1. Introduction

This manual provides essential information for the safe and efficient operation of your Sovol SV08 MAX CoreXY 3D Printer. The SV08 MAX is a high-speed, large-format 3D printer designed for precision and efficiency, featuring a CoreXY kinematic system, eddy current sensor leveling, and a robust aluminum frame.

Image 1.1: The Sovol SV08 MAX CoreXY 3D Printer, showcasing its large build volume and robust frame.

2. Safety Information

Please read and understand all safety instructions before operating the printer to prevent injury or damage to the device.

- Hot Surfaces: The print nozzle and heated bed reach high temperatures during operation. Avoid touching these components directly. Allow them to cool completely before handling.

- Moving Parts: The printer contains moving parts that can cause injury. Keep hands, hair, and loose clothing clear of the print head and gantry during operation.

- Electrical Safety: Ensure the printer is connected to a grounded power outlet. Do not operate with damaged power cords or plugs. Disconnect power before performing maintenance.

- Ventilation: Operate the printer in a well-ventilated area, especially when printing with materials that may emit fumes.

- Children and Pets: Keep children and pets away from the printer during operation.

3. Package Contents

Verify that all components are present upon unboxing:

- Sovol SV08 MAX 3D Printer (partially assembled)

- Power Cable

- USB Cable

- Filament Spool Holder

- Tool Kit (includes wrenches, screwdrivers, spare nozzles, etc.)

- User Manual (this document)

- SD Card (with test files and software)

4. Setup

4.1 Assembly

The Sovol SV08 MAX comes mostly pre-assembled. Follow the included quick start guide for detailed assembly instructions. Key steps typically include:

- Attaching the gantry to the base.

- Connecting necessary cables.

- Mounting the filament spool holder.

4.2 Initial Leveling

The SV08 MAX features an advanced Eddy Current Sensor for automatic bed leveling. This system ensures a precise first layer without manual intervention.

Image 4.2: Close-up of the Eddy Current Sensor performing contactless bed leveling.

- Power on the printer.

- Navigate to the 'Leveling' menu on the 4.3-inch touch screen.

- Initiate the automatic bed leveling process. The Eddy Current Sensor will perform an 80-second full-bed scan.

- After automatic leveling, perform a Z-offset calibration using a piece of A4 paper to fine-tune the nozzle height.

4.3 Software and Connectivity

The printer is compatible with popular slicing software such as OrcaSlicer (Windows/Mac) and Cura-Ultimaker (Windows/Mac). A customized Cura-Sovol version is also available for Windows.

- Install your preferred slicing software on your computer.

- Connect the printer to your network via LAN or 5G/2.4G WiFi using the external antenna for a stronger signal.

- Configure the printer settings within your slicing software, including build volume (500x500x500mm) and nozzle diameter.

5. Operating Instructions

5.1 Filament Loading

The SV08 MAX features an Auxiliary Feeder System to ensure smooth filament delivery and detect potential issues.

Image 5.1: Diagram of the Auxiliary Feeder System with filament runout and tangle detection.

- Place the filament spool onto the spool holder.

- Feed the filament into the Auxiliary Feeder. The system will automatically push the filament into the extruder.

- On the touch screen, select 'Load Filament' and follow the prompts to heat the hotend and extrude filament until it flows smoothly.

5.2 Printing Process

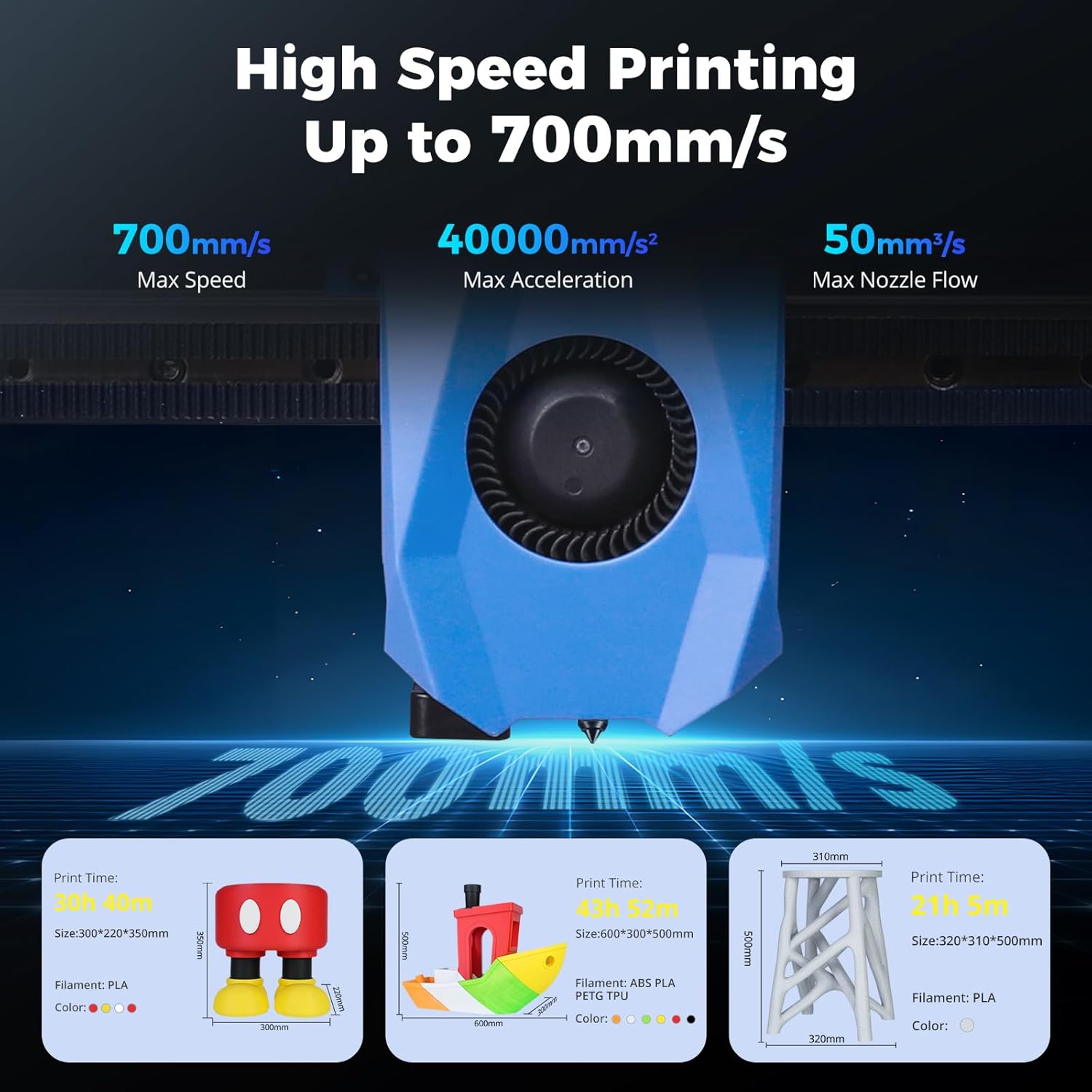

The SV08 MAX supports high-speed printing up to 700mm/s with a maximum acceleration of 40,000 mm/s² and a 50mm³/s high-flow nozzle.

Image 5.2: Illustration of the printer's high-speed capabilities, showing print head movement.

- Prepare your 3D model in the slicing software and generate the GCODE file.

- Transfer the GCODE file to the printer via network (WiFi/LAN) or USB drive.

- Select the desired file from the printer's touch screen and initiate the print.

- Monitor the print progress using the built-in 1280x720 HD camera, accessible remotely via Obico integration (requires internet connection).

Image 5.3: A laptop displaying the remote monitoring interface of the SV08 MAX's built-in camera.

5.3 Supported Filaments

The high-temperature hotend supports a maximum temperature of 300°C, allowing for a wide range of filament compatibility.

Image 5.4: Detailed view of the high-temperature hotend, capable of reaching 300°C.

Compatible filaments include:

- PLA

- TPU

- PETG

- ABS

- ASA

- PA (Nylon)

- PC (Polycarbonate)

- PLA-CF (Carbon Fiber Reinforced PLA)

- PETG-CF (Carbon Fiber Reinforced PETG)

- HP-PLA (High-Performance PLA)

The printer comes with two standard 0.4mm nozzles. Optional nozzle sizes (0.4mm, 0.6mm, 0.8mm) are sold separately.

6. Maintenance

6.1 Heated Bed Care

The 8mm thick aluminum hotbed with 1300W power provides rapid and even heating. Proper care ensures consistent adhesion.

Image 6.1: Visual representation of the high-power hotbed heating to 100°C.

- Clean the print surface regularly with isopropyl alcohol to remove residue and ensure optimal adhesion.

- Avoid using sharp objects to remove prints, as this can damage the print surface.

6.2 Nozzle Maintenance

- Periodically inspect the nozzle for wear or clogs. Replace worn nozzles to maintain print quality.

- Use the provided cleaning needles to clear minor clogs. For severe clogs, a cold pull or nozzle replacement may be necessary.

6.3 Linear Rails

The XYZ full linear rails provide smooth motion and durability. Periodically inspect and lubricate them according to manufacturer recommendations to ensure optimal performance and longevity.

6.4 Firmware Updates

Check the official Sovol website for the latest firmware updates. Keeping your printer's firmware up-to-date can improve performance and add new features.

7. Troubleshooting

7.1 Common Printing Issues

- Poor First Layer Adhesion: Re-calibrate the Z-offset. Ensure the print surface is clean. Adjust bed temperature in slicing software.

- Filament Clogging: The Auxiliary Feeder includes clog detection. If a clog occurs, try unloading and reloading the filament. Clean or replace the nozzle if necessary.

- Stringing/Oozing: Adjust retraction settings (distance and speed) and print temperature in your slicing software.

- Layer Shifting: Check that all belts are properly tensioned and pulleys are secure. Ensure the printer is on a stable surface.

7.2 Connectivity Issues

- WiFi/LAN Connection Failure: Verify network cables are securely connected. Ensure correct WiFi password is entered. Restart the printer and your router.

- Remote Monitoring Not Working: Check internet connection. Ensure Obico integration is correctly configured and the printer is connected to the internet.

8. Specifications

| Feature | Specification |

|---|---|

| Model | Sovol SV08 MAX |

| Build Volume | 500 x 500 x 500 mm (19.7 x 19.7 x 19.7 inches) |

| Product Dimensions | 28 x 27.6 x 29.5 inches |

| Item Weight | 87.8 pounds |

| Max Print Speed | 700 mm/s |

| Max Acceleration | 40,000 mm/s² |

| Max Nozzle Flow | 50 mm³/s |

| Max Hotend Temperature | 300°C |

| Hotbed Power | 1300W |

| Kinematics | CoreXY |

| Linear Rails | XYZ Full Linear Rails |

| Leveling System | Eddy Current Sensor |

| Extruder | Planetary Dual Gear Direct Extruder |

| Display | 4.3-inch Touch Screen |

| Camera | Built-in 1280x720 HD Camera |

| Connectivity | WiFi (5G/2.4G), LAN, USB, HDMI |

| Compatible Slicers | OrcaSlicer, Cura-Ultimaker, Cura-Sovol |

| Supported File Formats | STL, OBJ, STP, STEP, 3MF, AMF, GCODE |

| Frame Material | Aluminum with reinforcing ribs |

9. Warranty and Support

Sovol products are covered by a manufacturer's warranty. For specific warranty terms, technical support, or service inquiries, please refer to the official Sovol website or contact their customer service directly. You can also visit the Sovol Store on Amazon for additional information and resources.