 | 29.0 | 8.5 | 1.00 | 240 | |

| OP-LJZ096 | 13.76 | 57.0 | 11.0 | 1.97 | 450 | |

| OP-LJZ108 | 13.76 | 57.0 | 11.0 | 1.97 | 450 | |

| OP-LJZ136 | 17.76 | 64.0 | 15.0 | 1.97 | 450 | |

| OP-LGZ215 | 28.52 | 110.0 | 23.0 | 3.94 | 450 (x2) | |

| OP-LGZ271 | 35.52 | 150.0 | 30.0 | 3.94 | 450 (x2) | |

MCA: Minimum Circuit Amps

LRA: Locked Rotor Amperage

MCC: Maximum Continuous Current

FLA: Full Load Amperage

Danfoss Commercial Compressors

is a worldwide manufacturer of compressors and condensing units for refrigeration and HVAC applications. With a wide range of high quality and innovative products we help your company to find the best possible energy efficient solution that respects the environment and reduces total life cycle costs.

We have 40 years of experience within the development of hermetic compressors which has brought us amongst the global leaders in our business, and positioned us as distinct variable speed technology specialists. Today we operate from engineering and manufacturing facilities spanning across three continents.

Our products can be found in a variety of applications such as rooftops, chillers, residential air conditioners, heatpumps, coldrooms, supermarkets, milk tank cooling and industrial cooling processes.

![]()

Danfoss do Brasil Ind. e Com. Ltda.

Climate Solutions

danfoss.com.br

+55 0800 87 87 847

sac.brasil@danfoss.com

AF121386439414en-BRO901

© Danfoss | DCS (CC) | 2024.02

Documents / Resources

|

Danfoss OPTYMA Plus Condensing Unit [pdf] Instruction Manual OPTYMA Plus Condensing Unit, OPTYMA, Plus Condensing Unit, Condensing Unit |