ENGINEERING

ENGINEERING

TOMORROW

Installation guide

ELIMINATOR® Hermetic filter drier

Type DML / DMLE / DCL / DCLE

DML ELIMINATOR Hermetic Filter Drier

Refrigerants:

A1: R134a, R404A, R407C, R507, R22, R410A.

A2L: R32, R444B, R452B, R454B, R1234yf.

A3: R290, R600a.

For other refrigerants, please contact Danfoss representative.

Temperature range:

![]()

T min: -40 °C / -40 °F

T max: 70 °C / 160 °F

| Connector type | Filter size (cu.in) | Connector size (DML/DCL) | PS / MWP |

Solder pure copper |

DML/DCL: 1.5, 03, 05, 08,16, 30, 38, 60. DMLE/DCLE: 1.5, 03, 05, 08,16, 30, 60 | DML/DCL: 1/4″” – 1 1/8 “” ODM / ODF DMLE/DCLE: 1/4″” – 1 1/8 “” ODF” |

DML/DCL: 46 bar (667 psig) DMLE/DCLE : 50 bar (725 psig) |

| DML/DMLE/DCL/DCLE: 41 cu.in | DML/DCL: 1/2 – 5/8″” ODF DMLE/DCLE: 1/2 – 1 1/8″” ODF |

||

| DML/DCL: 3/4″ -1 1/8″ ODM / ODF | DML/DCL: 35 bar (500 psig) DMLE/DCLE : 50 bar (725 psig) | ||

| DML/DMLE/DCL/DCLE: 75 cu.in | DML/DCL: 3/4″” -1 1/8″” ODM / ODF DMLE/DCLE: 7/8″” – 1 1/8″” ODF | ||

Solder Cu-plated |

DML/DMLE/DCL/DCLE: 3 to 60 cu.in | DML/DCL: 1/4″” -1 1/8″” ODM / ODF DMLE/DCLE: 1/4″” – 1 1/8″” ODF | DML/DCL: 46 bar (667 psig) DMLE/DCLE: 50 bar (725 psig) |

| DML/DMLE/DCL/DCLE: 75 cu.in | DML/DCL: 7/8″” – 1 1/8″” ODF DMLE/DCLE: 7/8″” -1 1/8″” ODF | ||

Flare, Flare 0-ring and Face seal |

DML/DCL: 3 to 60 cu.in DMLE/DCLE: 05, 08 cu.in |

DML/DCL: 1/4″ – 3/4″ DMLE/DCLE: 1/4″ ; 3/8″ |

DML/DCL : 46 bar (667 psig) DMLE/DCLE: 50 bar (725 psig) A3 Refrigerants shall not be used |

![]()

Solder connectors (cu-plated / pure copper) with a diameter below 25 mm are approved for A3 refrigerants.

Connection sizes below 25mm are approved for A2L.

Filter size of 75 cu.in shall not be used with A3 refrigerants.

![]() Keep flames away from body

Keep flames away from body

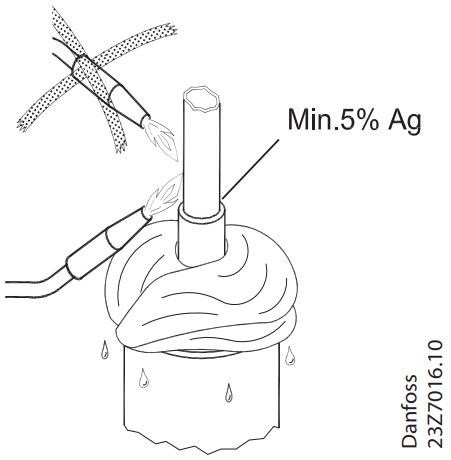

Customer best practices will still be needed:

*Use wet wrap when installing.

*Braze the joints

*Let them cool down

*Clean the welding area after the installation (remove remaining flux with a brush)

*This is an important operation and needs to be done with great care to remove all remaining flux.

*Paint/Anti-corrosive needs to cover all open steel parts, areas where the black original paint has been burnt due to brazing and at least 3 cm approx of the copper tube

*Paint the joints twice

© Danfoss | Climate Solutions | 2022.05

AN165086432065en-000601 ![]()

Documents / Resources

|

Danfoss DML ELIMINATOR Hermetic Filter Drier [pdf] Installation Guide DMLDML, DMLE, DCL, DCLE, DML ELIMINATOR Hermetic Filter Drier, ELIMINATOR Hermetic Filter Drier, Hermetic Filter Drier, Filter Drier |