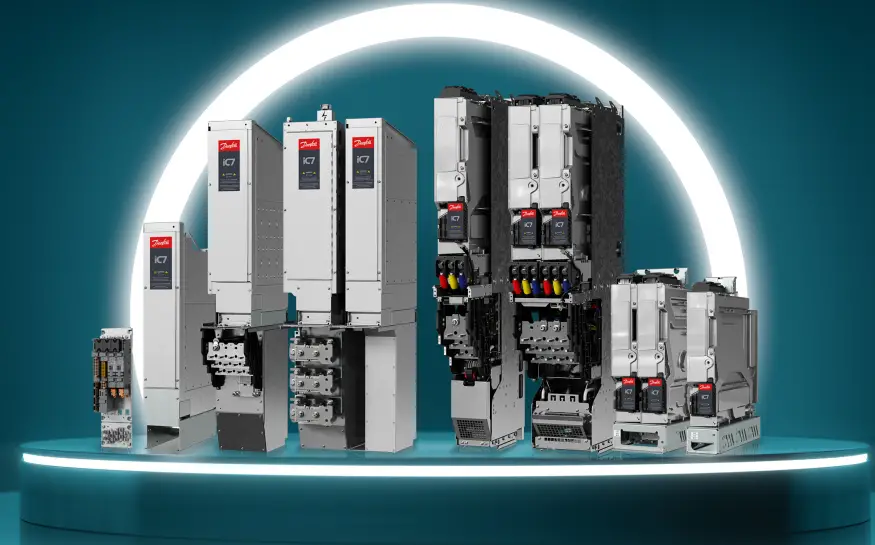

Danfoss iC7 Series System Modules

Specifications

- Product Name: iC7 Series System Modules

- Manufacturer: Danfoss

- Safety Standards: ISO compliant

- Authorized Personnel: Danfoss authorized, qualified personnel only

Product Information

The iC7 Series System Modules are advanced equipment designed for industrial applications. These modules ensure efficient control and monitoring of various processes within a system.

Installation Instructions

Installation Safety

Ensure the following safety measures are strictly adhered to during installation:

- Check the delivery contents for completeness and correctness.

- Avoid installing or starting up damaged units. Contact the shipping company in case of any damage.

- Follow the instructions provided in the guide and specific product guides.

- Ensure all personnel handling the product have read and understood the guide.

- Wear appropriate safety equipment to prevent injuries from sharp edges during mounting, cabling, or maintenance.

Target Group and Necessary Qualifications

Only Danfoss authorized personnel with specialized training should perform repairs on this equipment.

Safety Symbols

The guide includes safety symbols indicating different levels of hazards and important information. Pay close attention to these symbols throughout the installation process.

General Safety Considerations

Be aware of the following safety considerations:

- Ensure safety awareness to prevent injury and equipment damage.

- Disconnect all power sources before performing any electrical work on the drive to avoid electric shock.

- Wait for the specified time after power removal to discharge capacitors before servicing the drive.

Frequently Asked Questions (FAQ)

- Q: Who should perform repairs on the iC7 Series System Modules?

A: Only Danfoss authorized, qualified personnel with specialized training should handle repairs on this equipment to ensure safety and proper functioning. - Q: What should be done if there are signs of damage during installation?

A: Immediately contact the shipping company to file a complaint and avoid installing or starting up damaged units to prevent any risks or hazards. - Q: How to ensure safety during maintenance operations?

A: Ensure all personnel working on or with the product have read and understood the safety guide, wear appropriate safety equipment, and follow the provided instructions diligently to prevent injuries or accidents.

Installation Safety

Safety Overview

To install the product safely:

- Check that the content of the delivery is correct and complete.

- Never install or start up damaged units. If there are signs of damage, immediately contact the shipping company to file a complaint.

- Follow the instructions in this guide and the specific product guides.

- Make sure that all personnel working on or with the product have read and understood this guide and any additional product guides. Contact Danfoss if the given information is unclear, or information is missing.

- There can be sharp edges in the product that can cause cuts. Be careful to avoid injuries and wear the appropriate safety equipment during mounting, cabling, or maintenance operations.

Target Group and Necessary Qualifications

Correct and reliable transport, storage, installation, operation, and maintenance are required for the trouble-free and safe operation of the products. Only qualified personnel are allowed to perform all related activities for these tasks. Qualified personnel are defined as properly trained staff, who are familiar with and authorized to install, commission, and maintain equipment, systems, and circuits in accordance with pertinent laws and regulations. Also, the qualified personnel must be familiar with the instructions and safety measures described in this guide and other relevant guides. Non-qualified electricians are not allowed to perform any electrical installation or troubleshooting activities. Only Danfoss authorized, qualified personnel are allowed to repair this equipment. Specialized training is required to perform the activities related to repair.

Safety Symbols

The following symbols are used in Danfoss documentation.

![]() DANGER

DANGER

Indicates a hazardous situation which, if not avoided, will result in death or serious injury.

![]() WARNING

WARNING

Indicates a hazardous situation which, if not avoided, could result in death or serious injury.

![]() CAUTION

CAUTION

Indicates a hazardous situation which, if not avoided, could result in minor or moderate injury.

NOTICE

Indicates information considered important, but not hazard-related (for example, messages relating to property damage).

The guide also includes ISO warning symbols related to hot surfaces and burn hazard, high voltage and electrical shock, and referring to the instructions.

|

ISO warning symbol for hot surfaces and burn hazard |

|

ISO warning symbol for high voltage and electrical shock |

|

ISO action symbol for referring to the instructions |

General Safety Considerations

WARNING

LACK OF SAFETY AWARENESS

This guide provides important information on preventing injury and damage to the equipment or the system. Ignoring this information can lead to death, serious injury, or severe damage to the equipment.

- Make sure to fully understand the dangers and safety measures present in the application.

WARNING

ELECTRIC SHOCK

Drives contain hazardous voltage when a power source is connected to AC or DC terminals. Failure to disconnect all power sources can result in death or serious injury.

- Before performing any electrical work on the drive, disconnect, lock out, and tag out all power sources to the drive.

- There is more than one live circuit. See the relevant wiring diagram in the product guide.

WARNING

DISCHARGE TIME

The drive contains capacitors, which can remain charged even when the drive is not powered. High voltage can be present even when the warning indicator lights are off. Failure to wait the specified time after power has been removed before performing service or repair work could result in death or serious injury.

- Stop the drive.

- Disconnect all input and output power sources of the drive (for example permanent magnet type motors, batteries, or DC-link connections to other drives).

- Wait for the capacitors to discharge fully before performing any service on the equipment. The discharge time is 5 minutes. If the device is broken or fuses have tripped, the discharge time is longer.

- Use a measuring device to make sure that there is no voltage, before opening the drive or performing any work on the cables.

WARNING

UNINTENDED START

When the drive is connected to a power source, the system may start at any time, causing risk of death, serious injury, and equipment or property damage.

- Stop the drive and motor before configuring parameters.

- Make sure that the drive cannot be started by an external switch, a fieldbus command, an input reference signal from the control panel, or after a cleared fault condition.

- Disconnect the drive from the power source whenever safety considerations make it necessary to avoid unintended start.

- Check that the drive, motor, and any driven equipment are in operational readiness.

Lifting Safety

WARNING

LIFTING HEAVY LOAD

Not following the safe lifting instructions can result in death or serious injury and damage to the equipment.

- Follow local safety regulations on lifting.

- Use a lifting device that is in proper working condition and appropriate for the weight of the load.

- Test lift the load to verify the proper center of gravity. Reposition the lifting point if not level.

- Do not walk under, or place any part of your body under a suspended load.

WARNING

SWINGING HAZARD DURING LIFTING

The swing effect can cause serious injury and damage to the equipment. It occurs when lifting the product into a vertical position, just before the product reaches vertical position, when the center of gravity of the product surpasses the floor support point.

- Make sure that the lifting ropes are properly attached.

- Secure the lifting area.

- Lift the product slowly and carefully.

Mechanical Installation Safety

WARNING

ELECTRIC SHOCK WITHOUT ENCLOSURE

The IP00/Open Type drives do not have protective covers over all live components. Touching live components can cause death or serious injury.

- Install IP00/Open Type drives inside a cabinet or other enclosure that provides appropriate protection.

WARNING

BURN OR FIRE HAZARD WITHOUT ENCLOSURE

The IP00/Open Type drives do not provide comprehensive mitigation for burn or fire hazards.

- Install IP00/Open Type drives inside a cabinet or other enclosure that provides appropriate protection. Installing the drives into enclosures prevents the personnel from touching hot surfaces, and the spreading of a possible fire.

Electrical Installation Safety

WARNING

BRANCH CIRCUIT HAZARD

Unprotected branch circuits can cause an electrical or a fire hazard.

- Internal short circuit protection does not provide branch circuit protection. To protect the installation, all branch circuits in an installation, switchgear, and machines must be protected against short circuits and overcurrent according to national or international regulations.

WARNING

SHORT-CIRCUIT HAZARD

Unprotected drive system can cause an electrical or a fire hazard.

- Protect the drive system against short circuits. To protect the unit, use the fuses that are required by the manufacturer. The drive system provides full short-circuit protection against a short circuit on the motor output.

WARNING

ELECTRIC SHOCK HAZARD

The drive can cause a DC current in the PE conductor. Failure to use a Type B residual current-operated device (RCD) can lead to death or serious injury.

- When an RCD is used for protection against electric shock, only an RCD of Type B is allowed on the supply side.

WARNING

INDUCED VOLTAGE

Induced voltage from output motor cables that run together or near other power cables can charge equipment capacitors, even with the mains power turned off and locked out. Failure to run output motor cables separately, or to use shielded cables, could result in death or serious injury.

- Install output motor cables in separate conduits or use shielded cables.

WARNING

ELECTRICAL SHOCK HAZARD – HIGH LEAKAGE CURRENT

Leakage currents exceed 3.5 mA. Failure to connect the system properly to protective earth may result in death or serious injury.

- Ensure reinforced protective earthing conductor according to IEC 60364-5-54 cl. 543.7 or according to local safety regulations for high touch current equipment. The reinforced protective earthing of the drive can be done with:

- PE conductor with a cross-section of at least 10 mm2 Cu or 16 mm2 Al.

- PE conductor completely enclosed within an enclosure or otherwise protected throughout its length against mechanical damage.

WARNING

DIFFERENT TYPE OF FUSES

Using a different type of fuse than required can cause a fire.

- Replace fuses with the same type of fuse.

WARNING

OVERHEATED CABLES HAZARD

Incorrect cable installation or environmental conditions can cause cables to overheat. Overheated cables are a fire hazard.

- Use overload protection. The drive system is equipped with an internal overcurrent protection that can be used for upstream overload protection.

- To provide the overcurrent protection, use fuses or circuit breakers.

- Perform overcurrent protection according to local regulations.

- Use symmetrical power cabling with power units connected in parallel. Each power unit must have the same number of cables with an equal cross-section and equal length.

- Install cables according to local regulations and IEC/EN standards.

CAUTION

THERMISTOR INSULATION

Risk of personal injury or equipment damage.

- To meet the PELV insulation requirements, use only thermistors with reinforced or double insulation.

NOTICE

EXCESSIVE HEAT AND PROPERTY DAMAGE

Overcurrent can generate excessive heat within the drive. Failure to provide overcurrent protection can result in risk of fire and property damage.

- Additional protective devices such as short-circuit protection or motor thermal protection between drive and motor is required for applications with multiple motors.

- Input fusing is required to provide short-circuit and overcurrent protection. If fuses are not factory-supplied, the installer must provide them. Refer to the product-specific documentation for fuse specifications.

NOTICE

MOTOR DAMAGE

Protection against motor overload is not active by default. The ETR function provides class 20 motor overload protection. Failure to set the ETR function means that motor overload protection is not provided and property damage can occur if the motor overheats.

- Enable the ETR function. See the application guide for more information.

Safety in Liquid-cooling

WARNING

POISONOUS COOLANTS

Glycols and inhibitors are poisonous. If touched or consumed, they can cause injury.

- Prevent the coolant from getting into the eyes. Do not drink the coolant.

CAUTION

HOT COOLANT

Hot coolant can cause burns.

- Avoid contact with the hot coolant.

CAUTION

PRESSURIZED COOLING SYSTEM

Sudden release of pressure from the cooling system can cause injury.

- Be careful when operating the cooling system.

NOTICE

INSUFFICIENT COOLING CAPACITY

Insufficient cooling can cause the product to become too hot and thus become damaged.

- To make sure that the cooling capacity of the cooling system stays sufficient, make sure that the cooling system is vented and that the coolant circulates properly.

NOTICE

DAMAGE TO COOLING SYSTEM

If the coolant circulation is stopped too soon, high-temperature components can cause rapid local increase in the coolant temperature, which can damage the cooling system.

- Do not stop the cooling system when stopping the drive. Keep the coolant circulation flowing for 2 minutes after the drive has been stopped.

Designated Use

Installing and operating a Danfoss product not following the following preconditions is regarded as non-designated use. Danfoss does not take any liability for non-designated use.

Danfoss products are units intended for installation in electrical systems. They comply with the requirements of various directives and certifications. To see all valid certifications for the product, check the product label. When the product is installed in machinery or system, these have to comply with relevant national regulations.

In any case, the product and its components have to be operated in accordance with all national Occupational Safety & Health regulations and directives. Operation of Danfoss products is only allowed under observance of the respective EMC regulations. Operation of Danfoss products is only allowed under observance of the specifications and requirements given on the product label and in the product-specific documentation. Only use spare parts approved and provided by Danfoss. Using other spare parts can damage the product.

Safe Operation

The drive is not suitable as the only safety device in the system. Make sure that all needed extra monitoring and protection devices on drives, motors, and accessories are installed according to the regional safety guidelines and accident prevention regulations. Before activating any automatic fault reset functions or changing limit values, make sure that no dangerous situations can occur after restart. If the auto reset function is activated, the device connected to the drive output starts automatically after an automatic fault reset. Keep all doors and covers closed and terminal boxes screwed on during operation of the drive and when AC or DC supply is connected. Drive components and accessories can still be live and connected to AC or DC supply, even after the operation indicators are no longer illuminated.

Danfoss Drives Oy

Runsorintie 7

FIN-65380 Vaasa

drives.danfoss.com

Any information, including, but not limited to information on selection of product, its application or use, product design, weight, dimensions, capacity or any other technical data in product manuals, catalog descriptions, advertisements, etc. and whether made available in writing, orally, electronically, online or via download, shall be considered informative, and is only binding if and to the extent, explicit reference is made in a quotation or order confirmation. Danfoss cannot accept any responsibility for possible errors in catalogs, brochures, videos and other material. Danfoss reserves the right to alter its products without notice. This also applies to products ordered but not delivered provided that such alterations can be made without changes to form, fit or function of the product. All trademarks in this material are property of Danfoss A/S or Danfoss group companies. Danfoss and the Danfoss logo are trademarks of Danfoss A/S. All rights reserved.

Danfoss Drives Oy © 2024.01

Documents / Resources

|

Danfoss iC7 Series System Modules [pdf] User Guide iC7 Series System Modules, iC7 Series, System Modules, Modules |