MAC 10 LEDC 4×4 Fan Filter Unit

MAC 10 LEDC 4×4 Fan Filter Unit

Instruction Manual

***READ AND SAVE THESE INSTRUCTIONS***

Installation & Service Manual

Critical Operation Conditions of the MAC 10

- Touching of the HEPA filter will damage it, voiding the warranty on the filter. The screen is only to protect against an accidental ‘touch’ of the filter. Never place a hand or tool on the filter. Never lie filter face flat down on a surface always have filter on its side to protect from damage.

- Prior to powering the unit, verify that the unit has been wired into the correct voltage. The serial number label on the top of the MAC 10 unit has the required voltage.

- To insure you order the proper replacement parts or complete MAC 10 unit, record the part number and serial number. This information is located on the serial number label, located adjacent to the electrical box. If you can’t locate the Sales Order Number, please contact ENVIRCO for this information.

Part Numbers Covered by this Manual

Part Numbers Covered by this Manual

| 11185-XXX | MAC 10 LEDC 4×4 | Standard Filter |

| 11233-XXX | MAC 10 LEDC 4×4 | RSR Filter |

| 11233-Z XXX | MAC 10 LEDC 4×4 | RSRE Filter |

Note: A ‘Z’ in the part number indicates that the unit is special.

This may indicate a size change from standard or a special filter.

Please contact the factory for part numbers if this is the situation.

IMPORTANT

YOUR FAN FILTER UNIT HAS THREE MODES OF OPERATION. IT IS YOUR RESPONSIBILITY AS THE INSTALLER TO SET THE MODE AS REQUIRED. IF UNSURE CONTACT YOUR PROJECT MANAGER OR CONTROLS COMPANY.

THE MODES ARE SET BY SETTING THE 2 PIN DIP SWITCH. Units come set in manual mode from the factory. Please review installation requirements and set up with your end user (See page 8 for complete set up instructions).

Units come set in manual mode from the factory. Please review installation requirements and set up with your end user (See page 8 for complete set up instructions).

Warning

TO REDUCE THE RISK OF FIRE, ELECTRICAL SHOCK, OR INJURY TO PERSONS, OBSERVE THE FOLLOWING:

A. Installation work and electrical wiring must be done by qualified person(s) in accordance with all applicable codes and standards, including fire-rated construction.

B. When cutting or drilling into wall or ceiling, do not damage electrical wiring and other hidden utilities.

C. If this unit is to be installed over an area using liquid, such as water or chemical cleaning solutions, it must be marked as appropriate for the application.

D. Use this unit only in the manner intended by the manufacturer. If you have any questions, contact the manufacturer.

E. Before servicing or cleaning the unit, switch power off at unit service panel and lock service panel to prevent power from being switched on accidentally.

F. NOTE – The Mac 10 has not been investigated for use in fire resistance rated construction.

G. To fulfill our obligations towards Article 33, in accordance to European REACH Regulation No 1907/2006 EC, we hereby inform you that this article contains the following Substances of Very High Concern mentioned on the Candidate list:

Cadmium/ 1,3,5-triglycidyl-s-triazinetrione

ENVIRCO USA

101 McNeill Road

Sanford, NC 27330

Tel: 919-775-2201

Tel: 800-884-0002

Fax: 800-458-2379

Email: info@envirco.com

Installation

Note: The MAC 10 LEDC Fan Filter Unit is completely assembled at the factory with the exception of the optional ¼” (0.64 cm)-20 eyebolts that are used when hanging the unit from an engineered design support system and installation of the HEPA/ ULPA filters (eyebolts not included and need to be ordered separately, p/n 222449-001).

Step 1. Carefully remove the unit from the shipping carton and inspect for any damage that may have occurred during transportation (See Figure 1). Using the two handles attached to the lid, two workers minimum, are required to lift the unit from the box.

Recommendation: Review mode settings at this time as specified for installation (see page 7 for controls).

Note: When ordering RSR and RSRE units, the HEPA filters will be shipped separately to be installed into units after the fan box has been installed.

Step 2. If using rigidly supported grid (usually 2” (50 mm) or wider), raise unit through ceiling and lower onto the gasketed grid.

If using a flexible grid (typically supported with wires), the unit must be secured to an engineered design support system with s-hooks and chain. Screw the four eyebolts into the nutserts on the lid assembly before lifting into an overhead position (see Figure 2). Note: Confirm fan dimensions to match T-grid dimensions.

Step 2.1. It is recommended that you front load your MAC 10 4×4 to your T-Grid system by running your main T-Grid and two cross Ts (install fan box into grid), then running your main T again (see Figure 3).

Step 2.2. If using a support grid, continue…

Step 3. Raise the unit and secure it into place using the chosen support system method suspended from a structural support bracing.

Step 4. Have an electrician wire the unit to the appropriate voltage, according to the wiring diagram (page 17), and all national and local electrical codes. All units are equipped with a three position terminal block for field connection. Verify correct singlephase power, before energizing units.

Step 5. Turn on the power using the two position rocker switch (ON/OFF) located on the electrical box. For RSR/E units, let the unit run for a few hours to purge off particulate that may be adhered to the inside of the unit before installing the filters. Do not

run fan at full speed as this may cause overload condition.

Note: Your fan filter has been shipped separately.

Unit Control Box

2.1. ON/OFF Switch – Speed/Airflow Adjustment

All MAC 10 LEDC units are equipped with a two-position rocker switch (ON/OFF), which is located on the side of the electrical box, on top of the unit. All units are furnished with a Universal Control Card to enable adjustment of airflow or set to your means of communication. (see Page 7 for Universal Card Card Set Up). Note: The CAT5e/RJ45 network ports are non-directional (i.e. in or out). Be sure to examine your cabling to insure that there is no cross-over wired cables.

Note: The CAT5e/RJ45 network ports are non-directional (i.e. in or out). Be sure to examine your cabling to insure that there is no cross-over wired cables.

Universal Control Card Setup

PRODUCT OVERVIEW

The ENVIRCO Universal Control Card, version 2 (UCC2) provides control capability for ENVIRCO electronically commutated motor (ECM) based fan filter units (FFUs). UCC2 was developed to be a running change as a complete going-forward replacement for the legacy UCC. While the UCC2 has new capabilities over the legacy UCC, it maintains the mechanical, electrical, and software compatibility with the legacy UCC.

There are two additional capabilities optionally available with the UCC2. The first is auto-addressing, which is a new mode that is initiated and managed from a properly equipped ENVIRCO control console. Auto-addressing eliminates the need to uniquely setaddress IDs of each FFU independently. Instead, the control console sequences through and automatically assigns an address into FLASH memory for each properly daisy-chained network connected FFU.

The second UCC2 new capability is a new sensor interface allowing the UCC2 to directly connect to a plenum-based air pressure sensor without the need for an additional voltage transformer. Instead, the UCC2 has both AC and DC voltage output for activating an external sensor.

FEATURES

- Networkable via an RJ45 serial bus with MODBUS RTU protocol

- Supports auto-addressing when connected to an ENVIRCO auto-addressing capable control console

- Has AC and DC output power available connecting to and for activating external pressure sensors

- 0-10 VDC analog control

- Manual control via onboard potentiometer

- Simple connections

- Two RJ45 connections for daisy-chain network connections

- Screw terminals for analog control

- Text probe jacks for DC mV signal output of RPM and motor control set points

- LED diagnostics

- Support for external LED (10mA) remote status notification via 2-pin MTA connector

- Onboard green LED for board status notification

- Onboard red LED for network traffic

- Powered from network or local supply

CONTROL MODES

CONTROL MODES

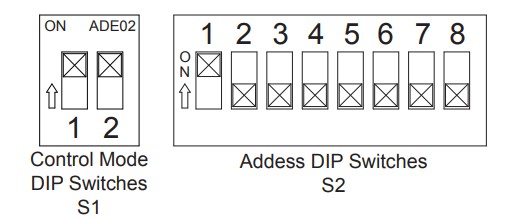

The UCC2 operates in one of three selectable modes. The Mode is selected using DIP Switch S1.

- MANUAL control, on-board potentiometer

- ANALOG control, Remote 0-10 VDC

- NETWORK control, MODBUS RTU

Note: Network mode can be configured using either DIP switch setting shown above.

Note: Network mode can be configured using either DIP switch setting shown above.

DIP switch pictorials are for reference and may be labeled differently by the manufacturer. Note: Network mode can be configured using either DIP switch setting shown above.

Note: Network mode can be configured using either DIP switch setting shown above.

DIP switch pictorials are for reference and may be labeled differently by the manufacturer.

Registers relevant to this mode:

- Register 1 “Start/Stop” (R/W)

– To enable motor, write a value of 1; To disable motor, write a value of 0 - Register 2 “Motor Set Speed” (R/W)

– Motor Target speed value. Values may be written from 0 to 100 - Register 6 “RPM” (R)

– Motor RPM. Read from the motor - Register 12 “Actual Motor Speed Instruction” (R)

– Speed control signal applied to the motor by the UCC2. (R/W) = Read/Write, (R) = Read Only

Automatic Addressing Mode:

On legacy UCCs, the board addressing was set using the 8-position dip switch. The UCC2 has a new capability called auto-addressing.

Auto-addressing is conducted and managed from a properly configured ENVIRCO console controller. The controller sequences through all of the UCC2-equipped FFUs and electronically programs them with a unique sequential 8-bit address. There are

three specific requirements for auto-addressing:

- Each FFU to be controlled must be loaded with a UCC2

- The system must contain a specialized ENVIRCO FFU control console

- Each FFU to be addressed must be properly daisy-chain networked

Daisy-chain networking connection overview:

- The overall control console’s RJ45 downstream control cable is connected to the “IN” marked RJ45 connector of the first FFU in the group, to be noted as FFU #1.

- Then, a CAT5 network cable is connected from FFU #1’s RJ45 “OUT” connector to FFU #2’s “IN” connector.

- All of the subsequent UCC2-equipped FFUs will be daisy-chain connected as noted in steps #1 and #2 above.

- The final FFU in the system to be controlled will have no cable connected to its “OUT” connector.

ELECTRICAL SPECIFICATIONS

Control and Interface Signals:

- External Speed 0-10V Input

• Input impedance 20k Ohms.

• MIN ON-to-OFF threshold: 190mV*

• MAX OFF-to-ON threshold: 240mV*

• ON (~215mV) to 9.89V linearly scales 1 to 99% speed.

• 9.89V or more deadbands to 100% speed. - External LED Output

• 10mA regulated

• LED forward voltages up to 5V - RPM Signal

• Signal Value: mVDC = RPM

• Ex: 900mV = 900RPM

• RPM Output Range: ~ 0, 5 to 2000 RPM (0, 5mV to 2000 mV DC)

• RPM Output Resolution: 5RPM (Zero, 400 steps from 5 to 2000 RPM inclusive)

• RPM Accuracy: +/- 3%

Electrical and Environmental Specifications:

| Specification | Min | Typical | Max | Units |

| Input Voltage | 22 | 24 | 42 | VAC |

| Supply Frequency | 50 | 50/60 | 60 | Hz |

| Input Power Consumption | na | na | 0.5 | VA |

| Ambient Operating Temperature | 0 | 25 | 50 | C |

Test Probe Jacks Points:

The test probe jacks may be used to measure the motor rpm or the PWM signal that is being output to the motor.

- In Manual or Analog Control Mode with an Address setting of 1 or greater, the test probe jacks output 0-2000 mVDC representing motor RPM. By changing the address DIP switches to 0, the test probe jacks will output 0-1000 mVDC representing 0-100% demand signal to the motor.

The address may be changed without interrupting power to the control card. - In Network Control Mode, 0-2000 mVDC always represents RPM.

ED Indicators:

- Onboard Status LED:

The Onboard Status LED is software controlled by the unit microcontroller. The Status LED is solid ON when RPM reported by the motor is greater than zero and OFF when RPM reported by the motor is zero. - External Status LED:

Support for an external Status LED (10mA current-controlled driver), via a 2-pin MTA connector, for remote system status notification. The external Status LED operates in the same manner as the Onboard Status LED. - Onboard Net LED:

The Onboard Net LED is driven directly by the receive data signal. The NET LED shows all network traffic on a 2-wire network.

The NET LED is intended to confirm low-level network connectivity, independent of microcontroller or firmware functionality. If A/B network wires are swapped, the NET LED will be normally on, providing quick diagnostics of this common condition.

| Net LED Status Definition | |

| LED OFF | Power Lost or No Communications |

| LED Flickering | Network Data Traffic In Progress |

| LED ON | A/B network wires are swapped |

RJ45 Network Cable Connections:

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

| Bus Power Pass Through | 0V (GND) | RS485 | 0V (GND) | Bus Power Pass Through | |||

| + | NC | NC | – | ||||

COMMUNICATION SPECIFICATIONS

Overview:

- MODBUS RTU protocol over RS485 (serial)

- 9600 baud rate, word length is 8, parity is none(n), stop bits=1

- 255 unique address values selectable by DIP switch settings

- (recommended network node capacity 200 nodes)

- Slew rate limited transceivers for improved network performance MODBUS Register Summary Table

- DO NOT USE CROSSOVER THIS MAY DAMAGE THE CONTROL CARD OR RENDER IT NON-OPERATIONAL.

MODBUS Register Specifications:

| Register | Name | R/W | Values & Defaults | Units | Origin | Comments |

| 1 | RUN/STOP | RW | 0,1 | 1 | RAM | power up from REG 14 |

| 2 | DEMAND | RW | 0-100 | % | RAM | power up from REG 10 |

| 6 | SPEED | R | 0,5-2000 | RPM | LIVE | |

| 9 | STATUS | R | see detail | – | LIVE | |

| 10 | DEFAULT SPEED | RW | 0-100 | 50 | EEPROM | applies to network only |

| 12 | CURRENT SPEED | R | 0-100 | – | LIVE | |

| 14 | DEFAULT RUN/STOP | RW | 0,1 | 1 | EEPROM | applies in network mode only |

To reset non-volatile registers to factory default values, write 170 (AA hex) to Register 14, and then cycle power.

Troubleshooting

Mode Choice:

Verify mode setting choice to DIP switch S1 (Control Mode), which is manual mode and then retry.

| Net LED Status Definition | |

| Green LED OFF | Power Lost or No Communications |

| Green LED Flickering | Network Data Traffic In Progress |

| Green LED ON | A/B network wires are swapped |

Motor Issues in Manual Mode:

(If you are in a network or analog mode, contact your controls contractor for troubleshooting assistance; if you continue to need assistance, contact the factory.)

Unit is not adjustable:

Step 1. Verify that rotation of the manual speed potentiometer does not change the RPM. If rotating does nothing, remove the electrical box cover, then remove the 4-pin motor connector from the control board and reinstall 180 degrees rotated. Also insure that the 4-pin connection wires are pushed down securely onto connector pins. Again adjust the knob to verify proper fan operation. Note: The 4 pin connector is on the 1/8” white cable from motor.

Low Air Velocity:

Step 1. Check to be sure that the manual speed potentiometer is set correctly.

Step 2. Check incoming power supply for proper voltage (120,208-240,277/24).

Step 3. Examine the HEPA filter.

High Air Velocity:

Step 1. Check to be sure that the air flow settings are correct.

Filter Issues:

Non-Laminar Flow and/or Excessive Contamination:

Step 1. Insure that no large obstructions are upstream of airflow pattern.

Step 2. Determine that no other air-moving devices are operating in or around clean room which disrupt room’s airflow pattern.

Step 3. Check air velocity and if low, conduct the “Low Air Velocity” procedure outlined above.

If failure continues, contact ENVIRCO Technical Support at 800-884-0002.

Service: Removal and Replacement of Standard Filters

WARNING

DISCONNECT THE UNIT FROM THE ELECTRICAL POWER SOURCE BEFORE ATTEMPTING ANY SERVICE

WARNING

THE STANDARD FILTER IS PROTECTED WITH AN EXPANDED METAL FACE SCREEN. THIS IS NEVER TO BE USED TO HANDLE THE FILTER. IT IS ONLY FOR PROTECTION AGAINST AN ACCIDENTAL TOUCH OF THE FILTER. ONLY HANDLE THE FILTER BY THE FRAME.

Note: All filters should be visually inspected for freight damage before installation. Since the filters are 4’ x 4’ in dimension it is necessary to use two workers when lifting the filter, and four workers for installation to avoid twisting or separation of the media seals. Handle the filter only by the frame and never place anything on the upstream filter side of the filter.

Additionally, it is important to keep the filter level to prevent any shearing force on the media itself.

For Standard Filters:

Tools Required: Phillips Head Driver, Battery Operated Drill

Step 1. Remove the 28 plenum housing screws. Retain for installation of new filter.

Step 2. The plenum housing must be raised up and placed out of the way to allow the filter to be turned and lowered through the ceiling opening. Service wiring may need to be disconnected by qualified personnel.

Step 3. Before replacing with the new filter, carefully inspect the new filter for any visible damage. Also inspect the gasket and the T-Bar to insure a tight seal. Replace if necessary.

Step 4. To replace a filter, raise the filter and rotate into position in the ceiling grid (with power off) , then lower the plenum housing into place. Reconnect wiring and hardware from previous steps that have been removed.

Step 5. Restore power and verify proper operation of FFU. Service: Removal and Replacement of RSR/E Filters

Service: Removal and Replacement of RSR/E Filters

WARNING

DISCONNECT THE UNIT FROM THE ELECTRICAL POWER SOURCE BEFORE ATTEMPTING ANY SERVICE

WARNING

THE STANDARD FILTER IS PROTECTED WITH AN EXPANDED METAL FACE SCREEN. THIS IS NEVER TO BE USED TO HANDLE THE FILTER. IT IS ONLY FOR PROTECTION AGAINST AN ACCIDENTAL TOUCH OF THE FILTER. ONLY HANDLE THE FILTER BY THE FRAME.

Note: All filters should be visually inspected for freight damage before installation. Since the filters are 4’ x 4’ in dimension it is necessary to use two workers when lifting the filter, and four workers for installation to avoid twisting or separation of the media seals. Handle the filter only by the frame and never place anything on the upstream filter side of the filter. Additionally, it is important to keep the filter level to prevent any shearing force on the media itself.

For RSR/E Filters:

Tools Required: Phillips Head Driver, Battery Operated Drill, 3/16” hex head ball driver (2ea)

Step 1. With the power off, remove the diffuser screen by removing the 6 each 10-32×1/2 screws, then carefully place in a safe location.

Step 2. Loosen the eight 1/4×20 socket head screws far enough to rotate the eight filter clips 90°. The filter may be loose enough to drop during this operation. If not, slowly pull the filter away from the knife-edge seal, taking care not to touch the filter face during this operation. It is important to pull the filter slowly away from the seal, so that the gel remains in the filter gel track.

Step 3. Carefully clean plenum assembly knife edge surface of residual gel material.

Step 4. Inspect filter for visible damage, if damaged set aside for replacement or repair.

Step 5. Inspect the gel seal, if reinstalling the removed filter. Determine if the gel has lost its ability to seal (i.e. the gel should reform to cover the track without voids or openings), if so repair the gel material or consider replacement of filter.

Step 6. Place the filter evenly against the filter-sealing surface of the RSR unit. Reposition filter clips and screws. The clips should be rotated and angled into place. It is recommended that four workers work on each corner of the filter simultaneously, holding the filter seated into the track. Hand tighten clips from opposite corners evenly until all clamps are tightened.

Step 7. Reinstall diffuser screen by hand-tightening the screws.

Step 8. Determine if recertification or testing of replacement is required.

Step 9: Restore power to FFU and verify proper operation of FFU.

Service: Standard and RSR Motor Removal and Installation

WARNING

DISCONNECT THE UNIT FROM THE ELECTRICAL POWER SOURCE BEFORE ATTEMPTING ANY SERVICE

WARNING

ELECTRICAL SERVICE SHOULD ONLY BE PERFORMED BY A LICENSED OR QUALIFIED ELECTRICIAN.

Tools Required: Phillips Head Driver, Battery Operated Drill, (2) 8” adjustable wrenches, 10 mm hex head wrench, #2 screwdriver, and slip joint pliers

Step 1. To gain access to the motor, remove the ceiling panel next to the unit, if applicable.

Step 2. Switch the ON-OFF switch to the off position.

Step 3. Loosen the electrical box cover screws (2), and slide/lift off cover.

Step 4. Make note of all wire routing and locations for later reinstallation.

Step 5. Disconnect 4-pin and 5-pin wire harnesses from the electrical box housing and remove the tubing for test port, if installed.

Step 6. Remove the twelve mounting screws to free the motor/blower assembly from the lid assembly. If using power drivers, set the unit to a low torque setting to avoid stripping the sheet metal screws. Carefully remove housing assembly, paying attention to wire routing.

Step 7. Unwire the control cap by removing the cap cover and unplugging the cable connector to the motor from inside, then pull back through the grommet next to the motor. Rubber grommet will need to be removed for connection clearance.

Step 8. Remove the six 10 mm bolts from the motor mounting plate to motor housing assembly.

Step 9. Using one adjustable wrench, loosen the hex nut that attach the blower wheel to the motor shaft while holding motor shaft still with the second wrench. Remove blower wheel from motor shaft and the c-clip for reuse with new motor.

Step 10. Remove the motor mounting hardware from the backside of the motor mounting plate. Replace with the new motor and reassemble by reversing the above order.  Service: RSR/E Motor Removal and Installation

Service: RSR/E Motor Removal and Installation

WARNING

DISCONNECT THE UNIT FROM THE ELECTRICAL POWER SOURCE BEFORE ATTEMPTING ANY SERVICE

WARNING

ELECTRICAL SERVICE SHOULD ONLY BE PERFORMED BY A LICENSED OR QUALIFIED ELECTRICIAN.

Note: Minimum 2 person project.

Tools Required: 3/16 Ball Driver, Phillips screw bit, Head Driver, Battery Operated Drill, (2) 8” adjustable wrenches, 10 mm hex head wrench, #2 standard screwdriver, and slip joint pliers

Step 1. Diffuser Screen Removal.

Step 2. HEPA Filter Removal.

Step 3. Remove (10) baffle mounting screws, carefully remove baffle.

Step 4. Disconnect the 4-pin and 5-pin control cables at the cap.

Step 5. Remove cover of cap to access motor cable for disconnection and routing back to motor – two screws for cap cover/ mounting of cap have nuts needing to be re-used.

Step 6. At the motor mounting plate, remove the (4) gussett screws at the corners, then the (6) bolts of the lower blower assembly.

Step 7. Remove blower wheel using (2) adjustable wrenches, one to hold motor shaft and the other to losen the 3/4” hex nut. Once wheel is removed, then using screwdriver, pull c-clip from motor shaft.

Step 8. Carefully route motor wire through grommet hole after removing rubber grommet to allow for cable connection and clearance.

Step 9. Remove hex nuts and washers from (4) mounting studs of motor to separate motor from plate.

Step 10. Install new motor and components in reverse order.

Wiring Diagrams

Replacement Parts List

Replacement Parts List

| MAC 10 4×4 Parts | Part Number |

| Grommet | 63388 |

| Motor – 120/240/277 ECM w/ Program | 24397-025 |

| Choke 5.5 amps | 64103 |

| Transformer 120/24 volts | 63667 |

| Transformer 220/24 volts | 63666 |

| Transformer 277/24 volts | 63665 |

| Venturi ring | 64115 |

| Blower Wheel Poly | 63825 |

| Universal Control Card | 265888 |

| Pressure Switch | 63415-001 |

| Filter HEPA Standard 47.63 x 47.63 White Painted Metal Screen | 69575-004 |

| Filter RSR/RSRE 45 x 45 x 3 HEPA | 69604-001H |

| Filter RSR/RSRE 45 x 45 x 3 ULPA | 69604-001U |

| Rocker Switch | 63739-002 |

| Finger Guard | 63576-003 |

| RSR-Filter Clip (RSR) | 38205-001 |

| Screw 1/4-20×1/2 (RSR) | 63152 |

| Washer Flat Nylon .20 ID | 120456-005 |

| Eyebolts | 222449-001 |

| Diffuser Screen Aluminum | 842732-001 |

Note: Verify filter size by contacting factory (see page 3).

Limted Warranty

LIMITED WARRANTY: Unless otherwise expressly stated in ENVIRCO’s published specifications for the Goods, ENVIRCO warrants that Goods are free from defects in material and workmanship, except for services which are warranted to be performed in a competent and diligent manner in accordance with any mutually agreed specifications. The foregoing warranty shall apply for eighteen (18) months from the date of shipment from ENVIRCO’s facility, except for services for which the warranty shall apply for ninety (90) days from the date of performance (the “Warranty Period”). Provided Buyer informs ENVIRCO in writing of any breach of warranty prior to the expiration of the applicable Warranty Period, ENVIRCO shall, as its sole obligation and Buyer’s sole and exclusive remedy for any breach of this warranty, repair or replace/re-perform the Goods which gave rise to the breach or, at ENVIRCO’ option, refund the amounts paid by Buyer for the Goods which gave rise to the breach. Any repair, replacement or re-performance by ENVIRCO hereunder shall not extend the applicable Warranty Period. The parties shall mutually agree on the specifications of any test to determine the presence of a defect. Unless otherwise agreed upon by ENVIRCO in writing, Buyer shall bear the costs of access, de-installation, re-installation and transportation of Goods to ENVIRCO and back to Buyer. These warranties and remedies are conditioned upon (a) the proper storage, installation, operation, and maintenance of the Goods and conformance with the proper operation instruction manuals provided by ENVIRCO or its suppliers or subcontractors, (b) Buyer keeping proper records of operation and maintenance during the applicable Warranty Period and providing ENVIRCO access to those records, and (c) modification or repair of the Goods only as authorized by ENVIRCO. ENVIRCO does not warrant the Goods or any repaired or replacement parts against normal wear and tear or damage caused by misuse, accident, or use against the instructions of ENVIRCO. Any modification or repair of any of the Goods not authorized by ENVIRCO shall render the warranty null and void. EXCEPT AS EXPRESSLY SET FORTH HEREIN, ENVIRCO MAKES NO OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTIES OF MERCHANTABILITY, NONINFRINGEMENT OR FITNESS FOR A PARTICULAR PURPOSE WHICH ARE HEREBY DISCLAIMED TO THE EXTENT PERMITTED BY APPLICABLE

LAW.

Testing

Each MAC 10 LEDC filter unit is thoroughly tested at the factory before shipment. However, because of the “rigors” of shipping, ENVIRCO encourages its re-test after installation. ENVIRCO recommends that the customer contact an independent organization, with technicians trained and experienced in performance evaluation and maintenance of clean air equipment.

HEPA filters (Type J) are tested to IEST-RP-00034. ULPA filters are tested to (Type F) IEST-RP-00034. All filters are UL 900 recognized. Your filters may have special requirements, please see original engineering specifications for you specific project.

All units that are airflow tested at ENVIRCO are tested using a Shortridge Airdata Multimeter 870 with a Velgrid head. The recommended method of reading is to place one corner of the Velgrid head 1-1/4” from the corner of the filter face and then take four reading evenly spaced along the four foot side, then repeat these reads three additional times. This gives a total of 16 reading to test the unit. All advertised data is based on using the Velgrid with 16 readings (256 velocity points). ENVIRCO recognized the using 16 reading during a cleanroom start-up may be time consuming and recommends using 4 Velgrid readings taken on each 2×2 filter section will approximate the same as 16 readings.

Additional independent testing on the ENVIRCO Mac 10 4×4 shows that using two-2×4 hoods simultaneously give airflow data (cfm) with 5 percent of a duct traverse using 10 diameters of straight duct upstream of the fan intake.

Clean air solutions built for you.

MORE INFORMATION AVAILABLE AT WWW.ENVIRCO.COM

Industrial

Cleanroom Products

- MAC 10 Original

- MAC 10® IQ™

- MAC 10® IQ™ LAF

- MAC 10® LEAC™

- MAC 10® LEAC2™

- MAC 10® LEDC™

- Ducted Ceiling Module:® DCM & RSR

- AC or DC Control Systems

- MAC-T Ceiling Grid System

Hospital & Healthcare

Hospital & Healthcare

- IsoClean and IsoClean with Ultraviolet Light

- AirCeil®

- Hospi-Gard® Room Pressure Monitor® Enviramedic Products

- HOR Horizontal Flow Enclosure

- HCF Horizontal Flow Surgery Room

- VOR Vertical Flow Surgery Isolator

Pharmaceutical

Pharmaceutical & Medical Device

- Unimodule M2 Vertical Laminar Flow Workstation

- METD 100% Exhausted Vertical Flow Workstation

- Laminar Downflow Module

Laboratory & Research

Laboratory & Research

- 100-Plus Horizontal or Vertical Flow Clean Bench

- Unidirectional Flow Horizontal Flow Bench (LF)

- TT Table Top Horizontal Flow Clean Bench

- EnviraLab Sterility Module: ESM

ENVIRCO

101 McNeill Road | Sanford, NC 27330, USA

tel: 919.775.2201 | toll free: 800.884.0002 | fax: 800.458.2379

www.envirco.com | email: info@envirco.com

Form P/N#: 267278 Rev. 01/24

Copyright © 2017 ENVIRCO. All Rights Reserved.

Documents / Resources

|

ENVIRCO MAC 10 LEDC 4x4 Fan Filter Unit [pdf] Instruction Manual MAC 10 LEDC 4x4, MAC 10 LEDC 4x4, MAC 10 LEDC 4x4, MAC 10 LEDC 4x4 Fan Filter Unit, MAC 10 LEDC 4x4, Fan Filter Unit, Filter Unit, Unit |