BASF FORWARD AM TECHNICAL GUIDE

BASF FORWARD AM TECHNICAL GUIDE

Machining and Processing Guide

for Ultracur3D® RG 3280

RG 3280 Machining and Processing

This guide provides essential information on the machining parameters and processing recommendations for RG 3280. The guide covers drilling, milling, tapping, sanding, and tumbling processes to achieve optimal results.

MORE ABOUT

Ultracur3D® RG 3280

Disclaimer: These recommendations are non-binding and do not release the purchaser from suitability tests.

Cutting parameters for milling and drilling – Ultracur3D® RG 3280

| n (RPM) | Revolutions per minute |

| vc [m/min] | Cutting speed |

| d [mm] | Cutting tool diameter |

| Drilling | |||

| Tool | n [RPM] | vc [m/nin] | Comment |

| D4,2 HSS Drill | 1800 – 2200 | 25 – 30 | Good and easy progression. Only low pressure to reduce chipping on entrance and exit of hole. Drill the hole in small steps. Holes >D5 should be printed and redrilled |

| D8,5 HSS Drill | 1000 – 1500 | 25 – 40 | |

| vf [mm/min] | tool speed |

| n | Revolutions per minute (RPM) |

| fz [mm] | blade feed |

| zn | # Blades of cutting tool |

We recommend to start slow (bold values in the tables) and gradually increase until good results are found with the used equipment.

Freshly sharpened tools give best results.

| Milling | ||||

| Tool | n [RPM] | vc [m/min] | vf [mm/min] | Comment |

| D10 Carbide coated 4 bladed HSS mill cutter | 1800 – 2500 | 55 – 100 | 200 – 500 | Cutting depth of 0,5mm – 1mm work well for higher feed rates, ~0,2mm for slower feeds, resulting in smoother surface. Up cut milling gives better results. |

| D40 HSS 6 bladed mill cutter | 1000 – 1500 | 100 – 150 | 100 – 300 | Cutting depth of 0,5mm – 1mm work well for higher feed rates, ~0,2mm for slower feeds, resulting in smoother surface. Up cut milling gives better results. |

Other processing reccomandations – Ultracur3D® RG 3280

TAPPING

- Use cutting oil to greatly improve results.

- Manual tapping works effectively up to a diameter of M5. Larger diameters tend to chip.

- Ideally, threads should be printed directly and only recut.

SANDING

- Sanding quickly evens out small irregularities.

- Regular sandpaper of any grit can be used for effective results.

- Consistent sanding pressure ensures a smooth and uniform surface finish.

TUMBLING

- Parts made from Ultracur3D® RG 3280 can be smoothed in a polishing machine or tumbler.

- After 90 minutes at 290 RPM with PM10 grinding chips (medium size and roughness abrasive medium), edges are slightly rounded and the surface is smooth and homogeneous.

List of used equipment – Ultracur3D® RG 3280

| Equipment | Purpose |

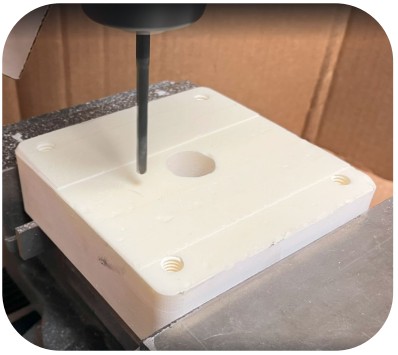

| Drill Press | Used for drilling holes with precise control |

| Drill Bit Set | Various sizes used for drilling and tapping |

| Cutting Oil | Used to improve the quality of tapping |

| Tapping Tool | Used for manual tapping of threads |

| Sanding Machine | Used for sanding surfaces to smooth out irregularities |

| Tumbling Machine (Otec Eco Maxi) | Used for tumbling parts to achieve a smooth and homogeneous surface |

| Grinding Chips (PM10) | Abrasive medium used in the tumbling process |

| Machined Part | Example of a part machined for testing |

Documents / Resources

|

BASF RG 3280 Machining and Processing [pdf] User Guide RG3280, RG 3280 Machining and Processing, RG 3280, Machining and Processing, and Processing, Processing |