COMPACT

COMPACT

ESPRESSO MACHINE

#236ECEM1C #236ECEM2C

236ECEM1C Compact Espresso Machine

![]() CONFORMS TO UL 197

CONFORMS TO UL 197

CONFORMS TO NSF/ANSI 4

Note: Save these instructions for future reference.

SAFETY INFORMATION

TO BE REPAIRED ONLY BY TRAINED SERVICE PERSONNEL.

Read the Manual: Before using your espresso machine for the first time, carefully read the user manual.

It will contain specific instructions, safety tips, and cleaning guidelines.

Placement: Situate your espresso machine on a stable, level, and heat-resistant surface away from heat sources.

Electrical Safety: Ensure your machine’s plug is compatible with the electrical outlet’s voltage. Never use an extension cord or a damaged power cord.

Grounding: Ensure the espresso machine is properly grounded to prevent electric shock.

Cord Safety: Keep cords away from wet areas and do not let them hang over counters to prevent tripping hazards, risk of fire, and electric shock.

Water Safety: Use only filtered and softened water in your espresso machine. Unsoftened water will decompose dissolvable minerals and turn to limescale after boiling. The limescale will reduce the machine’s thermal efficiency and machine’s lifetime.

Child Safety: Supervise children around the espresso machine, especially when it is in use. Hot water and steam can cause burns.

Hot Surfaces: Avoid touching hot surfaces during and immediately after use. Use appropriate protective gear when necessary. The steam wand, hot water wand, and brewing group can reach very hot temperatures.

Use caution while operating.

Cleaning and Maintenance: Regularly clean and maintain the espresso machine according to the instructions to ensure safe and hygienic operation.

Chemical Usage: If using cleaning chemicals, follow the guidelines for safe handling and storage.

Ventilation: Ensure the espresso machine has adequate ventilation to prevent overheating and ensure efficient operation.

No Modifications: Never modify your espresso machine in any way. This could create safety hazards and void your warranty.

Emergencies: In case of a malfunction, immediately turn off and unplug the espresso machine. Do not attempt to repair it yourself. Contact the manufacturer for support.

Regularly Inspect: Check the power cord for damage. If there are any signs of wear or fraying, replace the cord immediately.

Element Check: Inspect the heating elements regularly for proper function and absence of damage.

Safe Disposal: If the espresso machine is no longer usable, dispose of it responsibly following local guidelines for electronic waste.

Proper Usage: Teach users how to properly use the espresso machine to prevent mishaps and ensure consistent results.

Instruction Labels: Ensure any operational or safety labels on the espresso machine are visible and legible.

Do Not Operate Unattended: Avoid leaving the espresso machine unattended while it is use.

Output Settings: No default coffee output setting is provided. Settings must be made manually during setup.

INITIAL SETUP

Inspect the Packaging: Take a close look at the exterior of the packaging to check for any signs of damage that might have occurred during shipping.

Unboxing: Open the packaging carefully. Use scissors or a box cutter to open the box without damaging the machine or any parts.

Remove All Components: Take the machine and any accessories out of the box. Refer to the parts diagram to ensure that you have all the necessary components.

Place in Location: Choose a stable, level surface near a cold water supply and an appropriate electrical outlet.

Ensure the location meets the space requirements for safe operation and maintenance access.

Water Connection: Install a water filtration system to meet the specified water quality standards. Connect the machine to the cold water supply using the provided hoses, ensuring all connections are secure to prevent leaks.

Electrical Connection: Ensure your machine’s plug is compatible with the electrical outlet’s voltage. Never use an extension cord or a damaged power cord. Plug in the machine to the power source. Initial Setup: Once connected, turn the main switch clockwise to power up the machine. The unit will automatically start filling with water until the appropriate water level is reached.

Heating: The boiler element will be activated, heating the whole system. Heating will stop when the boiler pressure reaches the appropriate level. Do not operate the machine until the pressure gauge is in the green zone.

OUTPUT VOLUME/FREQUENCY SETUP

NO DEFAULT COFFEE OUTPUT SETTING IS PROVIDED. SETTINGS MUST BE MADE MANUALLY DURING SETUP.

- Ensure that both the water level and steam pressure are in the green zone before proceeding.

- There are two identical button suites on 2-group models. For these models, start by programming the buttons on the furthest group to the left and then move right. The programmed outputs will serve as default for the right group until programmed differently.

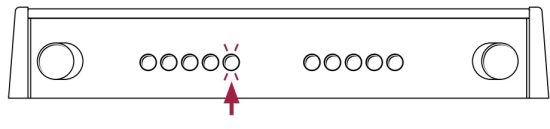

Entering Programming Mode

- Switch the machine off by means of the main switch.

- Press and hold the continuous coffee button from group 1 (group in the left side of the machine) and then switch the machine on. Wait 5 seconds until the button’s lights are steady.

Programming the Output

Programming the Output

- Press and hold the desired output button until the brew group starts dispensing water.

- Wait until you have obtained the required dose and press the same button to stop the dispensing.

- Repeat these steps for all programmable buttons in the left group head.

- These settings will serve as default for the right group head (if applicable) unless programmed differently.

CLEANING

WARNING — THE STEAM WAND, HOT WATER WAND, AND BREWING GROUP CAN REACH VERY HOT TEMPERATURES. USE CAUTION WHILE CLEANING. PROPERLY ALLOW THE MACHINE TO COOL DOWN.

CLEANING SHOULD BE DONE PERIODICALLY THROUGHOUT THE DAY AND AT THE END OF EVERY DAY.

Preparation

- Cool Down: If the machine was in use recently, give it sufficient time to cool down. Allow at least 30 minutes, depending on the model.

- Unplug: Unplug the machine from the electrical outlet to avoid electrical shocks.

- Gloves: Wear gloves to keep both the machine and your hands clean.

Cleaning Non-Electrical Parts

- Water Temperature: Use warm water and mild dish soap for washing the removable parts.

- Soft Sponge: Use a non-abrasive sponge or cloth to wash the removable parts, avoiding any scratches.

- Brushing: Use a soft-bristled brush to clean hard to reach areas.

- Safe Cleaners: If necessary, use a non-abrasive, food-safe cleaner.

- Sanitizer: Use a sanitization liquid before reassembly.

Exterior Cleaning

- Turn off and unplug the machine.

- Wipe the machine’s exterior with a soft, damp cloth. Use gentle, non-corrosive cleaning agents if necessary, applying them to the cloth rather than directly on the machine to avoid damage.

Portafilter and Basket

- Rinse the portafilter with warm water after each brewing cycle to dissolve residual oils in the filter basket and outlet nozzle and prevent oils from affecting the quality of coffee.

- Disassemble the portafilter and place all parts in cleaning solution. DO NOT immerse plastic portion in cleaning solution to avoid deterioration.

- Use a non-abrasive brush or cloth for thorough cleaning.

- Rinse all components with clean water. Wipe with a soft, clean cloth only.

Brew Group

- Ensure that the portafilter and all components are properly cleaned.

- Turn off the machine with the main switch.

- Place a reverse flushing silica plate in the portafilter and apply about 2-3 grams of detergent. Attach the portafilter onto the machine and check for tightness.

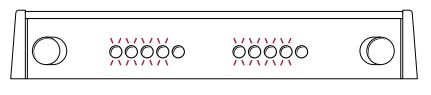

- Next, start the auto backwashing process.

– Press and hold the two regular cups button in group head 1 (left) and without releasing it, start the machine with the main switch and wait until all the LEDs of the buttons for the “Continuous Coffee” option starts to flash. The cleaning process will finish after 15 cycles or after pressing the continuous coffee button again.

– To exit the automatic cleaning mode, turn off and restart the machine with the main switch.

Steam Wand Maintenance

- After making steamed milk, use a slightly moistened soft cloth to wipe steam tube.

- After wiping, release a steam burst through the tube to remove any residual milk remaining in the nozzle.

- If hardened milk residuals remain in the steam tube, disassemble and immerse tube in hot water for about 20 minutes to soften. Reassemble and repeat Step 1.

Drip Tray and Waste Bin

- Empty and rinse the drip tray and waste bin daily to prevent odor and residue buildup.

- Wash with warm, soapy water, rinse thoroughly, and dry before replacing.

Water Reservoir - Regularly empty and clean the water reservoir to prevent scale buildup and maintain water quality.

- Refill with fresh, filtered water daily.

Deliming - Contact a service professional to delime the unit every 6 months.

Filter

The manufacturer recommends replacing the filter element on the resin exchange filter after processing 53 gallons of water (about 3,000–4,000 cups of coffee). This schedule can be expected to vary based on the quality of water used in your machine.

OPERATION

Start-Up Procedure

- Initial Setup Procedures: Refer to the “Initial Setup” section of the manual to ensure that your machine is ready for operation.

- Plug in the Machine: Make sure all controls are in the “OFF” position before plugging in. Plug unit into the power outlet.

- Turn It On: Locate the power switch and rotate clockwise.

- Purge the Group Head: Place the portafilter in the group head and press the continuous run button to purge the group head; let the water flow for around 30 seconds and wait until the machine reaches working temperature, checking that the gauge shows 1 bar pressure in the boiler.

Brew Espresso

- Grind Beans: Grind coffee beans to a fine consistency.

- Fill Portafilter: Fill the portafilter with coffee grounds. Make sure not to overfill the portafilter, or it will not reattach onto the machine properly.

- Tamp: Tamp the coffee grounds into the portafilter using a tamper (recommended: 236TAMPSS).

- Attach the Portafilter: Secure the portafilter to the espresso machine with a quarter turn.

- Select Output: Use any of the presets to brew or use the continuous flow button. If using continuous flow, the brewing will continue until it is pressed again, stopping the brewing process.

- Froth Milk (Steam Wand Operation): If necessary, you can froth milk by filling a frothing pitcher with milk, holding at an angle, and inserting the steam wand. Twist the steam knob counterclockwise to release steam until the milk is properly frothed.

MONTHLY CHECKS—Inspect for Wear

Purpose: To regularly check all components for signs of wear, tear, or damage, and replace as necessary.

- Turn off and disconnect the machine from the power source.

- Inspect the plug and cord for any indications of excessive wear, which may encompass discoloration, burn marks, cuts, and tears.

- Inspect all seals, gaskets, and hoses for signs of wear or leakage.

- Check the integrity of electrical cords and plug points.

- If any issues are detected, consult a service provider for recommended actions or replacements.

PROFESSIONAL SERVICING—Annual Maintenance

Purpose: To ensure that specialized features like electrical components and temperature controls are working correctly.

- Schedule an annual service appointment with a certified technician who specializes in hot beverage equipment.

- The technician will perform a comprehensive inspection, checking electrical components, plumbing connections, and refrigeration units.

- Calibration tests may be performed to ensure optimal temperature and carbonation levels.

- Any worn or damaged parts will be replaced.

- Obtain a detailed service report for your records, beneficial for both warranty claims and future troubleshooting.

TROUBLESHOOTING

WE STRONGLY RECOMMEND THAT ANY SERVICING BE PERFORMED BY AN AUTHORIZED SERVICE.

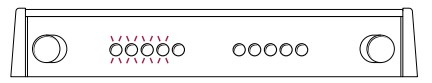

Level Safety Alarm

- This alarm is indicated by all of the programmable LED buttons flashing.

- It indicates that the level gauge has exceeded the safety time established without detecting water in the boiler. While the alarm is on, you will only be able to make coffee with the continuous coffee button, but the other buttons will remain locked.

- To remove the level alarm, turn off the machine and then turn it on again with the main switch. The machine will then start to fill the boiler with water again.

- If the gauge still fails to detect water, the machine will once activate the level safety alarm after the safety time has elapsed; in this case, call a qualified service technician.

Flowmeter Alarm

- This alarm is indicated by all programmable LED button is flashing (except for the continuous output button).

- This alarm allows you to prepare coffee with all the touch pad keys, but the amount of water will not be programmed.

- After the dose, it will cut off for safety reasons and the alarm will appear once again. In this case, call a qualified service technician.

PARTS IDENTIFICATION

#236ECEM2C

| # | DESCRIPTION |

| 1 | Hot Water Knob |

| 2 | Group Head 1-Touch Pad |

| 3 | Cup Rails |

| 4 | Group Head 2-Touch Pad |

| 5 | Steam Knob |

| 6 | Main Switch |

| 7 | Steam Outlet |

| 8 | Drainage Tray Grille |

| 9 | Drainage Tray |

| 10 | Feet |

| 11 | Hot Water Outlet |

| 12 | Portafilter |

| 13 | Brew Group |

| 14 | Pressure Gauge |

BEVERAGE SELECTION BUTTONS

BEVERAGE SELECTION BUTTONS

| # | DESCRIPTION |

| 1 | Short Coffee Button |

| 2 | Long Coffee Button |

| 3 | Two Short Coffee Button |

| 4 | Two Long Coffee Button |

| 5 | Continuous Coffee Button |

Documents / Resources

|

Estella 236ECEM1C Compact Espresso Machine [pdf] User Manual 236ECEM1C, 236ECEM2C, 236ECEM1C Compact Espresso Machine, 236ECEM1C, Compact Espresso Machine, Espresso Machine, Machine |